Title Page

-

Site conductedt

-

Conducted on

-

Prepared by

-

Location

-

Engineer name

- Adam Fishwick

- Paul Kelsey

- Antony Evans

- Ben Gould

- Graham Marshall

- Jamie Heavey

- Jason Bradshaw

- Kyle Weaver

- Mark Gardner

- Stephen Heavey

- Paul Wood

- Lee Griffiths

- Steven Emmerson

- Jason Beckett

- Steve Staniforth

- Joel Lomax

- Bryan Gay

- James Boyle

- Mick Duke

- David Ferguson

- Stuart Hatton

- Ryan Haddon

- Simon Creasey

- Terry Ecclesall

- Dean Ellam

- Stuart Ilsley

- Gavin Roberts

- Ben Newman

- Gary Hall

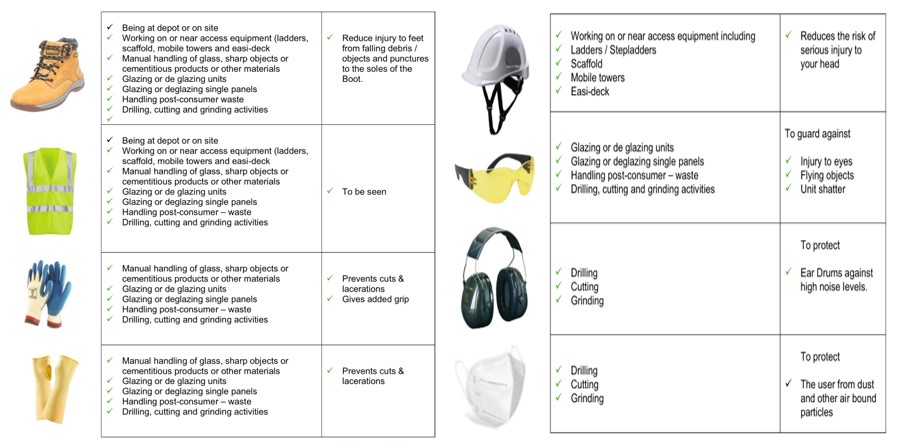

PPE

PPE

-

PPE

-

Was the engineer equipped with the correct PPE for the job in hand

- Yes

- No

- N/A

-

The engineer was asked why He/she was not wearing the correct PPE for the job in hand

- The Engineer Has not Been Issued With the Correct PPE

- The Engineer Has Asked for PPE But has not Been Supplied

- The Engineer Was Refused PPE by the Depot

- Safety boots

- High Visibility Vest

- Cut Resistant Gloves

- Cut Resistant sleeves

- Hard Hat

- Safety Glasses

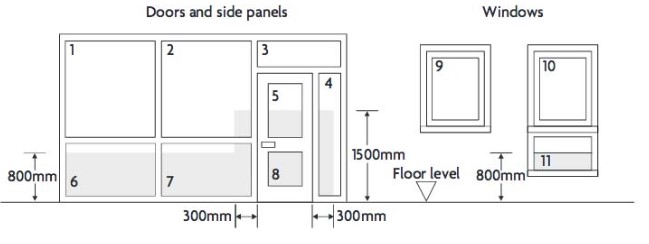

Replacement of a Casement / Tilt and Turn Window frame

-

Measure before Removal

-

Did the Engineer successfully Replace the Casement / Tilt and Turn Window

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in the Replacement of the Casement / Tilt and Turn Window

- The Engineer Measured the Existing Casement / Tilt and Turn Window Frame Prior To Removal

- The Engineer Failed to Measure the Existing Casement / Tilt and Turn Window Frame Prior To Removal

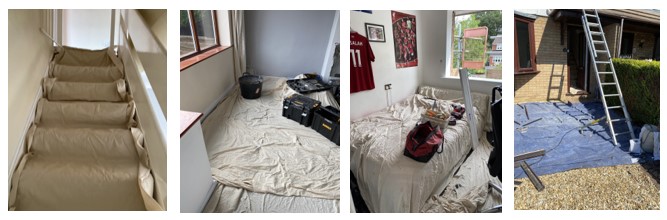

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer failed to Apply Dust Sheets to the Working Areas

- On Removal of the Frame the Engineer Removed the Existing Frame to a Safe and Secure Area

- On Removal of the Frame the Engineer Failed to Removed the Existing Frame to a Safe and Secure Area

- The Engineer Used a Ladder Stand Off and Stabilizer When Using Ladders

- The Engineer Failed to Use a Ladder Stand Off and Stabilizer When Using Ladders

- The Engineer Cleaned the Aperture From Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Failed to Clean the Aperture From Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Bedded the Frame to Cill to the company recommendation

- The Engineer Failed to Bed the Frame to Cill to the Company Recommendation

- The Engineer Bedded the Frame to Cill to the Company Recommendation

- The Engineer Bedded Down the Cill to the Substrate to the Company Recommendation

- The Engineer Checked the Window for PLUMB, LEVEL and Free from TWIST Prior to Fixing the Window

- The Engineer Did Not Check the Window for PLUMB, LEVEL and Free from TWIST Prior to Fixing the Window

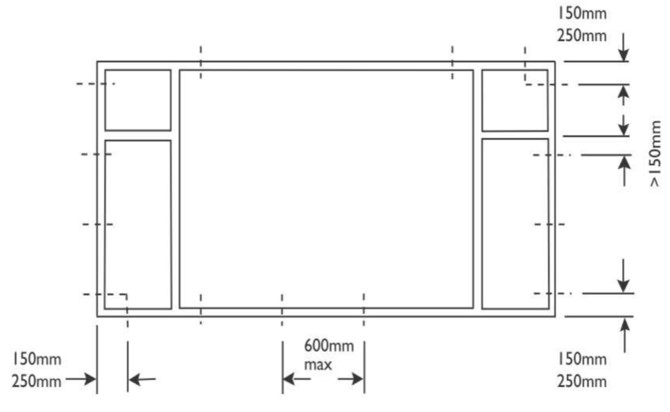

- The Engineer Affixed the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA Regulations

