Information

-

Inspection Title. R116- Heavy Duty Dense Graded Asphalt. (Ed 8 / Rev 4) .

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

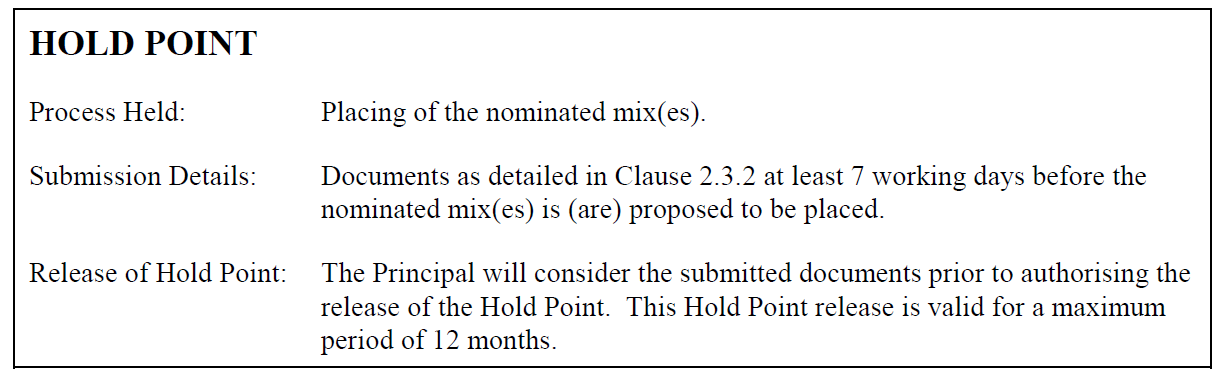

2.3 NOMINATED MIXES

-

-

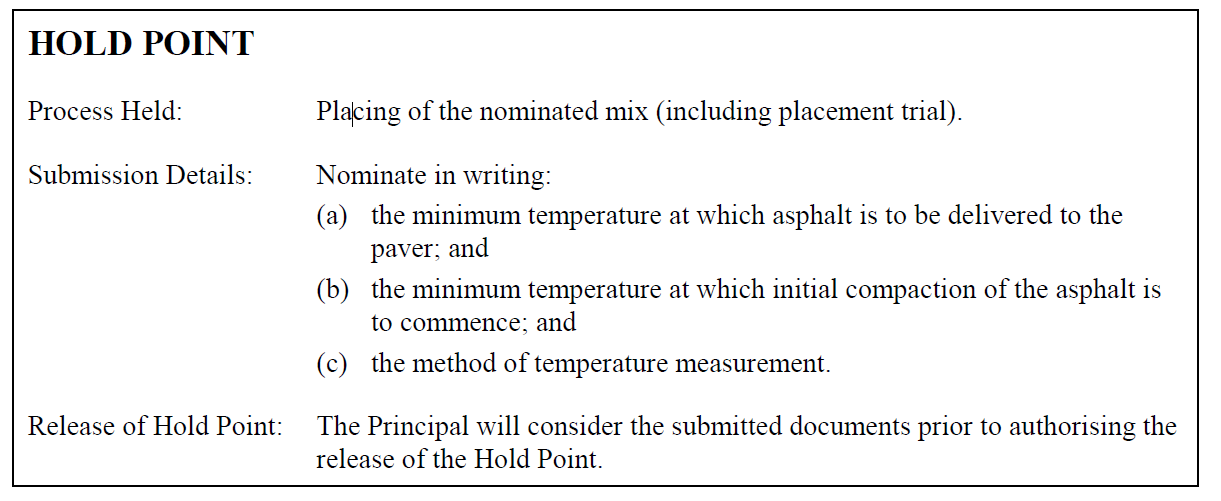

Has the principal released the Hold Point.

Cl 2.4 PRODUCTION of ASPHALT.

