Title Page

-

Conducted on

-

Job number/s

-

Location

-

Job description

Confined space risk assessment

-

Is it a Confined Space?

To establish if a space is a potential Confined Space the following questions need to be answered. The first step is to examine the physical characteristics and the inherent hazards of the space itself, not the task or any tasks to be performed within that space. -

Is the space an enclosed or partially enclosed space that is not intended or designed primarily as a place for human occupancy?

-

Is the space liable at any time to have?<br>a) An oxygen concentration outside the safe oxygen range<br>b) A concentration of airborne contaminant that may cause impairment, loss of consciousness or asphyxiation<br>c) A concentration of flammable airborne contaminant that may cause injury from fire or explosion<br>d) Engulfment in a stored free-flowing solid or rising liquid that may cause suffocation or drowning.<br>

-

This works area is NOT deemed to be a confined space. Continue works as per your SHEWMS and/or work instructions. Notify a supervisor if you are unsure about the outcome of this assessment.

-

This works area IS deemed to be a confined space. Continue with the risk assessment below.

Atmospheric conditions

-

Test the atmosphere for 5 minutes around the entry and at different locations in the space (e.g. working area, top, middle, bottom) and record the readings below

-

Gas monitor serial number

-

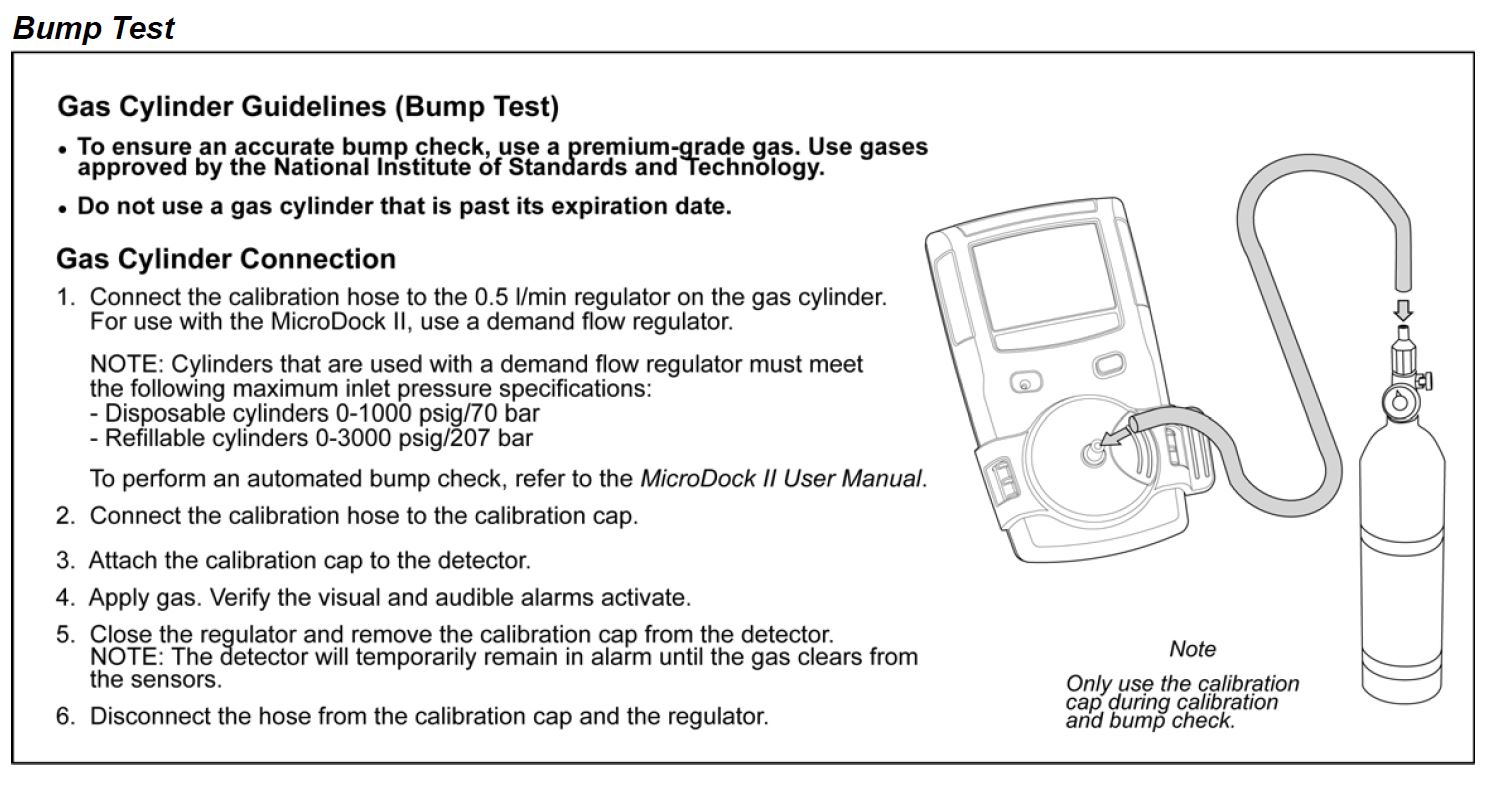

Do you know the bump test procedure?

-

Which type of monitor are you using?

-

This gas monitor can not be bump tested on site, return to storeman for testing.

-

-

Has the gas monitor been successfully bump tested this shift?