- The Engineer Failed to Affix the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA Regulations

- The Engineer Packed Between the Substrate and the Frame to Prevent Frame Distortion

- The Engineer Did Not Pack Between the Substrate and the Frame to Prevent Frame Distortion

- The Engineer Foamed Around the perimeter of the Frame

- The Engineer Failed to Foam Around the perimeter of the Frame

- The Engineer Used Masking Tape Prior to Sealing of the Frame

- The Engineer Failed to Use Masking Tape Prior to Sealing of the Frame

Replacement of Residential / Stable Door Sash

-

Protect the Property

-

Did the Engineer successfully replace the Residential / Stable Door Sash as Set Out in The Manual

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in the Replacement of the Sash to a Residential / Stable Door

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- The Engineer ensured the welds were aligned Correctly Prior to Removal of Sash and Noted Adjustments to be Made on Application of Top hinge

- The Engineer Failed to ensure the weld alignment Was Correct To allow Adjustment to be Made if Required Prior to Removal of Sash

- The Engineer Measured the Existing and the Replacement Door Sash Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Door Sash Prior To Removal

- The Engineer Applied Levels to Door Frame in the Correct Manner to Ensure the Frame is Plumb , Level and Free From Twist

- The Engineer Failed to Apply Levels to Door Frame in the Correct Manner to Ensure the Frame is Plumb , Level and Free From Twist

- The Engineer Deglazed the Residential Door Sash Without Issue

- The Engineer Deglazed the Residential Door Sash But Failed to Mark the Beads

- The Engineer Stored the Glass or Panel in a Safe and Proper Manner to Prevent Injury to Others Without Prompt

- The Engineer Did Not Store the Glass or Panel in a Safe and Proper Manner to Prevent Injury to Others

- The Engineer Aligned the Hinge to the Sash Correctly as Set Out in the Manual (Measuring Down from Longest Leg to Shoulder of Hinge)

- The Engineer Failed to Align the Hinge to the Sash as Set Out in the Manual. Leaving Unnecessary Holes in the Sash

- The Engineer Applied the Door Sash to the Frame as Set Out in the Manual

- The Engineer Failed to Apply the Door Sash to the Frame as Set Out in the Manual

- The Engineer Set Middle And Bottom Hinges and Cut Back the Gaskets

- The Engineer Set Middle And Bottom Hinges BUT Failed to Cut Back the the Gaskets

- The Engineer When the Sash had been Adjoined to the Frame Opened the Door and Tightened the Retaining Grub Screws

- The Engineer Failed to Open the Sash and Tightened the Retaining Grub Screws

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe style UK without issue been instructed to do so

- The Engineer Failed Toe and Heal the Door Correctly

- The Engineer had no Issue in the Relocation or Replacement of the Hinges

- The Engineer Struggled with the Replacement of the Residential Door Sash as He/she Failed to Identify the Hinge to the Frame Required Relocation

- The Engineer Struggled when Trouble Shooting the Issue

Replacement of a Composite Door Slab

-

Did the Engineer Successfully Replace the Composite Door Slab

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in Composite Door Slab Replacement

- The engineer did not check the door for Plumb, Level and free from TWIST prior to fitting new slab

- The engineer checked the door for Plumb, Level and free from TWIST prior to fitting new slab

- The previous report did stated door was In or Out of plumb and level and Free from Twist prior to fitting new slab

- The previous report did Not state door was In or Out of plumb and level and Free from Twist in His/her Report

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Did Not Apply Dust Sheets to the Working Areas

- The Engineer Checked the Slab Prior to Removal for Equal Airgap Around the Slab to Ensure Correct Frame Size

- The Engineer Did Not Check the Slab Prior to Removal for Equal Airgap Around the Slab to Ensure Correct Frame Size

- The Engineer Removed Slab Without Issue

- The Engineer Had Difficulty in Removing the Slab

- The Engineer Removed the Cassettes and Glass Without Issue

- The Engineer had Issues When Replacing Cassettes and the Glass Snapping a Glass Lock Clip

- Did the Engineer Align the Slab within the Frame to Achieve an Equal Airgap

- The Engineer Failed to Align the Slab Within the Frame to Achieve an Equal Airgap

- The Engineer Moved the Hinge Across Without Difficulty Due to Wrong Hinge Location

- The engineer struggled with the hinge repositioning

Replacement of a Residential Door Frame

-

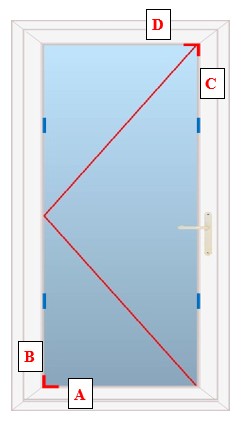

Toe & Heal - RED Packers denote position of toe & heal - BLUE Packers Denote Security packing positions

-

Did the Engineer successfully Replace the Residential Door Frame

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in the Residential Door Frame Replacement

- The Engineer Measured the Existing Residential Door Frame Prior To Removal

- The Engineer Failed to Measure the Existing Residential Door Frame Prior To Removal

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- On Removal of the Frame the Engineer Removed the Existing Frame to a Safe and Secure Area

