Title Page

-

TECHNICIANS

-

TECHNICIAN 1

-

TECHNICIAN 2

-

CLIENT

-

WIND FARM

-

MACHINE

-

DATE

-

REGISTER Nº

RELATED DOCUMENTATION

SAFETY DOCUMENTATION (ITBs)

-

ITB_10500026361_XX_00-00-SAFE ACCESS TO GROUND PLATFORM

-

ITB_10500026362_XX_00-01-STOPPAGE AND START UP OF THE TURBINE

-

ITB_10500026363_XX_00-02-DISCONNECTION AND CONNECTION OF COMMUNICATION WITH CONTROL CENTER

-

ITB_10500026364_XX_00-03-SIGNS AND DEMARCATION OF THE AREA

-

ITB_10500026365_XX_00-04-ACCESS AND STAY IN THE TOWER

-

ITB_10500026366_XX_00-05-ACCESS AND STAY IN THE NACELLE

-

ITB_10500026367_XX_00-06-LOCK AND UNLOCK THE ROTOR

-

ITB_10500026368_XX_00-07-BLADES EARTHING

-

ITB_10500026369_XX_00-08-SAFE ACCESS TO THE HUB

-

ITB_10500026370_XX_00-09-SAFE ACCESS TO THE NACELLE ROOF

-

ITB_10500026371_XX_00-10-APPLY AND RELAX MECHANICAL BRAKE

-

ITB_10500026372_XX_00-11-DEPRESSURIZATION AND PRESSURIZATION HYDRAULIC UNIT

-

ITB_10500026373_XX_00-12-BLOCKING AND UNLOCKING OF BLADES

-

ITB_10500026374_XX_00-13-DISCONNECTION AND CONNECTION OF ELECTRICAL CABINETS

-

ITB_10500026375_XX_00-14-DISCONNECTION AND CONNECTION OF HIGH VOLTAGE CABINET

-

ITB_10500026376_XX_00-15-SAFE ACCESS TO THE TRANSFORMER COMPARTMENT

-

ITB_10500026377_XX_00-16-LIFTING OF LOADS

METHOD STATEMENTS

-

MS_10500035720 CONNECT THE PC TO THE CONVERTER MODULES

-

MS_10500035721 CHECKING THE GSC INVERTER AND MSC INVERTERS AT ABB CONVERTER

-

MS_10500035722 CHECKING AND TESTING THE CROWBAR

-

MS_10500035723 CHECKING THE CHOPPER OPERATION

START SECTION 1 AND INSPECTION

-

BOTH TECNICIANS

-

AUDITIVE INSPECTION OF THE BLADES

-

VISUAL INSPECTION OF THE BLADES

-

TECHNICIAN 1

-

VISUAL INSPECTION OF THE FASTENING ELEMENTES OF THE DOOR, HINGES, AND STATUS OF THE DOOR

-

VISUAL INSPECTION OF THE DOOR SAFETY SINGS AND TOWER NUMBER

-

VISUAL INSPECTION OF THE ACCESS LADDER

-

VISUAL INSPECTION OF THE BOLTED JOINT FOUNDATION FIRST SECTION (OUTSIDE) (TORQUE MARKS, AND STATUS)

-

VISUAL INSPECTION OF THE FALGE OF FIRST SECTION WITH THE FUNDATION (OUTSIDE)

-

VISUAL INSPECTION OF THE FUNDATION LOOKING FOR CRACKS

-

CHECK IF THE DOOR FILTERS ARE INSTALLED AND IN GOOD CONDITION

-

CHECK THE ESTATUS OF THE DOOR CLOSING DEVICE

-

VISUAL INSPECTION OF THE DOOR FRAME (RUST, PAIN DEFECTS, SEALING RUBBER, ETC)

-

CHECK THE STATUS OF STATUS OF THE GROUND CABINET (EXTERNAL)

-

CHECK THE STATUS OF THE GROUND CABINET (INTERNAL), CABLES, COVERS, ELEMENTS

-

CHECK THE SAFETY LINE INSPECTION DATE

-

CHECK THE INSPECTION DATE OF THE ELEVATOR, AND IF IT IS IN SERVICE

-

VISUAL INSPECTION OF THE SAFETY STICKERS AT GROUND PLATFORM

END SECTION 1, START SECTION 2

-

TECHNICIAN 2

-

VISUAL INSPECTION OF THE YAW DECK (OIL, GREASE,…)

