Information

-

Restaurant #

-

Conducted on

-

Prepared by

-

Location

-

Restaurant Manager/Person in charge

Equipment

General Restaurant performance

-

- Review Business Recap for key performance metric (Print from Restaurant PC, Business Management)

- Review SOS Total Time (Print from Restaurant PC, SOS application)

- Review VOG Restaurant Report

- Evaluate routine POM observations to determine how guest service, cleanliness or other issues may impact efficiency

- Ensure that no parking cars policy is enforced, and that SOS manipulation is not occurring

Equipment

-

Headset

-

Condition

-

Audio In

-

Audio Out

-

# Is the following equipment in working condition and programmed correctly? Note any issues found.

-

Drive-Thru OCS

-

Drive-Thru Speaker (Verify audio quality)

-

Drive-Thru Mic (Verify audio quality)

-

Grill Timers/Conditions

-

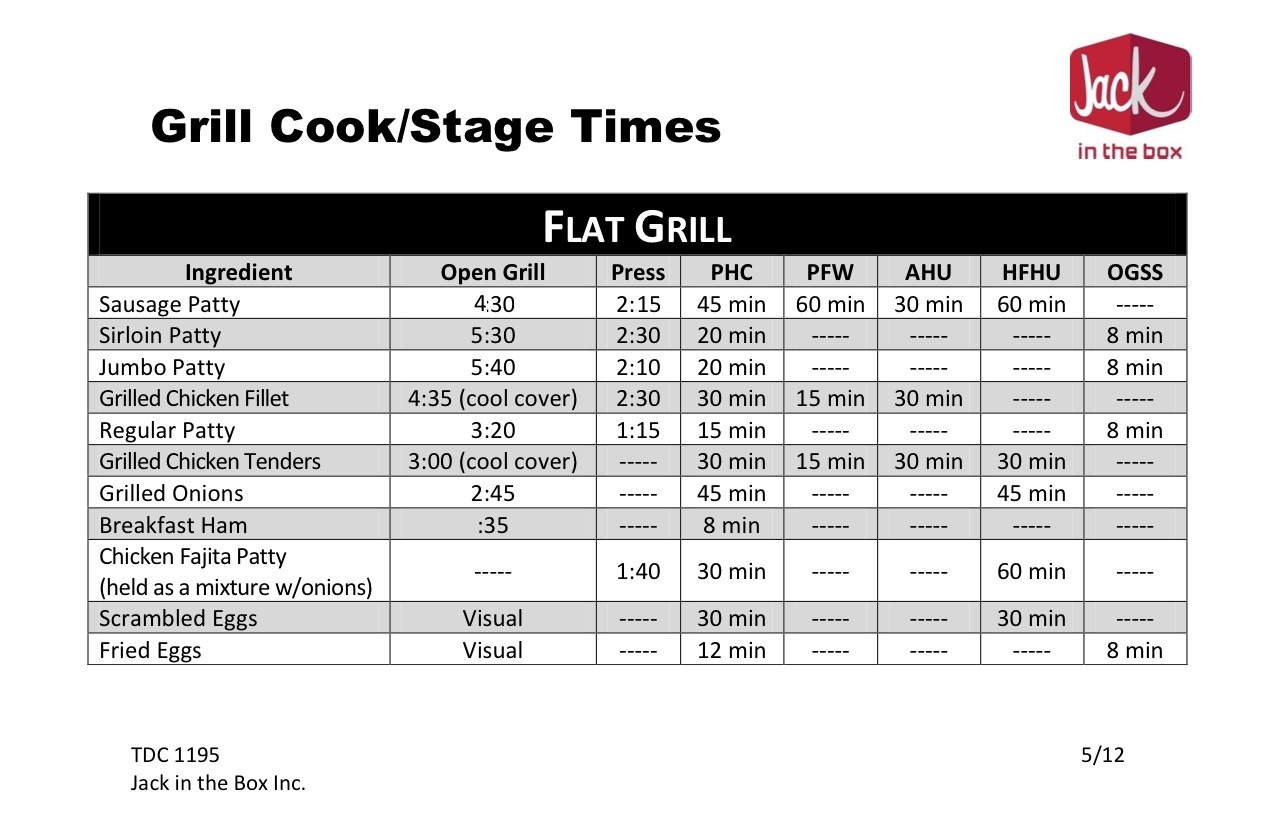

Flat Grills

-

Sausage Patty (C) 4:30 mins (F) 2:15 mins<br> (P) 1:40 mins (F) 0:50 mins

-

Sirloin Patty (C) 5:30 mins (F) 2:45 mins<br> (P) 2:30 mins (F) 1:15 mins

-

Jumbo Patty (C) 5:40 mins (F) 2:50 mins<br> (P) 2:10 mins (F) 1:05 mins

-

Grill Chicken Fillet (C) 4:35 mins (Cool Cover) (F) 2:17 mins<br> (P) 2:30 mins (F) 1:15 mins

-

Regular Patty (C) 3:20 mins (F) 1:40 mins<br> (P) 1:15 mins (F) 0:38 mins

-

Grill Chicken Tenders (C) 3:00 mins (Cool Cover) (F) 1:30 mins

-

Grill Onion (C) 2:45 mins (F) 1:50 mins

-

Breakfast Ham 0:35 mins

Note: There is no timer button programmed for Ham. Manually count and visually check for browning on each side -

