Information

-

Inspection Title. B80 Steel Reinforcement and Embedments Ed 5 / Rev 0

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

6 SUPPLY and FIXING of STEEL REINFORCEMENT and EMBEDMENTS

-

Cl 6.1 Have compliance certificates for the reinforcement material supplier/fabricator been received. (Australian Certification Authority)

-

Cl 6.2.1 Is the reinforcement bars or welded wire fabric the type and size referred to on the drawings.

-

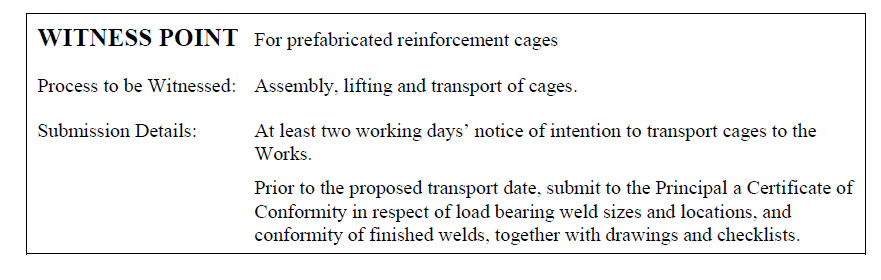

Cl 6.3.1 Is the reinforcement fabricated to the shape and dimension shown on the drawings and within the tolerance given in Cl 6.9. Table B80.15

-

Cl 6.3.2 Has the reinforcement been bent by either cold bending around pins, or by uniform heat not exceeding 450DegC for a period not exceeding 2 minutes and (not cooled by quenching). <br>No bending of previously bent and straightened, or bend in reverse again, within 20 bar diameters of the previous bend, of reinforcement rod <br>

-

Cl 6.3.3 Do all welds conform to RMS 204 and the bar manufacturer's recommendation. <br>Do not field weld Grade 500L reinforcement. <br>Have the welded splices been tested. <br>No welding of reinforcement for prestressed members after the prestressing tendons have been placed in the reinforcement assemblies or cages being assembled.

-

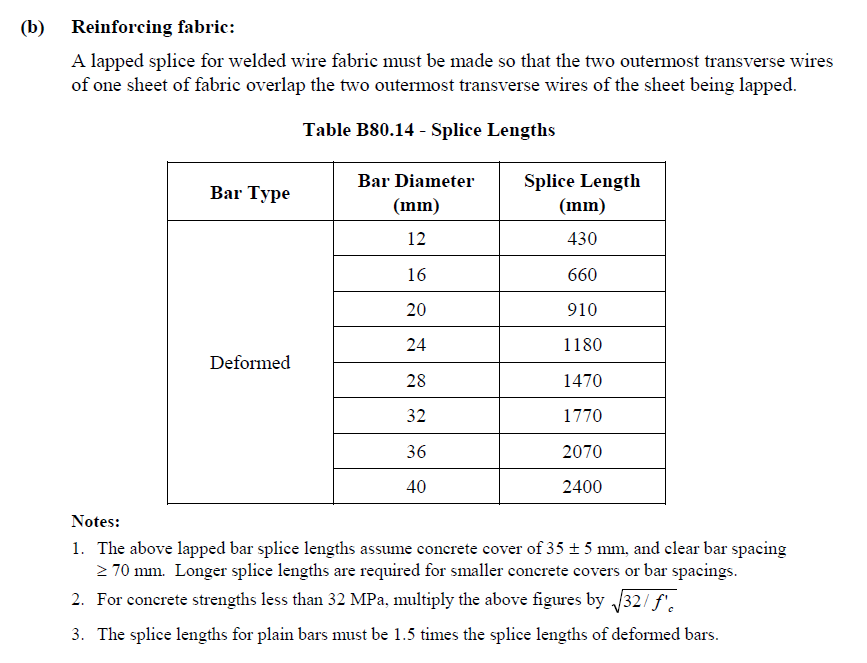

Cl 6.3.3 Have the load bearing welds for lifting or transporting of prefabricated reinforcement cages must be designed by a suitably qualified person with extensive experience in the design, welding and handling of prefabricated cages.

-

Cl 6.4.1 Are the splice location as shown on the drawings. <br>Have additional locations been approved by the Principal.

