Information

-

PGH Order Number (SAP)

-

Despatching Site

-

Date and Time

-

Conducted By

-

Drivers Name

-

Transport Company Name

Declaration

-

Has Driver Been Inducted

-

Has driver provide GVM/GCM, Tare Weights and payload on entry

-

Using the vehicles entry information and delivery docket has the correct QTY and Product been loaded onto the vehicle

-

Using the vehicles entry information has the load been positioned in accordance with drivers instructions, mass management, dimension and positioned so that load restraint can be applied

-

Using the entry information and the delivery docket has the load mass exceeded the allowable GCM/GVM

-

Driver Declaration: - I am fit for duty - I am free from drugs and alcohol - I have had all require rest breaks in accordance with Fatigue Management Laws - I have the required hours left to complete my load in accordance with Fatigue and Speed Laws - I have reviewed my delivery point and route to ensure all mass and road restrictions can be followed - My vehicle and equipment is suitable for the task and in working order. All maintenance tasks are up to date - The load has been loaded as per my directions and in accordance with all Mass, Dimension and Restraint requirements - I have reviewed the quality and integrity of all elements of the load and am satisfied that the load in a condition suitable for transport.

Method of Restraint

-

What method of load restraint has the carrier advised they will be using

-

Blocking and tie down is a combination of forward blocking structures and Straps and Angles. Here is an example of what this should look like

-

Please take a photo of the carriers load after it is restrained

-

Blocking and containment can be completed differently depending on the specific certification the carrier may hold. Attached is an example

-

Please take a photo of the carriers load after it is restrained

Forward Restraint

-

What form of forward blocking is the carrier using

-

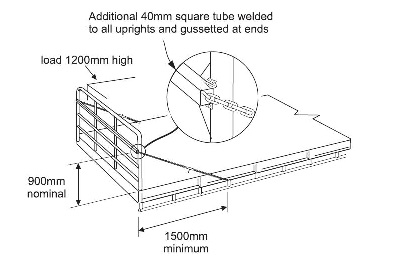

Requirements for a Chained Headboard

-

Has Carrier used correct method for chained headboard

-

Rigid Headboard

-

Has carrier used correct method for rigid headboard

-

Tuatliner Headboard

-

Hass Carrier used correct method for tautliner headboard

Side Restraint

-

What Method of Side restraint is the carrier using

-

Had each row been strapped and have full length Angle to tyne holes been used

-

Had each row been strapped and have full length Angle to tyne holes been used

-

Are the gates hinged. Are the latches positive locks. Do the gates go higher than the packs.

-

Has the carrier provided a copy of his certified system.

-

DO all gates have full infill so that no brick can fall from truck. Have all rows of gates been secured with 2.5t webbing strap

-

DO all gates have full infill so that no brick can fall from truck. Have all rows of gates been secured with 2.5t webbing strap

-

Have all rows been strapped and angled (Note angles do not have to be full length).

-

Have all rows been strapped and angled (Note angles do not have to be full length).

Intermediate blocking

-

Has the load been split to assist with axle mass management

-

If gates are greater than 100mm then carrier must block. What method has the carrier used for intermediate blocking

-

A single 8mm chain must also be used unless carrier has supplied written certification

-

Has carrier applied the correct method for intermediate blocking

-

If intermediate headboard is not attached to truck then 2 chain are required

-

Has carrier applied the correct method for intermediate blocking

-

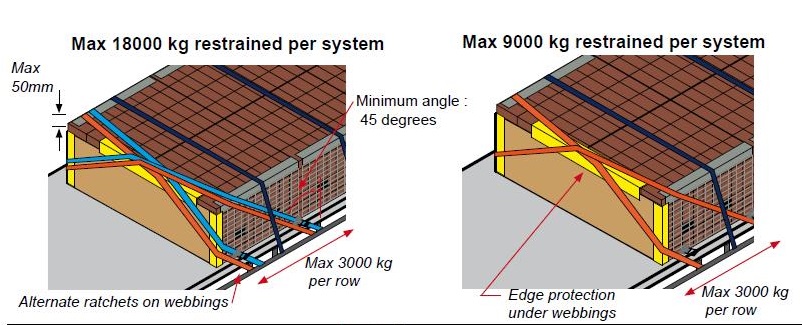

Depending on weight the number of cross over straps will change. Look at the attached and confirm what carrier required

-

Has the carrier correctlly applied the cross over method

-

Has the carrier used dunnage to fill all gaps greater than 100mm. This could be stacks of pallets, timber or other structures

-

Has the carrier used dunnage correctly

Rear Restraint

-

Are there gaps greater than 100mm rearward

-

WHat method has the carrier used to block or tiedown rearward

-

Structures can vary here is an example

-

Has carrier used structure correctly

-

Chains must be 8mm and wrapped around rear of packs and secured. (Note these do not need to be tensioned with a dog)

-

Has carrier used chain correctly