Information

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

1.0 - Safety Files

-

1.1 - Is the safety on file and accessible across the site ?

-

1.2 - Are weekly safety meetings held and are documented notes and attendance rosters available ?

-

1.3 - Are weekly site inspections being performed and documented?

-

1.4 - Are JSA/SRA risk assessments complete and up to date ?

-

1.5 - Are EHS policies and procedures, including customer requirements, effectively communicated to contractors and subcontractors?

-

1.6 - is there a means of assigning responsibility for tracking closure of open compliance items?

-

1.7 - Are GE safety orientation talks being performed and documented?

-

1.8 - Are toolbox talks being performed and documented?

-

1.9 - Has the initial site inspection been performed?

-

1 10 - Has a contractor EHS review been completed for any subcontractors and contractor?

2.0 - Health and Welfare

-

2.1 - Are there an adequate number of toilets supplied to the site? (>20 employees => 1 toilet per 40 workers; >200 employees => 1 toilet per 50)?

-

2.2 - Are hand washing stations available on site?

-

2.3 - Is drinking water available on site and distributed properly? (note: container must be labeled, secured, and cups provided.)

-

2.4 - Is there adequate lighting for non daylight operations?

-

2.5 - Are all industrial hygiene hazards identified in the JSA/SRA risk assessments for the task performed? i.e. asbestos and lead abatement

-

2.6 - Are activities identified in question 2.5 above done by trained, qualified and/or licensed contractors?

-

2.7 - Are only qualified and trained employees allowed to install, adjust, and operate laser equipment?

-

2.8 - Does the site have security plan available?

-

2.9 - Does the site have a emergency data sheet maintained and posted and where applicable an expat roster?

-

2.10 - Where required are work hours being tracked?

-

2.11 - If he site is located on a refinery or chemical plant was the trailer sitting risk assessment completed?

3.0 - Emergency Preparedness and Prevention

-

3.1 - Is there a site specific Emergency Response Plan (evacuation plan, etc.) and is it posted?

-

3.2 - Are emergency contact numbers posted and verified?

-

3.3 - Have on-site/off-site medical service providers been identified?

-

3.4 - Have site personnel been trained in emergency procedures including reporting and evacuation?

-

3.5 - Are accident investigations conducted including near misses?

-

3.6 - Have on-site trained first aiders been identified?

-

3.7 - Is there a fire protection system or fire extinguishers posted on site and offices and other buildings?

4.0 - Housekeeping and Waste Management

-

4.1 - Are work areas clear of tripping hazards and debris?

-

4.2 - Are there designated disposal areas?

-

4.3 - Have recycling provisions been taken?

-

4.4 - Have approved waste vendors been identified?

-

4.5 - Are regulated wastes ( hazardous wastes and oils) shipped off site using an approved licensed transporter to an approved licensed facility?

-

4.6 - Are there adequate measures to prevent dirt from being transferred to public roads from the site?

-

4.7 - Are overall site conditions acceptable?

5.0 - PPE USE

-

5.1 - Hardhats

-

5.2 - Safety glasses and side shields?

-

5.3 - Boots and safety shoes

-

5.4 - Respiratory protection

-

5.5 - Hearing protection

-

5.6 - Is all other PPE identified by the outage safety plan available and being used where required? (examples safety vests, fall protection, specialized)

6.0 - Work at Heights

-

6.1 - Are guardrails placed where necessary? (Note! tape with minimal 2 meters (6.6 ft) clearance or ridged barricade with handrail and mid rail)?

-

6.2 - Are stairways with over 3 risers or ramps over 1.2 meters (4ft) high supplied with handrails?

-

6.3 - Are ladders used the way are designed? (Note! bifold fully extended, extension ladders extended 36" over the landing and tied off?)

-

6.4 - Scaffolds inspected and tagged accordingly?

-

6.5 -Scaffolds work platforms fully decked with scaffold grade boards in good condition?

-

6.6 - Scaffolds erected on secure base and mud-sills used on all surfaces?

-

6.7 - Scaffold provided with handrail, mid-rail, and toe boards when men are exposed underneath?

-

6.8 - Scaffolds tied off when height exceeds four times the base?

-

6.9 - Suspended scaffold equipped with independent lifelines, all systems including scaffold, cables, outriggers, counterweights designed set up and inspected by a competent person?

