Information

-

Inspection Title. B80 Concrete work for Bridgework- Formwork. Ed6 / Rev 5

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

5 FORMWORK

-

Cl 5.1 Does formwork, including all temporary supporting members conform to AS 3610 requirements.

5.2 FORMWORK DESIGN, DOCUMENTATION AND CERTIFICATION

-

Cl 5.2.3 Do the designed formwork drawings clearly note all construction requirements including. <br>Design assumptions, foundation preparations, footing details and precamber diagrams. <br>Can the erection and inspection be carried out without reference to any other documentation.<br>Design any steel girders used for support and all associated bolted or welded splices in accordance with AS5100 <br>All bolts and fasteners must conform to specification RMS B240

-

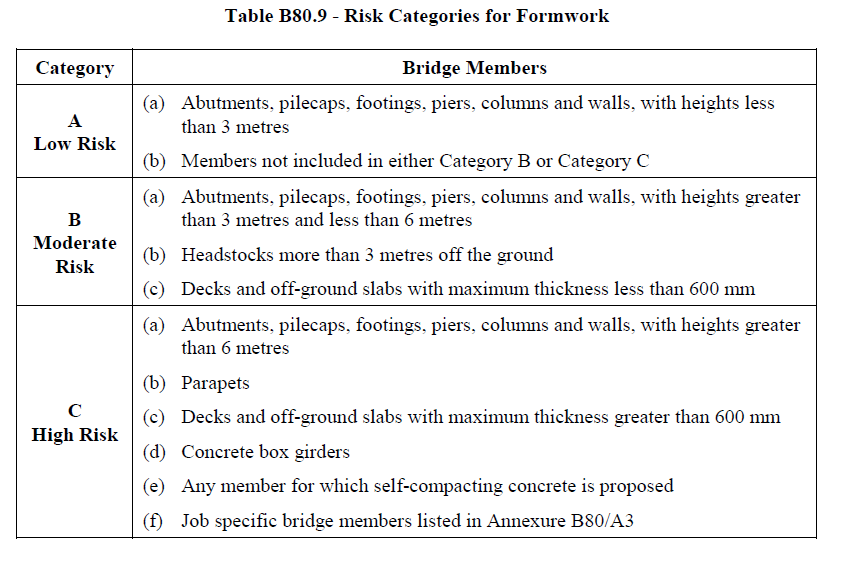

For the purposes of this clause, the formwork for the various members of the bridge structure is divided into three Risk Categories as detailed in Table B80.9.

-

-

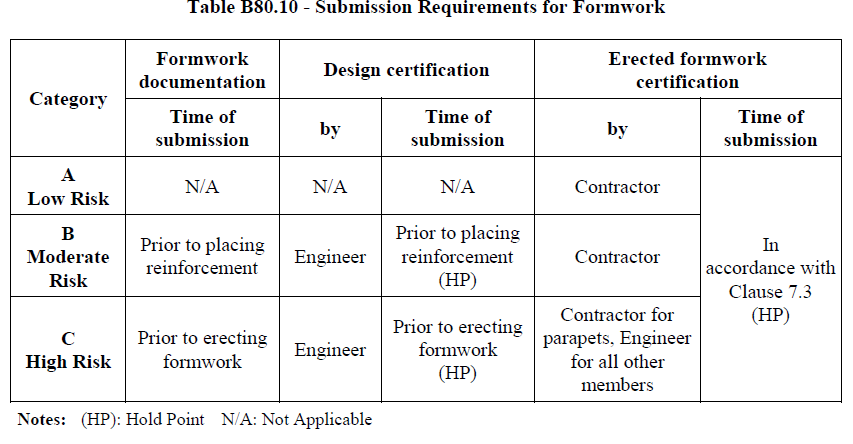

Table B80.10

-

Cl 5.2.4 The submission of all formwork documentation and certification for each category must be in accordance with table B80.10. <br>Is the certifying engineer a member of the Engineers Australia or (equivalent) and experienced in the design and erection of formwork of at least similar complexity. <br>The certification for the erected formwork must state that the formwork has been erected in accordance with either the formwork documentation for Cat A, or certified design for Cat B and C <br><br>Any changes proposed to the certified design or erected formwork must be accompanied by documentation and certification conforming to this clause.

-

HOLD POINT (Does not apply to Category A formwork)

Process Held: For Category B formwork – Placement of reinforcement. For Category C formwork – Erection of formwork.

Submission Details: For Categories B and C, formwork documentation and Engineer's design certification in accordance with Clause 5.2.

Release of Hold Point: The Principal will consider the submitted documents prior to authorising the release of the Hold Point. Where the Principal has concerns about the adequacy of the formwork documentation or certification, the Principal may order an independent verification of the formwork design at your expense before releasing the Hold Point. -

Cl 5.2.4 Has the principal released the Hold Point.

