Information

-

Conducted on

-

Dealer Contact/email

-

Prepared by

Program

-

Check for Program Audit

STF CD/Contents

-

Tab 1-STF Manual accessible to all

Tab 2-Training Records

-

Do you have training record attendance sheets

-

Do you have New Employee Orientation records (sign-off sheets) @ the Dealership or at your Corporate Office?

-

Do you have Safety Committee (managers,employees) that meets at least once a year?

-

Does at least one employee have current DOT Haz-Mat Certificate(s) (3yrs)

-

AC Certificate(s) for techs that do AC repairs<br>

-

Power Industrial Truck Operators License(s) (3yrs)

Tab 3-Audit/Inspection

-

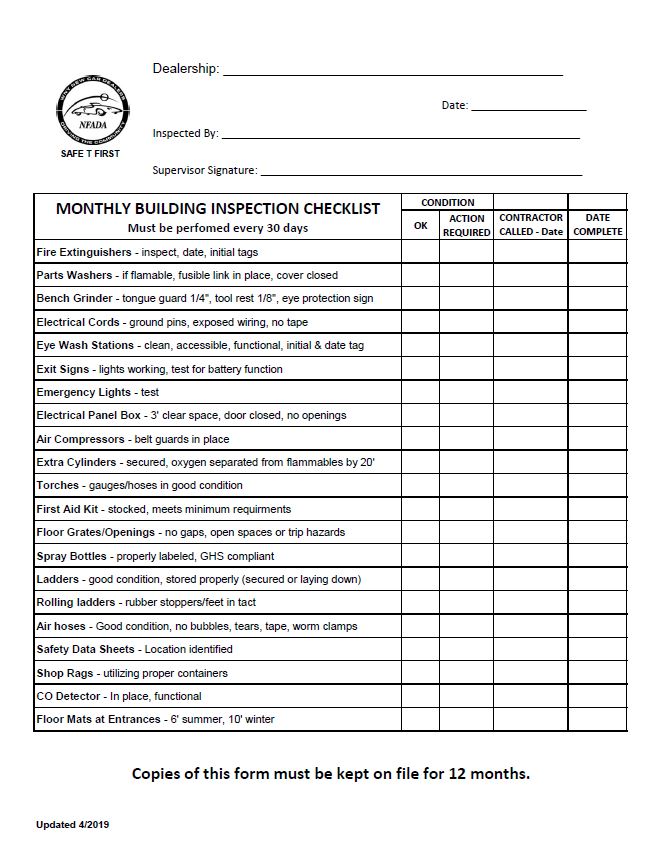

Most recent safety inspection report

- Yes

- No

- N/A

- Reference

-

http://www.nfada.com/members_only/pdfs/MonthlyBuildingInspectin4-2019.pdf

Tab 4-Emgency Action/Fire Prevention

-

Do you have an Emergency Action Plan with Evacuation Maps, and is it posted in each department?

-

Do you conduct Fire Drills (annual)

-

Check if you have a Collision Center

Tab 5 Respiratory Protection Collision Shop

-

Medical Surveillance Evaluation (as required)

-

Respirator Training/Fit Test (annual)