- On Removal of the Frame the Engineer Failed to Remove the Existing Frame to a Safe and Secure Area

- The Engineer Cleaned the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Did Not Clean the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Bedded the Frame to the Cill to the Company Recommendation

- The Engineer Failed to Bed the Frame to the Cill to the Company Recommendation

- The Engineer Bedded Down the Cill to the Substrate to the Company Recommendation

- The Engineer Failed to Bed Down the Cill to the Substrate to the Company Recommendation

- The Engineer Checked the Product for Plumb, Level and Free from Twist prior to fixing the Product

- The Engineer Did Not check the Product for Plumb, Level and Free from Twist Prior to Fixing the Product

- The Engineer fixed the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Failed to fix the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Packed Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Did Not Pack Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Foamed the Perimeter of the Frame

- The Engineer Failed to Foam the Perimeter of the Frame

- The Engineer Used Masking Tape Prior to Sealing of the Frame

- The Engineer Failed to Use Masking Tape Prior to Sealing of the Frame

- The Engineer Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Did Not Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Ensured the Site was Clean and Free from Debris Before Departing Site

- The Engineer Did Not Ensured the Site was Clean and Free from Debris Before Departing Site

Replacement of a Residential / Stable Door

-

Pipes and Wires can be hidden in the most unexpected places. Always Check. Even on a new installation

-

On removal and replacement of the casement frame did the engineer Follow the company and FENSA Guidelines

- Yes

- No

- N/A

-

The engineer failed to follow the correct procedures

- The Engineer Measured the Existing Residential Door Frame Prior To Removal

- The Engineer Failed to Measure the Existing Residential Door Frame Prior To Removal

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- On Removal of the Frame the Engineer Removed the Existing Frame to a Safe and Secure Area

- On Removal of the Frame the Engineer Failed to Remove the Existing Frame to a Safe and Secure Area

- The Engineer Cleaned the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Did Not Clean the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Bedded the Frame to the Cill to the Company Recommendation

- The Engineer Failed to Bed the Frame to the Cill to the Company Recommendation

- The Engineer Bedded Down the Cill to the Substrate to the Company Recommendation

- The Engineer Failed to Bed Down the Cill to the Substrate to the Company Recommendation

- The Engineer Checked the Product for Plumb, Level and Free from Twist prior to fixing the Product

- The Engineer Did Not check the Product for Plumb, Level and Free from Twist Prior to Fixing the Product

- The Engineer fixed the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Failed to fix the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Packed Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Did Not Pack Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Foamed the Perimeter of the Frame

- The Engineer Failed to Foam the Perimeter of the Frame

- The Engineer Used Masking Tape Prior to Sealing of the Frame

- The Engineer Failed to Use Masking Tape Prior to Sealing of the Frame

- The Engineer Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Did Not Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Ensured the Site was Clean and Free from Debris Before Departing Site

- The Engineer Did Not Ensured the Site was Clean and Free from Debris Before Departing Site

Tear down and rebuild of French door sashes. Removal and replacement including, Glass, hinges, Gearing, sash realignment and Toe & Heal of product

-

Prepared cill for bedding down frame

-

Did the engineer complete the task without issue

- Yes

- No

- N/A

-

Was the engineer competent in the repair and replacement of French Door Sash's

- Did the engineer apply dust sheet to the working area

- The engineer deglazed the French door sashes without issue

- The engineer had issues deglazing the French door

- The engineer stored the glass and sashes in a safe and proper manner to prevent injury to others without prompt

- The engineer did not store the glass or panel in a safe and proper manner to prevent injury to others

- The engineer had no issue in removal of the French door sashes

- The engineer struggled with the removal of the French door sashes

- The engineer had no issues in the removal and replacement of the French door Liniar mullion

- The engineer struggled in the removal and replacement of the French door Liniar mullion

- The engineer is competent when trouble shooting issues

- The engineer struggled when trouble shooting the issue

- The engineer re-glazed and correctly toe and healed the sashes to the recommended Standard Expected by Safe style UK without issue been instructed to do so

- The engineer did not toe and heal to the company standard and requires further Training

Removal and replacement of a French Door

-

It is Good Practice to load all old frames and units directly onto the vehicle directly after removal

-

On removal and replacement of the French Door outer frame did the engineer Follow the company and FENSA Guidelines

- Yes

- No

- N/A

-

The engineer failed to follow the correct procedures

- The Engineer Measured the Existing Residential Door Frame Prior To Removal

- The Engineer Failed to Measure the Existing Residential Door Frame Prior To Removal

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- On Removal of the Frame the Engineer Removed the Existing Frame to a Safe and Secure Area

- On Removal of the Frame the Engineer Failed to Remove the Existing Frame to a Safe and Secure Area

- The Engineer Cleaned the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Did Not Clean the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Bedded the Frame to the Cill to the Company Recommendation

- The Engineer Failed to Bed the Frame to the Cill to the Company Recommendation

- The Engineer Bedded Down the Cill to the Substrate to the Company Recommendation

- The Engineer Failed to Bed Down the Cill to the Substrate to the Company Recommendation

- The Engineer Checked the Product for Plumb, Level and Free from Twist prior to fixing the Product

- The Engineer Did Not check the Product for Plumb, Level and Free from Twist Prior to Fixing the Product

- The Engineer fixed the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Failed to fix the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Packed Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Did Not Pack Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Foamed the Perimeter of the Frame

- The Engineer Failed to Foam the Perimeter of the Frame

- The Engineer Used Masking Tape Prior to Sealing of the Frame

- The Engineer Failed to Use Masking Tape Prior to Sealing of the Frame

- The Engineer Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Did Not Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Ensured the Site was Clean and Free from Debris Before Departing Site