-

VISUAL INSPECTION OF THE SAFETY STICKERS

-

VISUAL INSPECTION OF YAW DECK TRAPDOOR

-

VISUAL INSPECTION OF THE LIGHT AND SOCKET

-

VISUAL INSPECTION OF LEAKS OF THE YAW ACTIVE CLAMPS AND ITS ELEMENTS

-

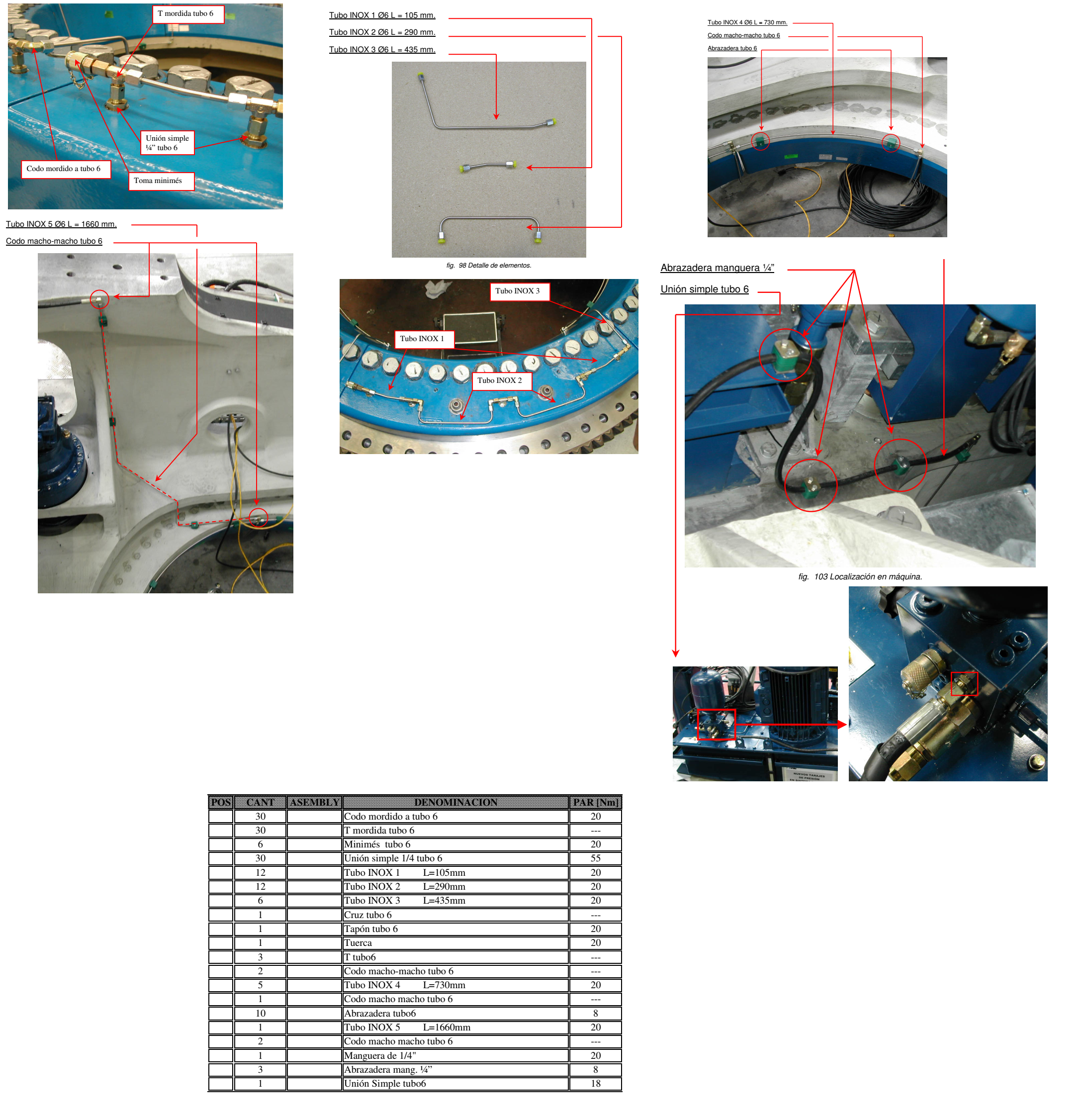

INFO: YAW CIRCUIT

-

VISUAL INSPECTION OF THE GEARBOX BODY LOOKING FOR DAMAGES OR OIL LEAKS

-

VISUAL INSPECTION OF THE BOLTED JOINT TOWER-NACELLE (TORQUE MARKS AND CONDITION)

-

VISUAL INSPECTION OF THE BOLTED JOINT YAW CLAMPS-NACELLE (TORQUE MARKS AND CONDITIONS)

-

VISUAL INSPECTION OF THE CAST FRAME

-

SERIAL NUMBER

-

VISUAL INSPECTION OF THE NACELLE ACCESS LADDER

-

VISUAL INSPECTION OF GEARBOX OIL LEVEL

-

VISUAL INSPECTION OF LEAKS FROM THE YAW GEARS

-

CHECK THE EXTINGUISHER INSPECTION DATE AND HOLDER AT THE NACELLE

-

VISUAL INSPECTION OF THE EMERGENCY DESCENDER ANCHOR POINT (WEAR, RUST, ETC)

-

VISUAL INSPECTION OF THE HOIST HOOK

-

CHECK THE OPERATION OF THE HOIST (UP, DOWN, EMERGENCY BUTTOM, AND END SWITCHES)

-

VISUAL INSPECTION OF THE CHAIN STATUS

-

VISUAL INSPECTION OF THE FASTENING ELEMENTS OF THE CRANE ( TORQUE MARKS, BOLTD LOCKERS, ETC)

-

VISUAL INSPECTION OF THE REAR TRAP DOOR (FASTENING ELEMENTS, LOCKING ELEMENTS, FALL PROTECTION CHAIN)

END SECTION 2, START SECTION 3 (LOCK THE ROTOR)

-

BOTH TECHNICIANS

-

AUDITORY INSPECTION OF THE GEARBOX, GENERATOR AND MAIN SHAFT BEARINS

-

INFO: RUN THE GENERATOR SPEED TEST , SET AT 500 RPM, AND LISTEN THE NOISE OF THE GEARBOX GEARS AND BEARINGS, MAIN SHAFT BEARINGS, GENERATOR BEARINGS. NOTE ANY ANORMAL NOISE.

-

TECHNICIAN 1

-

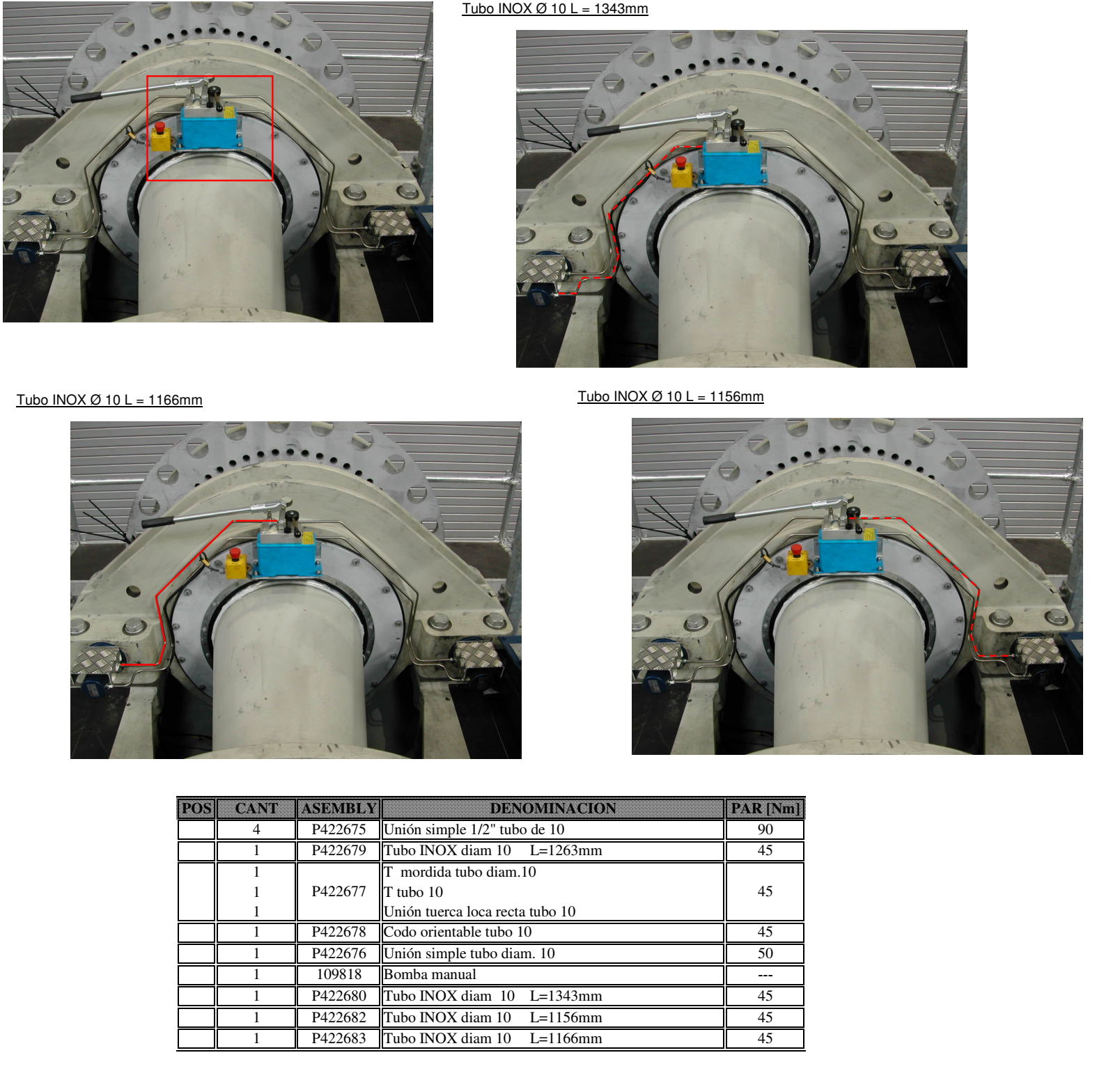

VISUAL INSPECTION FOR LEAKS AND GENERAL STATUS OF THE ROTOR LOCKING SYSTEM (PUMP, PIPES, CONNECTIONS..)

