Information

-

Inspection Title. BORED CAST-IN-PLACE REINFORCED CONCRETE PILES (WITH PERMANENT CASING)

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

2.1 PERMANENT STEEL CASINGS

-

Cl 2.1.1 Steel casings must have a wall thickness not less than that shown on the Drawings.

-

Cl 2.2.2 Provide evidence that the materials used comply with the relevant Australian Standards and RMS specifications. A mill certificate with appropriate NATA registration from the material supplier will constitute documentary evidence of compliance.

-

Cl 2.1.3 Unless otherwise specified, the inside diameter of the casing must be one of the following standard sizes:

-

Cl 2.1.3 (a) Casings fabricated from steel plate rolled to a circular cross-sectional shape and welded at the longitudinal joint to form segments which are then shop spliced into suitable lengths. The welds for the longitudinal joints and shop splices must be full penetration butt welds. The longitudinal joints for adjoining segments must be staggered by 90° to each other.

-

Cl 2.1.3 (b) Spirally welded tubes complying with AS 1579. The welds must be full penetration butt welds carried out using the submerged arc process from both sides of the tube.

-

The out-of-round (i.e. difference in measurements of two diagonals at right angles) of a casing must not exceed 1% of the internal diameter, provided that the concrete cover specified on the Drawings is maintained.

3 PILING PLANT AND EQUIPMENT

-

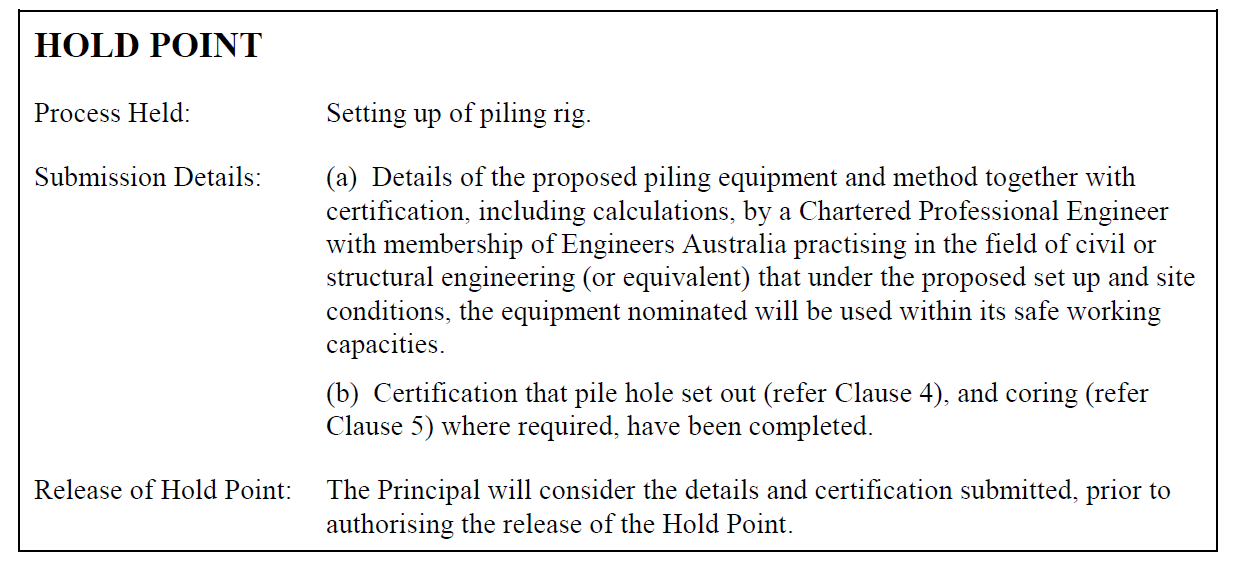

Without limiting the requirements of Specification RMS G22, prior to bringing any piling equipment or plant to the site provide drawings and calculations certified by a Chartered Professional Engineer with membership of Engineers Australia practising in the field of geotechnical engineering (or equivalent) of any working platforms or supports required to keep the piling rig stable and safe during piling operations at the site.

-

Has the Hold point been released

-

4 SET OUT

-

Set out the site with adequate recovery pegs and survey markers so that the drilling and/or piling rig can be set up accurately on the location and alignment for each pile.

5 CORING

-

When directed by the Principal and as required by site conditions, take 50 mm diameter cores prior to excavating the pile hole, to confirm the adequacy of the pile base and shaft.

6 EXCAVATION AND CLEANING OF PILE HOLE

-

Cl 6.1.2 Your Piling Supervisor must supervise and control the piling operations at all times.

-

Cl 6.1.2 During excavation of each pile, a Geotechnical Engineer, engaged by you, must also be in attendance to verify that the founding material in the pile rock socket meets the requirements shown in the Drawings.

