Title Page

-

Site conducted

-

Conducted on

-

Prepared by

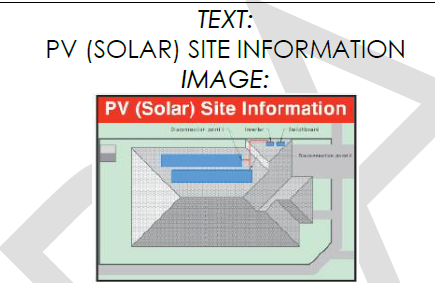

System Information

-

Size of system (kW)

-

Location of System

-

PV array mounting type

- Tilt Mount

- Flush Mount

-

Has the system been installed as per the SLD

-

Has the system been installed as per the Sturctural Certification

Inverter Bank

Labels

-

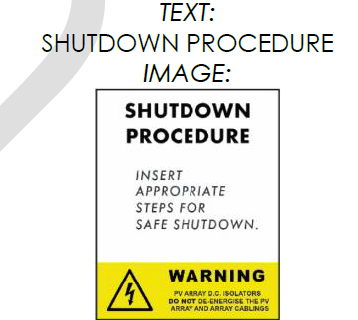

Where a system has PV array switch disconnectors the following warning<br>is installed on the inverter WARNING: PV ARRAY D.C. ISOLATORS DO NOT<br>DE-ENERGIZE THE PV ARRAY AND ARRAY CABLING - AS/NZS 5033:2014<br>5.5.3<br>

-

For systems over 600 V a warning sign indicating the following shall be<br>installed on the access door or gate: WARNING: HAZARDOUS VOLTAGE<br>AUTHORIZED ACCESS ONLY - AS/NZS 5033:2014 5.5.4<br>

-

Is the Shut Down procedure is correct and is permanently fixed at the inverter<br>and/or switchboard<br>

-

Any PV Array Junction Boxes are labelled "WARNING: HAZARDOUS DC<br>VOLTAGE"<br>

-

All PV cabling or conduit work clearly labelled as "SOLAR DC" every 2 mtrs,<br>supported and secured<br>

-

The DC Isolators are signed "PV Array DC Isolator" or similar, (wording must<br>align as specified on the Shut Down Procedure)<br>

-

All labels installed at the switchboard are indelible and sufficiently durable<br>for the intended purpose - AS/NZS 5033:2014 5.2

PV Array Checklist

-

Panel Manufacturer

-

Panel Model

-

Panel Type

-

Number of Panels

-

Panel DC Connector Manufacturer

-

Panel DC Connector Model

-

PV array short circuit current

-

PV array azumith / tilt

-

Number of Maximum Power Point Trackers (MPPT)

-

String fuse current / voltage rating

-

Is there sufficient space for panel ventilation?

-

Are the clamping zones to the manufacturer's guidlines?

-

Are there any visible panel defects - moisture, discolouration, delamination, fractures?

-

Are the panel cables secured to the panel frame with approved panel clips?

-

Is the array structure visibly attached and secured to the roof?

-

Are there any shading risks - inter-panel shading, surrounding obstacles etc.?

-

Were the solar modules listed on the CEC's list of approved products at the<br>time of the system's installation?<br>

-

Are the modules in the same string installed in the same orientation +/- 5<br>degrees?

-

Are all panel strings within 5% of maximum Voc?

-

Are all DC connectors of the same type/model from the same<br>manufacturer?

-

Is there sufficient string protection?

-

Are all earthing connections properly designed and installed?

-

Is there sufficient protection and coating of earthing connections?

-

Are all metal array components of similar metal?

-

Does the designed array fit on the available roof area? (e.g. solar panels are<br>not positioned over roof edges or gutters)

-

Is the array’s maximum voltage VOC array max (at minimum temperature)<br>less than 600 VDC for Residential installation or less than 1000 VDC for<br>Commercial Installation?

-

Does the design of the system fall within the inverter’s MPPT window at the<br>minimum temperature?

-

Is the array's maximum voltage V array max (at minimum temperature) less<br>than the maximum VDC of the inverter?

