Title Page

-

Site conducted

JL/JT Front Bumper Production LPA

-

Date:

-

Your Name

-

Which Program are you auditing?

-

Select the JT Front Bumper workstation or cell/area

- FPA Assembly

- Station #1A

- Station #1B

- Station #2

- Station #3

- Station #5

- Station #6

- Station #7

- Station #8

- Packout

- Kitting

- Batch Build

- Blow Mold 1

- Blow Mold 2

- Blow Mold 3

- Blow Mold 4

- Blow Mold 5

-

Select the JL Front Bumper workstation or cell/area

- FPA Assembly

- Station #1A

- Station #1B

- Station #2

- Station #3

- Station #5

- Station #6

- Station #7

- Station #8

- Packout

- Kitting

- Batch Build

- Blow Mold 1

- Blow Mold 2

- Blow Mold 3

- Blow Mold 4

- Blow Mold 5

-

Which shift are you auditing?

-

Name of the operator that is being audited?

-

JL/JT Front Bumper - MGT SF 092-2 LPA Form Rev 0 content 11/16/18

Audit

-

High Risk - Verify the "Critical Safety/Quality" section of the OK to Produce Process was completed for this operation

-

Audit one of the following items from the OK to Produce for this process to verify compliance (Quality/Safety Alerts [no expired alerts posted], Training Matrix, First Piece Approval, In Process Verification). If a NC is found, alert the Production and Dept. Manager immediately.

-

High Risk - Verify there is a signed process/product deviation in place for any equipment, torques or labeling in by-pass and that the operator understands and is following the deviation

-

High Risk - Verify an error proofing device works as intended. (Focus on high RPNs from the PFMEA) If not, is there a reaction plan for these devices?

-

Verify Rabbit documentation is filled out in accordance with the procedure using the proper nomenclature. (Are all error proofing devices verified as scheduled?)

-

Ensure the Standard Operation Sheet and Job Element Sheet are located in the work cell

-

Verify appropriate PPE is called out on the SOS and worn by the operator

-

Verify the Team Member is following the MES including any known quality issues

-

If the JES calls out any key process symbols or customer interface characteristics, verify the operator understands the reasoning behind the denoted checks

-

Does the team member understand what determines clean vs. soiled contents in a drum? (Refer to QA below)

-

Clean rags - yellow step can. Soiled rags - red step can.

-

High Risk - Verify any torques are at the correct setting and in compliance (torque settings are noted on the torque boxes)

-

Verify required inspections are being completed

-

If inspection is done at this station, are visual aids present? (select N/A if no inspection is conducted)

-

High Risk - Ensure quality gate/verification station operations for this part are being followed for any relevant customer or internal quality issues.

-

Verify corrective actions are in place for the NCTs below if they apply to the station being audited

-

NCT 21103364 - 08/12/21 - INCORRECT BUMPER SEQUENCED - ENSURE OP PACKS OUT BUMPER IMMEDIATELY AFTER SCANNING

-

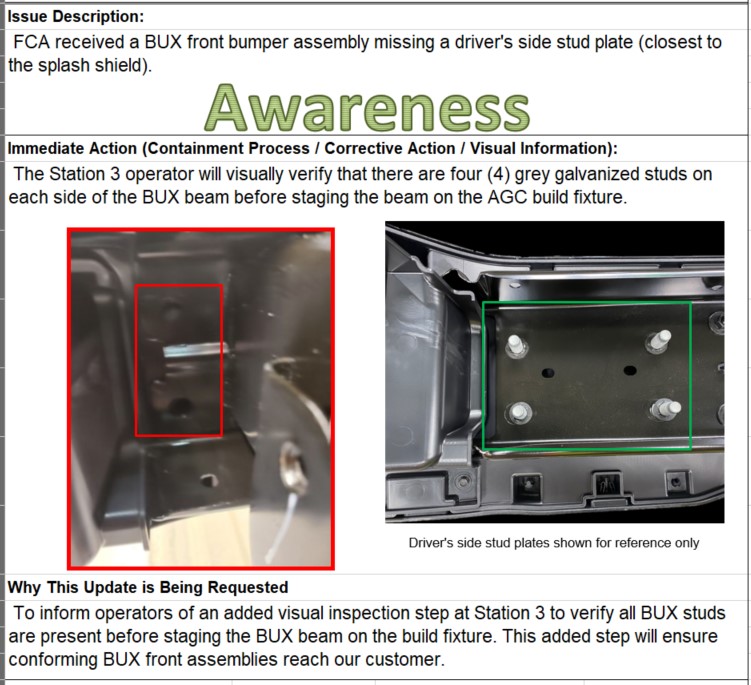

NCT 21103386 - 08/18/21 - ASSY SHIPPED TO CUSTOMER MISSING STUD PLATE, ENSURE QA BELOW IS FOLLOWED

-

GIM 21036335 - 08/19/21 - REBUILT BUMPER SHIPPED WITH FOG LAMPS NOT TORQUED. ENSURE ANY REBUILDS ARE BEING RUN THROUGH THE MES.