-

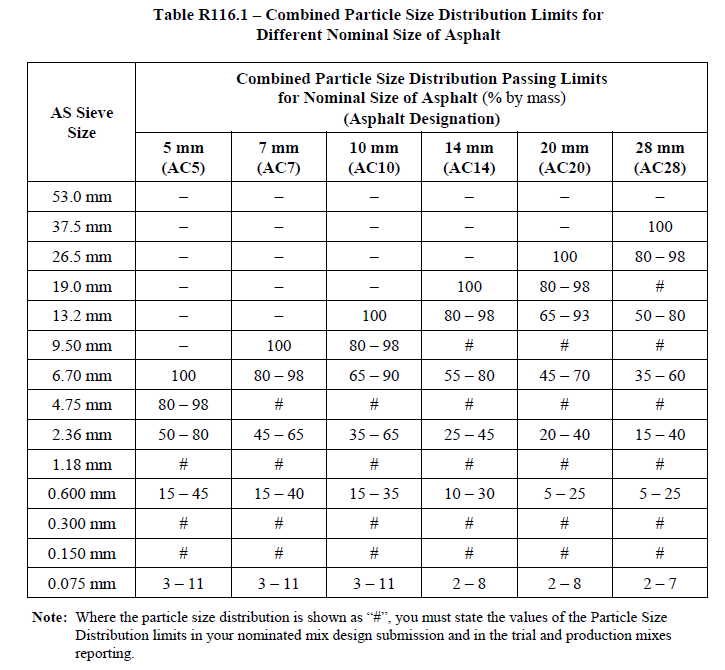

Cl 2.4.2.2 Do the actual combined PSD's remain within the limits of tables R116.1 . <br>

-

-

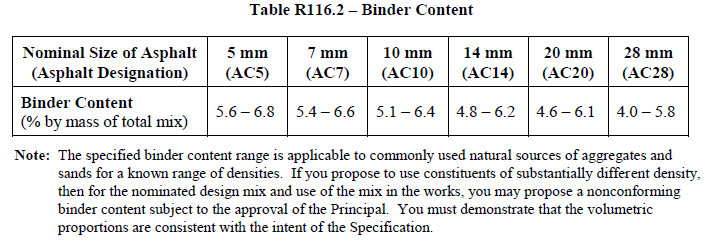

Cl 2.4.2.2 <br>Does the actual binder content remain within the limits of R116.2.

-

2.4.3 Asphalt Manufacturing Plant

-

Must produce auditable records. <br><br>

-

RAP materials must be dispersed uniformly throughout the mix.

-

Must have sufficiently capacity to supply asphalt for a continuous operation of the paver.

2.4.4 Storage and Handling

-

Cl 2.4.4 Storage and Handling. Binder<br>Heating and storage must comply with temperature and time limits set out in advisory note 7 published by AAPA. <br><br>Recirculate in delivery and/or storage tanks to get a uniform consistency. <br><br>

-

Recirculate in delivery and/or storage tanks to get a uniform consistency.

-

Have details been provided in the PQP of the procedures for acquisition, storage and handling of binder.

-

Cl 2.4.5 Manufacturing Temperatures. <br>Are thermometer registrations readable and accurate to within +-2 deg C. <br>The temperature of the asphalt must not have exceeded 175 dec C.

-

Cl 2.4.6 Is the sampling frequency of the asphalt as specified in Annexure R116/L

-

Cl 2.5 Transport of Asphalt. <br>Has sufficient transport capacity been allocated and provided. <br>Is efficient onsite management of asphalt deliveries being implemented.

Cl 3 PLACING ASPHALT.

-

Cl 3.1 Is the method of placing and finishing achieving:<br>A homogeneous product with a tight bound surface.<br>A uniform bond to the surface below<br>The finished pavement properties, specified in clause 4, within the specified tolerances. <br>No rapid cooling of the asphalt by application of water has taken place.

-

Cl 3.2 Has the surface been prepared in accordance with AS2150.

-

Cl 3.3 Is the asphalt being placed by a self propelled paving machine equipped and operated with automatic thickness control and automatic joint matching facility. <br>Hand placement only permitted for minor corrections of existing surface and in areas where placement with a paving machine is impractical. <br>Is the compaction procedure of the asphalt as detailed in the contractors PQP.

-

Cl 3.4 Has the traffic management been in accordance with the TMP and TGS. <br>Has traffic been kept off the surface until the asphalt has been placed, compacted and cooled sufficiently to carry traffic without damage to the work.

-

Cl 3.5 Has Asphalt or other material been prevented from adhering or entering grates, hydrants, valve boxes, service covers, bridge joints and other road fixtures <br>Has all waste asphalt been cleaned and removed from affected services and road fixtures.

-

Cl 3.6.1 Is the nominated layer thickness within the 3.0 to 5.0 times the nominal mix size. <br>