-

Cl 6.1.3 Tolerances on pile installation must conform to Section 7 of AS 2159, (75mm) except that the inclination tolerance for vertical piles is 1%, measured on the internal side of the casings.

-

Cl 6.1.4 Collect and treat the water resulting from your piling operations in accordance with Specification RMS G36.

-

Cl 6.1.4 Remove all excavated material from the Site, unless otherwise specified.

-

Cl 6.1.5 Make each pile hole safe with appropriate measures, including covering it with a secure lid whenever the pile is not under construction.

-

Cl 6.1.5 Leave the finished top of the casing at least one metre above ground level to prevent personnel and loose material from falling into the pile hole.

-

Cl 6.2.1 Are methods used to install the casings, excavating and cleaning the pile holes and for verifying the specified requirement have been met as proposed in the PQP.

-

Cl 6.2.2 Are full pentration butt welds over the the whole cross section of the casing if splicing is required.

-

Cl 6.2.3 Where necessary, Are methods acceptable to the principle to prevent the pile hole excavation below the casing from callapsing being used

-

Cl 6.2.4 Record and measure the operating parameters of the drilling rig when excavating the first pile hole.

-

Cl 6.2.4 Excavate subsequent pile holes after the first pile with the same drilling rig operating parameters and work methods as that recorded during excavation of the first pile hole.

-

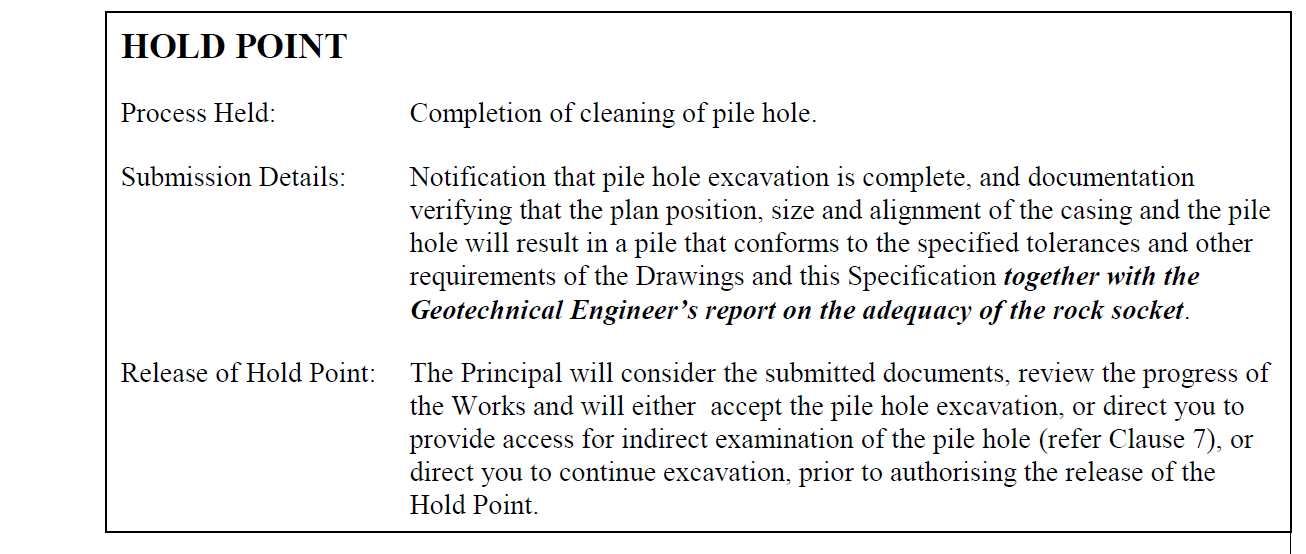

6.3.1 Direction By Geotechnical Engineer<br>Has the attending Geotechnical Engineer will verify the founding material in each pile rock socket and direct the Piling Supervisor as to when ground or rock of the class specified on the Drawings has been reached,

-

6.3.2 Further Excavation After excavation of the pile hole the principal will

- accept the level reached as the final pile toe

- direct that excavation be continued to a lower level.

-

Are appropiate methods being adopted by the piling operator to prevent callopse of the pile walls below the casing?

-

6.3.3 Side Wall Roughening and Base Cleaning<br>After roughening the side walls, clean the base of the pile so that intact rock is exposed over the pile base.

-

6.3.4 Acceptance of Pile Hole

-

Has the Hold point been released

-

Has the steel reinforcement and concrete been placed as soon as practical following final socket cleaning, and within 24 hours of the excavation of the pile hole.<br>

7 INDIRECT EXAMINATION OF PILE HOLE

-

<br>Verify conformity of the depth of each pile hole using a weighted tape at least at three locations.