Chicken Fajita (P) 1:40 mins (F) 0:45 mins

-

Scrambled Eggs Visual

-

Fried Eggs Visual

-

Flat Grill Stage Times

-

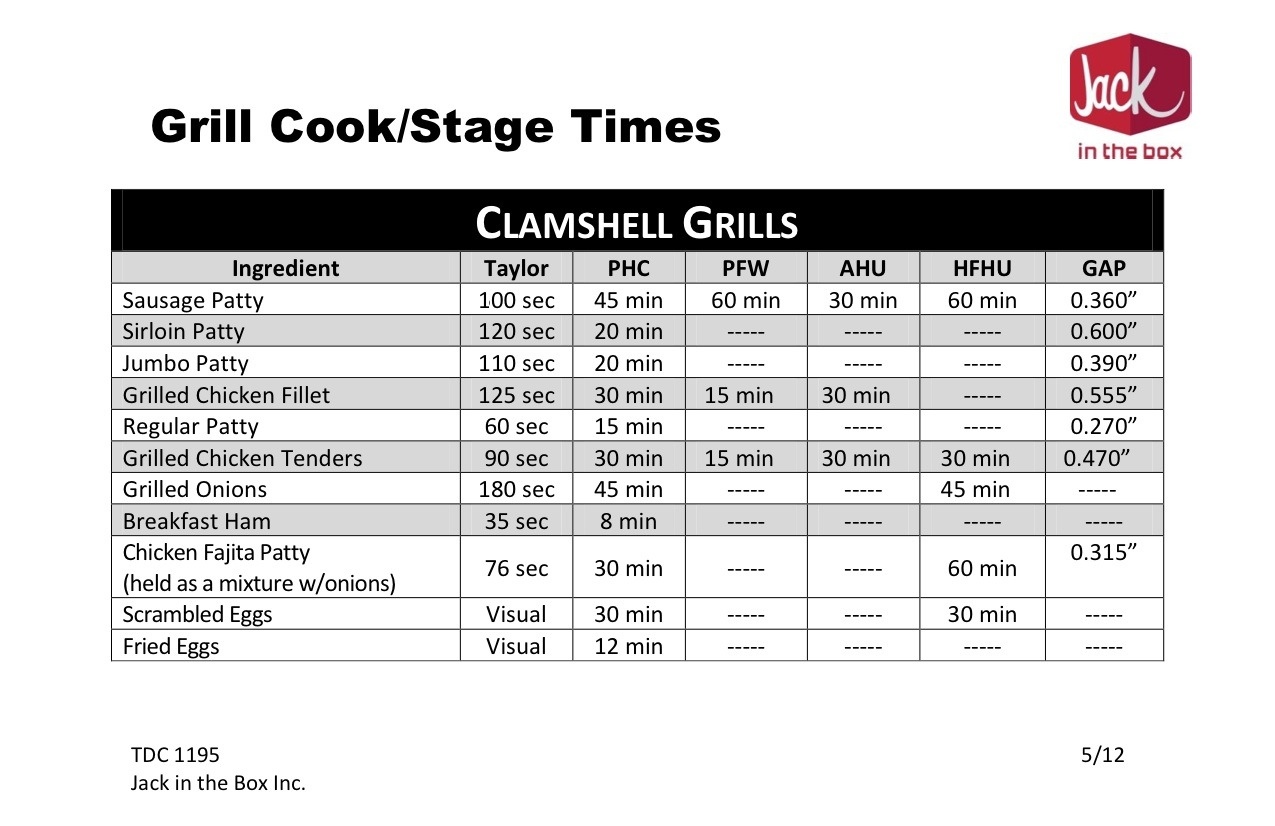

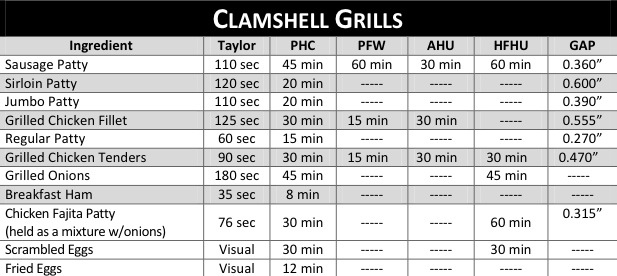

Clamshell Grills

-

Sausage Patty 100 sec<br>Gap setting 0.335

-

Sirloin Patty 120 sec<br>Gap setting 0.600

-

Jumbo Patty 110 sec<br>Gap setting 0.390

-

Grill Chicken Fillet 125 sec<br>Gap setting 0.555

-

Regular Patty 60 sec<br>Gap setting 0.270

-

Grill Chicken Tenders 90 sec<br>Gap setting 0.470