-

Does the design of the system fall within the inverter’s MPPT window at the<br>maximum temperature?

PV Array DC Isolators Checklist

-

Have rooftop DC isolators been installed?

-

DC isolator manufacturer

-

DC isolator model

-

Number of DC isolators

-

Are there any recalled DC isolators?

-

Is the load breaking DC isolator located adjacent to the array(s) correctly<br>rated for the required DC voltage and current?<br>

-

Is the isolator(s) [or Circuit Breaker] installed adjacent to the array(s)?

-

Are there any loose connections in the LV DC cables?

-

DC Isolator Dry and Sealed?

-

Has the insulation been exposed any more than necessary to terminate<br>the cable AS/NZS 3000:2018 3.7.2.2<br>

-

Have cables been correctly terminated to prevent the spreading or escape of<br>individual strands - AS/NZS 3000:2018 3.7.2.5 <br>

-

Has double insulation been maintained between all live conductor(s) and all<br>earthed or exposed conductive part(s)?

-

Are installed DC isolator(s) on the Electrical Regulator Authorities Council<br>(ERAC) list?

-

Are the DC isolator(s) at the array readily available?

-

Where the modules are installed on a tilt frame, the isolator shall be<br>protected from direct exposure to sun and rain by using either of the<br>following methods:<br>• Installation of a shroud as per 7.10.2; or<br>• Installation beneath the modules<br>CEC Guidelines Issue 13 April 2019 7.10

-

Where the panels are installed parallel to the roof, an adequate shroud shall<br>be installed over the isolator. PV DC Isolator(s) shall not be installed<br>under a solar module when the panels are parallel to the roof. CEC Guidelines<br>Issue 13 April 2019 7.10<br>

-

External mounting points used or if internal points used shall be the<br>designated points designed by the manufacturer with cover caps installed<br>- CEC Guidelines Issue 13 April 2019 8.3.4 to 8.3.7

-

Are isolators fixed on any portion of the panel - CEC Guidelines<br>Issue 13 April 2019 7.10

-

IP rating of the isolator has been maintained - AS/NZS 5033:2014 4.4.4.6 (b)<br>'Shall'<br>

-

Voltage at DC Isolator (VDC)

-

An array DC Circuit Breaker is present?

-

DC Circuit Breakers are non-polarized and properly designed

Inverter Checklist

-

Inverter Manufacturer

-

Inverter Model

-

Inverter Type

-

Number of Inverters

-

Maximum inverter DC input power

-

Maximum inverter DC current per MPPT

-

Maximum inverter DC input short circuit current per MPPT

-

Is the inverter operational?

-

Is ther inverter running at optimal performance?

-

Inverters are mounted in suitable location

-

Inverter(s) installed as per manufactures specification. 'Shall' CEC Guidelines<br>Issue 13 April 2019 10.1.1

-

Are the inverter(s) listed on the CEC's list of approved products at the time of the system's installation?

-

Earth fault alarm present or monitoring for system has been configured -<br>AS/NZS 5033:2014 3.4.3<br>

-

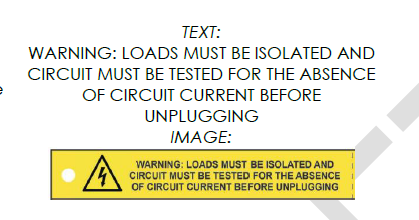

Are the DC cables connecting to the inverter mechanically secured in such a<br>manner that they cannot be inadvertently unplugged from the inverter?<br>

-

Perform the Anti-Islanding test & certify for distribution safety regulatory<br>requirement<br>

-

Are there any Loose connections in the LV cables?

-

Do all cable entries maintain the manufacture's IP rating?

-

Is the inverter securely and safely installed with all fixing / locking screws<br>present?<br>

-

Confirm the earthing of Inverter and external conductive parts.

-

Volt Var Setting

-

Inverter phase connection

Inverter AC Isolator Checklist

-

Has an inverter AC isolator been installed

-

Are all AC isolators ( if more than 3m from switchboard) mounted adjacent to the inverter?