- The Engineer Did Not Ensured the Site was Clean and Free from Debris Before Departing Site

Tear down and rebuild of Tilt & Turn sash. Removal and replacement including, Glass, hinges, Gearing, sash realignment and Toe & Heal of product

-

Know your Fixing Points

-

Did the engineer complete the task without issue

- Yes

- No

- N/A

-

undefined

- Did the engineer apply dust sheet to the working area

- The engineer deglazed the Tilt & Turn without issue

- Did the engineer store the glass or in a safe and proper manner to prevent injury to others without prompt

- The engineer had no issue in removal of the Tilt & Turn sash

- The engineer struggled with the removal of the sash

- The engineer had no issue in replacement of the Tilt & Turn sash

- The engineer had no issue in the relocation or replacement of the Gearing

- The engineer struggled with the replacement of the Tilt & Turn Gearing as he/she had failed to identify the direction of the gearing

- The engineer struggled when trouble shooting the issue

- The engineer re-glazed and correctly toe and healed the sash to the recommended Standard Expected by Safe style UK without issue been instructed to do so

- The engineer did not toe and heal to the company standard and requires further Training

- The engineer requires further training

Removal and replacement of a Tilt & Turn outer frame

-

Mask off before you seal a product

-

On removal and replacement of the Tilt & Turn outer frame did the engineer Follow the company and FENSA Guidelines

- Yes

- No

- N/A

-

The engineer failed to follow the correct procedures

- The Engineer Measured the Existing Residential Door Frame Prior To Removal

- The Engineer Failed to Measure the Existing Residential Door Frame Prior To Removal

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- On Removal of the Frame the Engineer Removed the Existing Frame to a Safe and Secure Area

- On Removal of the Frame the Engineer Failed to Remove the Existing Frame to a Safe and Secure Area

- The Engineer Cleaned the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Did Not Clean the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Bedded the Frame to the Cill to the Company Recommendation

- The Engineer Failed to Bed the Frame to the Cill to the Company Recommendation

- The Engineer Bedded Down the Cill to the Substrate to the Company Recommendation

- The Engineer Failed to Bed Down the Cill to the Substrate to the Company Recommendation

- The Engineer Checked the Product for Plumb, Level and Free from Twist prior to fixing the Product

- The Engineer Did Not check the Product for Plumb, Level and Free from Twist Prior to Fixing the Product

- The Engineer fixed the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Failed to fix the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Packed Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Did Not Pack Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Foamed the Perimeter of the Frame

- The Engineer Failed to Foam the Perimeter of the Frame

- The Engineer Used Masking Tape Prior to Sealing of the Frame

- The Engineer Failed to Use Masking Tape Prior to Sealing of the Frame

- The Engineer Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Did Not Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Ensured the Site was Clean and Free from Debris Before Departing Site

- The Engineer Did Not Ensured the Site was Clean and Free from Debris Before Departing Site

Tear down and rebuild of Slidex door sashes. Removal and replacement including, Glass, hinges, Gearing, sash realignment and Toe & Heal of product

-

Did the engineer complete the task without issue

- Yes

- No

- N/A

-

Was the engineer competent in the repair and replacement of Slidex patio Door

- Did the engineer apply dust sheet to the working area

- The engineer deglazed the Slidex door sashes without issue

- The engineer had issues when deglazing the Slidex door sashes

- The engineer stored the glass and sashes in a safe and proper manner to prevent injury to others without prompt

- The engineer did not store the glass or sashes in a safe and proper manner to prevent injury to others

- The engineer had no issue in removal of the Slidex sash

- The engineer had issues with the removal of the Slidex sash

- The engineer replaced the sash without any issue

- The engineer had issues with the sash replacement

- The engineer has no issues in the removal and replacement of the the new liniar lock when replacing

- The engineer had issues with the removal and replacement of new liniar lock when replacing

- The engineer had no issues with the removal and replacement of new liniar bogie wheels when replacing

- The engineer is competent when trouble shooting issues

- The engineer struggled with the removal and replacement of new liniar bogie wheels when failure occurred

- The engineer struggles when trouble shooting the issue

Removal and replacement of a Slidex Patio Door outer frame

-

On removal and replacement of the Slidex Patio Door outer frame, did the engineer Follow the company and FENSA Guidelines

- Yes

- No

- N/A

-

The engineer failed to follow the correct procedures

- The Engineer Measured the Existing Residential Door Frame Prior To Removal

- The Engineer Failed to Measure the Existing Residential Door Frame Prior To Removal

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- On Removal of the Frame the Engineer Removed the Existing Frame to a Safe and Secure Area

- On Removal of the Frame the Engineer Failed to Remove the Existing Frame to a Safe and Secure Area

- The Engineer Cleaned the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Did Not Clean the Aperture from Silicone, Foam Prior to Reinstalling the New Product

- The Engineer Bedded the Frame to the Cill to the Company Recommendation

- The Engineer Failed to Bed the Frame to the Cill to the Company Recommendation

- The Engineer Bedded Down the Cill to the Substrate to the Company Recommendation

- The Engineer Failed to Bed Down the Cill to the Substrate to the Company Recommendation

- The Engineer Checked the Product for Plumb, Level and Free from Twist prior to fixing the Product

- The Engineer Did Not check the Product for Plumb, Level and Free from Twist Prior to Fixing the Product

- The Engineer fixed the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Failed to fix the Frame to the Aperture Using the Mandatory Frame Fixing Positions as Set Out by the Company and FENSA regulations

- The Engineer Packed Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Did Not Pack Between the substrate and the Frame to Prevent Frame Distortion