-

6.10 - Is fall protection being used when exposed to heights over 1.8 meters ( ft) and there are no stationary fall protection systems?

-

6.11 -Personal platforms (man baskets) used correctly, lift permits, inspection reports, and pre-lift meetings?

-

6.12 - Is all personal fall protection inspected and in good shape?

-

6.13 - Are all hole coverings marked, secured, and built correctly?

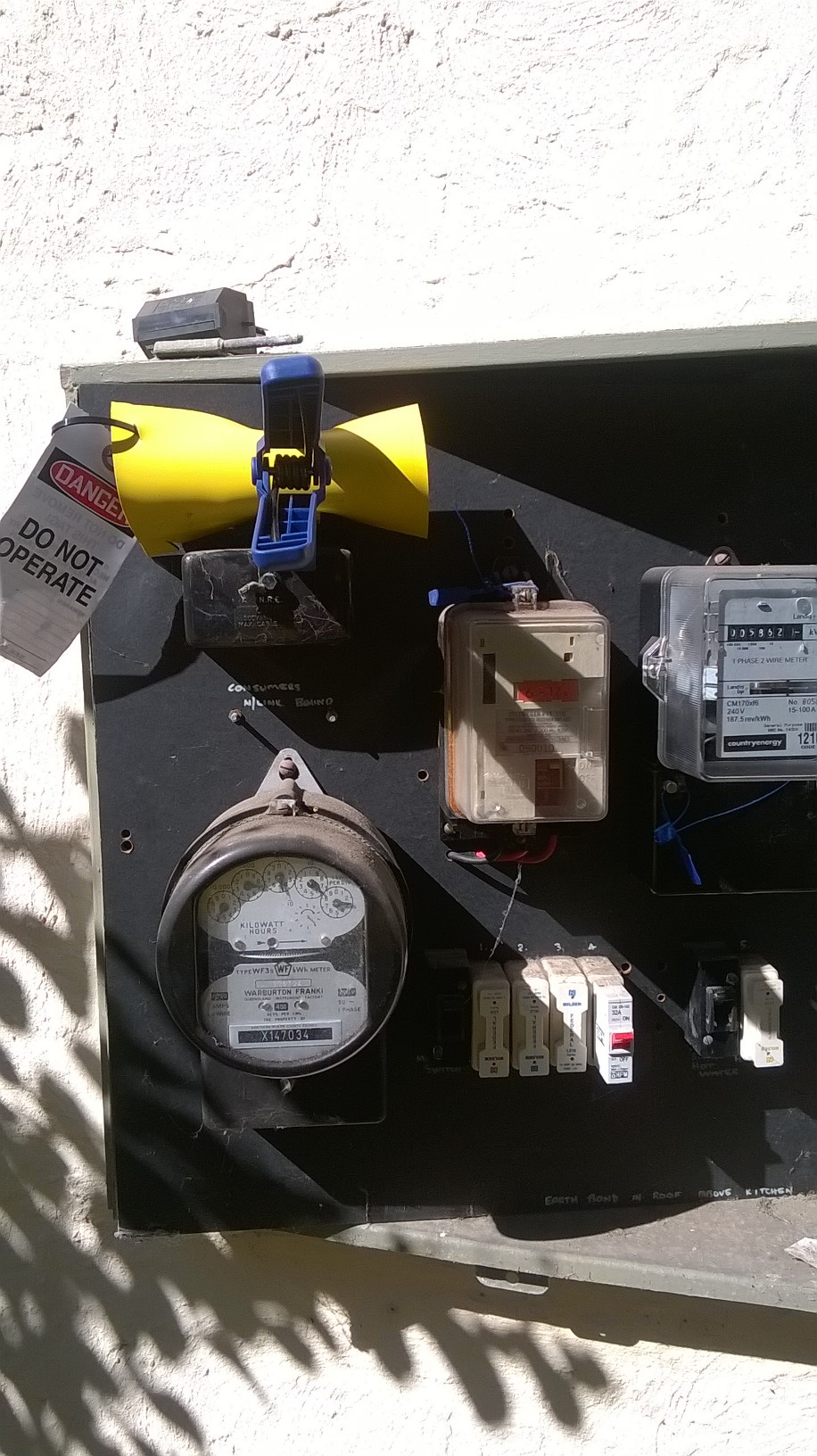

7.0 - Electrical Safety

-

7.1 - Have measures been taken to prevent the following from being within 3 meters (9.8ft) ( or 5 if voltage >50kv) of energized lines: scaffolding, cranes, and other mechanized equipment?