-

Grill Onion 180 sec

-

Breakfast Ham 35 sec

Note: There is no timer button programmed for Ham. Manually count and visually check for browning on each side -

Chicken Fajita 76 sec<br>Gap setting 0.315

-

Scrambled Eggs Visual

-

Fried Eggs Visual

-

Clamshell Stage Times

-

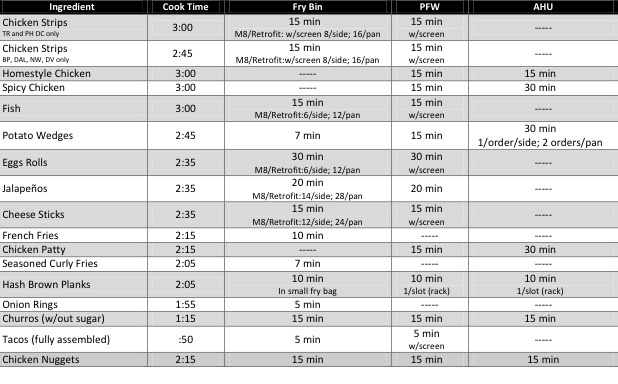

Fryer Timers/Conditions

-

Chicken Strips : 3:00 mins<br>(TR and PH DC only)

-

Chicken Strips : (C) 2:45 mins (S) 1:45 mins<br>(BP, DAL, NW and DV only)