-

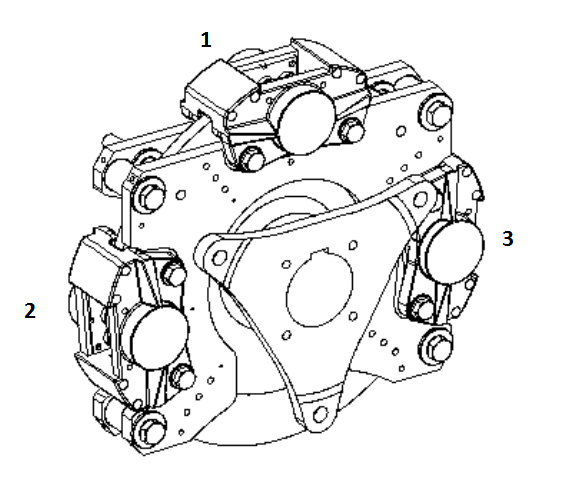

INFO: LOCKING SYSTEM DEVICE AND CIRCUIT.

-

CHECK THE TORQUE MARKS OF THE BOLTED JOINT MAIN SHAFT (RUST, DEFECTS OR MISSING BOLTS)

-

CHECK THE TORQUE MARKS OF THE BOLTED JOINT MAIN SHAFT HUB (RUST, DEFECTS OR MISSING BOLTS)

-

CHECK FOR SURFACE DEFECTS AT MAIN SHAFT (RUST, PAINT DEFECTS,…)