5.3 SURFACE FINISH

-

5.3.1 Is the formwork designed and constructed to produce the class of finish stated in B80 Cl 5.3.1.

TEST MEMBERS

-

Cl 5.3.2 HOLD POINT, Process Held: Erection or prefabrication of formwork for members specified in Annexure B80/A4 or on the drawings.

-

HOLD POINT (If test members are required)

Process Held: Erection or prefabrication of formwork for members specified in Annexure B80/A4 or on the Drawings.

Submission Details: Give the Principal two working days notice in writing of the proposed placement of concrete in the test member to permit observation of the process. Thereafter, give the Principal the opportunity to inspect the completed member.

Release of Hold Point: The Principal will consider the method of construction and the finished test member, prior to authorising the release of the Hold Point. -

Cl 5.3.2 Has the Principal released the Hold Point.

Cl 5.4 SITE RELATED REQUIREMENTS

-

<br>Formwork for concrete intended for composite action with a member previously constructed must be designed as per clause 5.4

Cl 5.5 CONSTRUCTION JOINTS

-

Have the construction joints been located as per the drawings and been prepared correctly. <br>Are construction joints at the base of columns or walls at least of 100mm above the tops of the footings or pile caps. <br>Are construction joints on visible faces formed using suitably dressed timber beading, or by other means, so that the joints are straight and regular.

Cl 5.6 MATERIALS FOR FORMWORK SURFACES.

-

Is the formwork for exposed concrete surfaces steel plate conforming to AS/NZS 1594 or plywood conforming to AS/NZS 2271.<br>Are a all forms placed in a neat and symmetrical pattern.

Cl 5.7 ERECTION OF FORMWORK.

-

Cl 5.7.1 Has the formwork been strictly erected in accordance with certified formwork documentation and drawings. <br>Have commercial quality form release agents, oil or grease been used and applied correctly. <br>Have any traces of the form release agents been removed from reinforcement, tendons and embedments. <br>Has all loose wire, dirt, wood chips, hardened concrete or mortar, and all other foreign matter been removed. <br>Are the joints in the formwork mortar tight.

-

Cl 5.7.2 Has the erected formwork been checked by survey.<br>Are records being maintained to comply with Cl 5.7.2.

Cl 5.8 TOLERANCES.

-

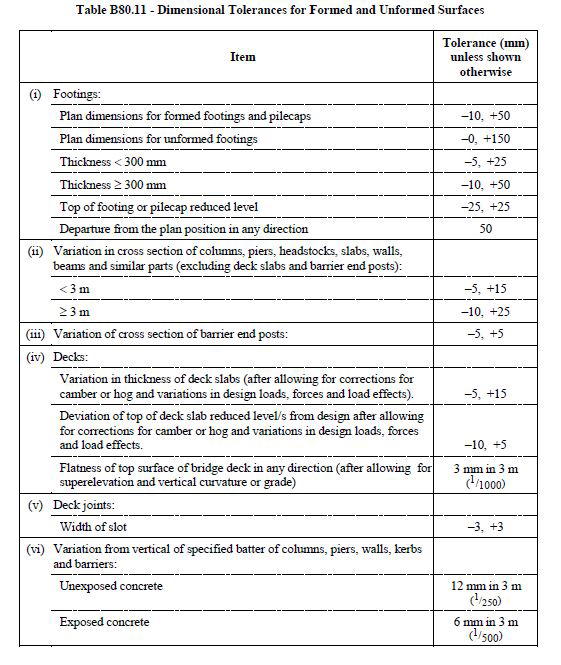

Is erected formwork within tolerances as stated in Table B80.11 and conform to surface finish requirements of clause 5.3.

-

Table B80(a)

-

Table B80 (b)

Cl 5.9 REMOVAL OF FORMWORK

-

Cl 5.9.1 Has the formwork been removed in such a way to achieve the specified characteristics, prevent damage to the old or recently placed concrete, and maintain safety at all stages of removal.

-

Cl 5.9.2 Has the formwork been removed within the allowable timeframe ( Refer drawings or Table B80.12)

-

Table B80.12

Cl 5.10 REPAIRS TO FORMED SURFACES.

-

Has a concrete repair method been approved by the principal.<br>Have the repairs been carried out promptly using the approved method and materials so that a general uniform appearance, texture and colour is achieved

G22 Safety and G36 Environmental

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Has a certificate rigger checked that the structural members are secure before the load is released.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Have scaffolds and falsework been erected safely and signed off by qualified personnel where applicable.

-

Are all accesses safe and sign posted.

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

G36 ENVIRONMENTAL

-

R44 Cl 1.7 Were erosion and sediment controls in place prior to the removal of any topsoil.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractor's NCR No

-

CAR no

-

Closed out.

-

RMS representative's name