Information

-

The name of the RCA will be automatic based on the answers on this page.

Choose the relevant plant – site…

Choose equipment involved – note this is for identification later so choose the equipment you can identify this issue with.

If it is NOT equipment based choose whether it is Personnel/Procedural or an Outside influence. -

Plant/Site

-

Equipment Involved (If applicable)

-

People Issue Involved (If not equipment based)

-

Commenced on

Root Cause Analysis

Clarify

-

Here we can choose if we are using the RCA electronic form or if you have completed a paper form or used a whiteboard or other medium to complete.

If you choose RCA it goes into the full format.

If you choose Load paper RCA/5Y follow instructions. -

Do you wish to complete an RCA or record a manual paper RCA or 5 Why into iAuditor .

-

At this point you can add a photo of any paperwork or whiteboard used for the RCA .

You can add actions – Note due to the way the system works you need to load details of actions twice. Press add element then type in the action/person responsible and due date – then click on the “paperclip” icon on the right of the action and click “action” here you renter the action required, assign to yourself or someone else- there is a list of all those registered on iAuditor or you can enter an email address manually. Also add the due date and a priority.

All actions are tracked and can be amended or updated on the ipads action screen.

The person being assigned the action will get an email asking them to complete the action and a due date.

Also on the bottom of the add element section is a follow up tab. This is how you finialise that action when it gets completed.

You can add as many actions as you need. -

Add a photo/s of your paper RCA and any supporting documents.

-

Add a photo/s of your paper RCA and any supporting documents.

-

Name and Signature of person loading this RCA or 5WHY into system.

If there are further actions to complete please record them here.

-

Action: enter details here and also click on "paperclip" icon to right and enter action/person responsible/due date/priority. This sends an email to the responsible person and tracks the action.

-

Responsible

-

Due Date

-

Follow up: completed ?

Overview

-

This Template follows the process of the GF Problem Solving RCA Form. You may use some or all sections of the RCA form although the initial steps of identifying the issue must be completed.

The Process:

Complete an RCA with all findings recorded using this template.

Ensure follow up actions are allocated to someone.

Review actions for completion and effectiveness during the regular RCA review meeting.

The Review meeting decides when the RCA is fully completed and able to be signed off. -

Do you need further detail on how to do a Root Cause Analysis ?

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

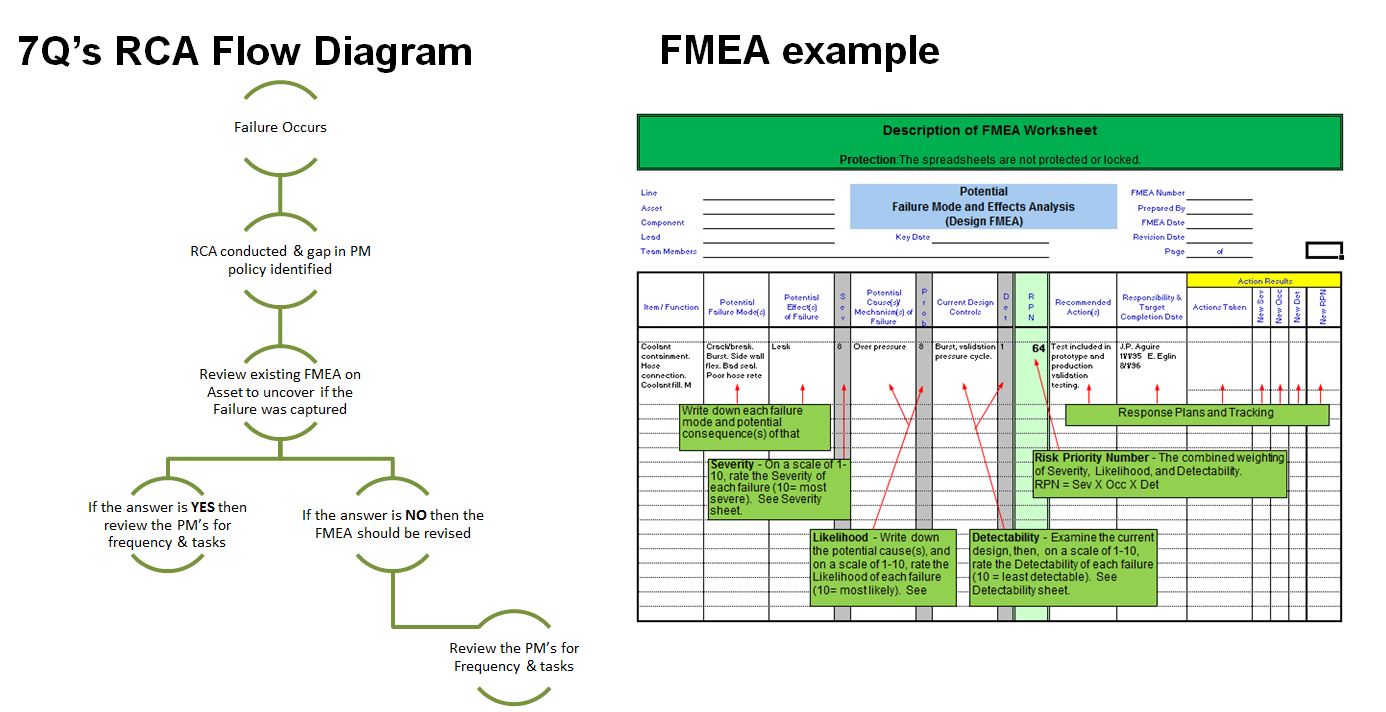

The key point of any RCA process is to get to the root cause and the eliminate reoccurrence.

If one or more actions resulting from the RCA process highlight a gap in the PM policy it is critical to do the following to maximise the opportunity

Review the existing FMEA for the asset to see if the failure that occurred was captured?

If the answer is YES move to point 3, if the answer is NO then the FMEA needs to be updated to capture the new failure mode and then points 3 and 4 completed.

Review the PM for the frequency it is conducted to ensure it provides the best opportunity to negate the failure and

Review the PM tasks to ensure it clearly explains to the reader how to carry out the task/s -

Add a photo/s as required to help identify the issue and area.

-

Next we have some clarifying questions for the RCA process.

Is it equipment or People/process based.

Date and time of incident/issue.

