Information

-

Inspection Title. B80 Concrete Placement

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

3 DESIGN OF CONCRETE MIXES

-

Cl 3.4 Has the curing method been agreed and is the material onsite.

-

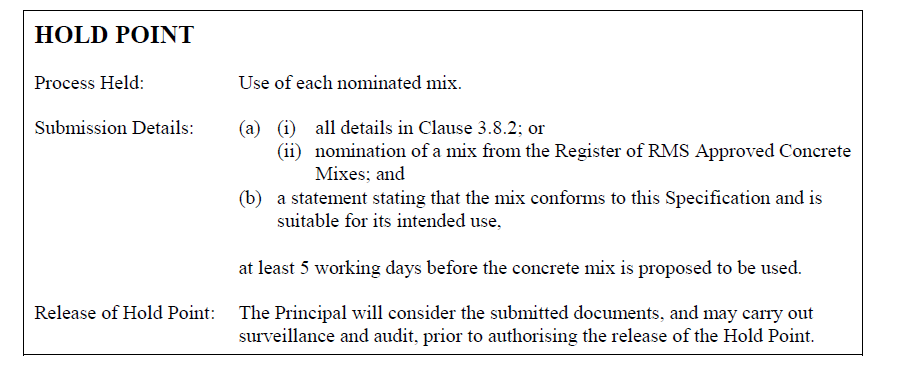

Cl 3.8.1 Has the Hold Point for the mix design been released.

-

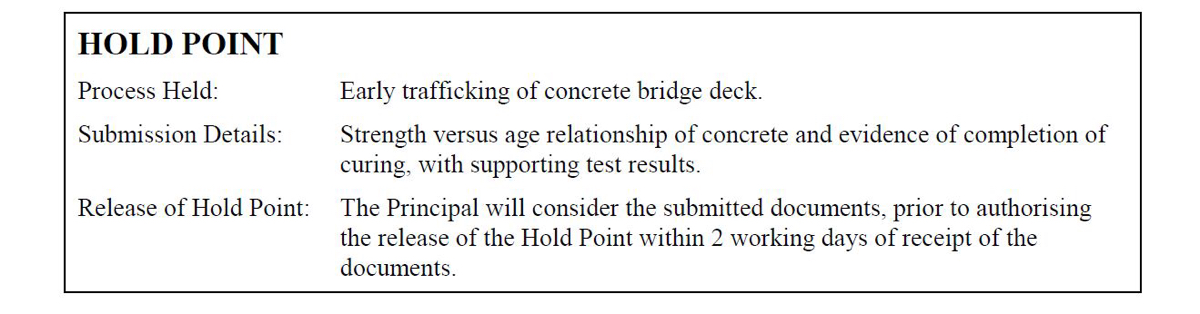

Cl 3.8.1 HOLD POINT

CL 4 SUPPLY and DELIVERY of CONCRETE

-

Cl 4.1 Has the conforming mix type concrete been delivered.

-

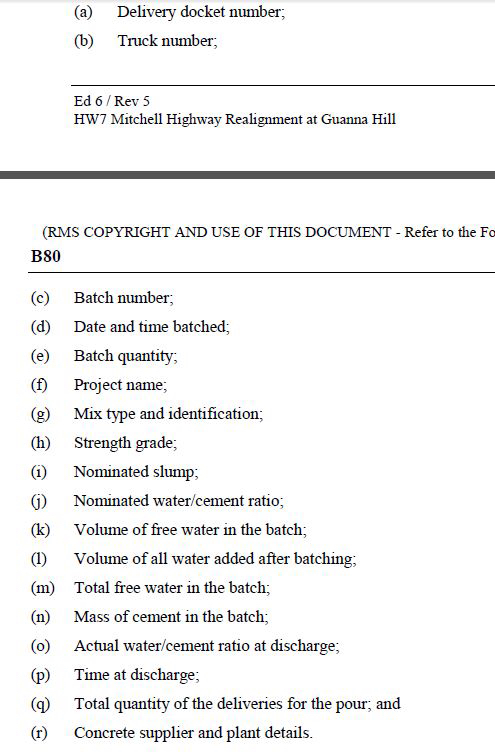

Cl 4.3.4 Have all concrete batches been delivered with a delivery docket containing the details listed in this clause (see Tables section)

-

Cl 4.35 Has the concrete been placed and compacted with 1.5 hours from batch (unless otherwise approved).

-

Cl 4.4 Have all loads delivered been slumped.

-

Cl 4.5 Has water only been added onsite if:<br>It is less than 45 minutes from batch. <br>Correct retempering procedure followed <br>The amount of water added recorded.<br>The load is re slumped.

-

Cl 4.6 Is the temperature of the concrete within range 10 deg C to 32 deg C.<br>For precast and cast-in-place piles 5 deg C to 35 deg C. <br>

6 SUPPLY AND FIXING OF STEEL REINFORCEMENT AND EMBEDMENTS

-

Cl 6.3.1 Has the reinforcement been fabricated as per the drawings and been placed with the correct cover.