-

Are all AC isolators correctly wired, rated and lockable?

-

Are all AC Circuit Breakers mounted in the switchboard?

-

Are all AC Circuit Breakers correctly rated and lockable?

-

Is the Azc cable voltage rise from inverter terminal to point of supply less than 2%?

Inverter DC Isolator Checklist

-

Is the Inverter DC isolator in-built or seperately installed?

-

Inverter DC isolator manufaturer

-

Inverter DC isolator model

-

Number of Inverter DC isolators

-

Are installed DC isolator(s) on the Electrical Regulator Authorities Council<br>(ERAC) list?<br>

-

Are there any recalled inverter isolators present?

-

Are all DC isolators securable and rated?

-

Does the DC enclosure(s) at the inverter have the required IP rating<br>(minimum IP56NW if outdoors) and has been installed to maintain that<br>rating??

-

Glands and seals installed where required to maintain IP Rating?

-

Are there any loose connections in LV DC cables?

-

Has double insulation been maintained between all live conductor(s) and all<br>earthed or exposed conductive part(s)?

-

Is the DC isolator (or DC Circuit Breaker) lockable in the off position?

-

Voltage at DC Isolator (VDC)

-

Are all inverter DC Circuit Breakers non-polarized and properly designed?

AC Connection & Switchboard Checklist

-

Connecting switchboard name & number

-

Solar CB rating

-

Is the switchboard location compliant & safe?

-

Is the arrangement associated with the solar components compliant & safe?

-

Are the solar AC cables and CBs rated to the inverter output?

Rooftop Checklist

-

Is there safe access to the roof?

-

Solar racking / mounting components manufacuter

-

Are the roof penetrations and/or the roof top components used in the wiring<br>system, including secondary shields, isolator shrouds, collared flashings,<br>multi- holed glands, conduits and conduit glands, suitably installed, sealed<br>and waterproof?

Photovoltaic Distribution Board (PVDB) Checklist

-

Is there a PVDB installed?

-

Are all circuit breakers correctly rated?

-

Is the cable correctly sized?

-

Is the PVDB rated for the installation and location?

-

Are all penetrations into the switchboard suitably sealed according to AS/NZ 3000:2018 2.10.7?

Framing & Mounting Structure Checklist

-

Do the PV mounting structure and attachments comply with AS/NZS 1170.2?

-

Does the mounting system meet manufactureres exclusion zones requirements as per AS/NZ 1170.2:2021

-

Are any galvanically dissimilar metals in contact with each other?

-

All earthing cables for the frame earth connections are of adequate size to<br>comply with Standards.

-

Do the PV array frame and module earthing connections and methods comply<br>with Australian Standards (AS/NZS3000:2018 and AS/NZS5033:2014)

-

Earth fault alarm type?

-

Does the PV array structure allow sufficient clearance to facilitate selfcleaning of the roof, to prevent any build- up of leaves and other debris?

-

Are all cables/wiring in the installation securely fixed in place to minimise any<br>movement of the cable?

-

Is there evidence of mechanical damage to LV cables?

-

Are all array cables:<br>(a) temperature rated for the application,<br>(b) UV resistant if exposed to the environment, and<br>(c) are flexible (multi-stranded) to allow for thermal/wind movement of<br>arrays/modules?<br>

-

Do all LV string cables comply with the requirements of:<br>(a) PV1-F,<br>(b) UL 4703, or<br>(c) VDE-AR-E 2283-4?

Conduit & Cabling Checklist

-

Conduits installed so that they are adequately supported - 'Shall' CEC<br>Guidelines issue 13 April 2019 9.1.6

-

Positive terminal PV array to inverter specifications

-

Are all roof penetrations for the cabling system sealed?

-

Is the array wiring and wiring to the inverter protected from mechanical<br>damage? (this requires a visual inspection of all cables related to the system<br>and therefore might require checking on the roof)<br>

-

Is the DC cable voltage drop less than 3%?

