Information

-

Audit title

-

Serial number

-

Serial number

-

Client / Site

-

Start time

-

Prepared by

-

Location

-

Mandatory site pictures

Service Report

At the time of the initial diagnostic mobilization, the Technician will note any deficiencies in the existing system regarding compliance with UL325 standards and advise the customer of same. Systems that do not comply with current UL325 standards may or may not be serviced at this time at our discretion.

PERFORMANCE VERIFICATION TESTS

-

Testing conditions (Weather, Temperature, etc)

-

Serial number

-

Location of Controller

-

Is there a generator on site?

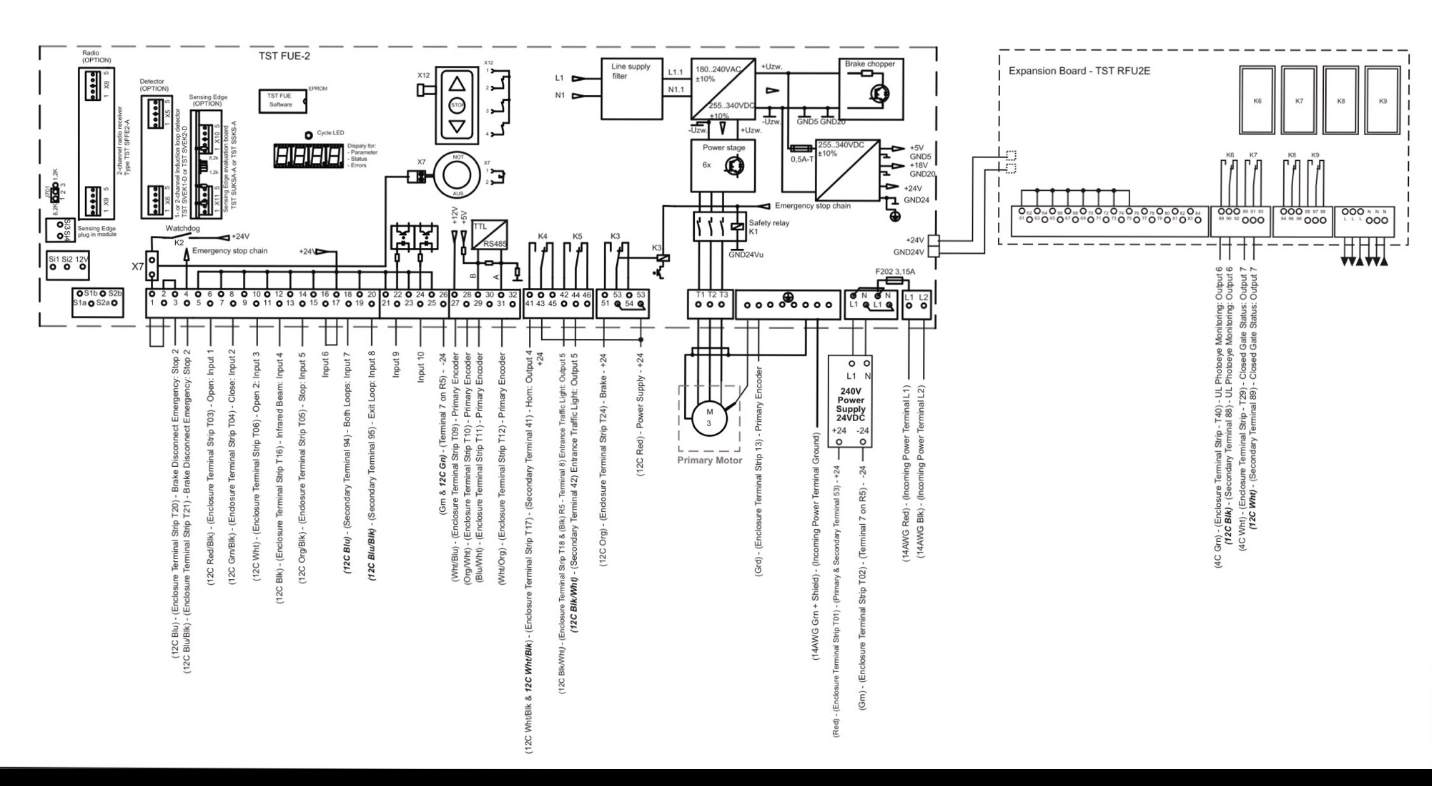

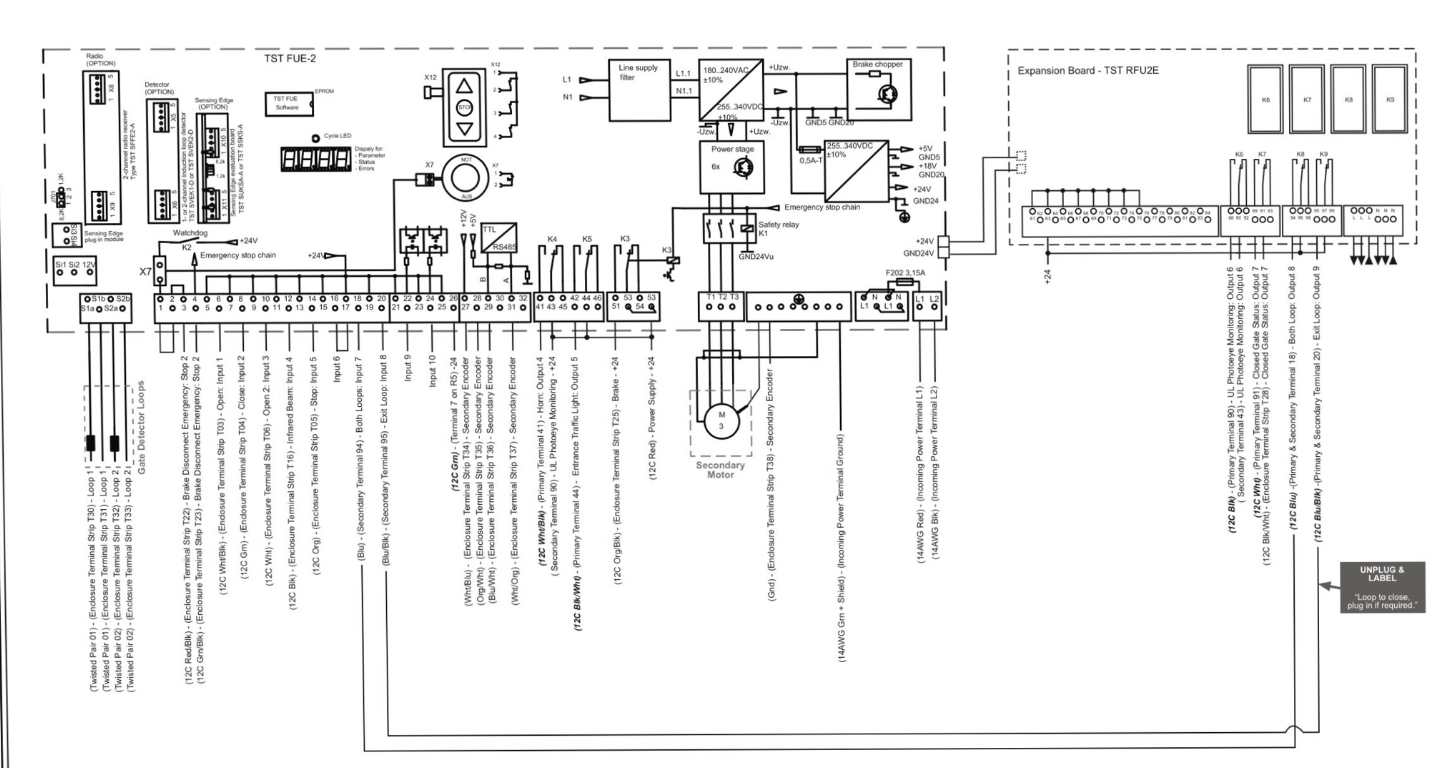

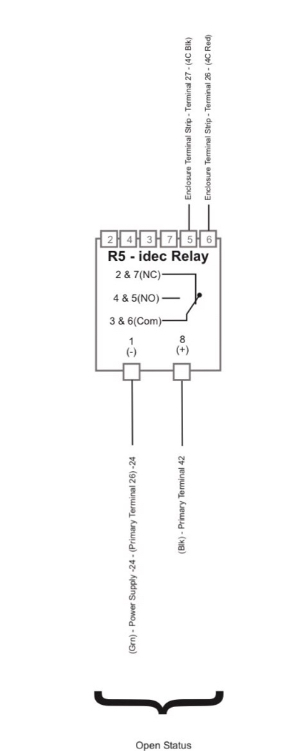

