Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

1 HSE and Laboratory Construction & Layout

-

Are you as a visitor informed about safety procedures?

-

Is there an emergency/fire alarm system? Is the system tested at least monthly?<br>

-

Is there an emergency site plan and evacuation excercise at least annually?

-

Are all staff given HSE training as part of their induction?<br>

-

Are Risk Assessments performed on the laboratory activities? <br>

-

Are safety incidents and near misses reported and recorded? <br>

2 Quality Systems and Assurance

-

Does the Laboratory and Inspection division have a documented quality system in place? Is the system accredited?<br>

-

Does the lab have a Quality Manual? Is it regularly reviewed?<br>

-

Is there an internal audit program for the quality system?<br>

-

Are test methods audited internally?<br>

-

Does the lab take part in an industry precision monitoring scheme? If so which one & how many samples?<br>

-

Is there a schedule to rotate who participates in the scheme?<br>

-

Does someone have responsibility for reviewing the results and investigating outliers (Z>2)? <br>

-

Does the laboratory take part in any other precision / proficiency schemes?<br>

-

How does the laboratory keep up to date with test methods and specifications? <br>

-

Does the laboratory have a procedure to identify and communicate changes in the test methods and specifications?<br>

-

If the lab has any supplementary procedures (eg translations of methods) for testing are they aligned with the current method version? <br>

-

Are non-conforming work items/complaints raised, recorded and actioned? <br>

-

Is there a procedure for product retesting (e.g. Where a test is performed multiple times on a sample)<br>

-

Do they sub-contract out any testing to other laboratories? Which tests and why? <br>

-

The laboratory is responsible for all reported data. Is there adequate assurance around the sub-contractor laboratory (e.g. through quality accreditation, correlation membership, etc.)? Is consideration given to HSE issues? <br>

3 Operations

-

Is there a clear and defined staff structure at the laboratory?<br>

-

What is the formal communication route between Laboratory and BP? Is it effective?(eg GCAS, email, other means)<br>

-

Is there a nomination or test request review procedure in place?<br>A) Is there evidence of who reviewed the nomination before undertaking the work? <br>B) Where changes are identified, how are they communicated? (internally/externally)<br>

-

Are the samples given a unique number for traceability? And adequately labelled?<br>

-

Is there a daily work log? <br>

-

Are the sample storage procedures adequate for the product type?<br>

-

Does the office complete the input data into GCAS?<br>

-

Is there a formalised route for communicating product quantity and quality issues to the client (both within and out of office hours)? <br>

-

Is there a alternative laboratory available should any of the instruments fail at short notice?<br>

-

Are results reported within required timeframe? Is there sufficient provision for conducting urgent analysis out of normal office hours?<br>

-

Where there is a shift system, is there a handover procedure? <br>

4 Training

-

What is the training procedure for new employees including? <br>A) site induction<br>B) HSSE and PPE<br>C) Quality system<br>D) Test methods<br><br>

-

Does the training procedure cover different stages of training?<br>How are the levels / stages controlled? Is there clear definition on who can report, calibrate etc<br>

-

Are there written training records for each staff member? (including evidence of)<br>A) The requirements of method precision (against a sample of known result) have been met?<br>B) Multiple samples documented? (minimum of 3 samples, covering the range of products tested)<br>C) Is the method number & version recorded?<br>D) Date range for which training was carried out?<br>E) Statement that method has been read?<br>F) Signatures of trainer and trainee?<br>

-

How is the trainer identified? Is their competency regularly assessed? <br>

-

Are re-training requirements defined (e.g. due to time elapsed or method/instrument changes)? <br>

-

Is there a skills matrix identifying which lab staff are trained in each test? <br>

-

Do staff attend external industry seminars, workshops, etc.?<br>

5 Equipment and Calibration/Verification

-

Is there a register of lab equipment including schedules for calibration/verification? <br>