What shift it occurred on.

Name and signature of person leading RCA.

You can also add names of anyone else participating. -

Is an Asset involved (breakdown or equipment issue) or is this process/people related ?

- Equipment

- Process (Product/prep/procedure)

- People

-

Issue is related to ?

-

Asset Involved

-

Description of "other" Asset

-

Date and time of incident

-

Shift issue occurred on

-

Name and Signature of person leading RCA

-

Name and Signature of person attending Note you can have multiple names and signatures if reqd in each box.

-

Name and Signature of person attending Note you can have multiple names and signatures if reqd in each box.

-

Name and Signature of person attending Note you can have multiple names and signatures if reqd in each box.

-

Name and Signature of person attending Note you can have multiple names and signatures if reqd in each box.

-

Name and Signature of person attending Note you can have multiple names and signatures if reqd in each box.

Step 1. Observe the problem firsthand, preferably as a Team. Get the facts. This is the most important step as all other steps depend on the accuracy of this step.

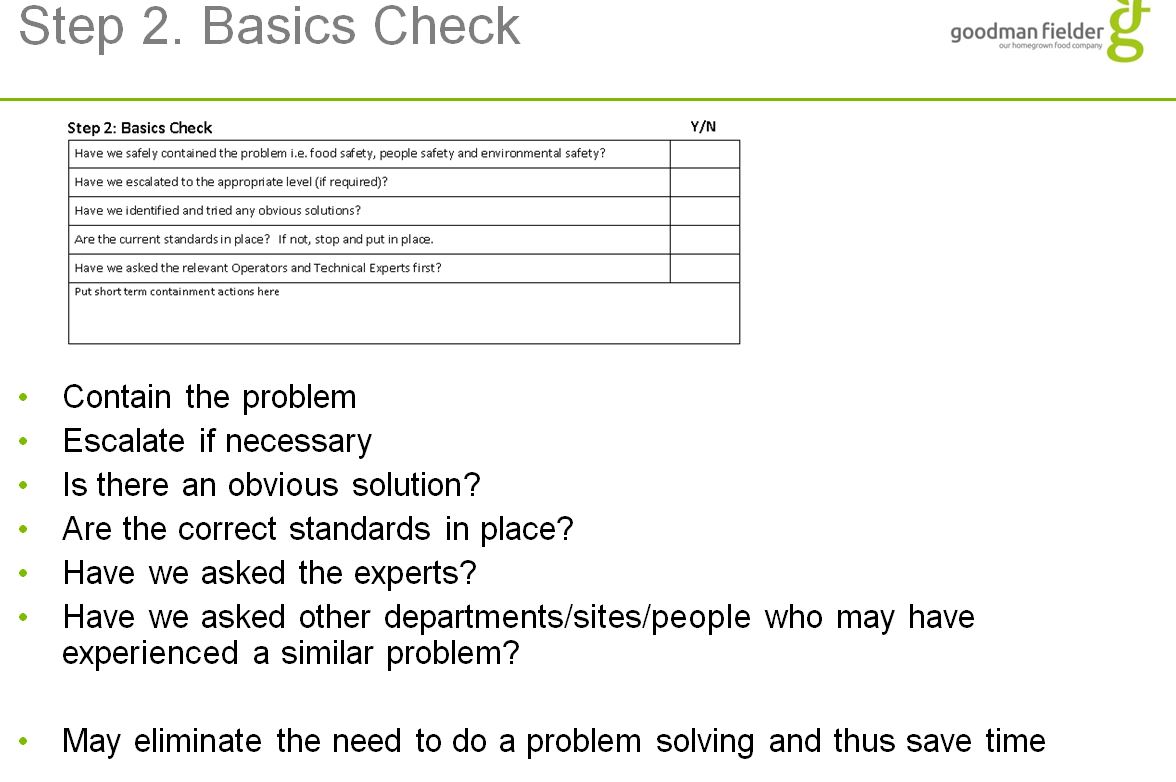

Step 2. Basics Check

-

Have we safely contained the problem i.e. food safety, people safety and environmental safety ?

-

Have we escalated to the appropriate level (if required)

-

Have we identified and tried any obvious solutions ?

-

Are the current standards in place ? If not, stop and put in place .

-

Have we asked the relevant Operators and Technical Experts first ?

-

Add any short term containment actions here.

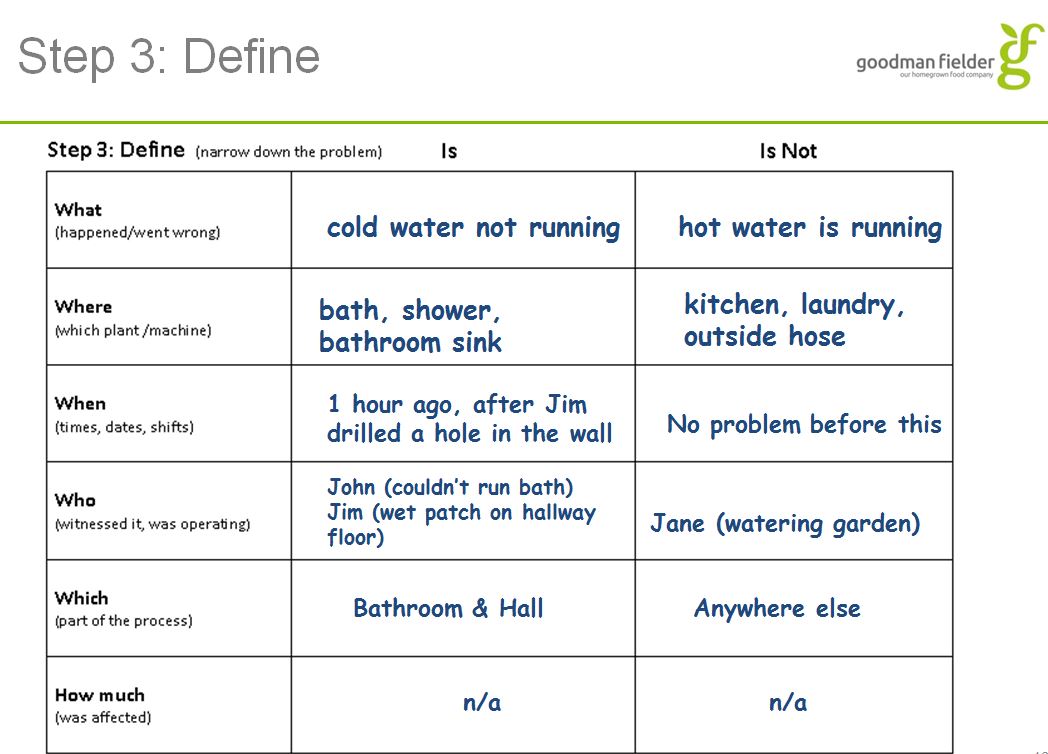

Step 3: Define (Narrow down the problem)

-

What (happened/went wrong) Define what it is and what it is not.....