-

Homestyle Chicken : 3:00 mins

-

Chicken Patty : (C) 2:15 mins

-

Spicy Chicken : 3:00 mins

-

Fish : 3:00 mins

-

Potato Wedge : (C) 2:45 mins (S) 1:45 mins

-

Eggs Rolls : (C) 2:35 mins (S) 1:35 mins

-

Jalapeños : (C) 2:35 mins (S) 1:35 mins

-

Cheese Sticks : (C) 2:35 mins (S) 1:35 mins

-

Chicken Nuggets : (C) 2:15 mins (S) 1:15 mins

-

French Fries : (C) 2:15 mins (S) 1:15 mins

-

Season Curly Fries : (C) 2:05 mins (S) 1:05 mins

-

Hash Brown Planks : 2:05 mins

-

Onion Rings : (C) 1:55 mins (S) 0:55 mins

-

Churros (W/out Sugar) : 1:15 mins

-

Tacos (Fully assembled): 0:50 mins

-

Fryer Cook Times

-

Holding/Staging equipment Timers/Conditions

-

Grill Flat/ Clamshell Holding Times

-

Sausage Patty PHC: 45 mins PFW: 60 mins AHU: 30 mins<br> HFHU: 60 mins

-

Sirloin Patty PHC: 20 mins

-

Jumbo Patty PHC: 20 mins

-

Grill Chicken Fillet PHC: 30 mins PFW: 15 mins AHU: 30 mins

-

Regular Patty PHC: 15 mins

-

Grill Chicken Tenders PHC: 30 mins PFW: 15 mins AHU: 30 mins<br> HFHU: 30 mins

-

Grill Onion PHC: 45 mins HFHU: 45 mins

-

Breakfast Ham PHC: 8 mins

-

Chicken Fajita PHC: 30 mins

-

Scrambled Eggs PHC: 30 mins

-

Fried Eggs PHC: 12 mins

-

Flat Grill

-

Clamshell

-

Fryer Holding Times

-

Chicken Strips : FB # 15 mins PFW # 15 mins<br>(TR and PH DC only) (W/ screen) (W/ screen)

-

Chicken Strips : FB # 15 mins PFW # 15 mins<br>(BP, DAL, NW and DV only) (W/ screen) (W/ screen)

-

Homestyle Chicken : PFW # 15 mins AHU # 15 mins

-

Chicken Patty : PFW # 15 mins AHU # 45 mins UHC # 45 mins

-

Spicy Chicken : PFW # 15 mins AHU # 30 mins

-

Potato Wedge : FB # 7 mins PFW # 15 mins AHU # 30 mins

-

Fish : FB # 15 mins PFW # 15 mins

-

Eggs Rolls : FB # 30 mins PFW # 30 mins

-

Jalapeños : FB # 20 mins PFW # 20 mins

-

Cheese Sticks : FB # 15 mins PFW # 15 mins

-

Chicken Nuggets : FB # 15 mins PFW # 15 mins AHU # 15 mins

-

French Fries : FB # 10 mins

-

Season Curly Fries : FB # 7 mins

-

Hash Brown Planks : FB # 10 mins PFW # 10 mins AHU # 10 mins

-

Onion Rings : FB # 5 mins

-

Churros (W/out Sugar) : FB # 15 mins PFW # 15 mins AHU # 15 mins

-

Tacos (Fully assembled): FB # 5 mins PFW # 5 mins

-

Fryer Holding Time

-

Toaster Timers/Conditions

-

Jumbo Bun : 0:55 mins

-

Regular Bun : 0:45 mins

-

Bakery Style : 0:55 mins

-

Tortillas : 0:20 mins

-

Biscuit : 0:55 mins

-

Croissant : 0:30 mins

-

Waffle : 0:45 mins

-

Microwave Timers

-

#1 Exploding Chicken 0:35 mins

-

#2 Grill Sandwich 0:35 mins

-

#3 Bacon Cheddar●Steak&Egg 0:27 mins<br> Pancakes ●Load Nuggets<br> Stacked Grilled Cheese

-

#4 Grilled Onions●Meaty Burrito 0:14 mins<br> /Side of peppers

-

#5 Pita Bread●Grilled Cheese 0:08 mins

-

#6 SD Cheesesteak Melt●Extra Bowl 0:45 mins

-

#7 Mini Cookies 0:09 mins

-

#8 Bacon 0:55 mins

-

#9 Blank

-

#10 Teriyaki Bowls (1 complete setup) 1:36 mins

Staffing & Training

Staffing

-

Is variance in Sales Forecasting for the last 6 weeks +/- 2%?

-

Is the restaurant staffed with appropriate numbers of management and team members?