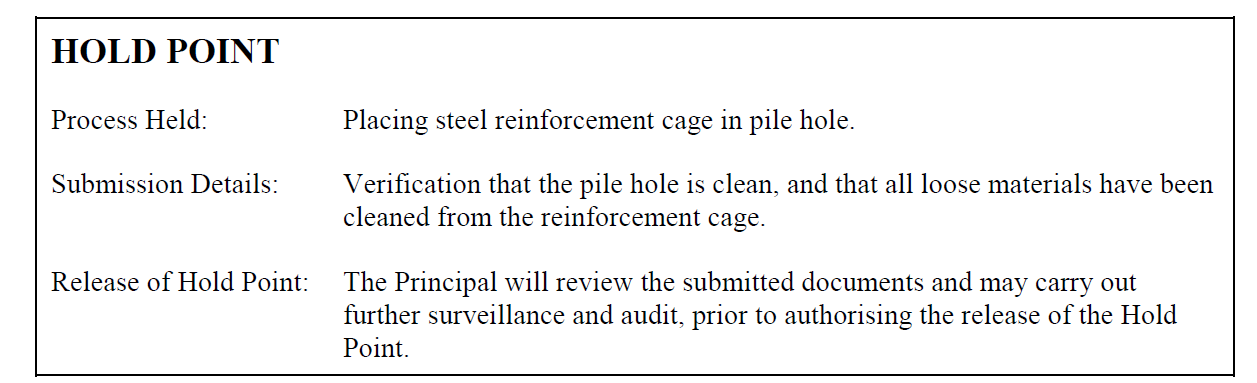

8 REINFORCEMENT

-

Cl 8 The spacers attached to the cage must be of an approved type and distribution capable of providing the specified concrete cover and maintaining the cage in the specified position, over the whole length of the pile, after placement and during concreting.

-

Cl 8 Is the reinforcement cage free from loose and adhering material.

-

Cl 8 Has the Hold point been released .

-

-

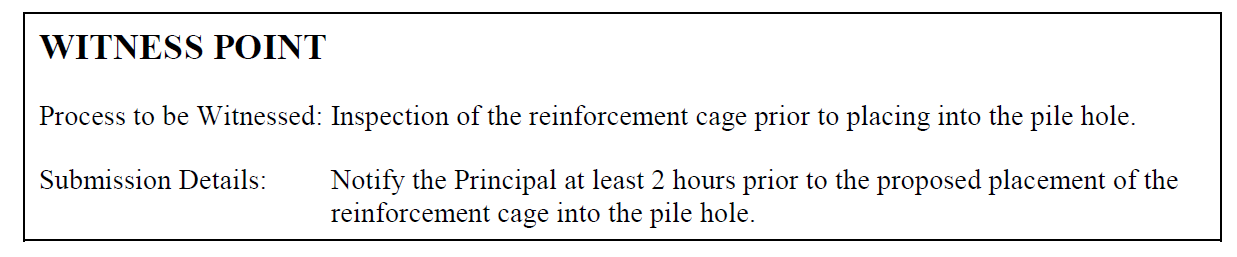

Cl 8 Was the Witness point witnessed

-

9 CONCRETE

-

Cl 9.1 Was the concreting of the pile commenced within 2 hours of the release of the Hold Point in Clause 8.

-

Cl 9.2 Which method was was used to place the concrete

- A centrally placed rigid hopper and pipe to a depth

- Tremie methods in a continuous process

-

Cl 9.3 Is the mix delivered as specified

-

Cl 9.4 Tremie concrete placement carried out in accordance with specified requirements.

-

Cl 9.4 Tremie pipe joints watertight throughout

-

Cl 9.4 End of tremie pipe remains 2m below top surface of concrete

-

Cl 9.4 Was concreting continued until sound concrete appears a minimum of 400 mm above the required pile cut-off level, to avoid defective concrete at or below cut-off level.

-

Cl 9.5 During concreting, Were a records maintained of the depth of the tremie outlet and the level of the concrete in the pile hole, and the corresponding volume of concrete placed.

10 CUT-OFF AND CLEAN UP OF TOP OF PILE

-

Cl 10 Was the pile head left undisturbed for a minumim of 24 hours after completeion of concreting.

G22 Safety and G36 Environmental

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Has a certified rigger checked that the structural members are secure before the load is released.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Have scaffolds and falsework been erected safely and signed off by qualified personnel where applicable.

-

Are all accesses safe and sign posted.

-

Are all electrical equipment tested and tagged and in good condition.

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

-

Have any environmental incidents or potential incidents been observed.

ENVIRONMENTAL

-

Have erosion and sedimentation control measures been installed and maintained?

-

Have nearby/adjacent waterways been protected from potential concrete, grout and curing compound spills?

-

Has concrete wash out area been defined and used?

-

Has mud been prevented from being deposited on roadways.

-

Are there any environmental incidents or potential incidents observed?

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name