- The Engineer Foamed the Perimeter of the Frame

- The Engineer Failed to Foam the Perimeter of the Frame

- The Engineer Used Masking Tape Prior to Sealing of the Frame

- The Engineer Failed to Use Masking Tape Prior to Sealing of the Frame

- The Engineer Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Did Not Toe and Healed the Product in Compliance with the Company Standard

- The Engineer Ensured the Site was Clean and Free from Debris Before Departing Site

- The Engineer Did Not Ensured the Site was Clean and Free from Debris Before Departing Site

Replacement of a Sash to a Casement Window

-

Know your toughened areas

-

Did the Engineer successfully Replace the Casement sash

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in the Replacement of the Sash to a Casement Window

- The Engineer Applied Dust Sheets to the Working Area

- The Engineer Failed to Apply Dust Sheets to the Working Area

- The Engineer Deglazed the Sash Without Issue

- The Engineer Had Issues Deglazing the Sash Leaving Marks to the Bead

- The Engineer Stored the Glass in a Safe and Proper Manner to Prevent Injury to Others Without Prompt

- The Engineer Failed to Store the Glass in a Safe and Proper Manner to Prevent Injury to Others And to be Prompted to do So

- The Engineer Had no Issue in Removal of the Casement Sash

- The Engineer Struggled With the Removal of the Larger Casement Sashes

- The Engineer Had no Issue in the Relocation or Replacement of the Casement hinges

- The Engineer Had Issue With the Relocation and Replacement of the Casement hinges

- The Engineer Replaced The Sash Without Any Issue

- The Engineer Had Difficulty in Replacing the Sash

- The Engineer Moved keeps Due to Misalignment Without Issue

- The Engineer Had Issues When Trying to Realign the Keeps

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe Style UK

- The Engineer Failed to Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe Style UK

-

Was the engineer competent in the repair and replacement of casement Window Sash

- The Engineer Applied Dust Sheets to the Working Area

- The Engineer Failed to Apply Dust Sheets to the Working Area

- The Engineer Deglazed the Sash Without Issue

- The Engineer Had Issues Deglazing the Sash Leaving Marks to the Bead

- The Engineer Stored the Glass in a Safe and Proper Manner to Prevent Injury to Others Without Prompt

- The Engineer Failed to Store the Glass in a Safe and Proper Manner to Prevent Injury to Others And to be Prompted to do So

- The Engineer Had no Issue in Removal of the Casement Sash

- The Engineer Struggled With the Removal of the Larger Casement Sashes

- The Engineer Had no Issue in the Relocation or Replacement of the Casement hinges

- The Engineer Had Issue With the Relocation and Replacement of the Casement hinges

- The Engineer Replaced The Sash Without Any Issue

- The Engineer Had Difficulty in Replacing the Sash

- The Engineer Moved keeps Due to Misalignment Without Issue

- The Engineer Had Issues When Trying to Realign the Keeps

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe Style UK

- The Engineer Failed to Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe Style UK

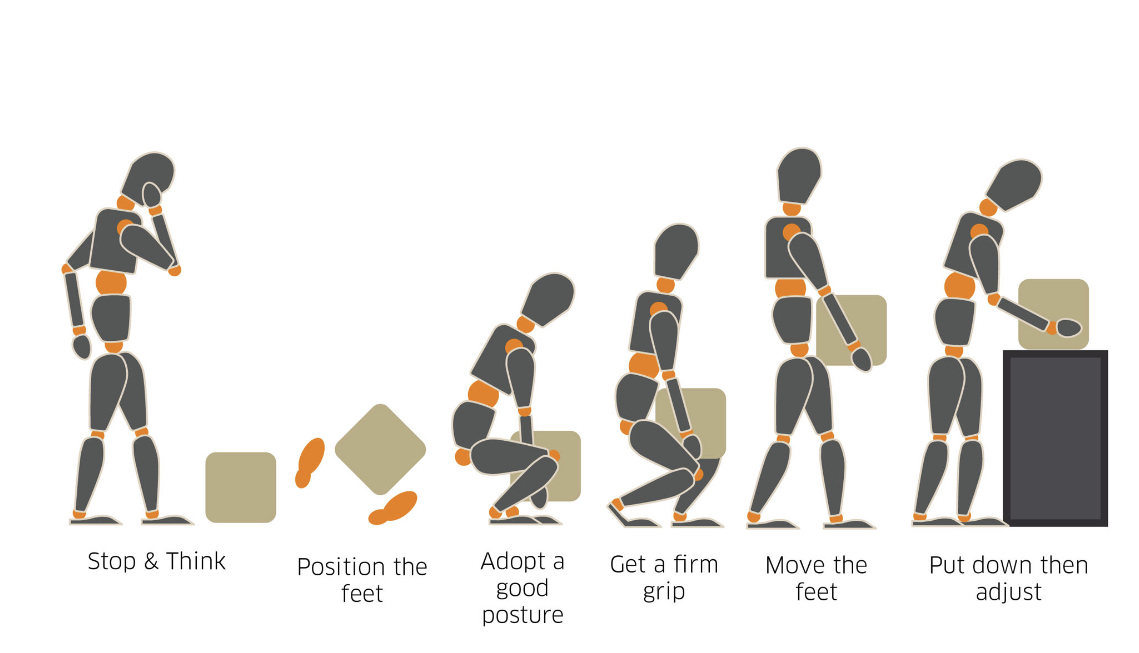

Manual Handling

Manual Handling

-

Manual Handling

-

Did the engineer adhere to the manual handling techniques

- Yes

- No

- N/A

-

Educate engineers on manual handling

- Think Before You Lift. Plan the Lift. Where is the Sashes, Glass and Timber Frame to be Placed? Will Help be Needed to Bear Weight of Sashes or Glass Units ? Is There Equipment You Could Use, Such as Suckers or Straps, That Could Help with the Lift?