-

Where (which plant/machine) Define what it is and what it is not.....

-

When (times/dates/shifts) Define what it is and what it is not.....

-

Who (witnesses/operators) Define who was involved and who was not.....

-

Which (part of the process or machinery) Define what it is and what it is not.....

-

How Much (was affected) Define what is and what it is not.....

-

Please Enter details of the product being produced, bake times or specific parameters.

-

Add photo/s as required to identify the problem.

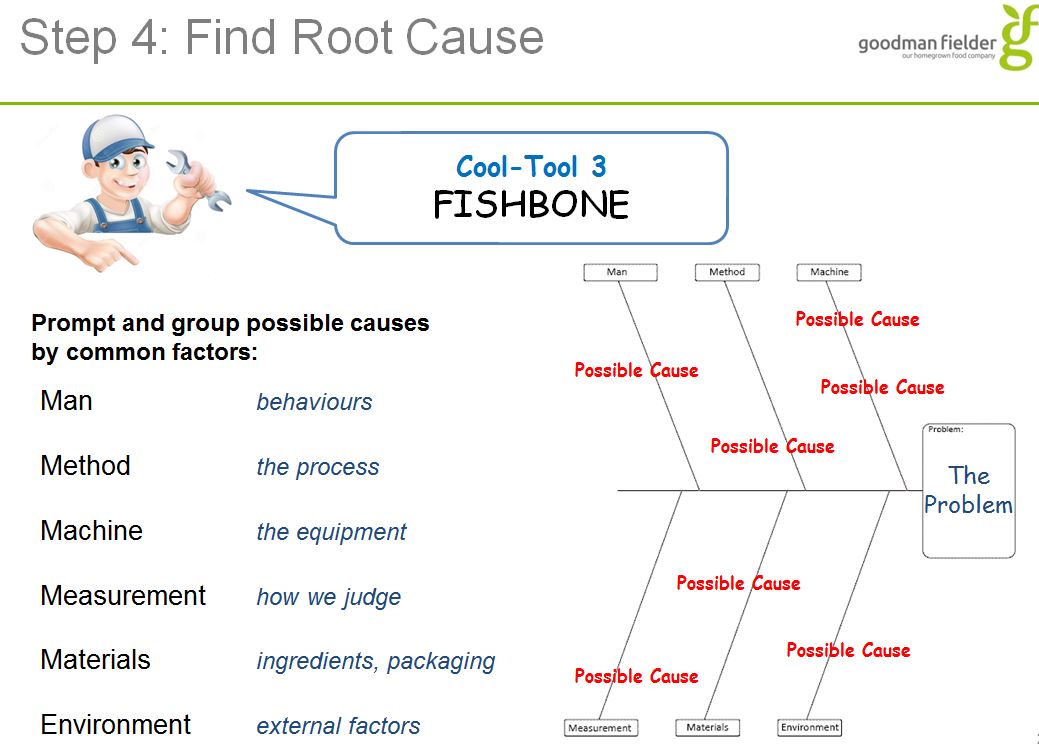

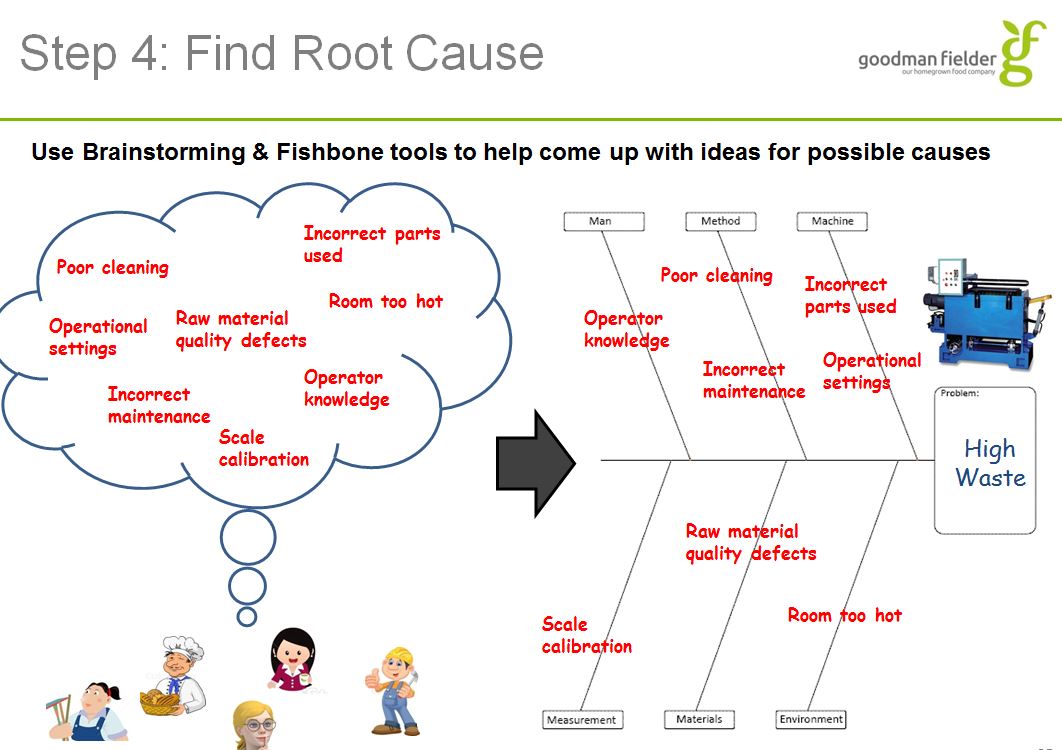

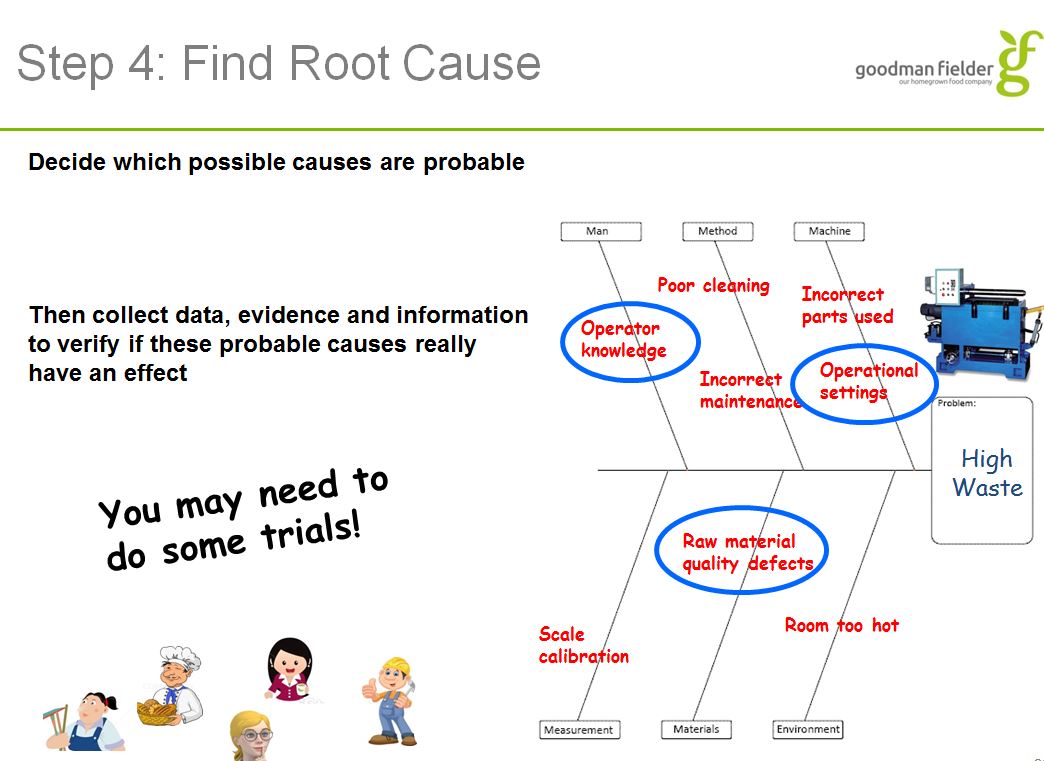

Step 4: Find Root Cause

-

Add photos as required

-

For each Category here list possible causes as you would on a Fishbone (you may use a fishbone on a whiteboard or paper and then just add the single most probable or you can list every item. Add elements to provide data if reqd.

You do not need to fill in every category.

You can add a photo to help identify the problem.

Under each of the MAN/Method/Machine/Measurement / Material and Environment we can list possible direct causes, add photos, drawings, sketches etc to help problem solving now and in the future.

You press the ADD button to open up the opportunity to put in photos etc and it will also suggest a few possible causes for that category.

If you only have 1 or two basic probable direct causes or are transferring information from a whiteboard you can just list the most probable direct cause in the field available.

Man

-

You can click on add element and then add comments/pictures/drawings as well as see suggested contributing factors for this criteria. You can add as many elements as you wish or if you know the most probable direct cause just write this cause into the below field.

-

Add media

-

Add drawing

-

CONTRIBUTIVE FACTORS

-

BBS factors : * eyes not on task * mind not on task * fatigue * Overconfidence * line of fire * lack of balance

-

PPE : training provided efficient training verified

-

Communication : - supervisor to employee - employee to supervisor - employee to employee

-

MOST PROBABLE DIRECT CAUSE ( to be defined after completing the above elements, click add element as many times as needed then choose the most probable causes for this section. You can add photos, drawings or utilise the suggested contributing factors in each element. )

METHOD

-

You can click on add element and then add comments/pictures/drawings as well as see suggested contributing factors for this criteria. You can add as many elements as you wish or if you know the most probable direct cause just write this cause into the below field.

-