-

CHECK FOR LEAKS AT MAIN SHAFT BEARINGS

-

VISUAL INSPECTION OF BEARING BLADES DUST SEALS

-

VISUAL INSPECTION OF THE REAR SUPPORTS OF THE HUB CONE

-

TECHNICIAN 2

-

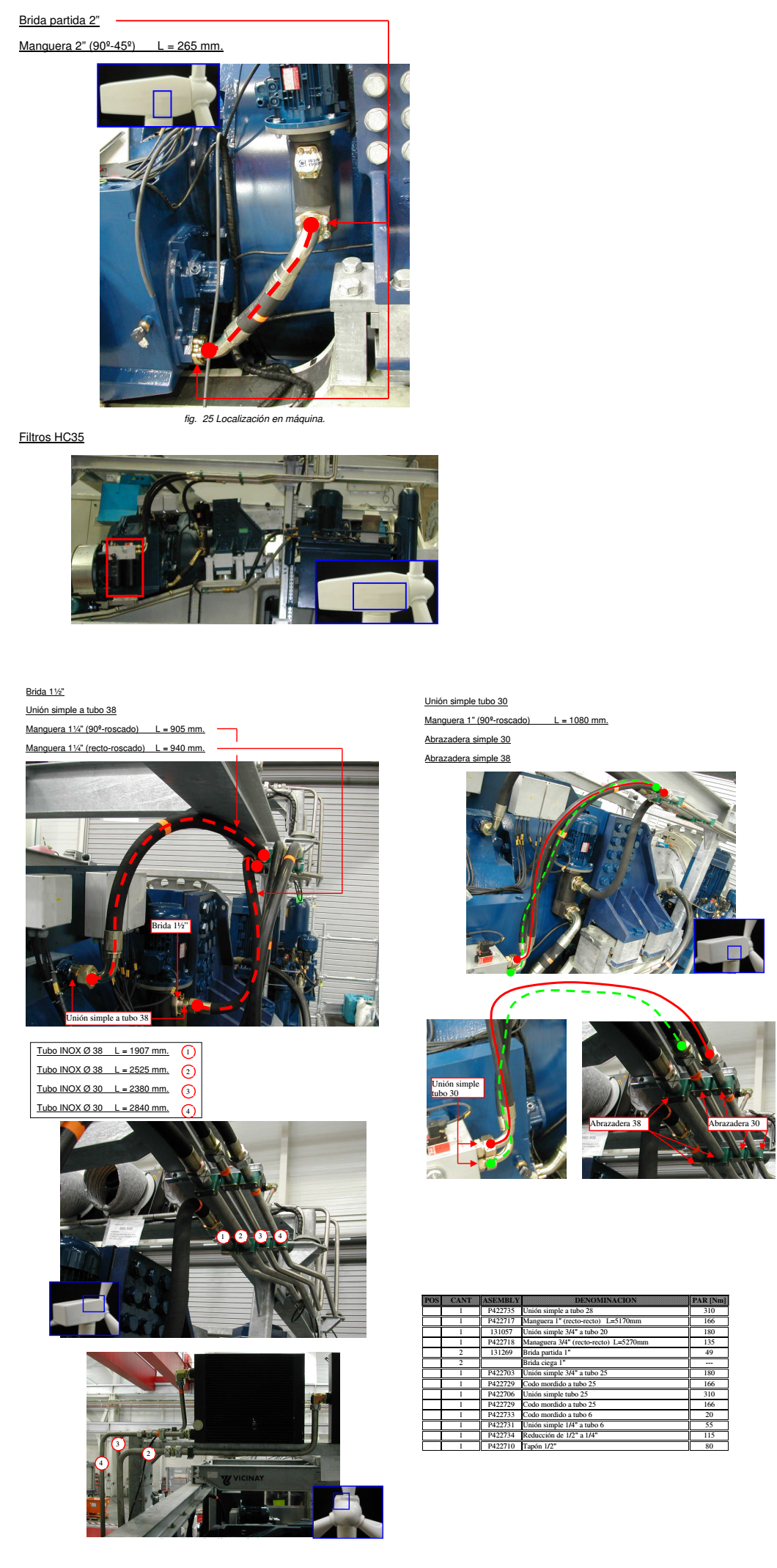

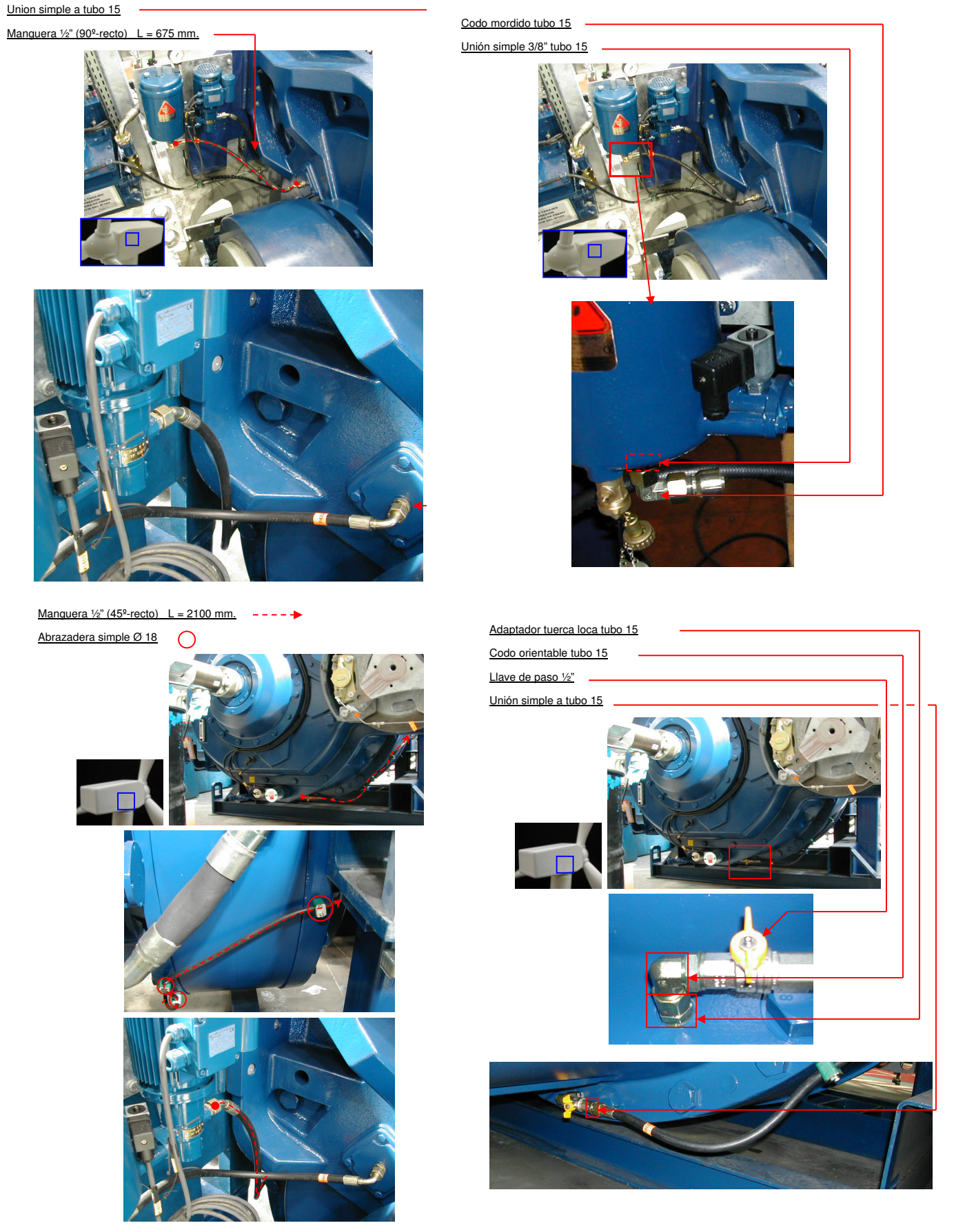

CHECK THE HYDRAULIC HOSES IN THE NACELLE FOR LEAKS, CRACKS OR BUBBLES.

-

INFO: HYDRAULIC CIRCUIT AT NACELLE

-

CHECK FOR LEAKS AT HYDRAULIC UNIT STATION AND ANY OTHER DEFECTS AT THE H.U. STATION (CABLES, CONNECTORS OF EV, RUST,...)