-

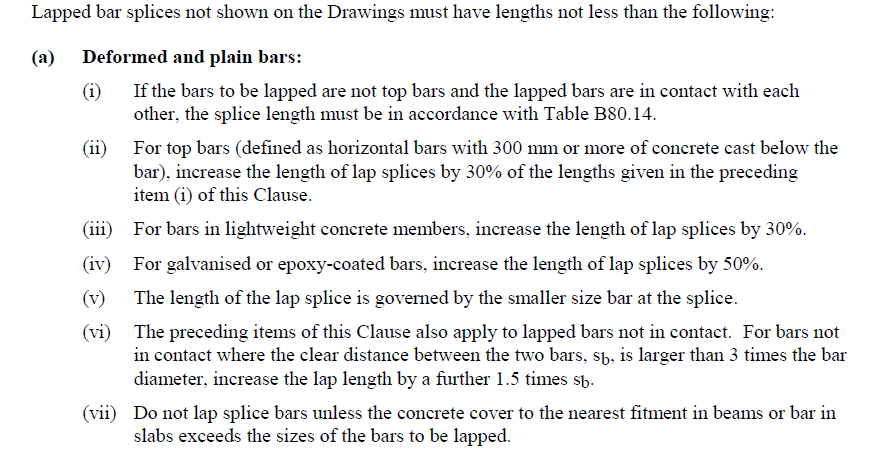

Cl 6.4.2 Lapped Splices

-

Cl 6.4.2 Lapped Splices

-

Cl 6.5 Has the reinforcement been supported above the surface of the ground.

-

Cl 6.6 At the time of placing concrete is the surface condition of the reinforcement clean as not to impair its bond to the concrete or its performance in the binder.

-

Cl 6.7.2 Has the reinforcement been kept clear of formwork or blinding concrete by using concrete, compressed cement, or plastic chairs <br>No wire chairs, pieces of timber or coarse aggregate been used to support reinforcement. <br>Have the chairs been placed sufficiently to ensure maintaining the correct cover.

-

Cl 6.7.3 Was the witness point notified

-

-

Cl 6.7.4 Are the supports for the screeding rails and height pins durable sacrificial non- corrosive materials compatible with the concrete or are they capable of being completely removed from the deck after final screeding.

-

Cl 6.7.5 Is there evidence that the placement of embedment's has been planned in detail.

-

6.7.6 Has the contractor's inspection, verified that reinforcement, welding and embedment placement is correct BEFORE the placed reinforcement and/or embedment becoming inaccessible.

-

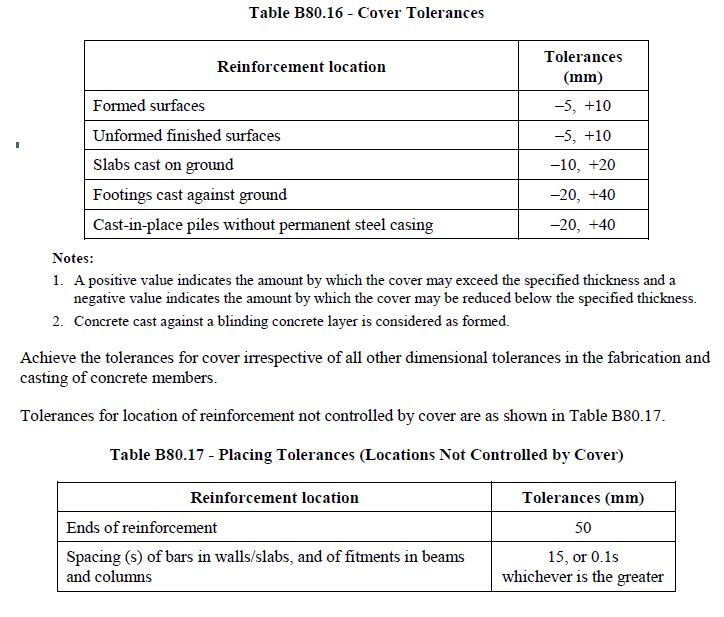

Cl 6.8 Are the covers to reinforcement as per drawings , or within the tolerances shown in tables B80.15, B80.16 & B80.17

-

-

G22 Safety and G36 Environmental

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Has a certified rigger checked that the structural members are secure before the load is released.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Have scaffolds and falsework been erected safely and signed off by qualified personnel where applicable.

-

Are all accesses safe and sign posted.

-

Are all electrical equipment tested and tagged and in good condition.

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

G36 ENVIRONMENTAL

-

R44 Cl 1.7 Were erosion and sediment controls in place prior to the removal of any topsoil.

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name