Title Page

-

Site conducted

-

Conducted on

-

Auditor

-

Site

-

Gate Number

-

Gate Number

-

Gate Number

-

Gate Number

-

Gate Number

-

Gate Number

-

Gate Number

-

Gate Number

-

Tail Number

- N1013A

- N1049A

- N1093A

- N1181A

- N1229A

- N1321A

- N1327A

- N1361A

- N1373A

- N1381A

- N1399A

- N1409A

- N1427A

- N1439A

- N1487A

- N1489A

- N1499A

- N1709A

- N1997A

- N227AZ

- N229AZ

- N233AZ

- N239AZ

- N241AZ

- N307AZ

- N311AZ

- N313AZ

- N317AZ

- N331AZ

- N337AZ

- N347AZ

- N353AZ

- N359AZ

- N367AZ

- N379AZ

- N381AN

- N389AZ

- N397AZ

- N409AZ

- N419AZ

- N431AZ

- N432AX

- N433AZ

- N443AZ

- N449AZ

- N457AZ

- N459AZ

- N479AZ

- N491AZ

- N499AZ

- N5113A

- N5147A

- N5153A

- N5167A

- N5179A

- N5209A

- N5227A

- N5233A

- N5237A

- N5261A

- N5479A

- N5683A

- N5693A

- N617AZ

- N641AZ

- N714AX

- N739AX

- N744AX

- N749AX

- N750AX

- N761CX

- N762CX

- N763CX

- N768AX

- N774AX

- N7901A

- N7907A

- N7919A

- N791AX

- N7933A

- N7949A

- N795AX

- N8011A

- N8059A

- N919AZ

- N929AZ

- N937AZ

- N947AZ

- N967AZ

-

What aircraft type is this?

-

Please observe a minimum of 3 observations when answering the below questions (as applicable)

Aircraft Loading

-

Two (2) Associates are utilized to move ULDs within the aircraft. Associates are only allowed to push the ULDs on the same side while loading the aircraft (AGOM 4.11.4.2)

-

ULDs checked for damage to ensure airworthiness and all restraining devices (locks, straps, curtains are properly secured before ULD is loaded (AGOM 4.11.4.1) (AGOM 4.11.4.2)

-

All empty ULDs must be physically verified to be empty before positioning on the aircraft (AGOM 4.11.4.9)

-

Verifier physically walks ULDs into position and inspects lock positions (AGOM 4.10.5.6/4.11.4.9)

-

AA’s not actively loading stay 20 feet away from loader when elevator raised more than six (6) feet (AGOM 3.4.10.1)

-

AA actively loading remain eight (8) feet from loader chassis while elevator is raising/lowering (AGOM 3.4.10.1)

-

ULDs (AKE/DQF/DPE) moved to/from the deck or dolly at a 45-degree angle (AGOM 3.4.11)

- All compliant

- One ULD non-compliant

- More than one ULD non-compliant

- N/A

-

Bulk bins have the required two (2) inch gap for fire suppression system (AGOM 4.11.2) (Please select all that apply)

- No bulk loaded

- 737 FWD compliant

- 737 FWD non-compliant

- 737 AFT compliant

- 737 AFT non-compliant

- N/A

-

ULDs (AAX / LAY only) for aircraft bulk loading will be positioned with the curtain side resting on the exterior locks. No gap between<br>the ULD and the dolly edge (AGOM 3.3.2.4)

Departure

-

-

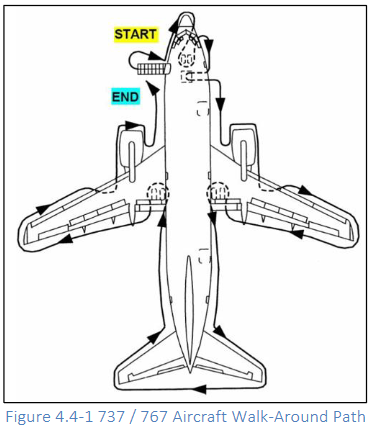

Departure walk around completed clockwise with photos of doors and flashlight used if insufficient lighting (AGOM 4.12.3)

-

15 minutes prior to aircraft arrival and departure, conduct a FOD walk of the aircraft parking area, removing any FOD found. FOD walks must consist of the ground operations Associates walking at arms-length along the entire aircraft parking area, removing foreign objects (AGOM 3.3.7)

-

Observe AAs wearing hearing protection during departure and select the answer that best applies (AGOM 3.3.2.2)

- All AAs wearing hearing protection

- One AA not wearing hearing protection

- More than one AA not wearing hearing protection

- N/A

-

Ensures safety cones remain in place until completion of all GSE activities around the aircraft and air stairs have been remove from the safety envelope. (AGOM 4.6.1)