-

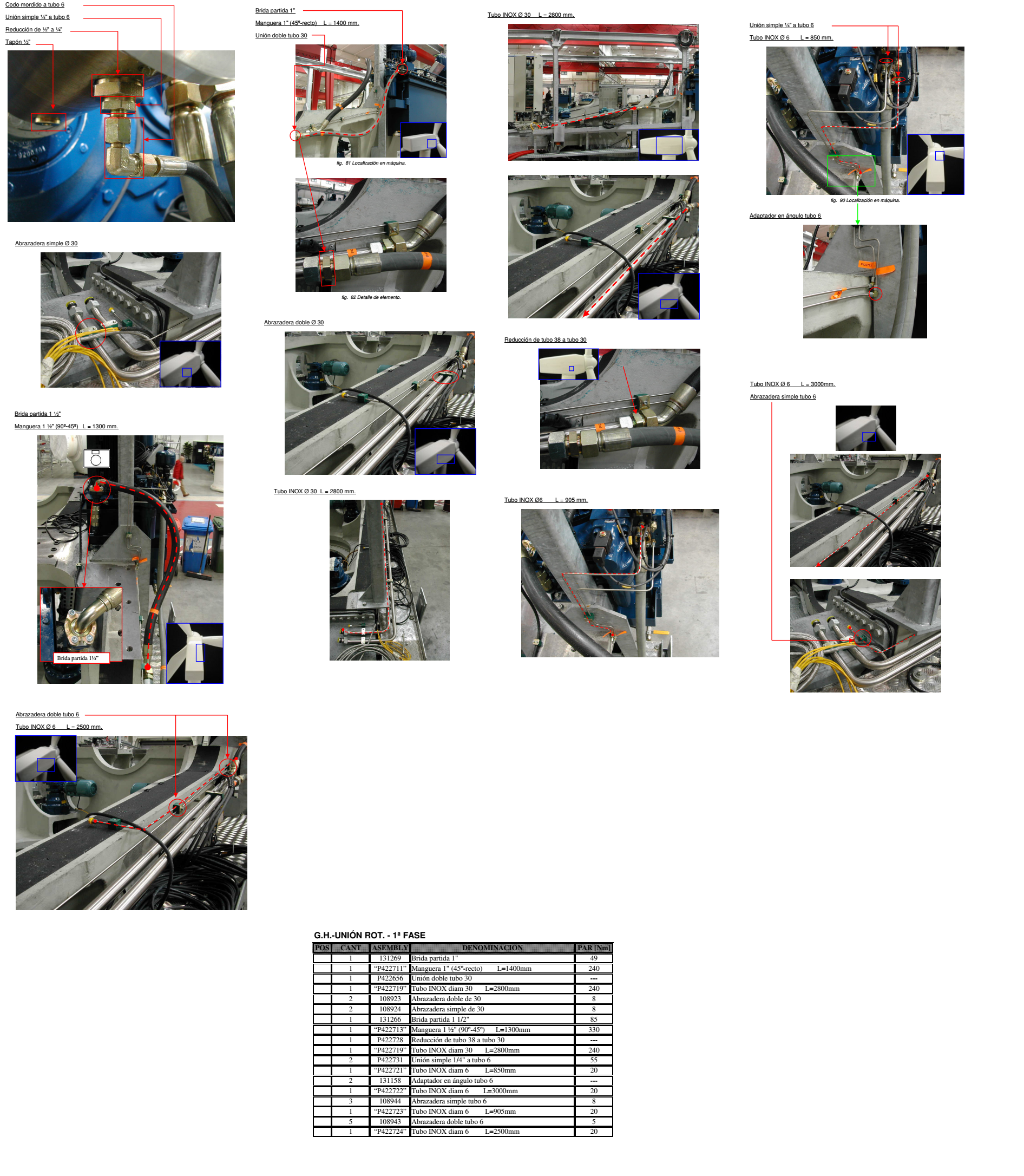

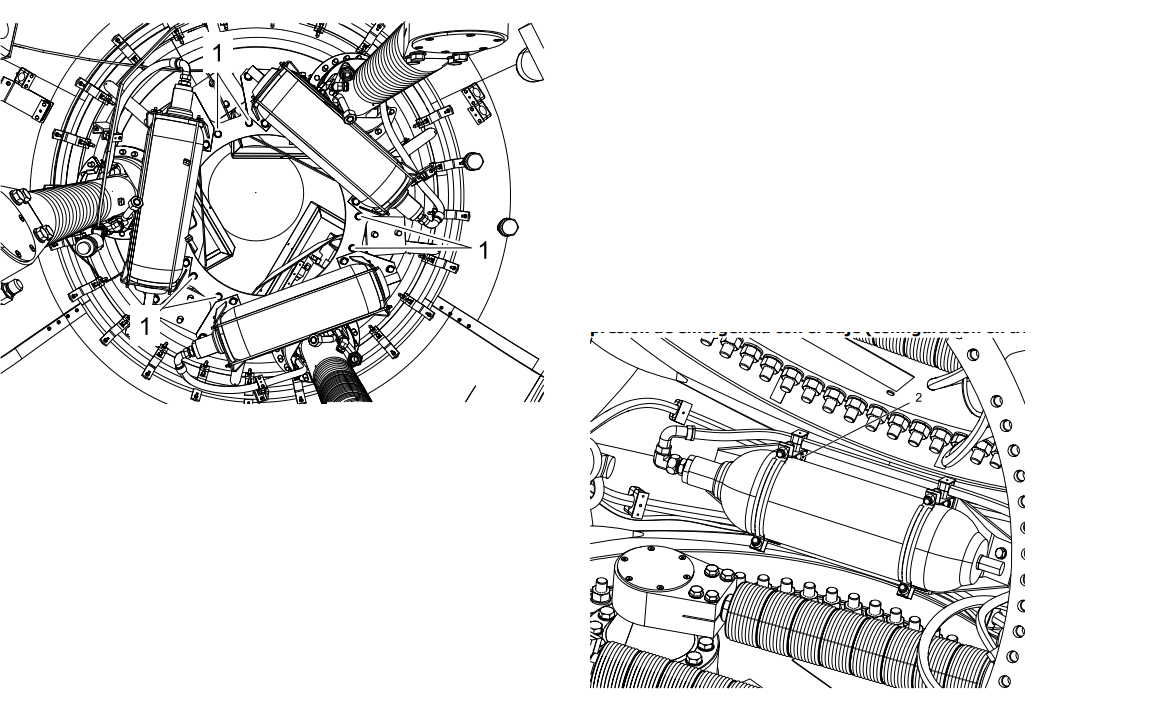

CHECK THE STATUS OF THE G.B COOLING SYSTEM (LEAKS IN HOSES, LEAK IN MECHANICAL PUMP, HOSES CONDITION…)

-

INFO: G.B. COOLING SYSTEM

-

VISUAL INSPECTION OF THE STATUS OF THE OFF LINE FILTER, ITS MOTOR, CABLES AND HOSES

-

INFO: G.B. OFFLINE FILTER

-

CHECK THE TORQUE MARKS OF THE GEARBOX REACTION ARMS

-

VISUAL INSPECTION OF THE CONDITION OF THE G.B. BODY (RUST, CRACKS, PAINT DEFECTS, ETC)

-

VISUAL INSPECTION OF THE CONDITION OF THE GENERATOR BODY (RUST, CRACKS, PAINT DEFECTS, ETC)

-

CHECK THE TORQUE MARKS OF THE GENERATOR LEGS

-

CHECK THE TORQUE MARKS OF THE GENERATOR GROUNDING CONNECTION

-

CHECK THE STATUS OF THE GENERATOR STATOR CABLES, TRAYS AND ENTRANCE TO THE CABINET

-

CHECK THE STATUS OF THE GENERATOR REFRIGERATION COOLER DRAWER EXHAUST

-

CHECK THE EXTERNAL ESTATUS OF THE NACELLE CABINETS (HANDLES, FILTER COVERS, SEALING RUBBERS, CLOSING DEVICE)

-

CHECK THE INTERNAL STATUS OF THE NACELLE CABINETS (COVER TRAYS, CABLE TRAYS, CABLES, MODULES, ETC.)

-

CHECK CABINETS REVISION (CONVERTER AND TOP)

END SECTION 3, START SECTION 4 (ROTOR LOCK AND BLADE LOCK AT 86º. ROTOR TURN IS REQUIRED)

-

TECHNICIAN 1

-

CHECK THE TORQUE MARKS AT THE BOLTED JOINT BETWEEN BEARING AND HUB

-

CHECK THE TORQUE MARKS AT THE BOLTED JOINT RING CONE SUPPORT AND HUB

-

CHECK THE STATUS OF THE RING CONE SUPPORT AND ITS FASTTENERS TO THE CONE

-

CHECK THE STATUS OF THE HUB ELECTRICAL CABINET SUPPORTS AND SILENT BLOCKS

-

CHECKT THE STATUS OF EXTERIOR CONDITION AND FILTERS OF THE HUB CABINET

-

CHECK THE OPERATION OF THE HUB LIGHT (MISSING, DAMAGE, OIL INSIDE, ETC

-

CHECK LOCKER DEVICE AT HUB CABINET DOOR OPERATION

-

CHECK INTERNAL LIGHT OF HUB CABINET OPERATION

-

VISUAL INSPECTION OF THE INTERNAL ELEMENTS OF THE HUB CABINET (CABLES, TRAYS, COVERS, ETC)

-

VISUAL INSPECTION OF THE HUB CABLE TRAY AND THE INLET OF THE CABLES, AND CABLE GLANDS OF THE HUB CABINET

-

VISUAL INSPECTION FOR LEAKS AT PICHT MANIFOLD BLOCKS AND VALVES

-

VISUAL INSPECTION ROUTING PITCH CABLES

-

VISUAL INSPECTION OF THE STATUS OF THE HOSES AND THEIR CONNECTIONS WITH THE MANIFOLD BLOCKS

-

VISUAL INSPECTION FOR OIL AND GREASE LEAKS OVER THE CONE

-

VISUAL INSPECTION FOR RUST IN THE PITCH CILINDERS REAR SUPPORTS

-

VISUAL INSPECTION OF THE HUB INNER CONDITION (OIL, GREASE, LOOSE PARTS, PARTS MISSING…)

-

VISUAL INSPECTION OF THE ACCUMULATOR FASTENERS

-

INFO: CHECK THE TORQUE MARKS OF THE SUPPORTS AND CLAMPS

-

TECHNICIAN 2

-

VISUAL INSPECTION OF YAW CROWN AND YAW GEAR PINIONS

-

INFO: TURN THE YAW BY MEANS THE YAW MANUAL TEST. THIS INSPECTIONS MUST BE DONE IN AS MANY STEPS AS NECESSARY, APPLYING THE ISOLATIONS BEFORE TO ACCESS TO THE YAW CROWN

-

FUNCTIONAL TEST OF THE YAW (NOISES. MOTOR CONSUPTION)

-

INFO: RUN THE YAW MANUAL TEST, TURN FIRST TO CW AND LATER CWW, CHECK THE CONSUMPTIONS DOWNSTEEN THE KM180x AND 181x CONTACTORS OR TERMINALS X5: U, V, W (1 TO 4)

-

M180A

-

M180B

-

M181A

-

M181B

-

FUNCTIONAL TES OF THE GEARBOX ELECTRICAL PUMP (NOISE, MOTOR CONSUMPTION)

-

GEARBOX OFFLINE PUMP FUNCTIONAL TEST

-

INFO: RUN THE OFFLINE PUMP TEST AND CHECK THE NOISE AND IT FUNCTION.

-

M480: ESTATUS, NOISE AND HOSES.

-

HYDRAULIC UNIT PUMP FUNCTIONAL TEST (NOISE, MOTOR CONSUMPTION)

-

INFO: RUN THE PUMP IN AUTO MODE AND CHECK THE CONSUMPTION DOWNSTEEN THE KM280 OR TERMINAL BLOCK X5: U5, V5, W5.