-

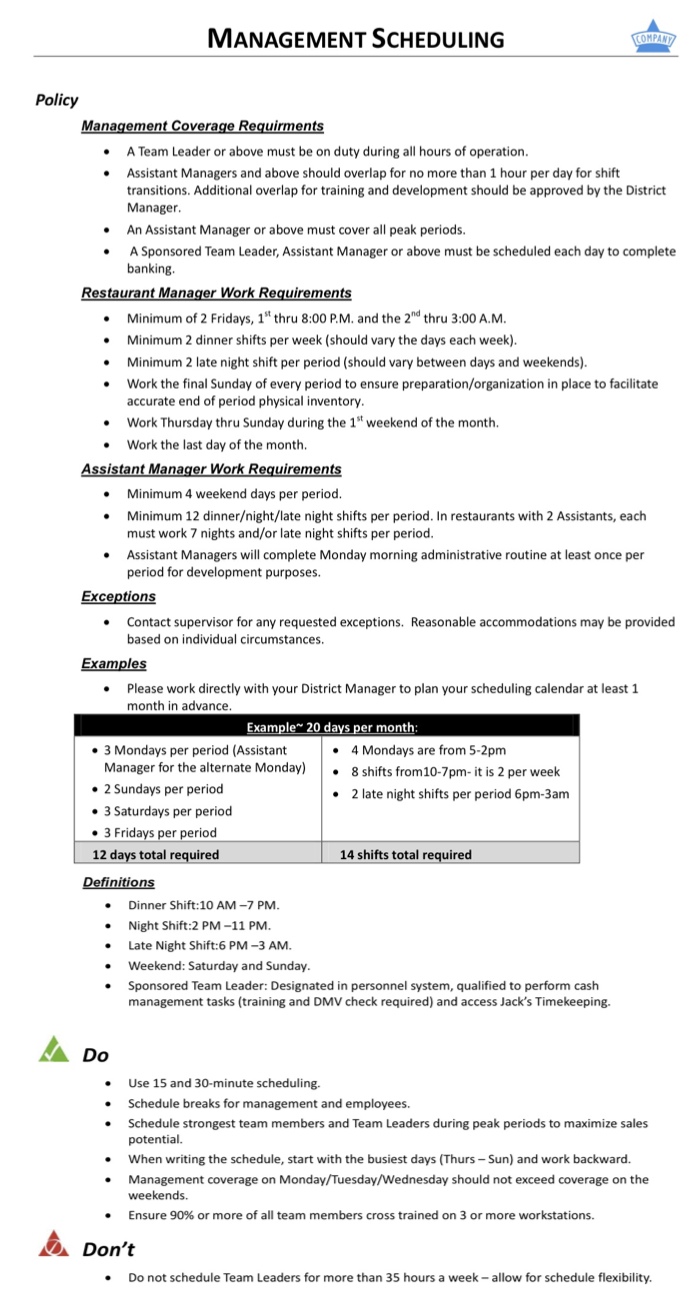

Is management scheduled according to the Management Scheduling Policy?

-

Management Scheduling

-

Is color coding used for non-SG activities?

-

Are half-hour meal breaks scheduled?

-

Are SG hours scheduled equal to the recommended number or +1?

-

Is 15-minute scheduling used?

-

Review CBT Workstation Certification Report, Cross Training percentage should be at 80% or above.

-

Training - Evaluate training needs through observation of performance and review of CBT Report Card.

Employee Name

-

Employee Name

-

Primary Position

-

Drink

-

Guest Service

-

Fryer

-

Grill

-

Kitchen

-

Cleaning

-

Preparation

-

Maintenance

Build-To Chart

Build-To Charts: Observe execution of continuous cooking and use of Build-To Charts.

-

Is manager consistently printing and posting accurate Build-To Charts for the grill and fryer daily?

-

Do employees understand how to read Build-To Charts and are they using them? Ask questions to validate.

-

- What is a build-to? (Ans: It tells me how many ingredients to have available during peak times)

- Why do we use build-to? (Ans: We can prepare products quicker if we have the ingredients available)

- Haw many jumbo patties are you supposed to be staging at this time frame? (Ans: Refer to grill Build-To Chart)

- How many chicken patties are you supposed to be staging at this time frame? (Ans: Refer to fryer Build-To Chart) -

Does communication occur to ensure Build-To Chart are adjusted and maintained throughout peak periods?