- Keep the Load Close to Waist for as Long as Possible While Lifting to Reduce the Amount of Pressure on the Back, Keep the Heaviest Side of the Load Next to the Body I.e.: The Frame or Sash. and Ensure the Lift is Coordinated Between You and Your Colleague.

- When Lifting a Large Frame or Unit Adopt a Stable Position Your Feet Should be Slightly Apart with 1 Leg Slightly Forward to Maintain Balance Ensuring You and Your Colleague Communicate Throughout the Lift Process.

- Ensure a Good Hold is Maintained on the Unit Sash or Frame. Where Possible, Hug the Load Close to the Body With one Hand to the Underside of the Unit and the Other Hand to the Side this will Stabilise and Steady the Lift Making a Stronger and More Solid Lift Than Gripping the Load Tightly With the Hands to the Sides Only.

- Do Not Bend Your Back when Lifting. This Can Happen if the Legs Begin to Straighten Before Starting to Raise the Load

- Know Your Limits. Do Not Lift or Handle More than you Can Easily Manage. There's a Difference Between What People can Lift and What They can Safely Lift. If You're in Doubt, Ask a Colleague to Assist with the Lift

Report Writing

-

If a Rebook Occurs While on Site With The Engineer and a Report is Required

- Yes

- No

- N/A

-

Has the Report Been Written With Enough Detail Including Parts, Trim, Scaffolding etc, to Allow the Following Engineer to Complete the Work on the Next Visit

- The Report included a Full Breakdown of All Issues Including, Locations, Part Quantities and Part Numbers, Scaffolding if Required and Time to Complete the Required Works on the Next Visit

- The Report Failed to included a Full Breakdown of All Issues Including, Locations, Parts Quantities and Part Numbers, Scaffolding if Required and Time to Complete the Required Works on the Next Visit

- The Report Included the Required Pictures of Why the Part or Product Was Been Replaced

- The Engineer Failed to Include the Required Pictures of Why the Part or Product Was Been Replaced

Replacement of Sash to Casement Window

-

Did the Engineer successfully Replace the Casement Sash as Set Out in The Manual

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in Casement Sash Replacement

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Did Not Apply Dust Sheets to the Working Areas

- The Engineer Measured the Existing and the Replacement Casement Sash Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Casement Sash Prior To Removal

- The Engineer Aligned the Hinge Correctly

- The Engineer Failed to Align Hinge Correctly, Leaving Unnecessary Holes in the Sash

- The Engineer Aligned the Claw Grip Correctly

- The Engineer Failed to Align the Claw Grip or They did not Align With each Other

- The Engineer Attached the Interlocking Wedges Correctly

- The Engineer Failed to Attach the Interlocking Wedges or They did not Align With each Other

- The Engineer Aligned the Keeps Correctly

- The Engineer Failed to Align the Keeps Correctly Leaving Unnecessary Holes in the Frame

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe style UK without issue been instructed to do so

- The Engineer Failed to Correctly Toe and Heal the Sash

- The Engineer Correctly Attached the Sash to the frame Without Issue

- The Engineer Failed Attached the Sash to the frame on First Attempt

Replacement of Tilt and Turn Sash to a Window / Door Sash

-

Replacement of Sash to Tilt and Turn Window / Door Sash

- Yes

- No

- N/A

-

Did the Engineer successfully replace the Tilt and Turn Window / Door Sash as Set Out in The Manual

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer failed to Apply Dust Sheets to the Working Areas

- The Engineer Measured the Existing and the Replacement Tilt And Turn Sash Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Tilt And Turn Sash Prior To Removal

- The Engineer Removed the Top Stay Hinge Pin Without Issue To Remove the Tilt and Turn Sash

- The Engineer Had Difficulty in Removing the Top Stay Hinge Pin To Remove the Tilt and Turn Sash

- The Engineer was Aware of the Correct Direction the Pin Should be Inserted To the Top Stay Hinge (To Prevent Plaster line Obstruction on Removal and Replacement)

- The Engineer was Not Aware that the Pin Should be Inserted From the Bottom of The Hinge and Not the Top (To Prevent Plaster line Obstruction on Removal and Replacement)

- The Engineer Correctly Placed the Sash onto the Pin, Inserted Sash into Frame then Applied the Pin in the Correct Way to Secure Sash to Frame

- The Engineer Correctly Placed the Sash onto the Pin, BUT Failed to Inserted Sash into Frame while Trying to Apply the Pin With the Sash in the Open Position

- The Engineer Aligned the Keeps Correctly

- The Engineer Failed to Align the Keeps Correctly Leaving Unnecessary Holes in the Frame

- The Engineer Was Able to Dismantle and Reassemble the Gearing on a Tilt and Turn Sash

- The Engineer Could Not Dismantle and Reassemble the Gearing on A Tilt and Turn Sash

- The Engineer Was Able to Point Out all Adjustment Points on A tilt and Turn Sash

- The Engineer Was Not Able to Point Out all Adjustment Points on A tilt and Turn Sash

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe style UK without issue been instructed to do so

- The Engineer Failed to Correctly Toe and Heal the Sash

Replacement of a Residential / Stable Door Sash

-

Replacment of Residential door Sash

- Yes

- No

- N/A

-

Did the Engineer successfully replace the Residential Door Sash as Set Out in The Manual

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- The Engineer Measured the Existing and the Replacement Door Sash Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Door Sash Prior To Removal

