Title Page

-

Audit #

-

Date

-

Area

-

Audit by

-

Directions

--------------------

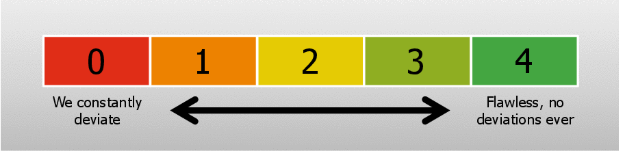

1. For each statement, choose the appropriate score. [Use image below as reference]

2. Tap on 'Note' or 'Image' under each question to add a comment or evidence

4. For identified failed items, assign a corrective action by tapping on 'Action', provide a description, assign to a member, set priority and due date.

5. Complete all items in the checklist & review score per section to identify the overall rate score. -

Take or attach a photo of workspace

SORT / SISIH

-

Only the required EQUIPMENT/TOOLS is present in the area. All obsolete, broken or unnecessary equipment not required for current projects are removed from the area or red tagged for removal.<br><br>Hanya peralatan yang diperlukan ada di kawasan tersebut. Semua peralatan usang, rosak atau tidak diperlukan untuk projek semasa,perlu dikeluarkan dari kawasan tersebut.

-

No irrelevant reference materials,document,etc. (E.g: Drawing)<br><br>Tiada bahan rujukan,dokumen, & lain-lain yang tidak berkaitan dengan kerja atau projek semasa.

-

No excess pieces of equipment,components,materials,etc. (E.g: Project component)<br><br>Tiada lebihan peralatan,komponen,bahan & lain-lain

-

Only the required SPARE PARTS and MATERIALS are present in the area. Items not required for current projects are removed from the area or red tagged for removal.

SET-IN-ORDER / SUSUN

-

Locations of tools,equipments,material & product are clear & well organized.<br><br>Lokasi alatan, peralatan, bahan & produk adalah jelas & teratur.

-

TOOLS have a designated storage area that is within reach of the user/operator. The location is properly labeled and a system is in place to identify tools that are absent (shadowboard, etc.)<br><br>ALAT mempunyai kawasan simpanan yang ditetapkan yang mudah dicapai oleh pengguna/pengendali. Lokasi dilabelkan dengan betul dan sistem disediakan untuk mengenal pasti alat yang tiada (papan bayangan, dsb.)

-

Locations for CONTAINERS, WIP'S, BOXES, BINS, etc. are clearly defined via signs or marked/taped lines and properly labeled.<br><br>Lokasi untuk BEKAS, WIP, KOTAK, TONG, dsb. ditakrifkan dengan jelas melalui tanda atau garisan yang ditanda/dirakam dan dilabel dengan betul.

-

PAPERWORK is properly labeled and has a clearly identified location that is away from work surfaces<br><br>KERTAS KERJA dilabel dengan betul dan mempunyai lokasi yang dikenal pasti dengan jelas yang jauh dari permukaan kerja

-

Work areas requiring PERSONAL PROTECTIVE EQUIPMENT (PPE) are clearly marked (floor tape, safety signs/labels, etc.)<br><br>Kawasan kerja yang memerlukan PERALATAN PERLINDUNGAN DIRI (PPE) ditanda dengan jelas (pita lantai, tanda/label keselamatan, dsb.)

-

FIRE HOSES, FIRE EXTINGUISHERS, and other emergency equipment are prominently displayed and are unobstructed.<br><br>HOS API, PEMADAM API, dan peralatan kecemasan lain dipamerkan dengan jelas dan tidak terhalang.

-

FLOOR/AISLES are clearly marked; forklift lanes, exits, dangerous areas, paths of egress, walkways, aisles, etc. are all marked with visible lines (floor tape/floor paint).<br><br>LANTAI/LORONG ditanda dengan jelas; lorong forklift, pintu keluar, kawasan berbahaya, laluan jalan keluar, laluan pejalan kaki, lorong, dsb. semuanya ditandakan dengan garisan yang boleh dilihat (pita lantai/cat lantai).

-

Working conditions are ERGONOMICALLY FRIENDLY - Tools and other times needed for daily work are stored at appropriate heights, related safety signage is displayed clearly, etc. <br><br>Keadaan kerja adalah MESRA ERGONOMI - Alat dan masa lain yang diperlukan untuk kerja harian disimpan pada ketinggian yang sesuai, papan tanda keselamatan yang berkaitan dipaparkan dengan jelas, dsb.

-

The workspace layout accommodates EASY UNOBSTRUCTED EXIT in case of emergency. The emergency exit route is posted in conspicious location for all to see<br><br>Susun atur ruang kerja memuatkan EASY UNOBSTRUCTED EXIT jika berlaku kecemasan. Laluan keluar kecemasan dipaparkan di lokasi yang mudah dilihat untuk dilihat oleh semua

SHINE / SAPU

-

Work surfaces (Workbenches, jigs, etc.) are kept clean free of waste, dust,water, oil,etc.<br><br>Permukaan kerja (Meja kerja, jig, dsb.) sentiasa bersih daripada habuk,sisa, air, minyak, dsb.