-

Does person-in-charge of the shift manage to use Build-To Chart?

-

Are staging systems used according to procedures?

-

Are continuous cooking procedures understood and followed? Ask questions to validate.

-

- What is continuous cooking? (Ans: Using either turn & place or remove & place for patties)

- why do we use continuous cooking? (ans: So we always have available during peak times)

- How do I know what turn & place or remove & place amount to use? (Ans: Refer to grill Build-To Chart)

- If during peak time, what remove & place or turn & place level, are you using? (Ans: I'm using a T&P of 2 patties)

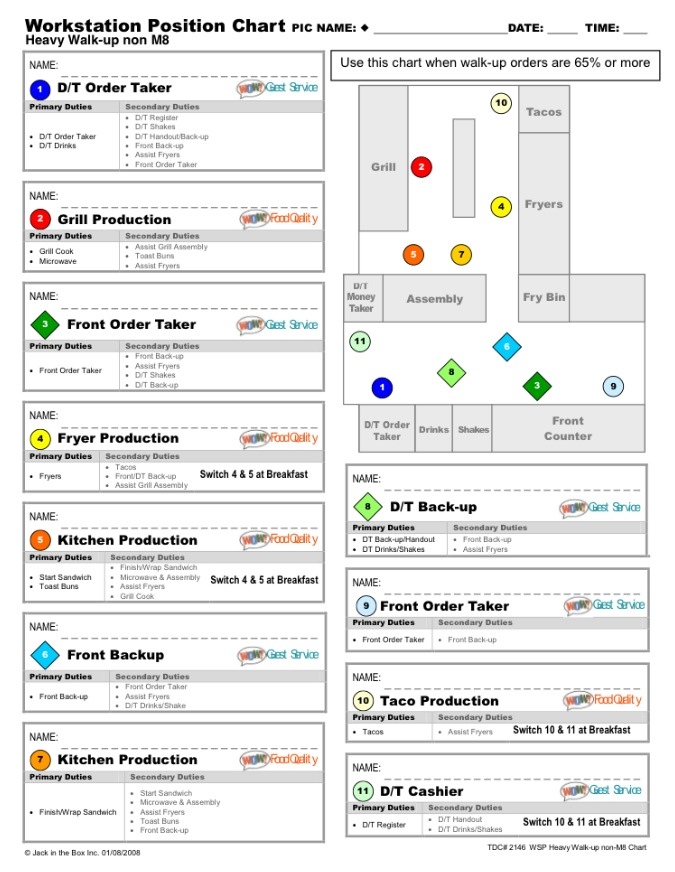

Workstation Positioning

Workstation Positioning

-

Do management and team members understand workstation positioning? Ask questions to validate.

-

- Why do we use Workstation Positioning? (Ans: Everyone knows what their primary job and what tasks to perform and when they don't have any tasks it tells them what they should be doing. It balances the workload among all employees)

- Whatnposition are you in? What are your primary duties? (Ans: Example - Position 4, primary duties are to cook fryer products)

- What are your secondary duties? (Ans: Back-up and grill assembly)

- What do you do if you do not have any primary duties? (Ans:!Do my secondary duties, back-up and grill assembly)

- What does it mean to "Slide"? (Ans: To move to a different position to perform secondary duties) -

Do employees stay in positions?

-

Is Double-bubble used appropriately?

-

Is there a visible sense of urgency to produce guest's order?

-

Mark 8 Workstation Positioning Chart

-

# Rate observed productivity level of each person during peak period.

-

(1) DT Order Taker Name:

-

(2) Grill Production Name:

-

<3> Front Order Taker Name:

-

(4) Fryer Name:

-

(5) Kitchen Production Name:

-

<6> DT Back Up Name:

-

(7) Kitchen Production Name:

-

<8> Front Back Up Name:

-

(9) DT Order Taker Name:

-

(10) Taco Production Name:

-

(11) Front Order Taker Name:

Pre-Rush Ready

Pre-Rush Ready

-

Are Workstation Daily Planners used and understood? Ask questions to validate.