-

Cl 6.7.2 Has the reinforcement supports been correctly positioned and secure.

7 PLACING, COMPACTING, FINISHING AND CURING OF CONCRETE

-

Cl 7.1 Has the concrete been placed, compacted, finished and cured so as to:<br>(a) prevent segregation or loss of materials

-

(b) Prevent premature stiffening.

-

(c) Prevent nonconforming displacement of reinforcement, fitments or embedments.

-

(d) Produce a dense homogeneous product which is monolithic between planned joints and/or the extremities of members, or both.

-

(e) Completely fill the formwork to the intended level, expel entrapped air, and surround all reinforcement, tendons, ducts, anchorages and embedments.

-

(f) Provide the specified finishes.<br>

-

(g) Control cracking, including that caused by plastic and drying shrinkage, concrete slumping, plastic settlement, crusting and thermal gradients.

-

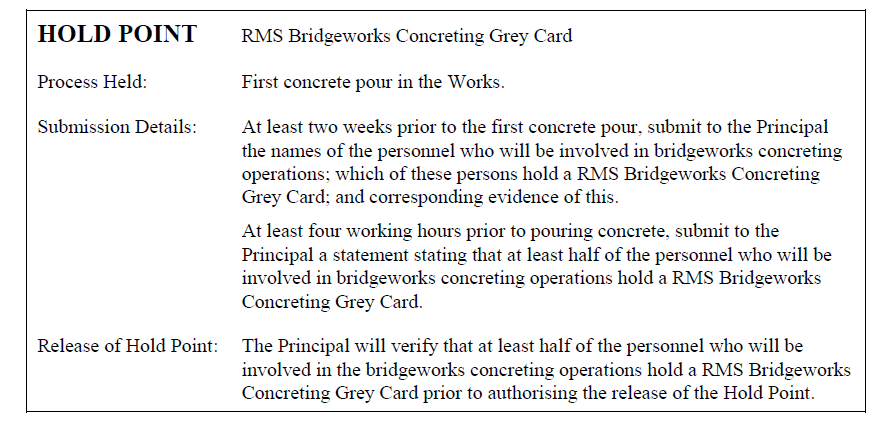

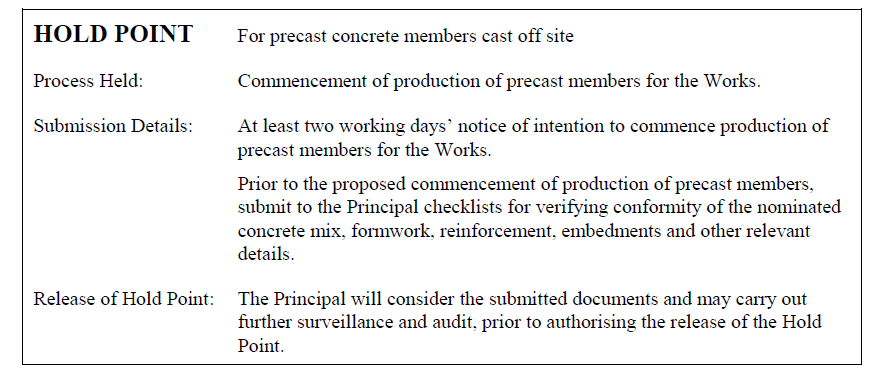

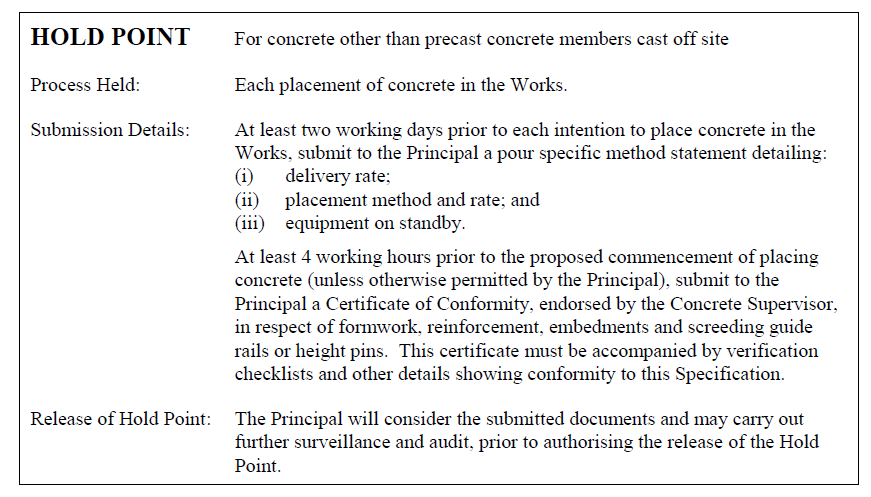

Cl 7.1 Has the HOLD POINT been released.