Add media

-

Add drawing

-

CONTRIBUTIVE FACTORS

-

work permit

-

pre-op inspection

-

SOP

-

MOST PROBABLE DIRECT CAUSE ( to be defined after completing the above elements, click add element as many times as needed then choose the most probable causes for this section. You can add photos, drawings or utilise the suggested contributing factors in each element. )

MACHINE

-

You can click on add element and then add comments/pictures/drawings as well as see suggested contributing factors for this criteria. You can add as many elements as you wish or if you know the most probable direct cause just write this cause into the below field.

-

Add media

-

Add drawing

-

CONTRIBUTIVE FACTORS

-

guarding inadequate machine guarding no guarding

-

Tools proper tool was not identified proper tool was not available

-

MOST PROBABLE DIRECT CAUSE ( to be defined after completing the above elements, click add element as many times as needed then choose the most probable causes for this section. You can add photos, drawings or utilise the suggested contributing factors in each element. )

MEASUREMENT

-

You can click on add element and then add comments/pictures/drawings as well as see suggested contributing factors for this criteria. You can add as many elements as you wish or if you know the most probable direct cause just write this cause into the below field.

-

Add drawing

-

Add media

-

CONTRIBUTIVE FACTORS

-

calibration measurement

-

MOST PROBABLE DIRECT CAUSE ( to be defined after completing the above elements, click add element as many times as needed then choose the most probable causes for this section. You can add photos, drawings or utilise the suggested contributing factors in each element. )

MATERIAL

-

You can click on add element and then add comments/pictures/drawings as well as see suggested contributing factors for this criteria. You can add as many elements as you wish or if you know the most probable direct cause just write this cause into the below field.

-

Add media

-

Add drawing

-

CONTRIBUTIVE FACTORS

-

recent process change

-

if chemical : SDS available

-

MOST PROBABLE DIRECT CAUSE ( to be defined after completing the above elements, click add element as many times as needed then choose the most probable causes for this section. You can add photos, drawings or utilise the suggested contributing factors in each element. )

ENVIRONMENT

-

You can click on add element and then add comments/pictures/drawings as well as see suggested contributing factors for this criteria. You can add as many elements as you wish or if you know the most probable direct cause just write this cause into the below field.