-

M280 CONSUMPTION AND NOISE TYPE THE CONSUMPTION IN NOTES

-

GEARBOX COOLING FANS FUNCTIONAL TEST (NOISE, MOTOR CONSUMPTION)

-

INFO: RUN THE G.B. COOLING FANS TEST, CHECK THE CONSUMPTION IN THE CONTACTORS OR IN THE TERMINAL BLOCKS AS INDICATE IN THE SCHEMATICS. TYPE THE CONSUMPTION IN NOTES OF MOTOR

-

M380 CONSUMPTION

-

M381 CONSUMPTION

-

M382 CONSUMPTION

-

H.U. COOLING PUMP FUNCTIONAL TEST (NOISE , MOTOR CONSUMPTION)

-

INFO: RUN THE H.U. COOLING TEST , CHECK THE CONSUMPTION DOWNSTEEN THE KM 281 OR IN THE TERMINAL BLOCKS X5: U19, V19, W19

-

M281 CONSUMPTION

-

GEARBOX OIL HEATING FUNCTIONAL TEST (CONSUMPTION)

-

INFO: RUN THE GB OIL HEATING TEST AND CHECK THE CONSUMPTION DOWNSTEEN KM 499 OR IN THE TERMINAL BLOCK X5: U10, V10, W10

-

KM 499 CONSUMPTION

-

GENERATOR MOTOR FANS FUNCTIONAL TEST (NOISE, MOTOR CONSUMPTION)

-

CHECK THE CONSUMPTIONS ON THE TCC REAR CABINET TERMINAL BLOCK X5 AS INDICATE THE FOLLOWING SCHEMATIC

-

M583 LOW (TYPE CONSUMPTION ON NOTES)

-

M583 HIGH (TYPE CONSUMPTION ON NOTES)

-

M584 LOW (TYPE CONSUMPTION ON NOTES)

-

M584 HIGH (TYPE CONSUMPTION ON NOTES)

-

M585 LOW (TYPE CONSUMPTION ON NOTES)

-

M585 HIGH (TYPE CONSUMPTION ON NOTES)

-

SLIP RING GENERATOR FAN FUNCTIONAL TEST (NOISE AND CONSUMPTION)

-

MEASURE THE CONSUMPTION DOWNSTREEN THE KM590 OR WIRES OF THE CABLE WA590

-

M591 CONSUMPTION AND NOISE

-

TRANSFORMER COOLING FANS FUNCTIONAL TEST (NOISE AND CONSUMPTION)