-

7.2 - Is all PPE compliant with NFPA 70E, inspected and where required tested prior to used?

-

7.3 - When grounding de-energized systems, are grounds placed as close as possible to the work and is the following order followed when attaching grounds: ground end shall be attached first, then the other end shall be attached and removed by means of insulated?

-

7.4 - Are GFCI's used (or an assured equipment grounding program) for all tools and equipment?

-

7.5 - Is temporary wiring either enclosed or in locations where they are not subject to physical damage?

-

7.6 - Are flexible cords and cables used in a manner which prevents trip hazards and are protected from damage including pinch points, sharp edges, and vechiles?

-

7.7 - Are cords and cables in good condition (not worn or frayed, grounding plug)

-

7.8 - Are electrical cords of the heavy duty grounding type with the three prong plugs in place?

-

7.9 - Are lights protected from breakage and nit hung by there cords unless so designed?

-

7.10 - Are electrical disconnects identified and in a readily accessible location?

-

7.11 - Are electrical installations in areas where there is a potential flammable atmosphere approved as intrinsically safe?

-

7.12 - Are battery and battery charging installations located in a ventilated area and provided containment?

-

7.13 - If batteries require require handling and refilling is proper PPE (aprons, goggles) and eyewash provided?

-

7.14 - Are means of over current protection (circuit breakers) readily accessible, clearly marked, and covered to prevent injury during their operation?

-

7.15 - Are electrical cabinets, boxes, and fittings provided with covers, with unused openings closed and protected from elements?

-

7.16 - Are the requirements of NFPA 70E fully implemented, and all work in compliance with this standard?

8.0 - Hand Tools and Electric Power Tools

-

8.1 - Are all hand and power tools maintained in a safe condition and no cracks, intact electrical cords/plugs, and operating switches?

-

8.2 - Are electrical power tools double insulated?

-

8.3 - Are all power operated tools equipped with guards if so designed?

-

8.4 - Are all points of operation of machines, abrasive wheels, bench/cylindrical grinders gaurded?

-

8.5 - Are hand tools free of damage i.e. mushroomed heads, cracked/splintered handles?

-

8.6 - Is proper PPE being used with hand power tools?

9.0 - Safety - Welding and Burning

-

9.1 - I s all welding and cutting done with proper PPE? (Notes: shaded glasses are not considered adquate protection)

-

9.2 - Are compressed gases stored correctly in work areas/points of use?

-

9.3 - Are hot work permits being issued according to site specific rules?

-

9.4 - Is a fire watch provided when burning or welding around flammables, combustibles, or when such materials maybe impacted?

-

9.5 - Is each welding cart or welding area unit provided with an approved fire extinguisher?

-

9.6 - Have measures been taken to protect personnel from arch flashes?

-

9.7 - Are all welding machines grounded properly?

-

9.8 - during use are cylinders secured in an upright position and placed far enough away from cutting and welding activates that the flame, slag, and sparks will not reach the cylinders?

-

9.9 - Are cylinder valves shut off when not in use? If cylinders are not used for 24 hours are regulators removed and the caps secured?

-

9.10 - In transport ar cylinders turned off and secured with caps on?

-

9.11 - Are O2 and acetylene regulators and fittings stored away from grease and oil and in good working condition?

10.0 - Chemical Storage and Handling

-

10.1 - Are MSDSs available on site? Are they accessible to employees?

-

10.2 - Is a completed chemical inventory available?

-

10.3 - Is poper labeling provided on all chemical containers?

-

10.4 - Is there adequate storage provided for flammable solids and lquids?

-

10.5 - Are preventative measures being taken to keep fuels from being spilt during refueling?

-

10.6 - Are controls in place to prevent hazardous chemicals being disposed of in dumpsters or other unauthorized areas?

11.0 Excavation

-

11.1 - is there a qualified excavation competent person on site?

-

11.2 - Are excavations inspected daily by a competent person?

-

11.3 - Is there egress and access provided every 7.5 meters (24.6 ft)?

-

11.4 - Is there adequate barricading provided around all sides of excavations and trenches?

-

11.5 - Are all heavey equipment prevented from traveling to near the edge of trenches?