-

Add drawing

-

Add media

-

CONTRIBUTIVE FACTORS

-

noise illumination floor walls

-

MOST PROBABLE DIRECT CAUSE ( to be defined after completing the above elements, click add element as many times as needed then choose the most probable causes for this section. You can add photos, drawings or utilise the suggested contributing factors in each element. )

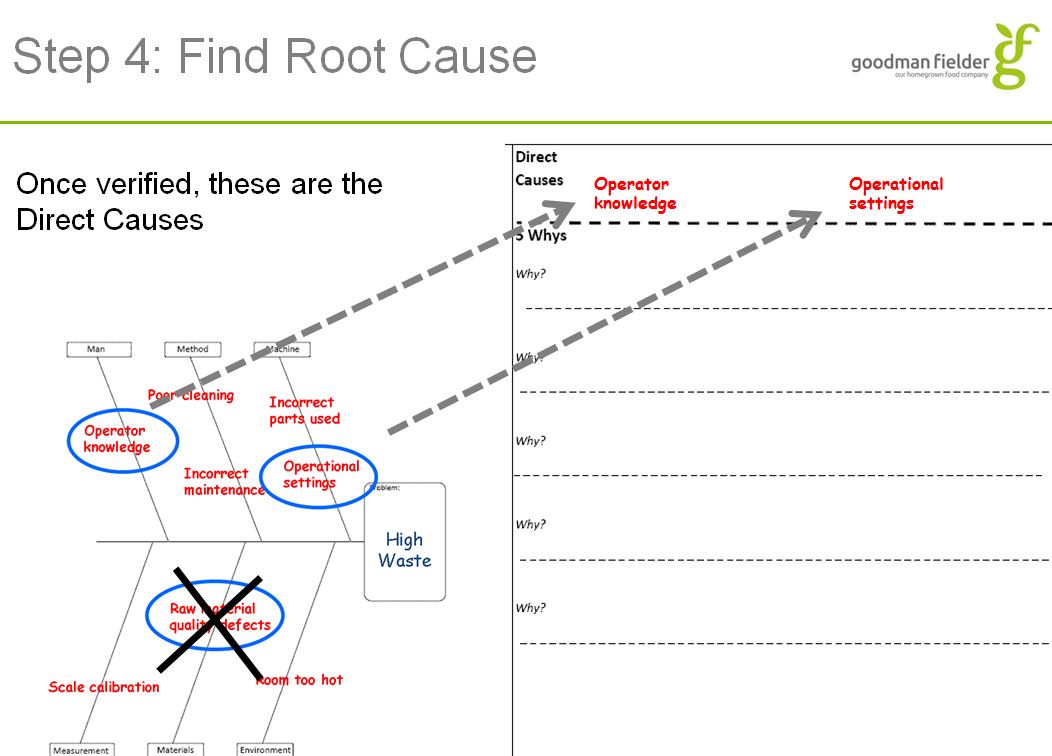

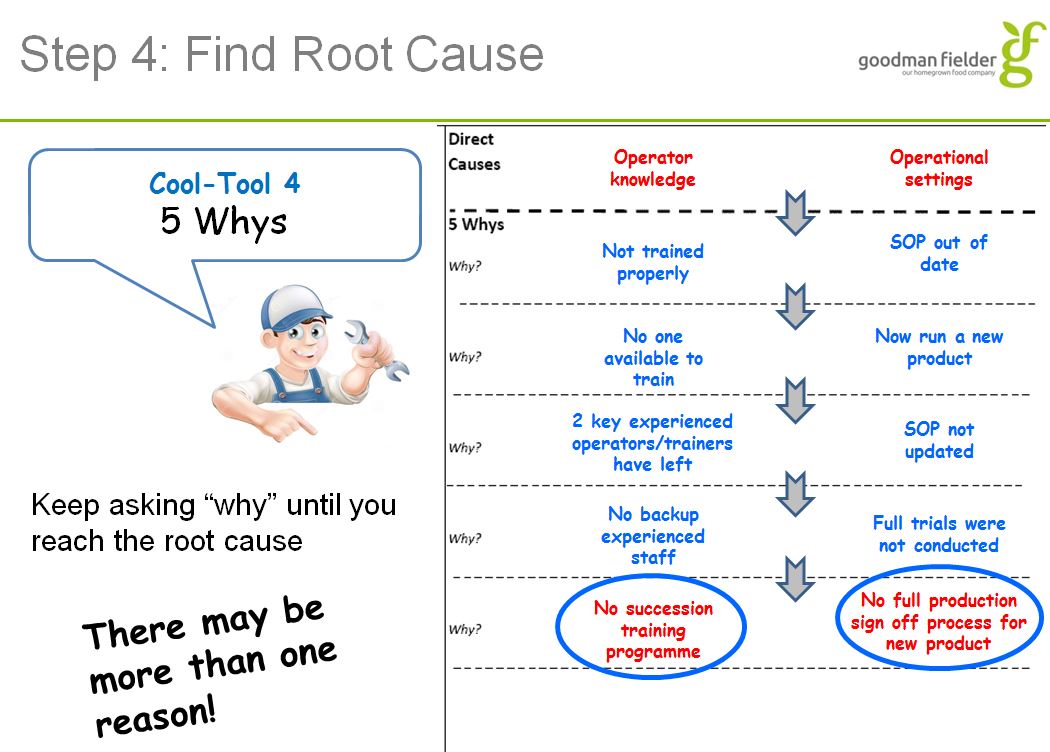

List Direct Causes most probable and conduct 5 Why Write most probable direct cause from above in first box. Ask Why ? up to 5 times to get to a Root Cause in the second box.

-

You now transfer one of the probable direct causes to here under the 5 whys.

Then together ask Why until you arrive at a Probable Root Cause – this is one that stands alone and if you ask Why you cannot drill down any further.

Place the Probable Root Cause in the field. These are the things we will action ……

You can also add photos at this point. -

Why? Why? Why? Why? Why?