-

CHECK THE CONSUMPTION AT TERMINAL BLOCK X4-4A OR X4-4B

-

M61x MOTORS CONSUMPTION

-

NACELLE COOLING FANS (HTK) FUNCTIONAL TEST (NOISE, MOTOR CONSUMPTION) IF APPLY

-

WAAT 52-1

-

WAAT 52-2

-

WAAT 52-3

-

WAAT 52-4

-

FUNCTIONAL TEST OF THE HTK ACTUATOR (CHECK THE GATES OPERATION) IS WARNING, THE SYSTEM IS FAULT, IF APPLY

-

AT101

-

AT102

-

FUNCTIONAL TEST OF THE LTK FANS (CHECK THE GATES OPERATION) NOTE IT IF WARNING APPEARS

-

BT 408

-

BT 409

-

BT 410

-

FUNCTIONAL TEST OF THE LTK HEATERS, CONSUPTION OF THE HEATER AND FUNCTION OF THE FAN, FASTENERS, IF APPLY

-

BT 401

-

BT 402

-

BT 403

-

BT 404

-

BOTH TECHNICIANS

-

FUNCTIONAL TEST OF THE HUB LTK ACCUMULATOR BLANKETS (CONSUMPTION) IF APPLY

-

FD 249

-

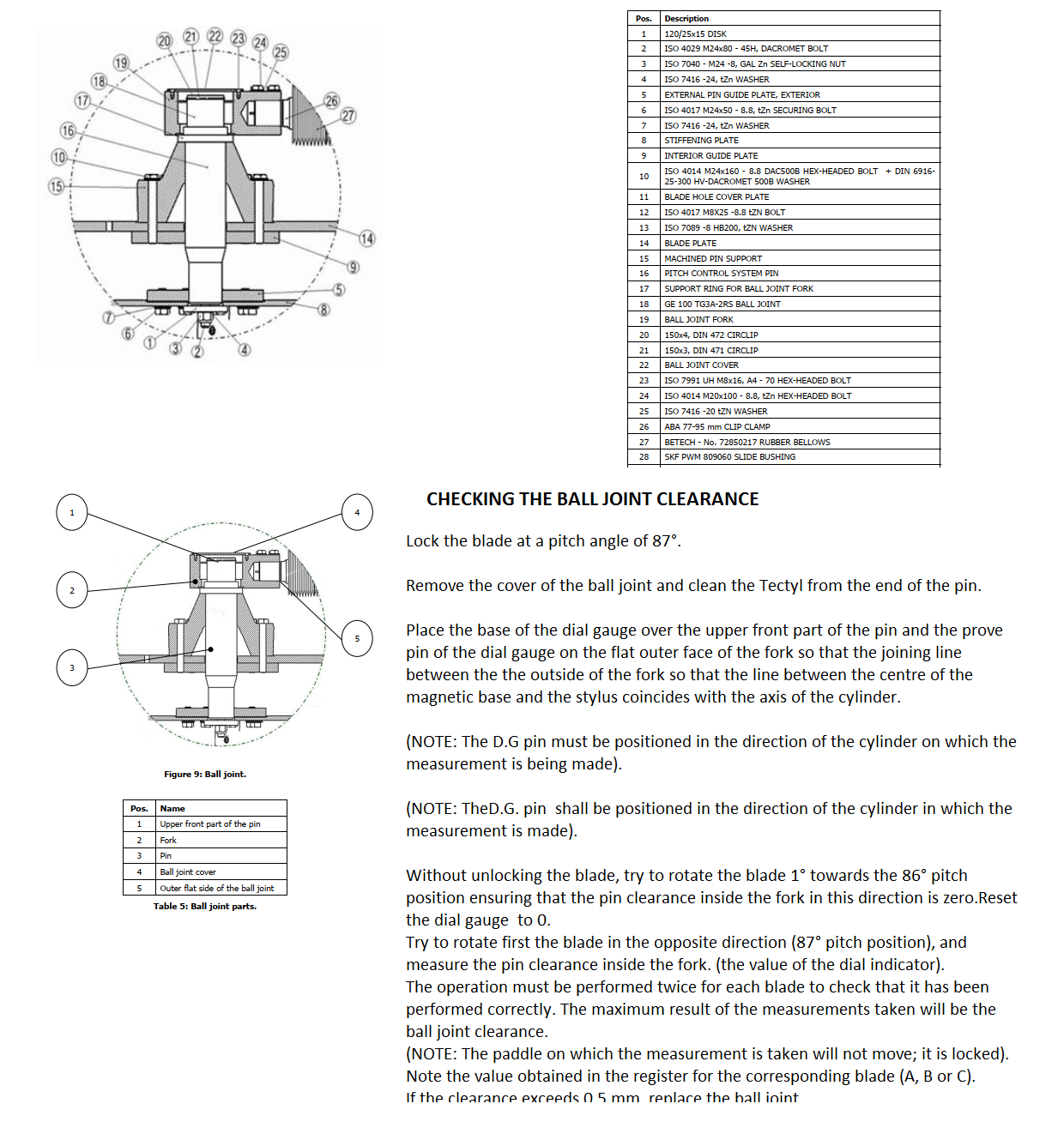

CHECK FOR CLEARANCE IN THE PITCH SYSTEM: BALL JOINTS AND PITCH SUPPORTS

-

CHECKING THE BALL JOINTS

-

-

BALL JOINT PITCH A

-

BALL JOINT PITCH B

-

BALL JOINT PITCH C

-

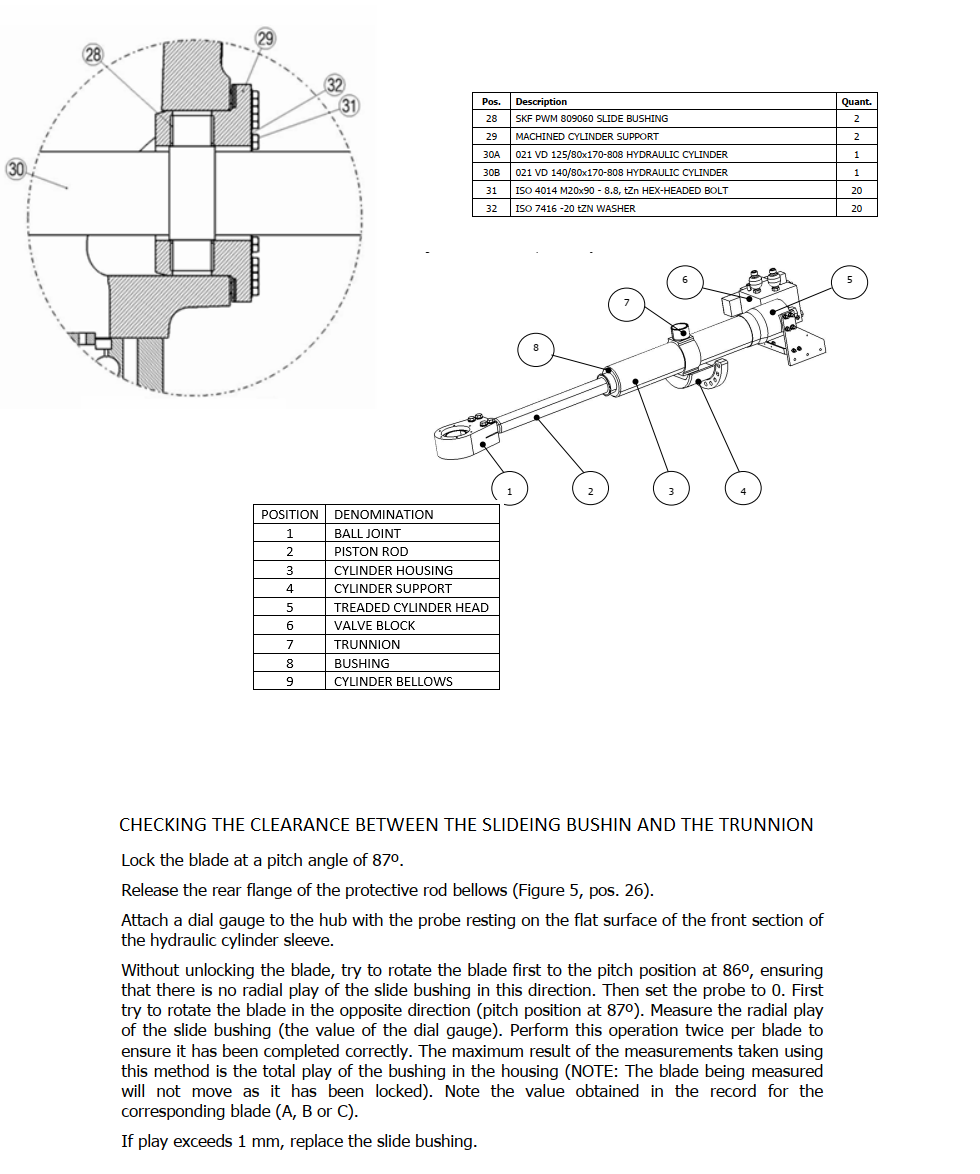

CHECKING THE SLIDE BUSHINGS

-

INFO

-

SUPPORT PITCH A

-

SUPPORT PITCH B

-

SUPPORT PITCH C

-

FUNTIONAL TES OF PITCH SYSTEM, EXECUTE SINE TEST (BLADE MOVEMENT, NOISE, ETC)

END SECTION 4, START SECTION 5 (ROTOR LOCK, FF005, FM014, FG590 AND FG008)

-

TECHNICIAN 1

-

INDICATE THE GENERAL CONDITION OF THE ROTOR CONNECTION BOX

-

CHECK THE SLIP RING GENERATOR CONDITION (RUST, CLEANNESS, ETC)

-

CHECK THE CONDITION OF THE ROTOR BUS-BARRS

-

CHECK THE STATUS OF THE RIGIDIZED BARS

-

CHECK THE STATUS OF THE BRUSH HOLDERS AND THEIR SPRINGS

-

CHECK THE CONDITION OF THE ROTOR CABLES INSIDE THE ROTOR BOX AND THEIR BOLTED JOINT

-

CHECK THE CONDITION OF THE ROTOR BRUSHES

-

MEASURE THE SIZE OF THE BRUSHES, THE SMOLLER ONES

-

TECHNICIAN 2

-

CHECK THE STATUS OF THE HSS COVERS AND THEIR FASTENING

-

CHECK THE CONDITION OF THE HIGHT SPEED SHAFT (TORQUE MARKS, RUST, COVERS, REFERENCE MARK, ETC)