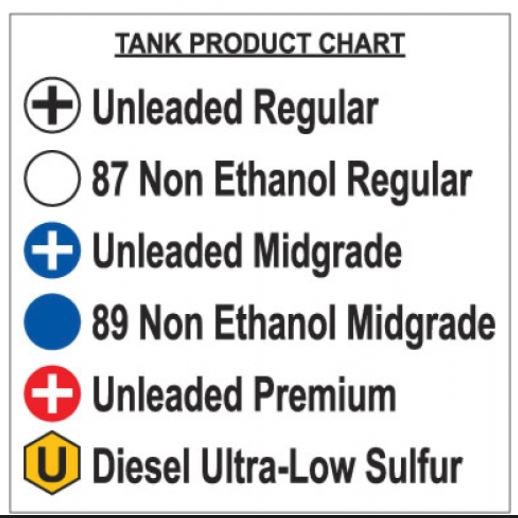

Tab 6 Storage Tanks/DEC Inspection

-

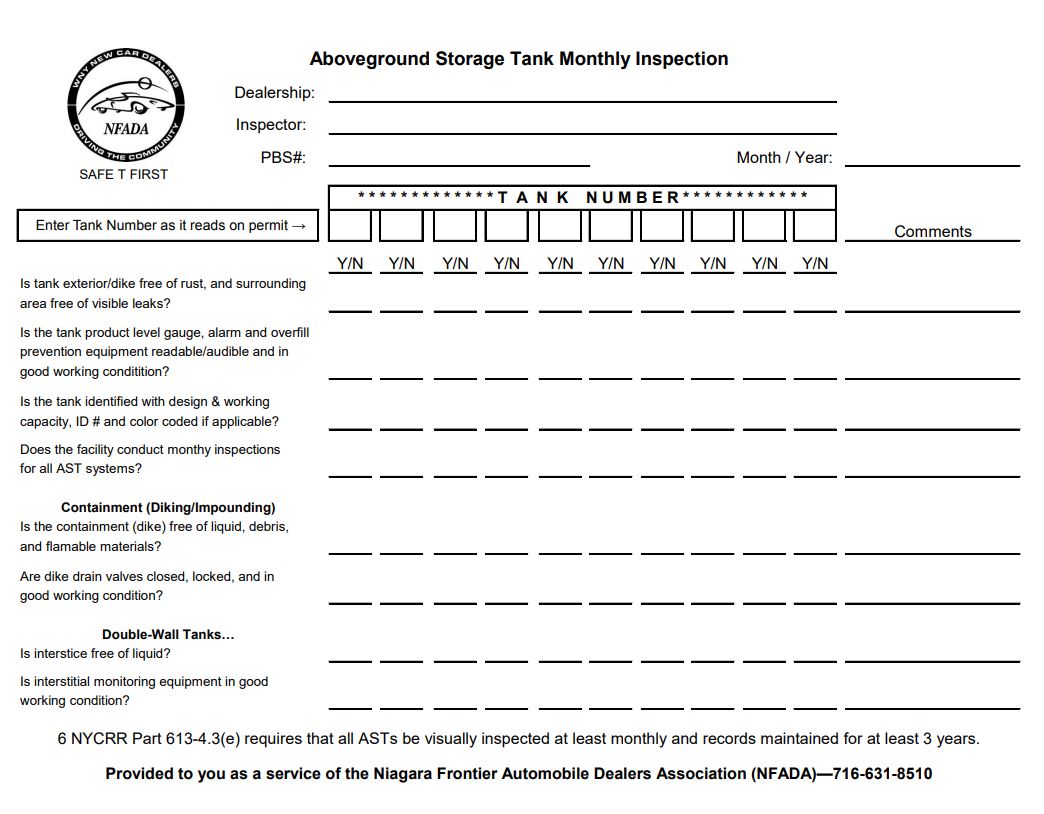

Copy of petroleum bulk storage tank certificate

-

D.E.C Data Base https://www.dec.ny.gov/cfmx/extapps/derexternal/index.cfm?pageid=4

-

Monthly DEC AST inspection reports (3yrs)

- Yes

- No

- N/A

- Reference

-

http://www.nfada.com/members_only/pdfs/MonthlyTankInspection4-18_000.pdf

-

Underground Storage Tanks

-

Copy of A/B Operator Training (indicated on tank permit?)