-

Probable Root Cause

-

Add photo/s as required

List Direct Causes most probable and conduct 5 Why Write Root cause in first box. Ask Why ? up to 5 times to get to a Root Cause in the second box.

-

Why? Why? Why? Why? Why?

-

Probable Root Cause

-

Add photo/s as required

List Direct Causes most probable and conduct 5 Why Write Root cause in first box. Ask Why ? up to 5 times to get to a Root Cause in the second box.

-

Why? Why? Why? Why? Why?

-

Probable Root Cause

-

Add photo/s as required

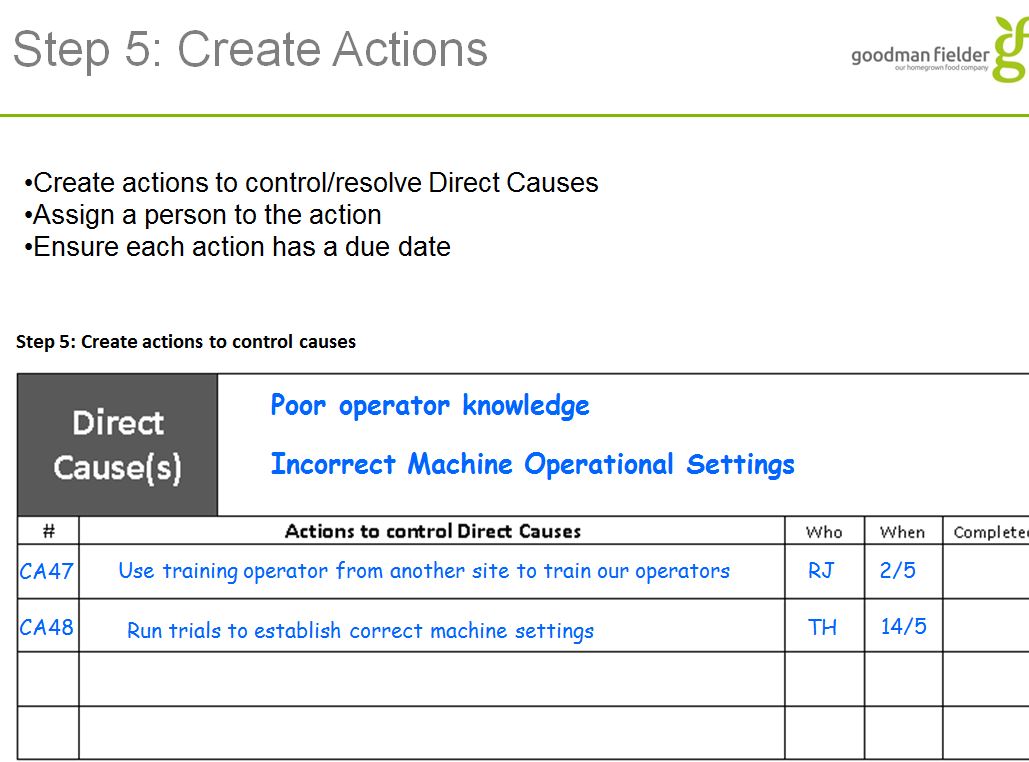

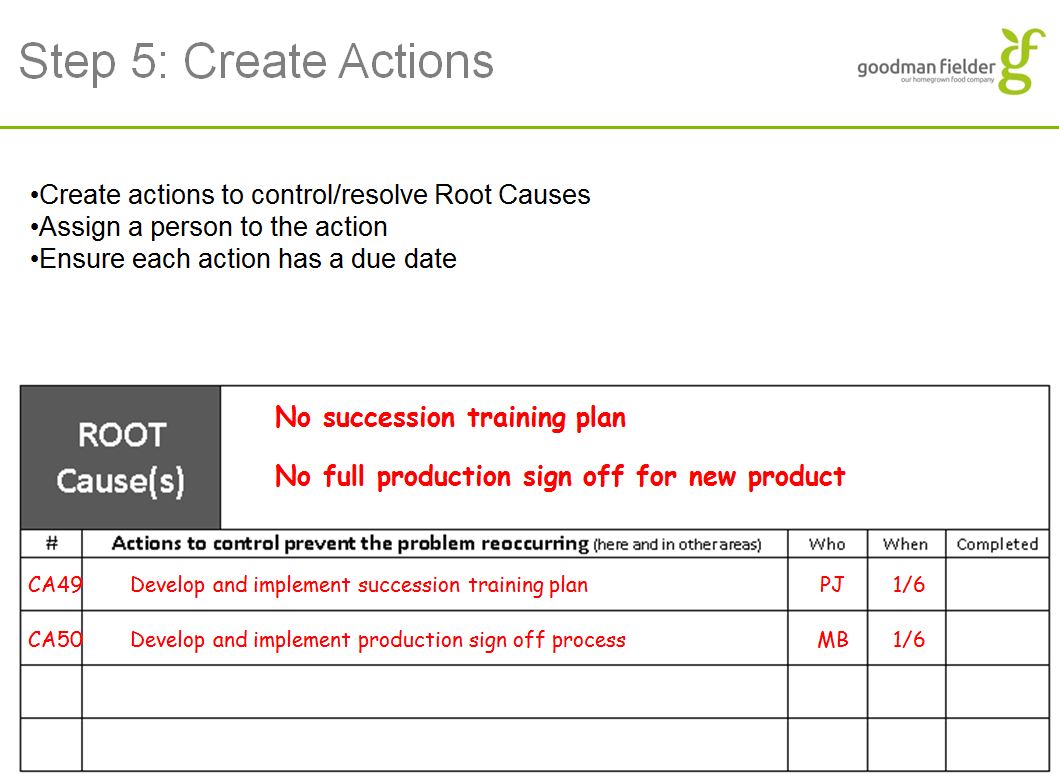

Step 5: Create Actions to control causes Corrective action Plan Add actions here as needed to address Direct Causes and Root Causes.

-

Step 5 is to Create actions:

Press the add element button to add an action.

Note due to the way the system works you need to load details of actions twice. Press add element then type in the action/person responsible and due date – then click on the “paperclip” icon on the right of the action and click “action” here you renter the action required, assign to yourself or someone else- there is a list of all those registered on iAuditor or you can enter an email address manually. Also add the due date and a priority.

