Information

-

Document No. (AL-RI-YY-MM)

-

Audit Title

-

Site

-

Conducted on

-

Prepared by

Introduction

-

While all employees should be vigilant to damaged racking, monthly racking inspections are undertaken only by employees who have attended a course on racking inspection.

If the employee undertaking the inspection is in any doubt about the classification of any damaged racking, he should consult the site manager, who will advise on the course of action.

Principal hazards:

1. Collapse of racking.

2. Fall of materials from racking.

3. Collision of forklift truck with racking.

The main risk resulting from these hazards is injury to employees or visitors.

Current controls:

1. Monthly racking inspections.

2. Column guards.

3. Locking pins.

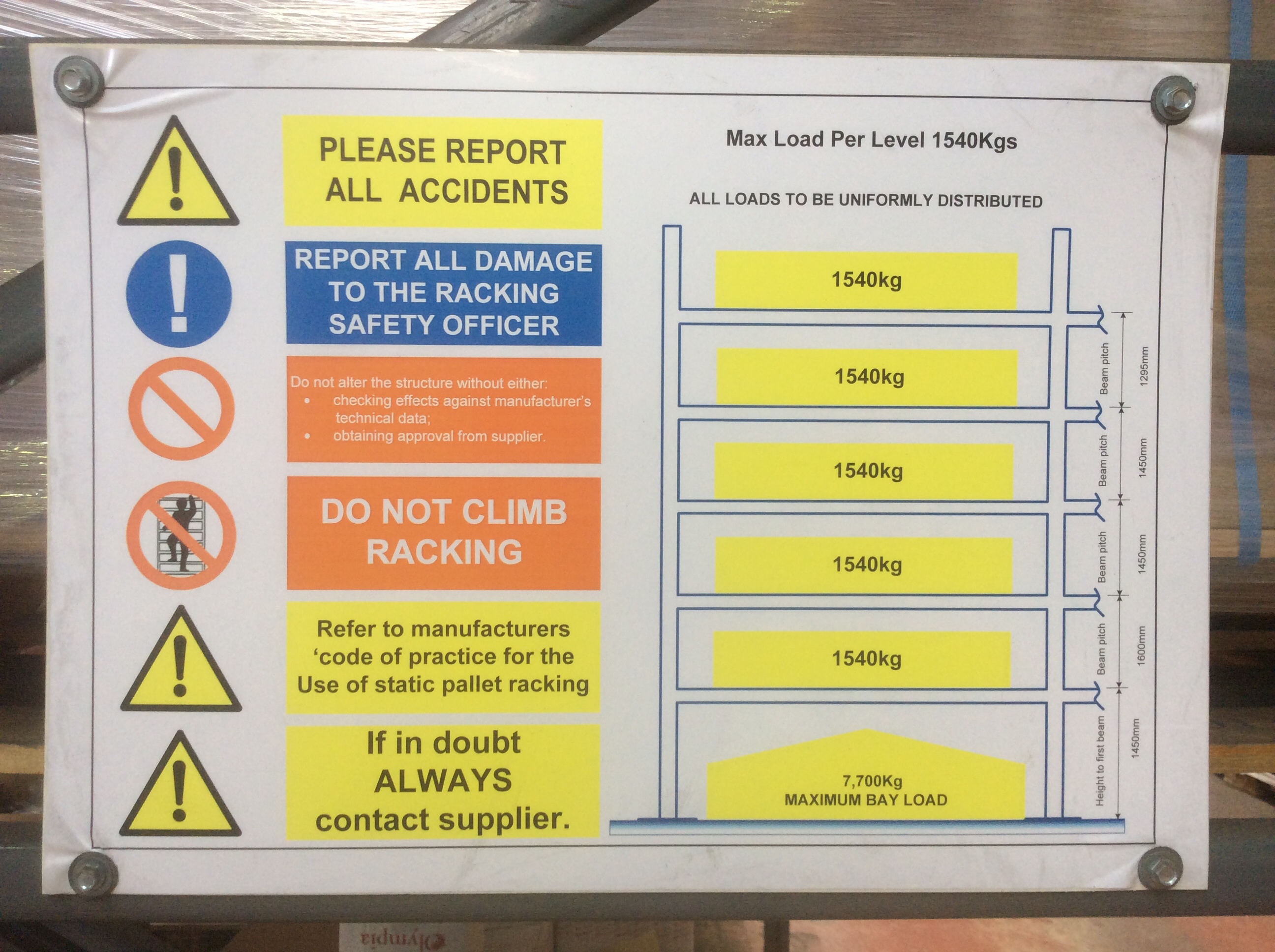

4. Safe working load signs.

5. 'Do not climb the racking' signs.