-

- What information is listed on the planner? (Ans: Stocking and cleaning tasks and some prep tasks)

- How do you use the planner to do your job more effectively? (Ans: Use to see what needed to be stocked at my station prior to rush)

- Why is it important to stock your station before the rush? (Ans: I will have all the ingredients I need to get through the rush and will not have to leave my station. If I have to leave my station is will cause me to get behind on my job) -

Are employees consistently ready for each rush?

-

Does the person-in-charge of the shift effectively manage Pre-rush, Rush and Post-rush activities?

-

Are prep, maintenance and admin activities avoided during peak periods?

Floor Communication

Floor Communication

-

Does the person-in-charge of the shift create a sense of urgency and motivate/influence the team?

-

Are floor communication processes (TIP-TAP-TOP) used?

-

Do employees understand use of headsets to help expedite orders? ask questions to validate.

-

- Do you know which positions should wear headsets at all times? (Ans: 1,2,4, PIC)

- Why should you wear headsets at all time? (Ans: Helps to expedite orders, Allow multiple employees to assist guests)

- Why is the headset better than relying on the grill speaker? (Ans: Can hear order immediately even if in the back) -

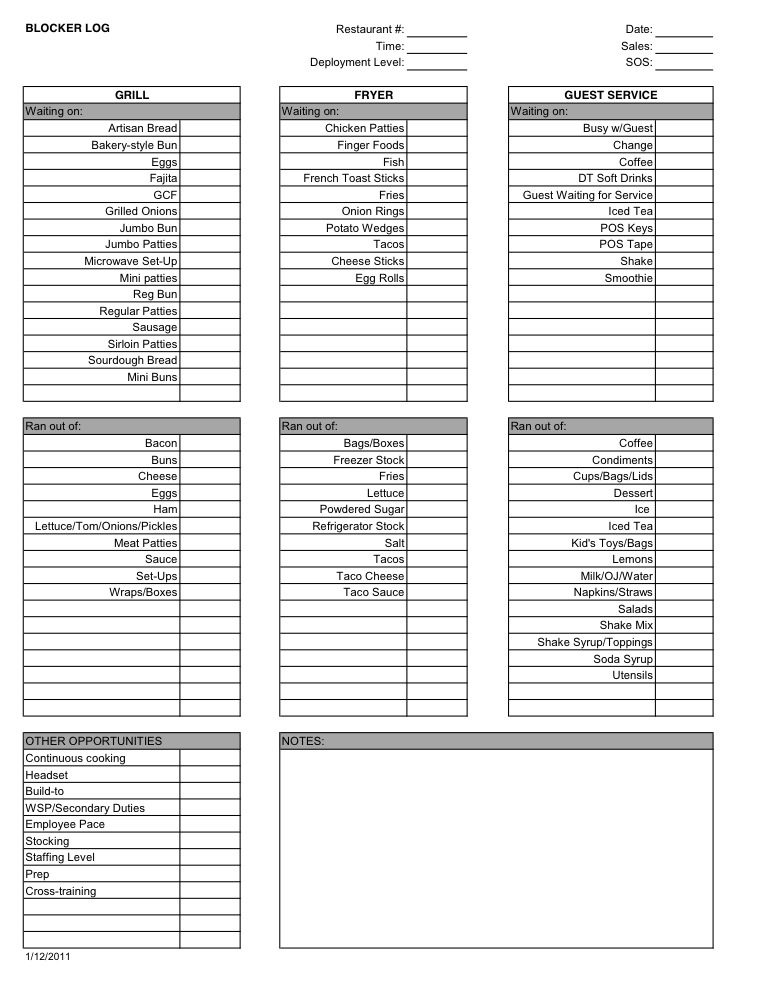

Does the person-in-charge of the shift analyze bottlenecks and coach to correct issues?

Analyze bottlenecks - Use the Blocker log to analyze bottlenecks.

-

Describe observed issues such as staffing, ingredients, specific workstations, equipment capacity or packaging.

-

Blocker Log is being used.

-

Blocker Log Form