All actions are tracked and can be amended or updated on the ipads action screen.

The person being assigned the action will get an email asking them to complete the action and a due date.

Also on the bottom of the add element section is a follow up tab. This is how you finialise that action when it gets completed.

You can add as many actions as you need. -

Action: enter details here and also click on "paperclip" icon to right and enter action/person responsible/due date/priority. This sends an email to the responsible person and tracks the action.

-

Responsible

-

Due Date

-

Follow up: completed ?

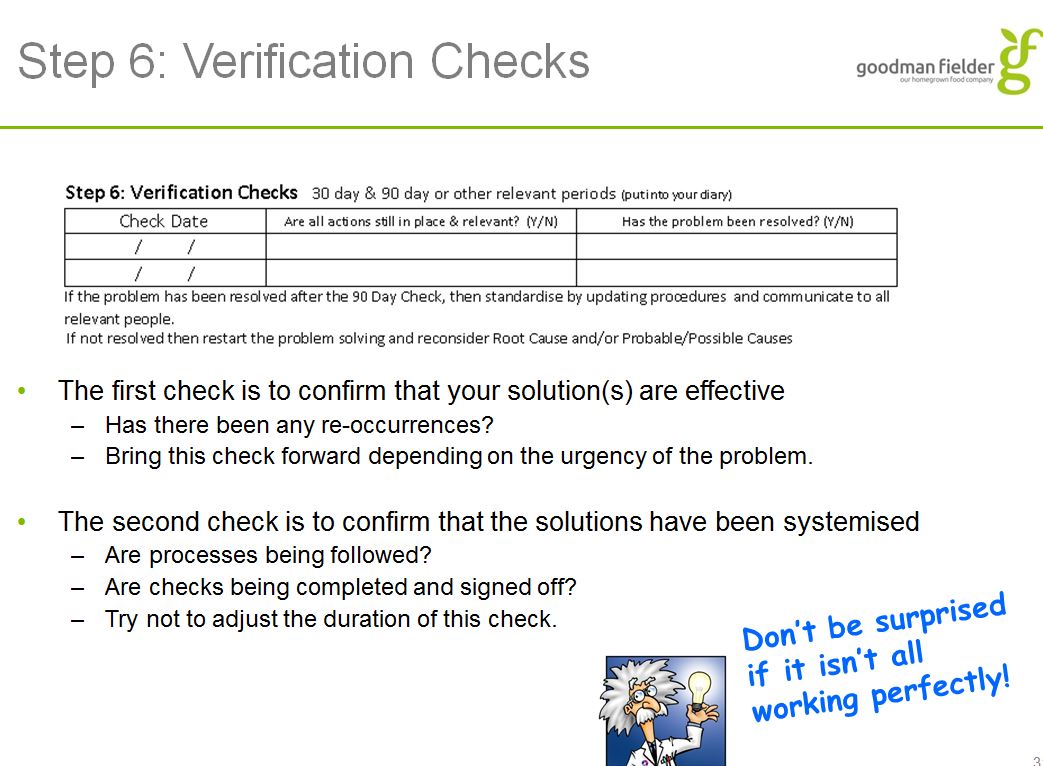

Step 6: Verification Checks

-

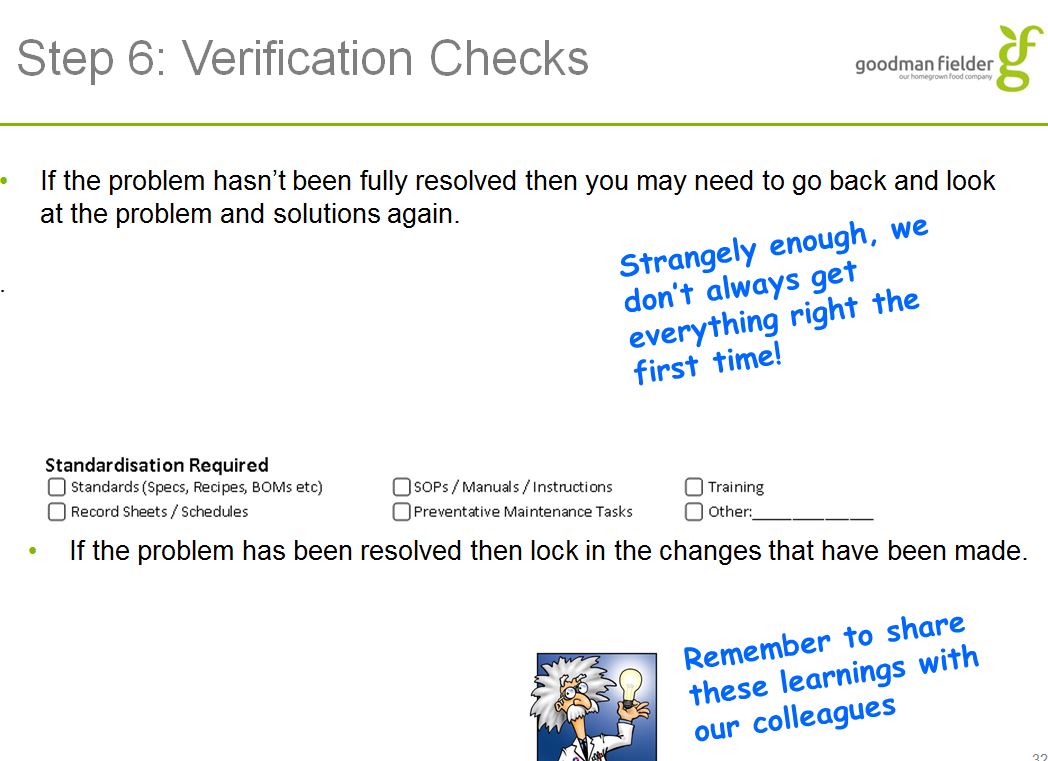

Is a 30 day and a 90 day check required ?<br>Using the "paperclip" on the right allocate an action to yourself or others in 30 days and 90 days for the following:<br>Are all actions still in place and relevant for (insert RCA detail) ?<br>Has the problem been resolved for (insert RCA detail) ?<br>For the 90 day check also annotate the following:<br>If problem is resolved standardise by updating procedures: Standards/SOPS/Training/Schedules/PMs or other

-

Do we need to incorporate the 7 Questions of Reliability centred Maintenance (7Q's) and Failure Modes effect analysis (FMEA) if any proposed actions require PM changes ?<br><br>• Review the existing FMEA to ascertain if the root cause was captured in existing FMEA, <br>• if the answer is no add the cause and the controls to avoid a reoccurrence<br>• if yes then review the controls / tasks for accuracy, timing and teams ability to carry out the actions<br>• modify the PM/s to reflect the changes <br>• Have the site maintenance team sign off the change and communicate it to production and site manager<br><br><br>If yes an action box will appear to enable a specific action for this task.<br>

-

GFA currently has a Root Cause Analysis (RCA) tool and a reliability optimising tool called the 7 questions of reliability centred maintenance (7Qs of RCM) to date these tools have been used separately.