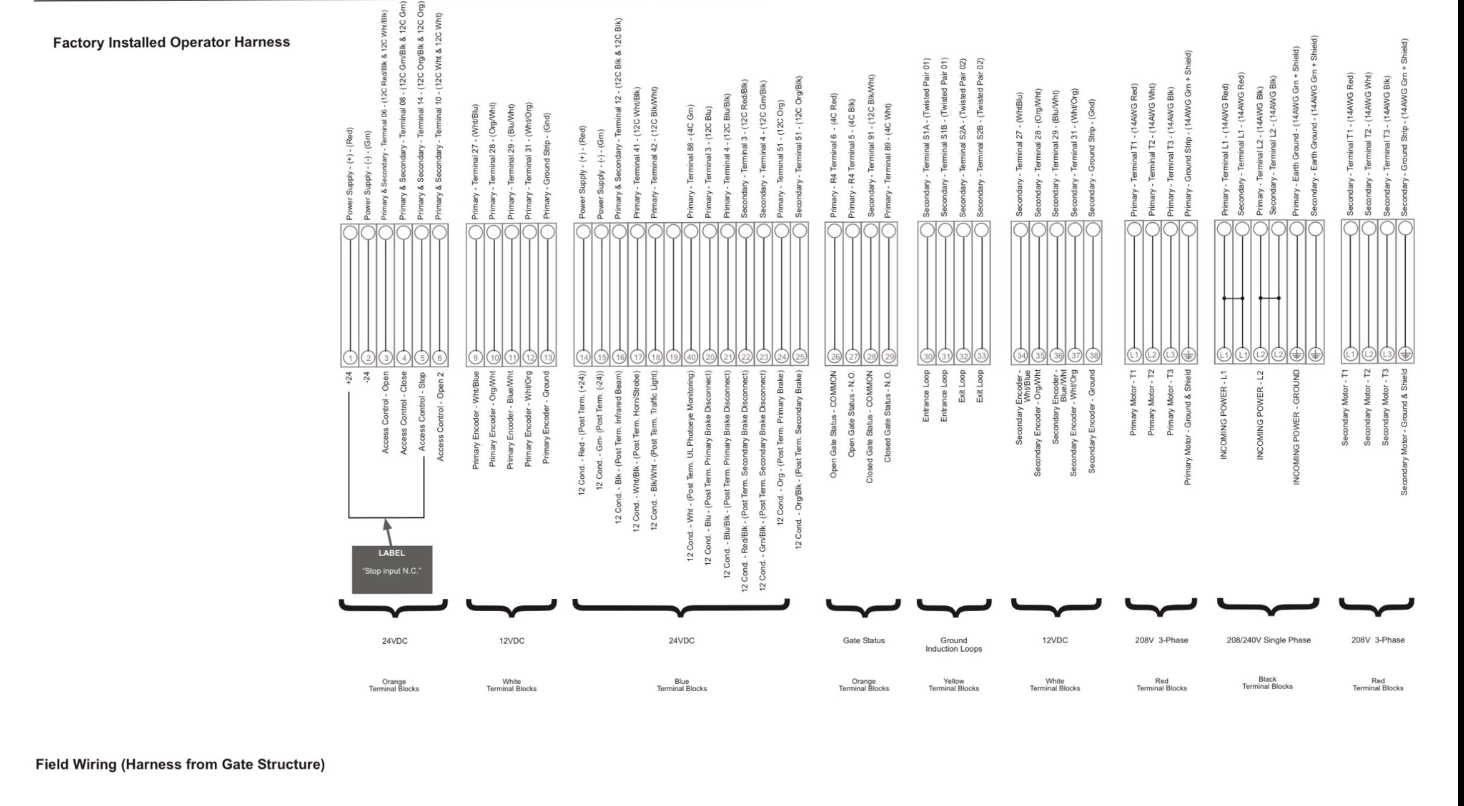

Electrical

-

Incoming voltage

-

Amperage

-

Are there any audible alerts

-

Are there any error codes

-

Error log

-

Are there any LED lights active in the open, close or stop terminals, indicating an inappropriate hold

-

Are there any LED lights active in the safety terminals, indicating an inappropriate hold