Further information is available via SEMA (Storage Equipment Manufacturers' Association www.sema.org.uk).

Uprights / Legs

-

Uprights can be damaged by being twisted or having a deflection.

-

-

If the upright's deflection is less than 1 in 200 (i.e. less than 2mm deflection over 1 metre height) then this is an amber risk. If the deflection is more than 1 in 200 (i.e. more than 2mm deflection over 1 metre height) then this is a red risk.

-

Are any uprights damaged?

-

Click on right for each damaged upright.

Damaged Upright

-

Enter the racking location of the damaged upright.

-

Take a photo of the damage (if appropriate).

-

Select the level of deflection (green, amber or red risk).

-

Green risk: Arrange for upright to be straightened.

-

Amber risk: Do not empty racking immediately. If upright is not repaired within 4 weeks this will become a red risk.

-

Red risk: All levels of racking must be offloaded immediately and isolated from future use until damaged upright has been replaced.

Horizontal Beams

-

Horizontal beams can also be damaged by being twisted or having a deflection.

-

-

If the beam's deflection is less than 1 in 200 (i.e. less than 2mm deflection over 1 metre length) then this is an amber risk. If the deflection is more than 1 in 200 (i.e. more than 2mm deflection over 1 metre length) then this is a red risk.

-

Are any beams damaged?

-

Click on right for each damaged beam.

Damaged Beam

-

Enter the racking location of the damaged beam.

-

Take a photo of the damage (if appropriate).

-

Select the level of deflection (green, amber or red risk).

-

Green risk: Arrange for beam to be straightened.

-

Amber risk: Do not empty racking immediately. If beam is not repaired within 4 weeks this will become a red risk.

-

Red risk: All levels of racking must be offloaded immediately and isolated from future use until damaged upright has been replaced.

Bracing

-

Horizontal and diagonal bracing can also incur deflections. If the deflection is less than 1 in 200 (i.e. less than 2mm defection over 1 metre length or height) then this is an amber risk. If the deflection is more than 1 in 200 (i.e. More than 2mm deflection over 1 metre length or height) then this is a red risk.

-

-

Is any bracing damaged?

-

Click on right for each item of damaged bracing

Damaged Bracing

-

Enter the racking location of the damaged bracing.

-

Take a photo of the damage (if appropriate).

-

Select the level of deflection (green, amber or red risk).

-

Green risk: Arrange for bracing to be straightened.

-

Amber risk: Do not empty racking immediately. If bracing is not repaired within 4 weeks this will become a red risk.

-

Red risk: All levels of racking must be offloaded immediately and isolated from future use until damaged bracing has been replaced.

Column Guards

-

Column guards should be fixed to the ground to ensure the racking is fully protected.

-

Are there any damaged column guards which need repair?

-

Click on right for each column guard needing repair.

Column guard

-

Enter racking location of column guard needing repair.

Signage

-

Signage is needed to warn employees and visitors of potential hazards and inform them of safe working practices. These include safe working loads signs and 'do not climb on racking' signs.

-

-

Are there any missing or damaged signs?

-

Click on right for each missing or damaged sign.

Missing or damaged sign

-

Enter details and location of missing or damaged sign.