-

Copy of Cathodic Test (annual)

-

Do you have 1320 gallons or more of petroleum bulk storage (includes 55 gallon drums)

-

Do you have a SPCC plan on file, is it current? (5yr review)

Tab 7-PPE (Assessment and Glove Testing on File)

-

Have you conducted PPE Hazard Assessment /Training (annual)

-

Service

-

Parts/Detail/Office

-

Collision

-

Hybrid Glove Tests (6 months)

Tab 8-Inspections (Inspection on File)

-

Monthly Building Inspections (12 months)

-

Fire Alarm Test Records (annual)

-

Automatic Sprinklers Inspection (annual)

-

Rolling Steel Fire Doors (annual drop test)

-

Lift Inspection Report (annual)

-

Forklift pre-operation inspection

-

Elevator Inspection (every 6 months)

Tab 9-Environmental Documentation

-

Waste Paint Pickup Manifests/Receipts

-

Parts Washer Solvent Pickup Manifests/Receipts

-

Oil/Water Separator Cleanout Receipts

Safety Data Sheets

-

SDS Binder

-

SDS Online

Tab 10-Additional Documentation

-

OSHA 300A/OSHA 301 (or equivalent) post 2/1-4/30

-

Comments

Postings

-

Check for Posting Audit

Dealer Signs

-

Yellow OFFICIAL INSPECTION STATION sign on outside of building? Form 110 (State)

-

State Regulation

-

Green Registered NYS MOTOR VEHICLE REPAIR SHOP sign on outside of building?

-

State Regulation

-

Does the dealership post an IDENTIFYING SIGN AT EVERY BUSSINESS LOCATION? (off premises bodyshop or showroom) (NYS DMV 78.26(b)) (State)