-

Is there a procedure for producing secondary (SQC) standards and managing the data?<br>A) Selection of material and appropriate storage <br>B) Number of determinations to generate mean and acceptable range<br>C) How is the acceptable range is generated and is there a check to ensure that it is appropriate.<br>D) How lab ensures production of new SQC's before the old standard expires?<br><br>

-

How are the results from secondary standards managed? <br>A) Does it allow for easy identification of trends/drift<br>B) Are trends/drift investigated?<br>C) Are outliers investigated? <br>

-

Are there procedures in place to ensure the accuracy of any new equipment/method is verified before testing samples for customers?<br>

-

Where calibration of equipment is performed by external companies, are they certified? Are they able to perform the calibration to the method requirements?<br>

-

Is calibration/verification carried out after maintenance? <br>

-

Where in-house or modified versions of the standard test method are used, how are they developed and verified? How is the modified method reported?<br>

-

Where equipment is found to be out of calibration (fails to meet the calibration criteria) is there a procedure to verify previously reported results?<br>

6 Sample Management

-

Is the lab responsible for drawing samples and if so are the personnel appropriately trained? <br>

-

What is the procedure for sample receipt? <br>

-

Does the lab have written procedures handling samples and preparing composite or sub samples? Are volatile samples chilled prior to opening?<br>

-

Are appropriate sample containers used (material and size)? <br>

-

Does the laboratory have suitable storage? Is it managed / catalogued appropriately?<br>

-

Does the laboratory specify adequate sample retention periods? <br>

7 Certificates and Laboratory Systems

-

What is the procedure for producing and issuing test certificates? (Are the results/certificate checked and signed by an authorised signatory)<br>

-

Is there a regular quality control check of certificates issued?<br>

-

Do certificates state the grade of fuel and which specification the fuel is certified against? <br>

-

Do they include specific details such as <br>A) Tank number<br>B) Sample type<br>C) Date & Signature<br>D) Batch number & volume <br>E) Batch composition (Traceabilty)<br>

-

Are the actual test methods used for each test stated? Where version numbers included are the up to date?<br>

-

Are all results clearly reported to the correct number of significant places and as stipulated in the method/specification?<br>

-

Is all paperwork related to the sample adequately stored for sufficient time and easily retrievable? <br>

-

Does the lab have a Laboratory Information Management System (LIMS) and if so do they have a backup system should the system fail?<br>

-

If the lab carries out re-certification testing this shall include evidence that the comparison checks have been completed. Are you satisfied that this is done properly and fully understood? <br>

8 Walk through observations

-

Are escape routes clearly marked and unobstructed? <br>

-

Are sufficient serviced fire extinguishers present and sealed (lab & storage areas)? <br>

-

Are staff wearing appropriate/adequate PPE? Are you requested to wear appropriate PPE as a visitor?<br>

-

Are storage and work areas clean and tidy and free of spills/waste? <br>

-

Does there appear to be sufficient fume extraction in the laboratory? Is the climate adequately controlled?<br>

-

Are emergency showers installed (and functioning) and uncluttered?<br>

-

Are eyewashes available and in date? (opened bottles should be discarded).<br>

-

Is there a first aid kit? <br>

-

Are solvents/acids/dangerous goods appropriately stored?<br>

-

Is waste segregation practiced? Eg.separate sharps bin? <br>

-

Are gas cylinders appropriately stored and secured upright? <br>

-

Does the equipment in the lab generally appear to be up to date, in good condition and in regular use? <br>

-

Are there maintenance records for each piece of equipment? <br>

-

Does the lab have clear equipment calibration / verification records? (including labels with calibration dates / status on the equipment)<br>

-

Do primary standards / certified reference materials have certificates?<br>

-

Is it clear which laboratory technician performed the test from a review of the worksheets and raw data? <br>

-

Is all paperwork related to a job order stored in a satisfactory manner and easily retrievable?<br>

9 Any other comments or information

-

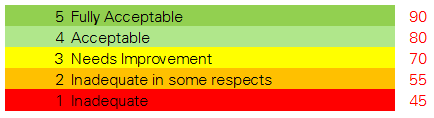

Audit Rating

-

Add signature