-

FLOORS are free from dirt, debris, oil, parts, hardware, empty boxes, etc. and all drains (if applicable) are clear of debris and clogs<br><br>LANTAI bebas daripada kotoran, serpihan, minyak, bahagian, perkakasan, kotak kosong, dsb. dan semua longkang (jika berkenaan) bersih daripada serpihan dan tersumbat

-

CONTAINERS, BOXES, BINS, ETX. are clean and not cracked, torn, or otherwise damaged. When stored, they are neatly stacked in their correct location.<br><br>BEKAS, KOTAK, TONG, ETX. bersih dan tidak retak, koyak atau rosak. Apabila disimpan, ia disusun dengan kemas di lokasi yang betul.

-

All PERSONAL PROTECTIVE EQUIPMENT (PPE) is maintained in sanitary and reliable condition and is properly stored in an easily accessible and labeled location when not in use.<br><br>Semua PERALATAN PERLINDUNGAN DIRI (PPE) diselenggara dalam keadaan bersih dan boleh dipercayai serta disimpan dengan betul di lokasi yang mudah diakses dan berlabel apabila tidak digunakan.

-

All CLEANING EQUIPMENT is neatly stored and is readily available when needed. <br><br>Semua PERALATAN PEMBERSIHAN disimpan dengan kemas dan mudah didapati apabila diperlukan.

-

All EQUIPMENT SAFETY - related warnings, signs, labels, floor lines, etc. are all clean, easy to read, not torn or damaged, and provide adequate protection<br><br>Semua KESELAMATAN PERALATAN - amaran, tanda, label, garis lantai, dsb. yang berkaitan semuanya bersih, mudah dibaca, tidak koyak atau rosak, dan memberikan perlindungan yang mencukupi

STANDARDIZE

-

TOOLS, EQUIPMENT, PAPERWORK, FURNITURE, ETC is stored neatly in designated areas and are returned to their proper homes immediately after use. <br><br>ALAT, PERALATAN, KERTAS KERTAS, PERABOT, DLL disimpan dengan kemas di kawasan yang ditetapkan dan dikembalikan ke tempat yang sepatutnya selepas digunakan.

-

TOOLS with calibration records are visible & clearly state when maintenance last occurred.<br><br>ALAT dengan rekod penentukuran boleh dilihat & jelas menyatakan bila kali terakhir penyelenggaraan dilakukan.

-

PRODUCT WASTE (excess leftover cable, containers, liquids, wrappers, etc.) is consistently and regularly cleaned up and removed from workspace.<br><br>SISA PRODUK (sisa kabel berlebihan, bekas, cecair, pembalut, dll.) dibersihkan secara konsisten dan kerap serta dikeluarkan dari ruang kerja.

-

PREVENTIVE MEASURES have been implemented to ensure the workplace meets 5S guidelines (e.g. systems that do not allow waste to accumulate such as return excess material)<br><br>LANGKAH PENCEGAHAN telah dilaksanakan untuk memastikan tempat kerja memenuhi garis panduan 5S (cth. sistem yang tidak membenarkan sisa terkumpul seperti memulangkan lebihan bahan)"

-

The WORK ENVIRONMENT satisfies the requirements of the work being performed- Lighting brightness and color, temperature, air flow and quality etc.<br><br>PERSEKITARAN KERJA memenuhi keperluan kerja yang dijalankan- Kecerahan dan warna pencahayaan, suhu, aliran udara dan kualiti dsb.

-

The RESULTS OF THE PREVIOUS AUDIT are posted and clearly visible for the entire team<br><br>KEPUTUSAN AUDIT TERDAHULU disiarkan dan dapat dilihat dengan jelas untuk seluruh pasukan

-

AREAS FOR IMPROVEMENT identified during the previous audit have been addressed and completed.<br><br>BIDANG PENAMBAHBAIKAN yang dikenal pasti semasa audit terdahulu telah ditangani dan diselesaikan.

SUSTAIN

-

All materials, WIP, stock & scrap stored in correct place and checked periodically (No overflow)<br><br>Semua bahan, WIP, stok & sekerap disimpan di tempat yang betul dan diperiksa secara berkala (Tiada limpahan)

-

Activity plan boards are up-to-date & regularly reviewed<br><br>Papan rancangan aktiviti adalah terkini & sentiasa disemak. (Planning board/ KPI board etc.)

-

Standard for tools storage, identification labels, & positioning are performed as per standard & checked periodically (Checklist Update)<br><br>Piawaian untuk penyimpanan alatan, label pengenalan, & kedudukan dilakukan mengikut standard & diperiksa secara berkala. (kemas kini senarai semak)

-

TIME AND RESOURCES are allocated to 5S activities (e.g., designated daily/weekly clean-up time, 5S Team Leader).<br><br>MASA DAN SUMBER diperuntukkan kepada aktiviti 5S (cth., waktu pembersihan harian/mingguan yang ditetapkan, Ketua Pasukan 5S).

-

All operators, team leaders, supervisors, etc. are assigned 5S ACTIVITIES to be completed at least once a week.<br><br>Semua pengendali, ketua pasukan, penyelia dan lain-lain diberi AKTIVITI 5S untuk diselesaikan sekurang-kurangnya seminggu sekali.

-

The team took the INITIATIVE to make improvements to the workplace that were NOT identified during the last audit. <br><br>Pasukan mengambil INISIATIF untuk membuat penambahbaikan di tempat kerja yang TIDAK dikenal pasti semasa audit yang lalu.

COMPLETION

-

Overall observation & recommendations

-

Name & Signature of Area Supervisor/ or any Assigned Employee