-

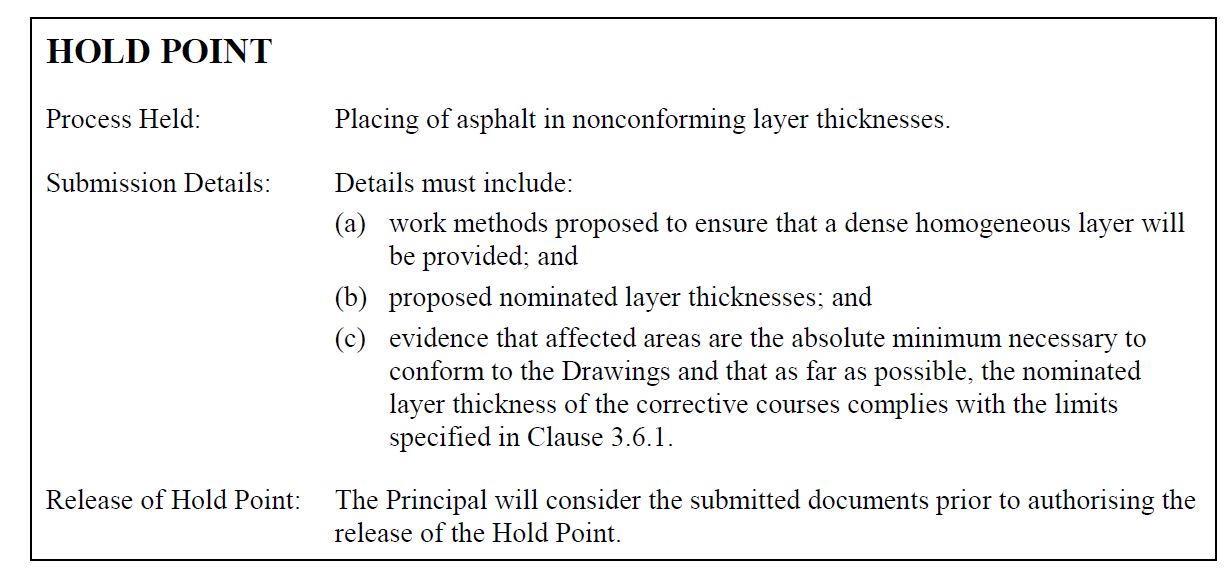

Cl 3.6.2 Has the Principal released the Hold Point. <br>

-

-

CL 3.7 Has the pavement temperature and wind velocity at the point of asphalt placing been measured and recorded. <br>Have the requirements of Cl 3.7 (a,b,c and D) been complied with. <br>Has tack coat or asphalt NOT been placed when the pavement surface is wet and/or rain is imminent.

-

Cl 3.8 Has the Hold Point been released.

-

Cl 3.9 Is the tack coat being applied to a surface that is clean, dry and free from loose material. <br>Is the tack coat applied evenly between .15 to .30 litres of residual bitumen per m2. <br>Has the contractor nominated in writing the proposed application rate prior to applying the tack coat. <br>Is a daily endorsed record of the average tack coat application per lot being submitted.<br>Is the tack coat intact at the commencement of asphalt placement. <br>

-

Cl 3.10 Is the procedure for the construction of joints detailed in the PQP. <br>Is this procedure being followed. <br>Has all loose, cracked and/or boney material removed from the paved material prior to placing the adjacent mat. <br>Longitudinal joints: coincide with the final traffic markings, ( unless otherwise approved by the principal). <br>Transverse joints; Formed at the commencement of each paving run.

Cl 4 FINISHED PAVEMENT PROPERTIES.

-

CL 4.1.1 Do Insitu air voids for the lots comply with table R116.7.

-

-

Cl 4.1.2 Has compaction control been carried out using statistical techniques as specified in RMS Q. <br>Bulk density can be determined from cores taken from site or nuclear density meter. <br>Are cores taken in accordance with AS 2891.9.2. <br>Air voids must be determined for: every change in underlying pavement material and layering within 300 mm of the surface to the layer being measured.<br>Every change in nominated mix and specific layer thickness. <br>

-

Cl 4.2.1 Is the course thickness between 45mm and 53 mm

-

Cl 5.3 Has the frequency for the testing of the asphalt been carried out in accordance with R116/L.

-

Cl 4.2.2 Have the CV and average values of each lot been done as per RMS Q

-

Cl 4.4.2 is there no ponding of water on the finished surface. <br>Does the surface comply with the straight edge tolerance in table R116.10.

Cl 5. CONFORMITY.

-

Cl 5.1 Is the asphalt homogeneous.

-

Cl 5.2 Have all sampling locations, frequencies and test methods been nominated in the PROJECT QUALITY PLAN.

-

Cl 5.3.1 Is the frequency of testing as specified in Annexure R116/L.

-

Cl 5.3.3 Has the results of testing been submitted with the required time frame <br>Test results for binder content , combined PSD and air voids in the laboratory compacted mix. (1 day) <br>Test results for the insitu air voids, course thickness and course shape within 3 working days of placing the asphalt.

-

Cl 5.5 have all non conformances been reported and closed out.

G22 Safety and G36 Environmental

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

G36 ENVIRONMENTAL

-

R44 Cl 1.7 Were erosion and sediment controls in place prior to the removal of any topsoil.

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name