-

Safety envelope is clear prior to pushback (AGOM 4.12.2)

Aircraft Loading

-

Two (2) Associates are utilized to move ULDs within the aircraft. Associates are only allowed to push the ULDs on the same side while loading the aircraft (AGOM 4.11.4.2)

-

ULDs checked for damage to ensure airworthiness and all restraining devices (locks, straps, curtains are properly secured before ULD is loaded (AGOM 4.11.4.1) (AGOM 4.11.4.2)

-

All empty ULDs must be physically verified to be empty before positioning on the aircraft (AGOM 4.11.4.9)

-

Verifier physically walks ULDs into position and inspects lock positions (AGOM 4.10.5.6/4.11.4.9)

-

AA’s not actively loading stay 20 feet away from loader when elevator raised more than six (6) feet (AGOM 3.4.10.1)

-

AA actively loading remain eight (8) feet from loader chassis while elevator is raising/lowering (AGOM 3.4.10.1)

-

ULDs (AKE/DQF/DPE) moved to/from the deck or dolly at a 45-degree angle (AGOM 3.4.11)

- All compliant

- One ULD non-compliant

- More than one ULD non-compliant

- N/A

-

Bulk bins have the required two (2) inch gap for fire suppression system (AGOM 4.11.2) (Please select all that apply)

- No bulk loaded

- 767-200 compliant

- 767-200 non-compliant

- N/A

-

ULDs (AAX / LAY only) for aircraft bulk loading will be positioned with the curtain side resting on the exterior locks. No gap between<br>the ULD and the dolly edge (AGOM 3.3.2.4)

Departure

-

-

Departure walk around completed clockwise with photos of doors and flashlight used if insufficient lighting (AGOM 4.12.3)

-

FOD walk conducted prior to aircraft departure at arm’s length (AGOM 4.12.2)

-

Observe AAs wearing hearing protection during departure and select the answer that best applies (AGOM 3.3.2.2)

- All AAs wearing hearing protection

- One AA not wearing hearing protection

- More than one AA not wearing hearing protection

- N/A

-

Ensures safety cones remain in place until completion of all GSE activities around the aircraft and air stairs have been remove from the safety envelope. (AGOM 4.6.1)

-

Safety envelope is clear prior to pushback (AGOM 4.12.2)

Aircraft Loading

-

Two (2) Associates are utilized to move ULDs within the aircraft. Associates are only allowed to push the ULDs on the same side while loading the aircraft (AGOM 4.11.4.2)

-

ULDs checked for damage to ensure airworthiness and all restraining devices (locks, straps, curtains are properly secured before ULD is loaded (AGOM 4.11.4.1) (AGOM 4.11.4.2)

-

All empty ULDs must be physically verified to be empty before positioning on the aircraft (AGOM 4.11.4.9)

-

Verifier physically walks ULDs into position and inspects lock positions (AGOM 4.10.5.6/4.11.4.9)

-

AA’s not actively loading stay 20 feet away from loader when elevator raised more than six (6) feet (AGOM 3.4.10.1)

-

AA actively loading remain eight (8) feet from loader chassis while elevator is raising/lowering (AGOM 3.4.10.1)

-

ULDs (AKE/DQF/DPE) moved to/from the deck or dolly at a 45-degree angle (AGOM 3.4.11)

- All compliant

- One ULD non-compliant

- More than one ULD non-compliant

- N/A

-

Bulk bins have the required two (2) inch gap for fire suppression system (AGOM 4.11.2) (Please select all that apply)

- No bulk loaded

- 767-300 compliant

- 767-300 non-compliant

- N/A

-

ULDs (AAX / LAY only) for aircraft bulk loading will be positioned with the curtain side resting on the exterior locks. No gap between<br>the ULD and the dolly edge (AGOM 3.3.2.4)

Departure

-

-

Departure walk around completed clockwise with photos of doors and flashlight used if insufficient lighting (AGOM 4.12.3)

-

FOD walk conducted prior to aircraft departure at arm’s length (AGOM 4.12.2)

-

Observe AAs wearing hearing protection during departure and select the answer that best applies (AGOM 3.3.2.2)

- All AAs wearing hearing protection

- One AA not wearing hearing protection

- More than one AA not wearing hearing protection

- N/A

-

Ensures safety cones remain in place until completion of all GSE activities around the aircraft and air stairs have been remove from the safety envelope. (AGOM 4.6.1)

-

Safety envelope is clear prior to pushback (AGOM 4.12.2)

-

Additional comments/observations