Title Page

-

Site conducted

-

Serial Number

-

Unit Number

-

SMU

-

Make/Model

-

Fire Suppression Foam Type

-

Conducted on

-

Prepared by

-

Fitter

-

Location

Requirements for transfer / movement of Plant

DOCUMENTATION

-

1 Photograph Pack – General Machine Machine photographed each side (4 locations)

-

2 Photograph Pack – Bucket Bucket photographed

-

3 Plant Files (Major Component History/Plant defect backlog)

-

4 Plant Manuals (Parts book/Service & Maintenance. Manuals/logbook)

-

5 SOS Report (Copy of last SOS Compartment history)

-

6 Last track inspection report Track Inspection report

-

7 Bucket inspection report Backhoe Bucket Condition Report

-

8 Last NDT report – Pressure Vessels (Copy of last NDT certificates)

-

9 Statutory brake test report Brake Testing Mobile Equipment

-

10 Asset Transfer form PR-FRM-GRP-001-015 –Asset Transfer Form

-

11 Fast fill service centre Fast Fill Requirements

-

12 Fast fill diesel Non pressurised system Fast Fill Requirements

-

13 Fire Suppression System Mobile Equipment Fire Suppression

-

14 Completion of Safety Bulletins Check for model relevant Safety Bulletins and obtain evidence of completion

SIGN OFF ON PLANT CONDITION

-

Plant fresh water washed, cleaned and free from mud and other debris build ups. Note: Any Plant being transported off site shall meet the required transport guidelines for cleanliness

-

Plant free from oil, coolant, fuel and grease leaks, minor oil weeps are acceptable

-

Paint work in good condition

-

Cabin interior clean, cab linings in good condition and no glass damage

-

All cab controls and gauges fully functional

-

Seat functional, clean and free form tears and damage

-

Components reflect forecast component life and no outstanding change outs required

-

No accident or operational damage

-

All scheduled service and inspections completed and updated in AMT

-

All defects rectified and updated in AMT

-

All structures (chassis & axle box assembly) free from cracking

-

Buckets to have Minimum 50% wear life remaining:

-

List Percentage Bucket Life

-

NOTE: If any conditions are not met, details shall be attached to the Plant Condition Report and the Fleet

Manager notified. -

CUSTOMER/ SITE SUPERINTENDENT SIGN OFF

-

FLEET MANAGER SIGN OFF

CHECK FOR WEAR AND CONDITION

-

LEGEND FOR COLUMNS:

1 – Defect found and repaired

2 – Defect found and recorded, machine safe to operate

3 – OK (All systems are working)

4 – Not Applicable (N/A)

COOLING SYSTEM POS

-

Coolant level, conditioner and leaks

-

Hoses and clamps

-

Fan and shrouds

-

Radiator core, tanks and cap (pressure relief)

-

Fan bearings, pulleys, belts and guards

-

Water pump and coolers

-

Monitoring system condition and type

-

Sensors and wiring

-

Air con compressor, pulley, belt and guard

-

Air con evaporator, condenser, hoses and valves

-

Heater hoses and taps

ENGINE POS

-

Oil level and leaks

-

Noise

-

Air cleaner, pre cleaner

-

Blow by, exhaust smoke

-

High idle and low idle

-

Exhaust and inlet leaks

-

Throttle linkage

-

Muffler and extension

-

Guards, shields, covers including turbo covers and

-

turbo oil feed line fire sleeves - condition/placement

-

Sensors and wiring

PUMP DRIVE POS

-

Oil level and leaks

-

Noise

-

Mountings and hoses

-

Driveline and universal joints

-

Sensors and wiring

FINAL DRIVES

-

Oil level and leaks

-

Noise

-

Breathers for blockage

-

Mounting and bolts

-

Sensors and wiring

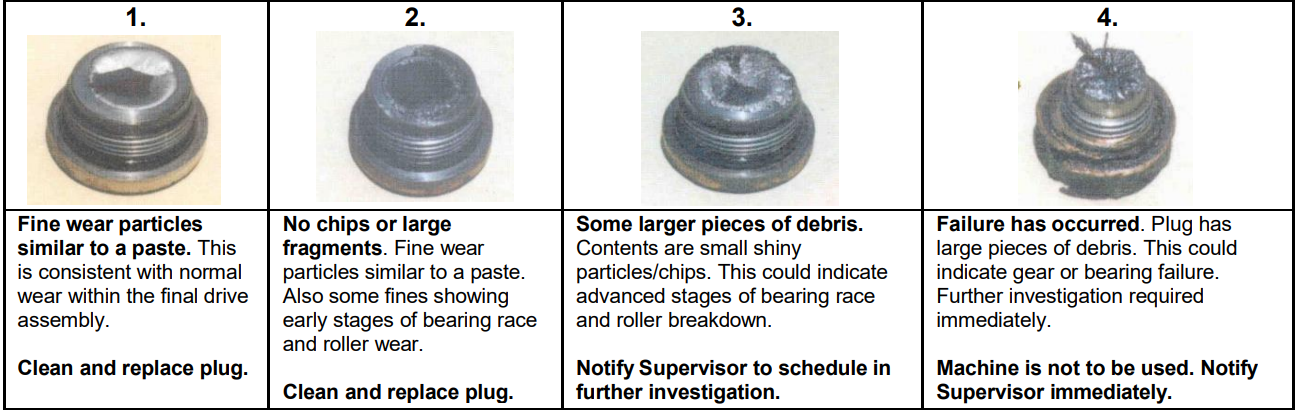

MAGNETIC PLUGS

-

LH Final Drive

-

RATING:

-

RH Final Drive :

-

RATING

-

CAB AND OPERATORS STATION

-

Cab general condition

-

Floor, walls and roof

-

Cab mountings and bolts

-

All cab wiring

-

Operation of controls

-

Operation of travel controls

-

Seat belt – retainer and operation

-

Seats and arm rests – suspension and adjustment

-

Windows and rubber

-

Wipers and washers

-

Mirrors and mounting

-

Doors, handles, seals and locks

-

Access ladders and walkways / egress

-

Air con controls and operation

-

Heater core, controls, hoses and operation

-

Horns, gauges and interior light

-

Audible alarm and warning lights

-

Travel alarm

-

Operation of all external lights

-

Two-way radio and aerial (list model)

-

AM, FM radio and aerial

-

Operation of all emergency stops – cab and ground level

-

Cab has had full detail

-

Pre-start checklist booklet

-

Access ladder & Service tail interlock

-

Access ladder in fill panels installed

-

Equipment height label installed showing normal and extended equipment heights

-

Breathsafe system installed and operating correctly

HYDRAULICS

-

Oil level and leaks

-

Noise

-

Pipes or hoses for damage or leaks

-

Drift rate, cycle times (check specs)

-

Main valve body adjustment and leaks

-

Rotary connection

-

Hand controls and linkages

-

Sensors and wiring

BOOM

-

Lift cylinders, pins and bushes

-

Boom to body, stick to boom pins and bushes

-

Check boom for dents, repairs or cracks

-

Hoses and pipes hydraulic and grease

-

All boom arch hoses genuine OEM – (If non-genuine OEM hoses are fitted, a workorder shall be raised to order OEM hoses and schedule the change outs.)

-

Ladders and walkway

-

Lights and wiring

STICK

-

Stick cylinder(s), pins and bushes

-

Stick pins, bushes and shims (need shims)

-

Hoses and pipes

-

Check stick for dents, repairs or cracks

-

Lights and wiring

BUCKET

-

Bucket cylinder(s), pins and bushes

-

Bucket linkage pins and bushes

-

All GET mounting and condition

-

Base edge condition

-

Side wear plate condition

-

Side walls for wear and straightness

FRAME

-

Chassis rust or cracks

-

Hose, pipes and clamps

-

Hydraulic tank, hoses and fittings

-

Fuel tank, pipes and fittings

-

Fuel tank vent breather fitted with overflow hose and directing fluid overflow away from potential hot<br>surfaces

-

Belly guards and mounting

-

Car body and guards

-

Wiring harness

-

Slew box

-

Slew ring movement and teeth condition

TRACK FRAME POS

-

Idlers

-

Sprockets

-

Carrier rollers

-

Track rollers

-

Tracks

-

Track adjuster - elastomer

-

Track frame mounting bolts

-

Hoses and pipes

GENERAL

-

Fire suppression

-

- Inspection current and charged

-

Hand held extinguishers

-

Inspection current and charged

-

Sizes =

-

Number =

-

Fire suppression strikers – cab and ground level

-

ISOLATION:<br>Starter motor isolation ground level – (YELLOW)<br>Battery isolation ground level – (RED)<br>Capable of being locked out

-

Battery and terminal condition

-

Paint condition

-

Pin retainers

-

Accident damage

-

ROPS or FOPS fitted and condition

-

Fenders

-

Handrails

-

Safety guards

-

Jump start receptacle

-

Collision avoidance

-

Asset ID visible

-

Call sign identification visible on 4 sides

-

Clearance labels – maximum and travelling

-

Accumulation of fuel, oil, grease, etc. that

-

may cause a fire hazard

-

Quick fill (service center) fitted, list type

-

Pressure vessel compliance

-

Fuel level

LIST ALL MODIFICATIONS

-

Details

EQUIPMENT

- Equipment with Track Pads

-

Pad Grip Lug Height (mm)

-

RH Track

-

LH Track

-

Pitch Extension (mm)

-

RH Track

-

LH Track

-

Tread Surface Height (mm)

-

RH Track

-

LH Track

-

Tumble Lug Height / Pitch (mm)

-

RH Track

-

LH Track

Equipment with Chains and Grousers

-

Grouser Height (mm)

-

RH Track

-

LH Track

-

Pitch Extension (mm)

-

RH Track

-

LH Track

-

Sprocket wear (mm)

-

RH Track

-

LH Track

-

Track Bushes (mm)

-

RH Track

-

LH Track

-

*Note: Attach Track Inspection Report for inspection details if required

COMMENTS and SIGN OFF

-

Details

Fitter

-

Name and Signature