-

11.6 - Are excavations >1.30 meters (4.2 ft) deep monitored for hazardous atmosphere when suspect?

12.0 - Motorized Equipment

-

12.1 - Reverse alarms audible on all bi-directional and obstructed view?

-

12.2 - Barricading provided for all swing radius's of operational equipment?

-

12.3 - No equipment left running while unattended?

-

12.4 - Are inspections conducted on aerial platforms and forktrucks?

13.0 - Cranes and Rigging

-

13.1 - are inspection records for lifting and hauling equipment available and up to date?

-

13.2 - is all rigging stored in safe manner so that it does not pose a tripping hazard or can be damaged by the elements?

-

13.3 - All rigging in good condition and found without damage?

-

13.4 - Is a signal man available?

-

13.5 - Safety latches provided and in good repair on hooks designed to use them?

-

13.6 - Are loads left attended while hoisted?

-

13.7 - Personnel not allowed under a load?

-

13.8 - Are all crane operators trained and qualified?

-

13.9 - Are lift Plans completed as required?

-

13.10 -Are forklift and other industrial truck operators trained?

14.0 - Concrete and Masonary

-

14.1 - Are power trowels equipped with automatic shutoff devices?

-

14.2 - Masonry saws, bushing, and chipping operation done with proper PPE. (Note! Gloves,ear protection,safety glasses, and face shield required)?

-

14.3 - Reinforcing steel protected against impalement hazards? ( note! Mushroom caps not effective protection against impalement hazards)

-

14.4 - Limited access zone established during masonary wall construction?

-

14.5 - Bracing adequate during wall construction?

-

14.6 - Concrete buckets used in a safe manor?

-

14.7 - All sanding or finishing practices that produce concrete dust are done while using respiratory protection?

15.0 -Confined Space

-

15.1 - Are all confined spaces posted as such throughout the site?

-

15.2 - Are permits for permitted confined and non-permitted confided spaces completed and posted at space?

-

15.3 - Hole watch provided for permitted confined spaces?

-

15.4 - Is craft knowledgable of the sites confined space procedures?

-

15.5 - Are air samples documented and posted prior to entry into confined space?

16.0 - LOTO

-

16.1 - Are contractors and employees knowledgeable in LOTO plan and procedures?

-

16.2 - Isthere a designated LOTO representative available at site?

-

16.3 - Have all system authorized employees/LOTO Admin been reviewed to ensure understanding of LOTO including verification

-

16.4 - Do system authorized employees/ LOTOAdmin have access to locks and tags? Do system authorized employees/LOTO admin hace access to multiple lock adapters (hasps) and other specialized LOTO devices?

-

16.5 - Do all LOTO locks meet the following requirements: unique and distinct from other locks used at site; used exclusively for LOTO, only one available key?

-

16.6 - Is the verification step completed for each LOTO?

-

16.7 - Are equipment specific LOTO procedures provided in the local language?

-

16.8 - If testing is done are correct procedures followed?

-

16.9 - Are equipment disconnects identified for each piece of equipment under a LOTO?

-

16.10 - Are power panels and other energy control devices located at the floor level or otherwise accessible for LOTO?

-

16.11 - Are LOTO clearances accessible?

-

16.12 - Are keys controlled?

-

16.13 - Are tags completed properly (LOTO no. tag no., equipment description, name, date)

-

16.14 - Are tags used unique to LOTO and some combination of red, white, and black?

-

16.15 - Have all system authorized employees/LOTO admin received LOTO training and refresher training which includes "try out" (verification step)?

-

16.16 - Have all affected employees received LOTO awareness training?

-

16.17 - Has contractor training been reviewed and documented?

-

16.18 - Are weekly LOTO inspections conducted?

-

16.19 - Is there a major commissioning activity underway in which a commissioning procedure has been developed?

17.0 -EHS Programs

-

17.1 - Are all persons on site trained for the tasks they are assigned?

-

17.2 - Are training records maintained?

-

17.3 - Describe and rate the cooperation between contractor(s) and the GE project team.

-

17.4 - Describe the effectiveness of GE project EHS.

-

17.5 - Discuss the relative number of safety problems on the project.

-

17.6 - Discuss the resolution of the safety problems on site.

-

17.7 - Discuss the auditor's overall estimation of the safety of this project.

Sign Off

-

On site representative

-

Auditor's signature