-

Is the operator properly grounded

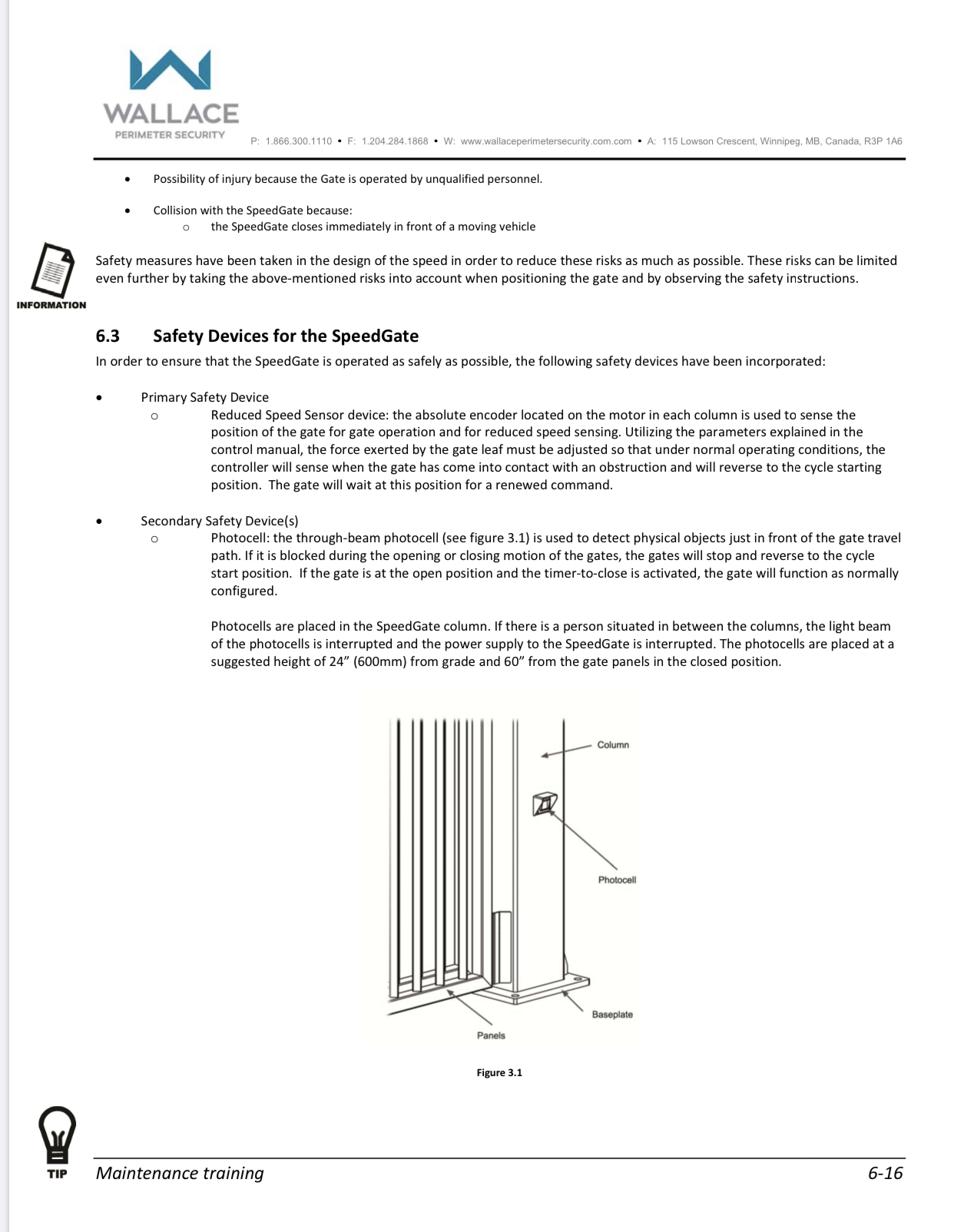

Photo eye

-

Does the photo eye(s) function as designed

-

When the photo has been triggered, does the gate reverse/stop as designed

Loop & Loop detector details

-

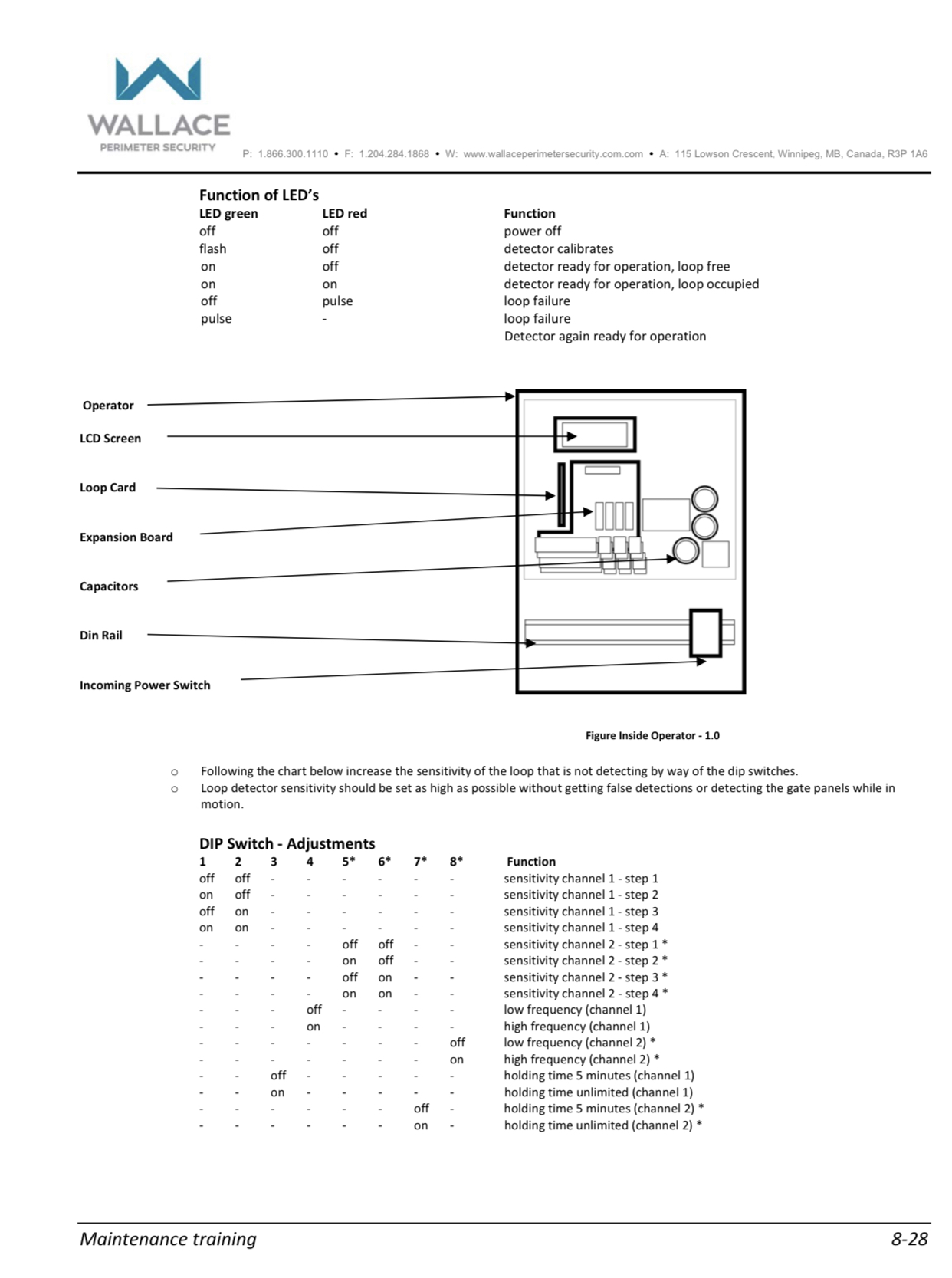

Does the loop detector function as intended

-

Do all loops test above the minimum 300 megohms required for proper function

-

Do loops appear to be in good condition (covered by sealant, leads twisted correctly, asphalt/concrete in good condition, etc.)