Other

-

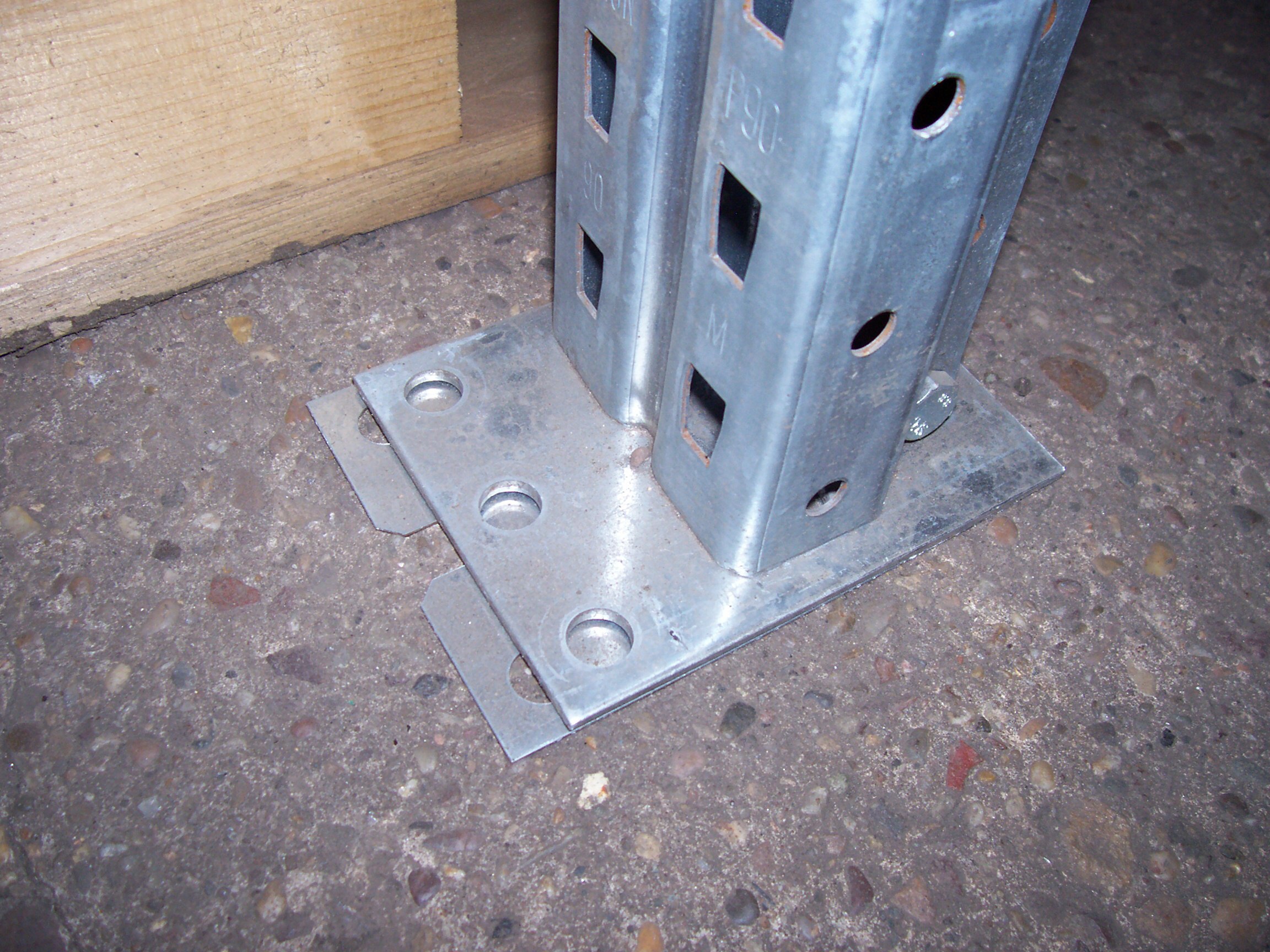

All racking parts must in working order. This includes:

- Base plates.

- Level plates.

- Floor fixings.

- Safety locks/pins.

- Splicers.

- Frame spacers.

- Shelf panels. -

-

Are there any other parts missing or damaged?

-

Click on right for each missing or damaged part.

Missing or damaged part

-

Select racking part.

- Base plate

- Level plate

- Floor fixing

- Safety lock/pin

- Frame spacer

- Shelf panel

- Splicer

- Other

-

Is the part missing or damaged?

-

Enter location of missing or damaged part.

Inspection Signoff

-

Sign to confirm inspection is complete.

-

Add signature