- The Engineer ensured the welds were aligned Correctly Prior to Removal of Sash and Noted Adjustments to be Made on Application of Top hinge

- The Engineer Failed to ensure the weld alignment Was Correct To allow Adjustment to be Made if Required Prior to Removal of Sash

- The Engineer Applied Levels to Door Frame in the Correct Manner to Ensure the Frame is Plumb , Level and Free From Twist

- The Engineer Failed to Apply Levels to Door Frame in the Correct Manner to Ensure the Frame is Plumb , Level and Free From Twist

- The Engineer Aligned the Hinge to the Sash Correctly as Set Out in the Manual (Measuring Down from Longest Leg to Shoulder of Hinge)

- The Engineer Failed to Align the Hinge to the Sash as Set Out in the Manual. Leaving Unnecessary Holes in the Sash

- The Engineer Applied the Door Sash to the Frame as Set Out in the Manual

- The Engineer Failed to Apply the Door Sash to the Frame as Set Out in the Manual

- The Engineer Set Middle And Bottom Hinges and Cut Back the Gaskets

- The Engineer Set Middle And Bottom Hinges BUT Failed to Simulate The Cutting Back the the Gaskets

- The Engineer When the Sash had been Adjoined to the Frame Opened the Door and Tightened the Retaining Grub Screws

- The Engineer Failed to Open the Sash and Tightened the Retaining Grub Screws

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe style UK without issue been instructed to do so

- The Engineer Failed Toe and Heal the Door Correctly

Replacement of French Door Sash / Sashes

-

Replacement of French Door Sash(s)

-

Did the Engineer successfully replace the French Door Sash(s) as Set Out in The Manual

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- The Engineer ensured the welds were aligned Correctly Prior to Removal of Sash and Noted Adjustments to be Made on Application of Top hinge

- The Engineer Failed to ensure the weld alignment Was Correct To allow Adjustment to be Made if Required Prior to Removal of Sash

- The Engineer Measured the Existing and the Replacement Door Sash(s) Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Door Sash(s) Prior To Removal

- The Engineer Applied Levels to Door Frame in the Correct Manner to Ensure the Frame is Plumb , Level and Free From Twist

- The Engineer Failed to Apply Levels to Door Frame in the Correct Manner to Ensure the Frame is Plumb , Level and Free From Twist

- The Engineer Marked the Beads and Deglazed the French Door Sash(s) Without Issue

- The Engineer Deglazed the French Door Sash(s) But Failed to Mark the Beads

- The Engineer Stored the Glass or Panel in a Safe and Proper Manner to Prevent Injury to Others Without Prompt

- The Engineer Did Not Store the Glass or Panel in a Safe and Proper Manner to Prevent Injury to Others

- The Engineer Aligned the Hinge to the Sash Correctly as Set Out in the Manual (Measuring Down from Longest Leg to Shoulder of Hinge)

- The Engineer Failed to Align the Hinge to the Sash as Set Out in the Manual. Leaving Unnecessary Holes in the Sash

- The Engineer Applied the Door Sash to the Frame as Set Out in the Manual

- The Engineer Failed to Apply the Door Sash to the Frame as Set Out in the Manual

- The Engineer Set Middle And Bottom Hinges and Cut Back the Gaskets

- The Engineer Set Middle And Bottom Hinges BUT Failed to Cut Back the the Gaskets

- The Engineer When the Sash had been Adjoined to the Frame Opened the Door and Tightened the Retaining Grub Screws

- The Engineer Failed to Open the Sash and Tightened the Retaining Grub Screws

- The Engineer Measured the Gap Between the Sashes and Obtained the 11mm Gap Between he Sashes at the Door Centre

- The Engineer Failed Measure the Gap Between the Sashes To Obtain the 11mm Gap Between he Sashes at the Door Centre

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe style UK without issue been instructed to do so

- The Engineer Failed Toe and Heal the Door Correctly

- The Engineer Once the Sash(s) had Been Adjoined to the Outer Frame Replaced the Restrictor Stays

- The Engineer Once the Sash(s) had Been Adjoined to the Outer Frame Failed to Replaced the Restrictor Stays

- The Engineer had no Issue in the Relocation or Replacement of the Hinges if Required Due to the Hinges Been Incorrectly Set at Time Of Manufacture

- The Engineer Struggled with the Replacement of the Residential Door Sash as He/she Failed to Identify the Hinge to the Frame Required Relocation

- The Engineer Struggled when Trouble Shooting the Issue

Replacement of a Casement Sash to a New Outer

-

Replacement of a Casement Sash to a New Outer

- Yes

- No

- N/A

-

Did the Engineer successfully Fit the Casement Sash to the New Bare Outer frame as Set Out in The Manual

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- The Engineer Measured the Existing and the Replacement Casement Sash Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Casement Sash Prior To Removal

- The Engineer Aligned the Hinge Correctly

- The Engineer Failed to Align Hinge Correctly, Leaving Unnecessary Holes in the Sash

- The Engineer Aligned the Claw Grip Correctly To Frame

- The Engineer Failed to Align the Claw Grip or They did not Align With each Other

- The Engineer Attached the Interlocking Wedges Correctly

- The Engineer Failed to Attach the Interlocking Wedges or They did not Align With each Other

- The Engineer Aligned the Keeps Correctly When Fitted to Outer frame

- The Engineer Failed to Align the Keeps Correctly Leaving Unnecessary Holes in the New Frame When Moved

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe style UK without issue been instructed to do so