-

NCT 21000094 - 09/02/21 - JT FRONT FOG LAMP WH SMASHED - ENSURE THE OPERATOR IS PERFORMING A PUSH-PULL-PUSH AND WITNESS MARKING THE FOG LAMP CONNECTION

-

NCT - 09/09/21 - JT FRONT FLASH IN TOW HOOK OPENINGS - VERIFY A RACK OF FINISHED BUMPERS TO ENSURE THERE IS NO FLASH IN THE TOW HOOK OPENINGS

-

GIM - 2/7/22 - J6 FRONT MISSING FASTENER DUE TO A DOUBLE TORQUE - ENSURE THE OPERATOR DOES NOT DOUBLE TORQUE ANY FASTENERS

-

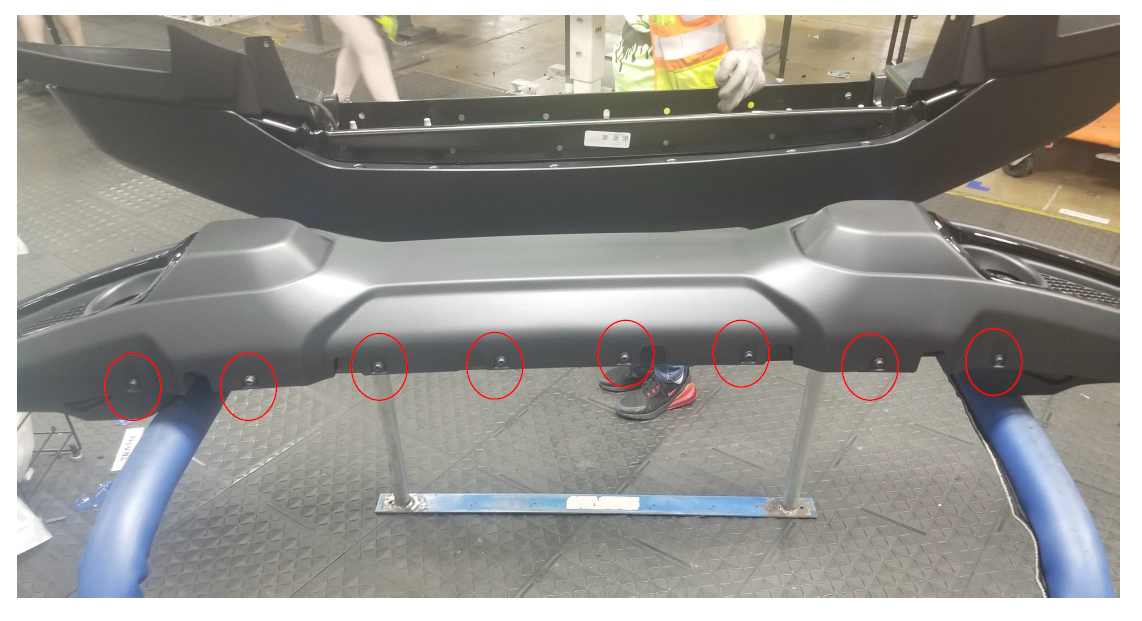

JT Front - Audit one rack of finished goods and verify there are 8 screws along the bottom edge as shown in the image below. If any are found missing, take a photo of the rack label and address with the TL/PM.

-

-

JL and JT Front - Audit one rack each of finished goods and verify the appliques are fully seated. If any are found missing, take a photo of the label and address with the TL/PM.

-

-

Review packaging instructions and ensure stacking/packing techniques of parts is appropriate/safe. Ensure FIFO practices are being followed.

-

High Risk - Verify the operator is green in the OJT for all required operations

-

Review 3 completed product assemblies to ensure conformance including proper part identification and packing technique

-

Is the line balance available in the work area?