Why should we use they together?

Often when an RCA process is used alone actions are generated leading to changes to PM’s. Frequently these are knee jerk in nature and either don’t add value or are poorly thought out. An example from our own business was the Carina de-panner. The asset had 21 separate PM policy's, most of which were put in place as reactions to past failures. As a result the asset was over maintained wasting parts and labour and many tasks had little or no obvious relevance. When the 7Q’s process was conducted all but 6 of the PM’s were removed and only tasks that were aligned to a failure code were absorbed. Applying this logic to the RCA actions will maximise the opportunity to eliminate the failure from reoccurring.

When should the 7Q’s process be used in conjunction with RCA?

When an RCA process outcome has actions that require changes to a PM policy. This often requires an existing Failure Modes and Effects Analysis (FMEA) to be reviewed at the asset ensuring clearer tasks are added the the PM policy's and potentially highlighting other additions not recognised in the RCA.

This user guide contains a step by step guide on how the process should be followed. -

The 7Questions of RCM (7Q’s) is a series of questions designed to build upon the last, ultimately to create a strong Preventative and Predictive maintenance process. The process looks at failure codes, parts, current PM’s and the gaps found through conducting the process and helps the users create a stronger PM and a system to look back upon if future failures occur.

The 7 questions

What are the functions and associated performance standards of the asset in its present operating context?

In what ways does it fail to fulfil its functions?

What causes each functional failure?

What happens when each failure occurs?

In what way does each failure matter?

What can be done to predict or prevent each failure?

What should be done if a suitable proactive task cannot be found?

It is in step 2-6 that an FMEA sheet is used to record the perceived failures and solutions. These are then reviewed against the preventative maintenance policy's (PM’s) and the PM’s are adjusted accordingly. -

-

Action: enter details here and also click on "paperclip" icon to right and enter action/person responsible/due date/priority. This sends an email to the responsible person and tracks the action.

-

Responsible

-

Due Date

-

Follow up: completed ?

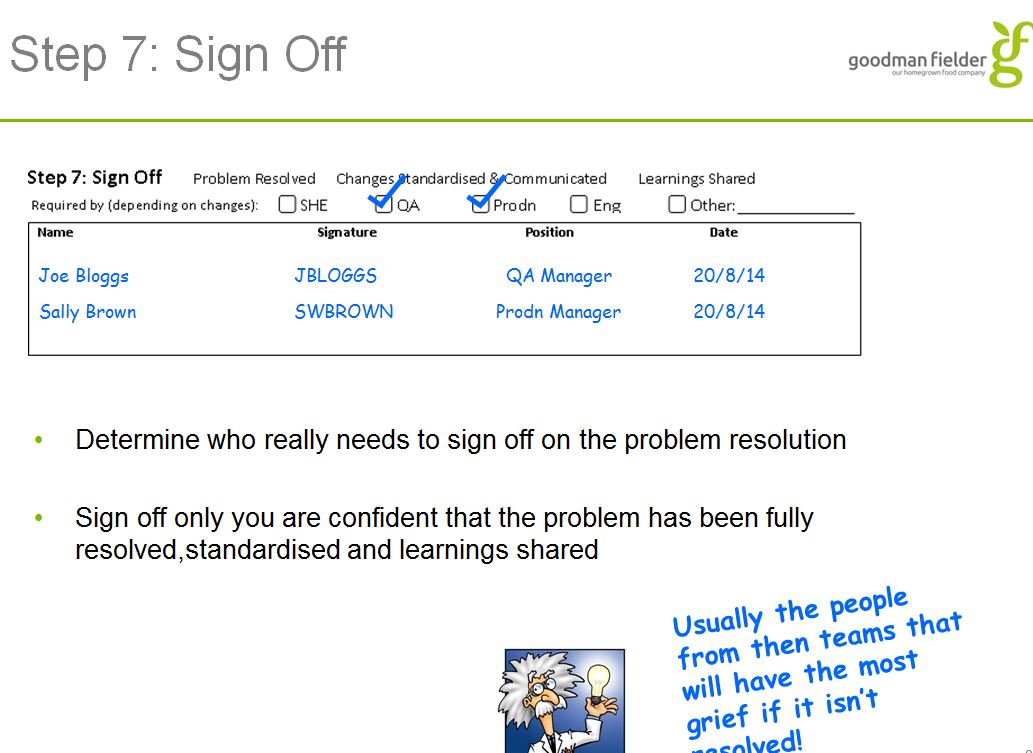

Step 7: Sign Off This is to remain open until Actions have been completed and it is decided in an RCA review meeting that the RCA is fully completed. The review meeting decides the appropriate signoff: Eg. SHS/QA/Production/Eng

-

Should all Site Managers be Notified of this RCA ?<br>Notification will be automatically sent to Site Managers that are Registered in iAuditor. (Note that list is incomplete at this stage)

-

Should all Maintenance Managers be Notified of this RCA ?<br>Notification will be automatically sent to Maintenance Managers that are Registered in iAuditor.(Note that list is incomplete at this stage)

-

This is NOT to be signed until the RCA is fully completed.

This should be done at an RCA review meeting if possible.

You are signing off that all actions are complete as well as the investigation.

This does not mean 30 and 90 day checks have been completed unless you decide as a group that that is critical and you should wait for that before signing off. -

Name and Signature of Initiating Person for RCA completion

-

Name and Signature of Maintenance Manager for RCA completion

-

Name and Signature of Production Manager for RCA completion

-

Name and Signature of Site Manager for RCA completion