-

-

Cl 7.3 Has the HOLD POINT been released

-

Cl 7.3 HP

-

Cl 7.4.2 Has the method of concrete placement met the following requirements. <br>(a) Concrete evenly placed in one continuous operation

-

Has the HOLD POINT released.

-

Cl 7.3A HP

-

7.4.2 (b) Concrete dropped from a height that segregation cannot occur.

-

Cl 7.4.3 Concrete vibrated correctly, using a sufficient number of vibrators.

-

Cl 7.5 Unless the principal approves special precautions , all concrete other than cast-in-place piles must not be placed if the air temperature in the shade is:<br>Below 5 deg C or above 38 deg C. <br>Predicted to be below 5 deg C in the 24 hours after placement.

-

Cl 7.5 For cast-in-place piles do not place concrete if<br>Ice exists on pile casings, embedments, steel reinforcement or in the pile holes.

-

Cl 7.8 Has all free water been removed from the area where concrete is to be placed. <br>If not then place in water using tremie concrete in accordance with Specification RMS B58 or RMS B59. <br>Do not place in water below 5 deg C.

-

Cl 7.9 Surface of construction joints must have;<br>Surface roughness not less than 3mm. <br>All loose material removed.

-

Cl 7.11.2 Deck and Approach Slab Surfaces. <br>Have the surfaces been finished using a vibrating screed on rails, suspended above reinforcement.

-

Cl 7.11.2.5.Is the finishing type either by wood floating or steel trowelling followed by sweeping. Is the quality of concrete finish acceptable.

-

Cl 7.12.1 Is the curing in accordance with the curing regime nominated in item (d) of clause 3.8.2

-

Cl 7.12.1 <br>Have all cast in place bridge decks or approach slabs for a minimum of 72 hours after finishing operations are completed.

-

Cl 7.12.2 Wet Curing: concrete must be wet and covered with canvas, hessian, geofabric with plastic sheeting, or other suitable materials and be kept wet continuously.

-

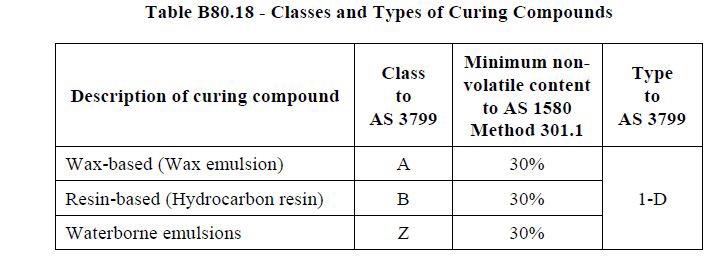

Cl 7.12.3.2 Curing compounds must conform to AS 3799 for Classes and Types specified in Table B80.18.

-

Cl 7.15 EARLY TRAFFICKING of BRIDGE DECKS

-

CL 7.15 HAS THE HOLD POINT been released.

8 PROPERTIES OF HARDENED CONCRETE

-

Cl 8.1 Have methods and frequencies of sampling and testing of concrete been in accordance with Annexure B80/L

5 FORMWORK

-

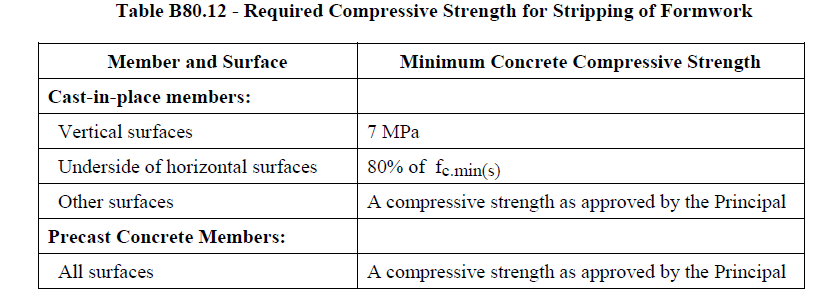

CL 5.9.2 Has formwork been stripped on or after the date that concrete achieved the required compressive strength.

As per table B80.12 -

Cl 5.9.2 Date formwork can be stripped.<br>Date formwork was stripped.

G22 Safety and G36 Environmental

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Has a certified rigger checked that the structural members are secure before the load is released.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Have scaffolds and falsework been erected safely and signed off by qualified personnel where applicable.

-

Are all accesses safe and sign posted.

-

Are the Worker on Foot procedures being followed.

-

Are all plant and vehicles fitted with beacons, reversing alarms and cameras where required.

-

Is all electrical equipment tested and tagged and in good condition.

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

G36 ENVIRONMENTAL

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Have nearby/adjacent waterways been protected from potential concrete, grout and curing compound spills.

-

Has a concrete washout area/s been defined and used.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name

Tables

-

Cl 4.3.4

-

Table B80.18