- The Engineer Failed to Correctly Toe and Heal the Sash

- The Engineer Correctly Attached the Sash to the New Frame Without Issue

- The Engineer Failed Attached the Sash to the New Frame on First Attempt

Replacement of a Tilt and Turn Sash to a New Outer

-

Did the Engineer successfully Fit the Tilt and Turn Sash to the New Bare Outer frame as Set Out in The Manual

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in the Fitting of a Replacement off a Tilt and Turn Sash to the New Frame

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- The Engineer Measured the Existing and the Replacement Tilt and Turn Sash Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Tilt and Turn Sash Prior To Removal

- The Engineer Placed the Jig to the Bottom of The Frame and drilled the two Holes to Accept the bottom Hinge

- The Engineer Failed to Place the Jig to the Bottom of The Frame and drilled the two Holes to Accept the bottom Hinge

- The Engineer Placed the Jig to the top of the Frame and drilled the two Holes to Accept the Scissor Arm Hinge

- The Engineer Failed to Place the Jig to the top of The Frame and drilled the two Holes to Accept the Scissor Arm Hinge

- The Engineer Placed the Top and Bottom Hinges into the Holes Drilled Prior to Fitting the Sash

- The Engineer Failed to Place the Top and Bottom Hinges into the Holes Drilled Prior to Fitting the Sash

- The Engineer Fitted the Cap Cover to the Bottom Hinge Prior to Fitting the Sash

- The Engineer Failed to Fit the Cap Cover to the Bottom Hinge Prior to Fitting the Sash

- The Engineer Placed the Tilt and Turn onto the Pin and Inserted the Top Scissor Stay into the Top Hinge Inserting the Pin in the CORRECT Orientation

- The Engineer Placed the Tilt and Turn onto the Pin and Inserted the Top Scissor Stay into the Top Hinge Inserting the Pin in the INCORRECT Orientation

- The Engineer Correctly Toe and Heal the Sash

- Score: 1

- The Engineer Failed to Correctly Toe and Heal the Sash

- Marked as flagged

- Score: 0

- The Engineer Aligned the Keeps Correctly When Fitted to Outer frame

- Score: 1

- The Engineer Failed to Align the Keeps Correctly Leaving Unnecessary Holes in the New Frame When Moved

- Marked as flagged

- Score: 0

- The Engineer Correctly Attached the Sash to the New Frame Without Issue

- Score: 1

- The Engineer Failed Attached the Sash to the New Frame on First Attempt

Replacement of Residential / Stable Sash to a New Outer

-

Did the Engineer successfully Fit the Residential / Stable Door Sash to the New Bare Outer frame as Set Out in The Manual

- Yes

- No

- N/A

-

In Which Area did the Engineer Pass or Fail in the Fitting of a Residential / Stable Door Sash to the New Frame

- The Engineer Applied Dust Sheets to the Working Areas

- The Engineer Failed to Apply Dust Sheets to the Working Areas

- The Engineer Measured the Existing and the Replacement Residential / Stable Door Sash Prior To Removal

- The Engineer Failed to Measure the Existing and the Replacement Residential / Stable Door Sash Prior To Removal

- The Engineer Measured - Door to Sides and Top of Frame to Obtain the 49mm from edge of frame He Also Checked weld Alignment of Sash to Frame Sash to confirm the Correct Sash Alignment Within The Frame, and Clamped Sash to Frame

- The Engineer Failed to Measure - Door to Sides and Top of Frame to Obtain the 49mm from edge of frame He Also Failed to Check weld Alignment of Sash to Frame Sash to confirm the Correct Sash Alignment Within The Frame, and Failed to Clamp Sash to Frame

- The Engineer Placed the Jig to the Frame in the Right Direction Top to Top

- The Engineer Placed the Jig to the Frame in the Wrong Direction Top to Bottom

- The Engineer Once the Door Was Set up, Placed the Jig (With The Bosses Pointing Upwards) to the Hinge and Drilled The Two Holes To Accept The Saddle And The Datum, Repeating for the remainder Hinges

- The Engineer Once the Door Was Set up, Placed the Jig (With The Bosses Pointing Downward) to the Hinge and Attempted to Drilled The Two Holes To Accept The Saddle And The Datum, The Engineer Was Stopped as This Would Have Caused Hinge Misalignment

- The Engineer Moved The Sash to Allow Hinges to Be Adhered To the Frame

- The Engineer Failed to Move The Sash to Allow Hinges to Be Adhered To the Frame

- The Engineer Inserted the Jig With the Bosses Pointing Downward into the Two Pre Drilled Holes and Drilled the further Two Required Holes

- The Engineer Inserted the Jig With the Bosses Pointing Upward Trying to manually align jig to the Two Pre Drilled Holes. The engineer was Stopped Prior to Drilling the Two Additional holes

- The Engineer Assembled The Saddle with the Datum adjoining Saddle and Datum to Frame and Screwed into Position - Repeating for the Remainder of the Hinges

- The Engineer Failed to Assemble The Saddle with the Datum Before adjoining Saddle to Frame, This would create Damage as the Datum Might not Align with the Saddle

- The Engineer Moved The Sash back into position and adjusted the saddle to accept the Sash Hinge, Pins and hinge caps were applied

- The Engineer Moved The Sash back into position But Failed to Adjust the Saddle to Accept the Sash Hinge. The Process was Stopped as this Would Create Damage to the Hinge

- The Engineer When the Sash had been Adjoined to the Frame Opened the Door and Tightened the Retaining Grub Screws

- The Engineer Failed to Open the Sash and Tightened the Retaining Grub Screws

- The Engineer Re-Glazed and Correctly Toe and Healed the Sash to the Recommended Standard Expected by Safe style UK without issue been instructed to do so

- The Engineer Failed Toe and Heal the Door Correctly