Service Write-up Area

-

Service-Write Area Please check one that apply

- Compliance Board Minus Child Seat Law

- Compliance Board Minus DEC PBS,Child Car Seat Law

- No Compliance Board

- Reference for labor rate

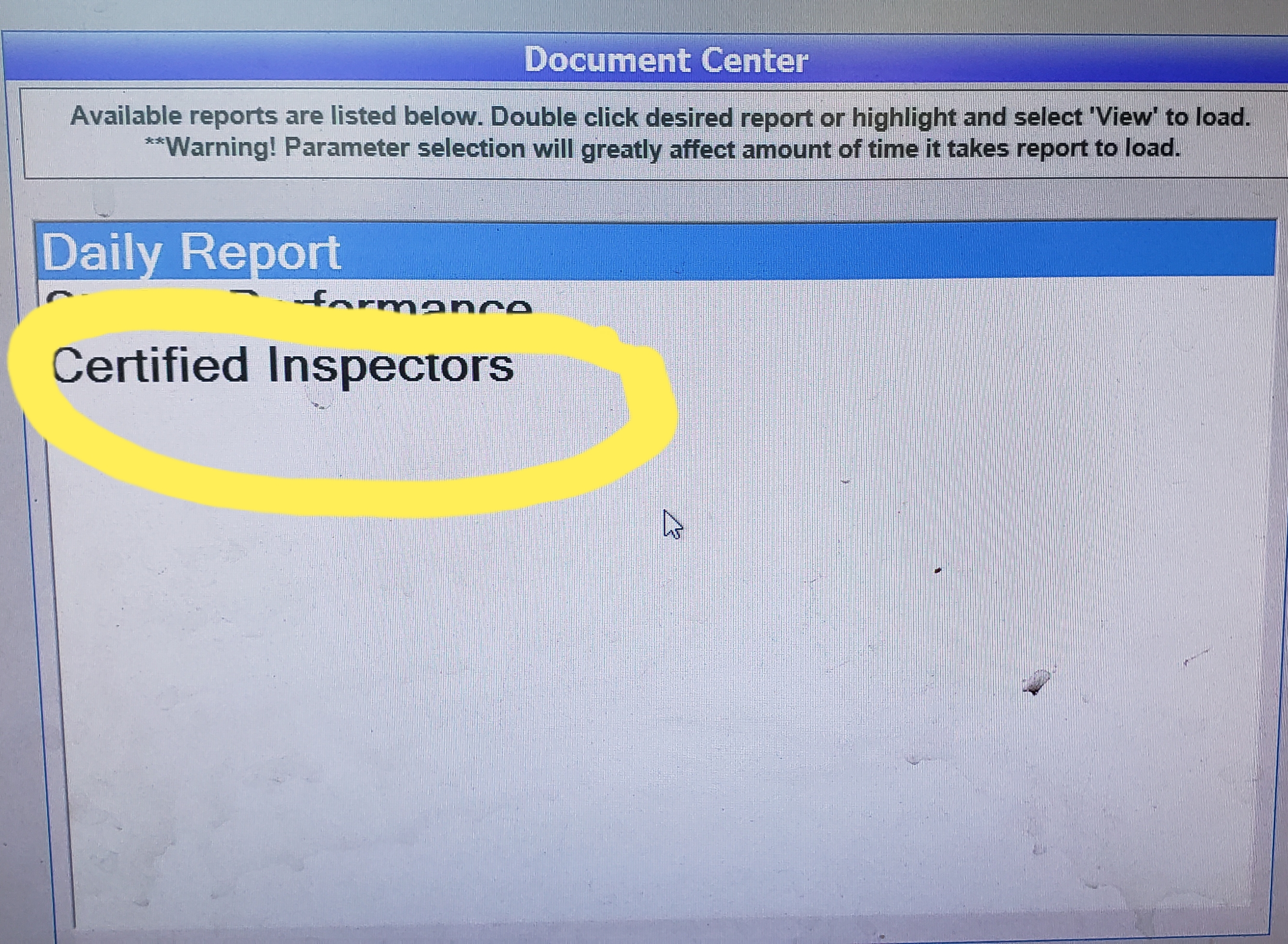

- Reference to Print NYS Inspectors

-

Is Compliance Board up to Date?

-

Does the dealership post a sign regarding CHILD SAFETY SEATS for rental vehicles stating "NYS law requires all children under age of 4 to be restrained in a federally approved child safety seat", as required by NYS DMV? (State)

-

Is the NYS Inspectors list up to date?

-

Is Compliance Board up to Date?

-

Does the dealership have NYS DEC permit displayed?

-

Does the dealership post a sign regarding CHILD SAFETY SEATS for rental vehicles stating "NYS law requires all children under age of 4 to be restrained in a federally approved child safety seat", as required by NYS DMV? (State)

-

Is the NYS Inspectors list up to date?