Gate inspection

-

Does the gate move freely and easily in manual operation

-

Is the gate level

-

Is the gate free of any visible damage

-

Is the gate aligned with the receiver

-

Is the gate path clear throughout the entire travel

-

Are the hinges properly greased and installed correctly

-

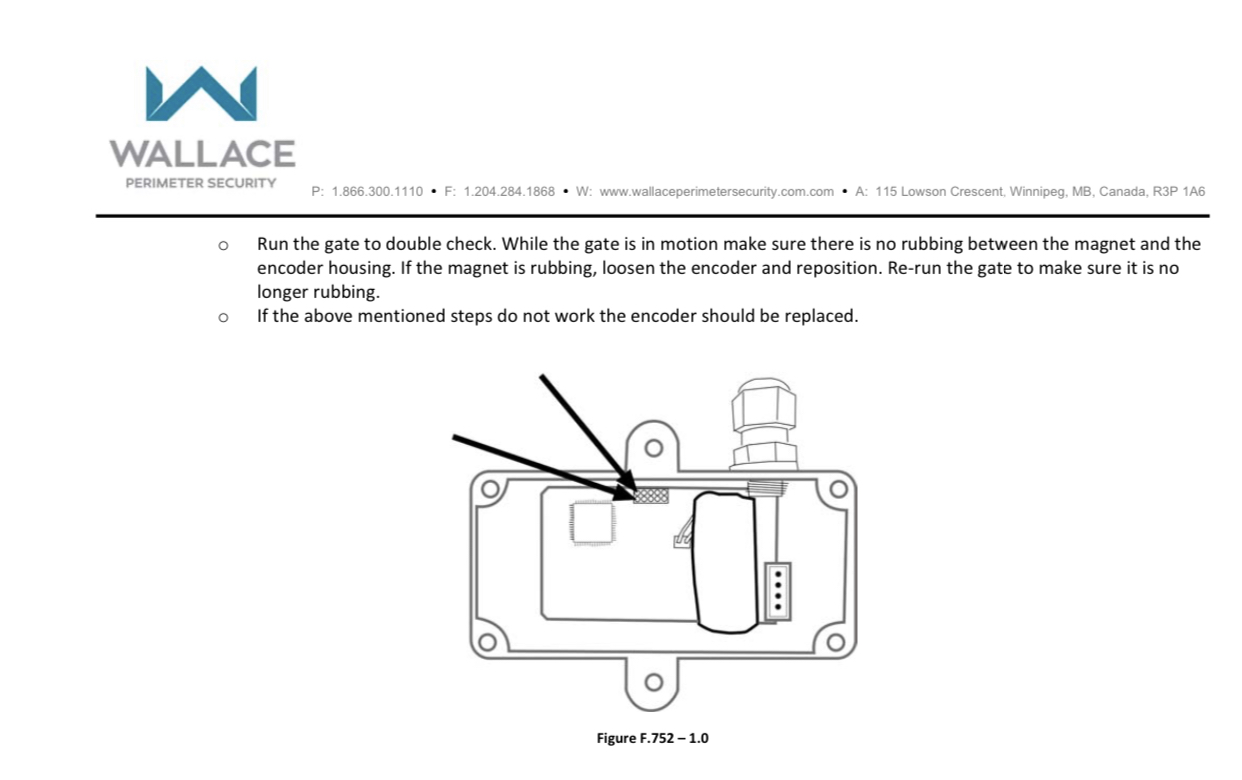

Encoder- The encoder should be securely fastened to the motor shroud fan. There should be no noise/ gate movement resistance when gate is manually/ automatically operated

-

wiring is properly terminated. Any unused wires should be properly isolated so as to prevent interference with operator wiring

-

Motor brake- When the gate is not in motion, the brake should hold the gate in position. When the gate is in motion, the brake should have power and be released, allowing gate movement.

-

Sensing edge (If equipped)- the resistance should meter 8.1-8.7K. when squeezed the reading should drop to zero