-

Verify gauge instructions are available for all gauges in use for this program if applicable

-

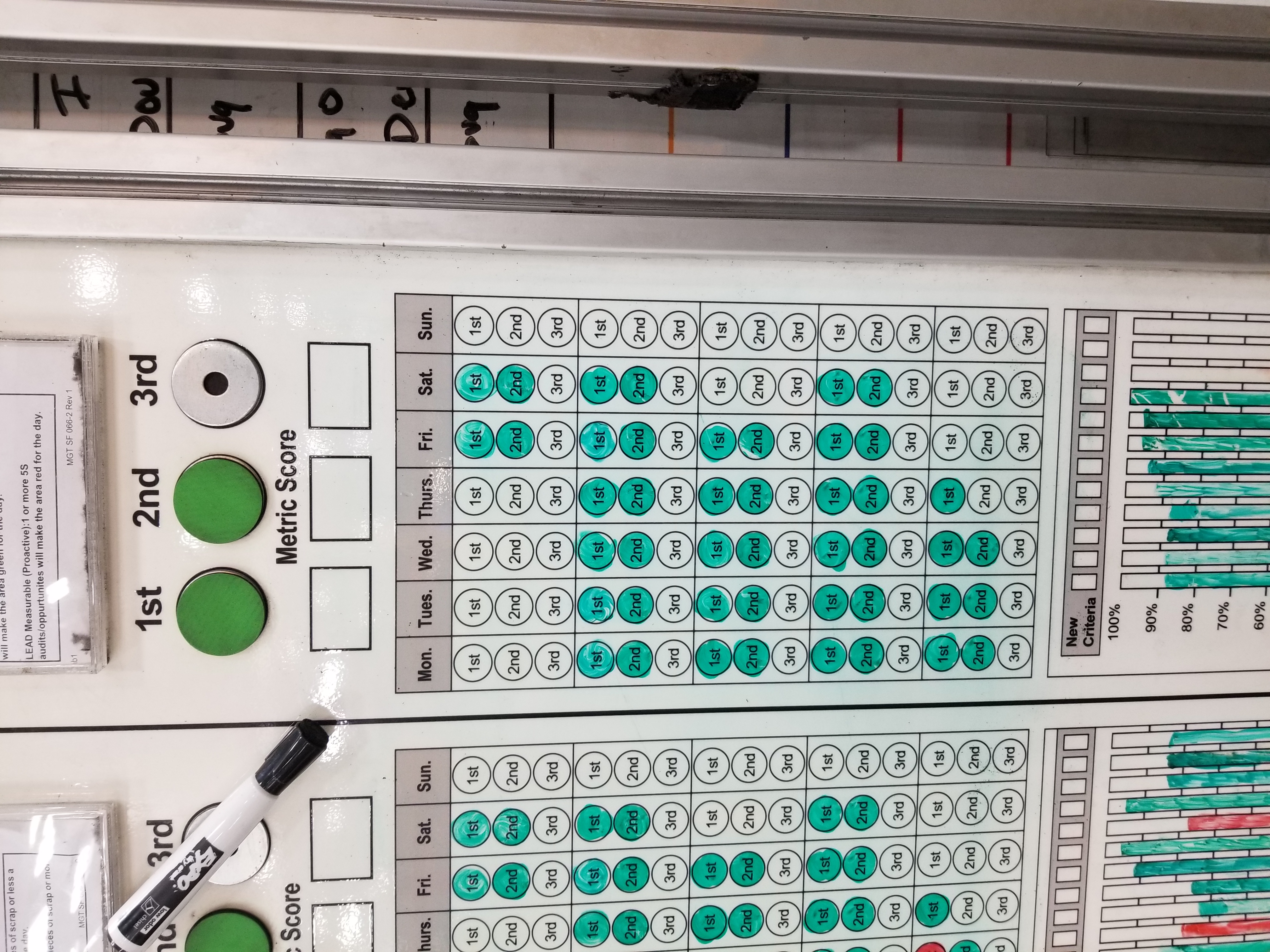

Verify the Safety, Quality, Timing, Cost, and Morale metrics have been updated for the last working shift prior to the start of today's shift for that team. (Ex: 2nd shift needs to update the last 2nd shift metrics prior to the start of today's 2nd shift)

-

Example of acceptable status

-

Verify Autonomous Maintenance is up to date if applicable.

-

Do all communication documents have a document name, initiator name and date?

-

Are all master and secondary documents controlled with a form number?

-

Verify any non-conforming parts have been properly identified with a red tag/tape and placed in the NC area. Note, if any NC is found, an action item is required and NC must be contained/corrected within 24 hrs.

-

Assign an action item for any continuous improvement items

-

Please review any findings with the area TL or Production Manager

-

If you completed this audit on a shared device/tablet, please sign out of the device once you complete this audit.