-

INDICATE THE MODEL

-

INFO

-

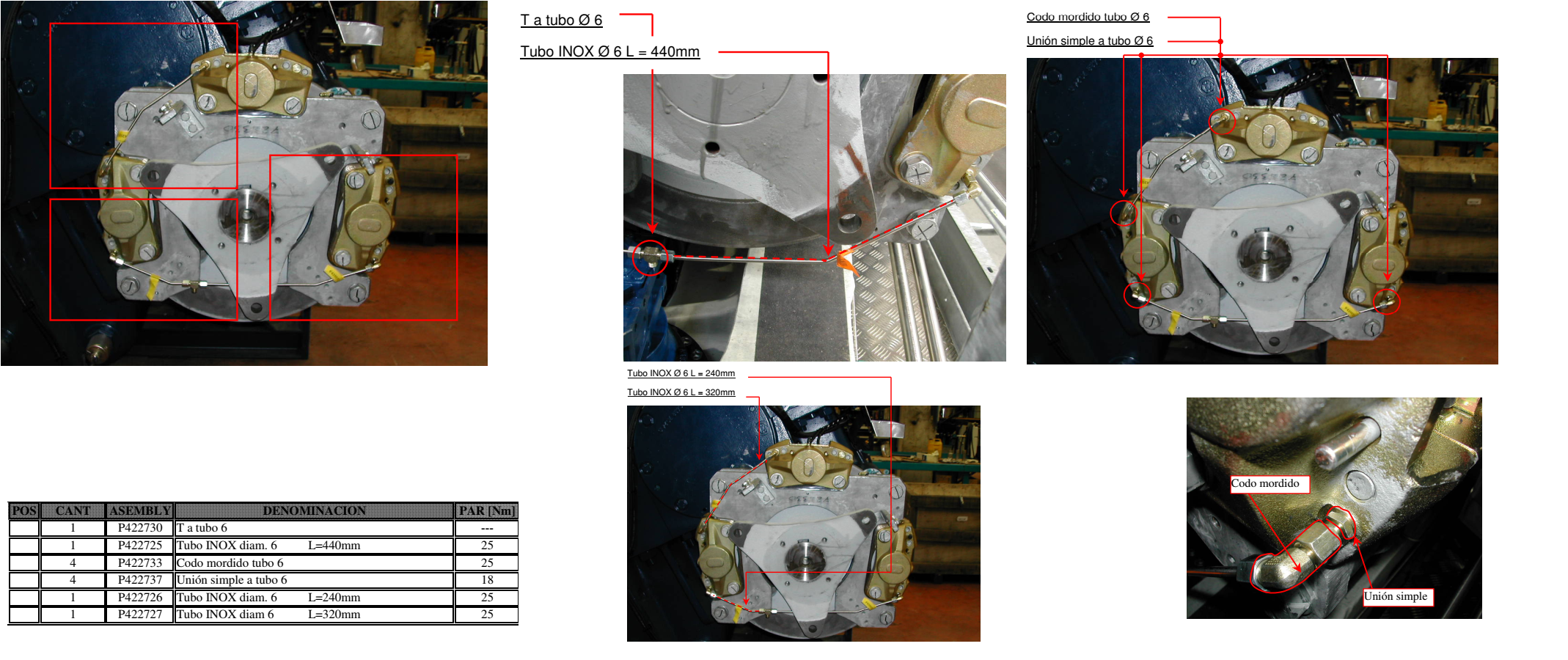

CHECK FOR LEAKS IN THE BRAKE SYSTEM

-

INFO

-

LEAKS FROM CALLIPERS, INDICATE WHICH ONE

-

CHECK THE STATUS OF THE BREAK DISK (RUST, OILED, CRACKS...)

-

CHECK FOR LEAKS IN THE PIPES AND CONNECTION TO THE CALLIPERS

-

INFO

-

INDICATE WHERE IS LEAKING FROM

END SECTION 5, START SECTION 6 (REMOVE, FM014, FG590, FF005)

-

TECHNICIANS 1 AND 2

-

VISUAL INSPECTION OF THE CONVERTER SLIDING CABINET AND ITS ELEMENTS

-

OPEN THE FG008 DOOR AND VISUAL CHECK OF THE STATTUS, NOTE THE Nº OF OPERATIONS OF THE FG008

-

OPEN THE FG002 DOOR AND VISUAL CHECK OF THE CONDITIONS (CABLES TRAYS, COVERS, CABLES, BREAKERS, ETC)

-

PERFOM THE MS_10500035721 TEST

-

CHECK THE OPERATION OF THE CONVERTER FANS, MS_10500035721 (VISUAL STATUS AND FUNCTION, NOISE, RUST)

-

TAKE THE SERIAL NUMBERS OF THE POWER STACK CONVERTER MODULES

-

ISU

-

LCL

-

INU 1

-

INU 2

-

CROWBAR

-

CHOPPER IF APPLY

-

SERIAL NUMBER

-

PERFORM MS_10500035722 TEST

-

PERFORM MS_10500035723 TEST IF INSTALLED

-

VISUAL INSPECTION OF THE CONVERTER BUS BARS

-

CHECK THE FIRMWARE VERSIONS

-

RDCU PARAMETER 04.01

-

RDCU PARAMETER 04.02

-

RDCU PARAMETER 04.03

-

NDCU PARAMETER 04.01

-

NDCU PAREMTER 04.02

-

NDCU PARAMETER 04.03

-

FAULT LOGGER BACK UP USING MS_10500035721 TEST, UPLOAD THE FILE

END SECTION 6, START SECTION 7 (REMOVE FG008, COLLECT THE TOOLS AND START LIFTING DOWN)

-

TECHNICIAN 1 TASK

-

COLLECT TOOLS, CLEAN, REMOVE ANY POI, COMPLETE THE WOC AND LIFT DOWN MATERIALS

-

TECHNICIAN 2 TASK

-

VISUAL INSPECTION AT ELEVATOR YAW PLATFORM ACCESS LADDER AND LIGHTS

-

VISUAL INSPECTION OF TE CONDITION AT ELEVATOR DECK (OIL, DIRT, DEFORMATION, ETC)

-

VISUAL INSPECTION OF THE STATUS OF THE CABLE PROTECTIONS

-

VISUAL INSPECTION OF THE ELEVATOR BARRIERS AND LOCKING DEVICES AT THE ELEVATOR DECK

-

CHECK THE SAFETY LINE INSPECTION DATE

-

CHECK THE STATUS OF THE SAFETY STICKERS

-

CHECK THE STATUS OF THE ELEVATOR DECK TRAPDOOR (DAMAGE AND SAFETY STICKER)

-

VISUAL INSPECTION OF THE CABLE LOOP AND BALCONY

-

VISUAL INSPECTION OF THE PLATFORM S2 S3 (OIL, DAMAGE, SEALING RUBER, ETC)

-

VISUAL INSPECTION OF TORQUE MARKS BOLTED JOINT S2S3

-

VISUAL INSPECTION OF THE FLANGE S3S2 CONDITION (RUST, OIL, PAINT DEFECTS)

-

VISUAL INSPECTION OF THE SECTION 3 SAFETY STICKERS

-

VISUAL INSPECTION OF THE CONDITION OF THE ELEVATOR BARRIEERS AT S2 PLATFORM

-

VISUAL INSPECTION OF THE STATUS OF THE S3 TOWER LIGHT

-

VISUAL INSPECTION OF THE GROUNDING CABLE CONNECTIONS (TORQUE MARKS)

-

VISUAL INSPECTION OF EARTHING WIRES BETWEEN S3S2

-

VISUAL INSPECTION OF THE PLATFORM SECTION 1 SECTION 2 (OIL, DAMAGE, SEALING RUBER, ETC)

-

VISUAL INSPECTION OF TORQUE MARKS BOLTED JOINT S1S2

-

VISUAL INSPECTION OF THE FLANGE S2S1 CONDITION (RUST, OIL, PAINT DEFECTS)

-

VISUAL INSPECTION OF THE SECTION 2 SAFETY STICKERS

-

VISUAL INSPECTION OF THE CONDITION OF THE ELEVATOR BARRIERS AT S1 PLATFORM

-

VISUAL INSPECTION OF THE GROUNDING CABLE CONNECTIONS (TORQUE MARKS)

-

VISUAL INSPECTION OF GROUNDING CABLES BETWEEN S2S1

-

VISUAL INSPECTION OF THE STATUS OF THE S2 TOWER LIGHT

-

VISUAL INSPECTION OF THE INNER FLANGE S1 TO FUNDATION (OIL, RUST, DIRT)

-

VISUAL INSPECTION OF THE INNER BOLTS TORQUE MARKS AND BOLTS CONDITIONS

-

VISUAL INSPECTION OF THE FUNDATION GROUNDING CABLES

-

VISUAL INSPECTION OF THE INNER FUNDATION (OIL, CLEANERESS, WATER, MATERIAL, ETC)