-

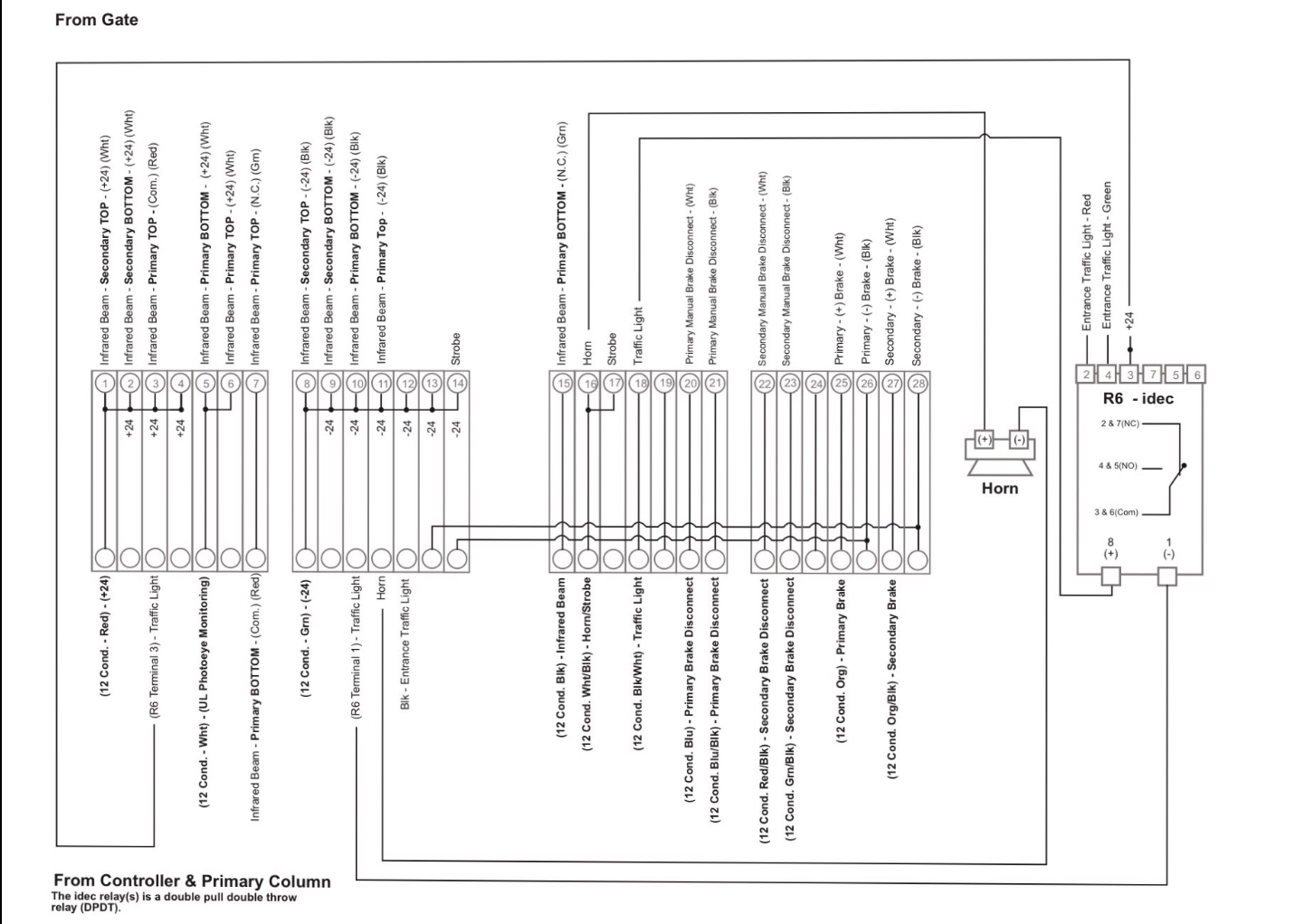

Wiring- All wires should be properly seated in the terminals in the operator and column termination box and securely tightened. All wires should be left in a state of cleanliness and should be labeled as required by specifications. Do NoT substitute wire color

-

Gate limits- The gate limits should be adjusted so the gate panels, when in the fully closed position, are all parallel . When fully open, the gate panel bumpers should be within 1/2” of each other.

Mechanical

-

Access Door Locking- All doors should lock and unlock as designed

-

Add media

-

Columns- Should be level and plum, anchors tighten to approximately 210 ft/ lbs. Column base plates must be appropriately grouted

-

Add media

-

Drive pin- and sure all fasteners are tighten to 90 ft/lbs. verify the drive pin is not contacting column cover plate at any point

-

Add media

Sign off

-

Wallace international is pleased to have supplied a speed gate automated gate for your facility. The product is expected to perform as designed providing basic maintenance is conducted on a regular basis. Maintenance required by the owner is detailed in the owners manual which was provided when the product was installed. Scheduled preventative maintenance is available through Wallace international, or a Wallace international approved installer.

-

By signing below, facility staff is/are acknowledging having attended the commissioning meeting upon completion of the installation. The meeting is held to a sure that they use, maintenance, and troubleshooting procedures for the product or understood by those responsible for the operation of the product. Signatures also indicate acknowledgment of receiving owners manual with copy of installation checklist and speed gate automated gate access keys.

Technician’s Recommendations

-

Comments

-

Completion time

Electronic Signature Acknowledgement-I agree that my Electronic signature is a Legally and Binding Equivalent to my handwritten signature. Whenever I execute an Electronic Signature, it has the same validity and meaning as my Handwritten Signature. I will not at ANY time in the future, REPUDIATE the meaning of my Electronic Signature or Claim that my Electronic Signature is not Legally Binding.

-

Wallace Perimeter Security Representative

-

Customer representative’s signature

Documents