-

Are all cables/wiring in the installation securely fixed in place to minimise any<br>movement of the cable? eg. use of steel cable ties<br>

-

Is the array wiring and wiring to inverter rated for the appropriate voltage and<br>current?

-

Is there evidence of mechanical damage to LV cables?

-

Are all array cables:<br>(a) temperature rated for the application,<br>(b) UV resistant if exposed to the environment, and<br>(c) are flexible (multi-stranded) to allow for thermal/wind movement of<br>arrays/modules?

-

Has the double insulation been maintained between the positive and negative<br>conductors/terminations within all enclosures?

-

Is there visible segregation between AC&DC and LV&ELV located in the same enclosure?

-

Does the installation minimise the spread of any fire which may occur within<br>the system? (Any new circuit breaker holder, junction box or similar must not<br>allow any fire to escape the enclosure onto any combustible material e.g.<br>circuit breaker box)

-

Are there any visibly exposed LV live parts?

-

Are there any signs of heat in electrical equipment and cable terminations?

-

Are all cables secured and fastened correctly, and are secured away from<br>any sharp edges?

-

Has earthing insulation resistance testing been completed?

-

Is there sufficient protection and resrtiction access?

-

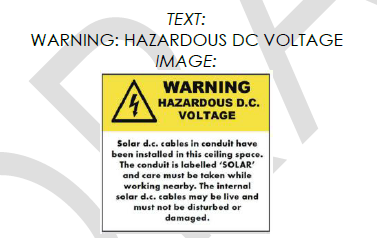

Are all DC cable(s) installed within the ceiling space, wall cavity or floor<br>enclosed in heavy duty conduit or equivalent?<br>

Labels Checklist

-

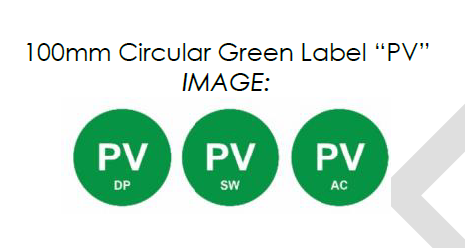

Is there a permanently fixed, clearly visible label on the outside of the meter box or main switchboard. Ensure the appropriate PV label has been used as per AS 5033:2021 5.4.

-

Is there a fixed label on the meter box or main switchboard.

-

Is there a permanently fixed label adjacent to the main switch for the grid supply.

-

Is there a permanently fixed label adjacent to the main isolators for the normal supply to the DB.

-

Is there a permanently fixed label adjacent to the main switch for the IES.

-

For inverters not adjacent to the switchboard, is there a permanently fixed label in a prominent location on the switchboard.

-

When the IES is directly connected to the switchboard, is there a warning label permanently fixed on the switchboard.

-

When the IES is connected to a DB, is there a warning label permanently fixed on the MSB and all related DBs.

-

Is there a permanently fixed sign to the AC isolator adjacent to the inverter.

-

Is there a permanently fixed sign/s to the DC isolator/s at the inverter.

-

Is the shutdown procedure permanently fixed on the inverter.

-

When multiple devices are used that are not ganged together, is there a permanently fixed label on all DC isolators.

-

Is there a warning label on PV DC cable junction boxes, including adjacent to PV modules.

-

When the wiring system is not directly behind and adjacent to the PV modules, is the PV cabling or conduit work clearly labelled every 2 metres.

-

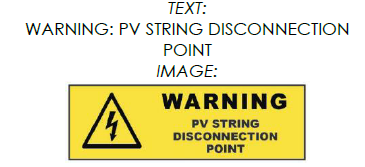

Where disconnection points have been utilised and cables run within ceiling spaces / accessible floor spaces, is there a fixed label at the access point.

-

Is there a permanently fixed label on load break disconnector/s. (Additional labels marked with identification name or number consistent with shutdown procedure are also required)

-

Is there a label attached to the PV module or structure 300mm from the disconnection point.

-

Is there a label attached to both the positive and negative cables within 100mm of their disconnection points.

Audit Summary

-

Overall system compliance

-

Overall system condition

-

Is the system functional

-

Has the system been isolated post-inspection