-

Stop and bump test before proceeding. If you are unable to bump test or the test was unsuccessful, notify your supervisor immediately.

-

Oxygen Oxygen Deficiency if < 19.5% Oxygen Enrichment if > 23.5%

-

Hydrogen Sulphide <10ppm

-

Carbon monoxide <30ppm

-

Lower Exposure Limit (LEL) % <10%

-

Are all readings within safe levels?

-

Continuous monitoring is to be carried out through the duration of the works in the workers breathing space.

Is entry necessary?

-

Can the task be done without entering the space?

-

Discuss with your supervisor.

-

Can the task be done using any other method?

-

Discuss with your supervisor.

Hazard assessment

-

Are there any unusual features and / or adjacent processes that may impact on the need, or safety, of entry.

-

Describe the feature/s or process/es and how you will control the risks.

-

Oxygen deficiency or surplus

-

List the controls

-

Combustible atmosphere

-

List the controls

-

Toxic atmosphere

-

List the controls

-

Fluids

-

List the controls

-

Contaminants

-

List the controls

-

Oxidisation, decomposition

-

List the controls

-

Moving equipment (in/outside)

-

List the controls

-

Engulfment

-

List the controls

-

Pressurised lines (air/fluid/gas)

-

List the controls

-

Machinery that may auto start

-

List the controls

-

Natural hazards, insects etc.

-

List the controls

-

Electrocution

-

List the controls

-

Ergonomics (poor posture)

-

List the controls

-

Difficult access/egress

-

List the controls

-

Fire/explosion

-

List the controls

-

Hazardous chemicals

-

List the controls

-

Excessive noise

-

List the controls

-

Poor lighting

-

List the controls

-

Dust

-

List the controls

-

Remote location

-

List the controls

-

Poor communication

-

List the controls

-

Competent person

Confined Space Permit

-

Did the Risk Assessment deem the work area as a confined space?

-

Complete the Confined Space Entry Permit below.

Confined Space Entry Permit

-

Work Controls

-

Confined space physically isolated from hazardous energy

-

Emergency response plan in place and understood

-

Confined space been cleaned and/or purged of contaminants

-

Appropriate type / suitable number of fire extinguishers

-

If hot works are undertaken, dedicated Fire Watch during and 30 minutes after works required and organised

-

Weather conditions considered e.g. risk of heavy rain/potential flooding

-

Adequate earthing to electrical equipment

-

All electrical equipment is intrinsically safe

-

Confined Space Entry Log

-

Breathing apparatus required and organised

-

Standby and entry personnel fit and competent

-

Gas testing / monitoring required and organised including Atmospheric Monitoring Log

-

Associated pipelines, tanks, valves certified gas /liquid/vapour free and isolated

-

Exclusion zone set up and adjacent works considered

-

Area barricaded and warning signage in place

-

Extraction / forced ventilation required and organised

-

Flammable/Combustible materials removed from area

-

First Aider with CPR competency required and organised

-

Communication equipment required, organised and tested

-

Safe & adequate access and egress

Additional PPE

-

PPE Required

- Face Shield

- Respiratory Protection

- Face Shield

- Hearing Protection

- Chin Strap

Permit issue/acceptance

-

Before issuing this permit, a rescue plan must be completed on the next page.

Persons working under permit

-

A person required to work under this Permit to Work (PTW) must comply with \ the following instructions:

1. Ensure you understand the scope of the work activity and your role / tasks.

2. Ensure you have read, and/or have had explained and understand the requirements of the SHEWMS and any associated Permits. Ask questions if you are unsure and report any concerns / issues immediately.

3. At the start of each working shift ensure the Permit Acceptor has had the Permit revalidated and obtained permission to commence work.

Notify the Permit Acceptor immediately if you become aware of a new hazard or change in conditions while performing the works.

Sign on

-

Sign on

Entry / Exit record

-

I’VE BEEN ADVISED OF AND UNDERSTAND THE CONTROL MEASURES AND PRECAUTIONS TO BE OBSERVED WITH THE ENTRY AND WORK IN THE CONFINED SPACE

Sign in/out

-

Time in

-

Sign in

-

Time out

-

Sign out

Permit close out - Completion of works

-

All works associated with this permit have been:

-

All persons and equipment accounted for:

-

Equipment checked and restocked correctly:

-

Work area & adjacent areas have been inspected after completion of the works and all hazards made safe:

-

Works completed

-

Permit issuer: I confirm that the works have been completed and that the area has been left in a safe condition.

-

No permit required.

Rescue Plan

-

IMPORTANT NOTE

Emergency procedures are to be rehearsed prior to works commencing. Should a change occur to the crew a new plan, with roles identified shall be made. -

Emergency Response Equipment required

- Gas monitor

- Tripod/Davit arm

- Safety harness

- Winch system

- Lighting

- Fall arrest

- Fall restraint

- Life line/Rescue rope

- Stretcher

- BA kit

- Arachnipod

-

Site Location Details (including muster / meeting points):

Roles and Responsibilities

-

Who will conduct the confined space rescue / retrieval?

-

Who will notify and meet emergency services:

-

Who will conduct First Aid/CPR:

Rescue Plan Details

-

Types of rescue arrangements.

-

Basic sketch of confined space work area and rescue arrangement.

Confirmation

-

Have all participants been briefed on and agree with the emergency rescue plan?

-

Do not commence works until all parties have been briefed and agree to the plan.