-

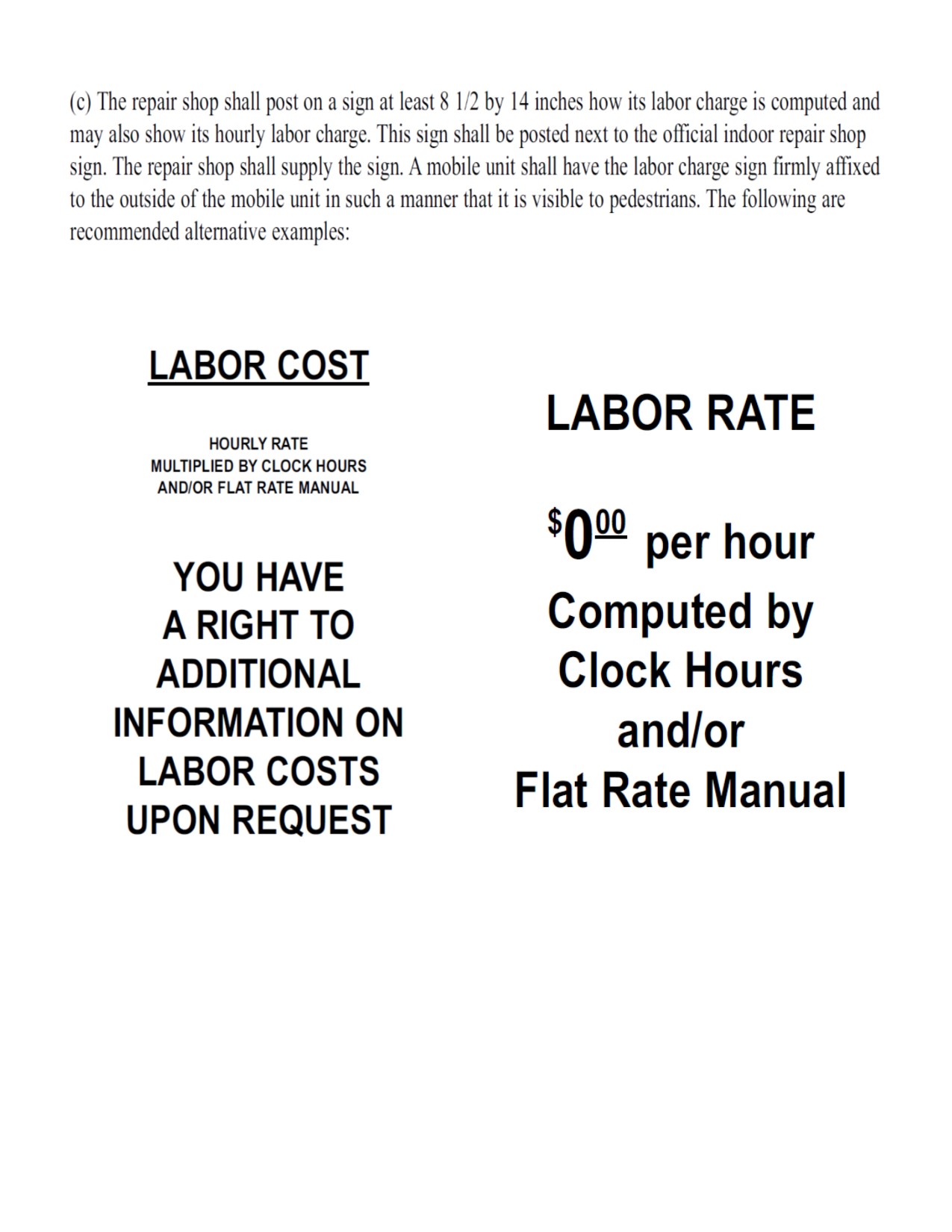

Does the dealership post on a sign at least 8 1/2 x 14 inches how its labor charge is computed? DMV(82.7c) (State)

-

Does the dealership have a Tax Certificate posted? DTF-17-A

-

Does the dealership have all required Business Certificates posted (MV dealer, MV inspection , MV repair shop)

-

Does the Dealership have a Official Indoor Repair Sign posted indoors, as required by NYS DMV (VS-47,82.7(a)) (State)

-

Does the dealership post a sign regarding Vehicle Inspection Violations, as required by NYS DMV? (VS140) State)

-

Does the dealership have an INSPECTION GROUPS AND FEE CHART sign posted as required NYS DMV? (VS-77) (State)

-

Is the NYS Inspectors list up to date?

-

Inspection Groups and Fee Chart

https://dmv.ny.gov/forms/vs77.pdf -

Does the dealership post the NYS WASTE TIRE MANAGEMENT FEE sign? (State)

-

Does the dealership have NYS DEC permit displayed?

-

Does the dealership post a sign stating " We Accept Used Oil For Recycling At No Charge" (State)

-

Does the dealership post a sign with "UNIVERSAL RECYCLING SYMBOL REGARDING VEHICLE BATTERY RECYCLING" stating " its illegal to discard vehicle batteries. State requires us to accept vehicle batteries at no charge for recycling" as required by NYS law? ( State)

-

Does the dealership post a sign regarding CHILD SAFETY SEATS for rental vehicles stating "NYS law requires all children under age of 4 to be restrained in a federally approved child safety seat", as required by NYS DMV? (State)

-

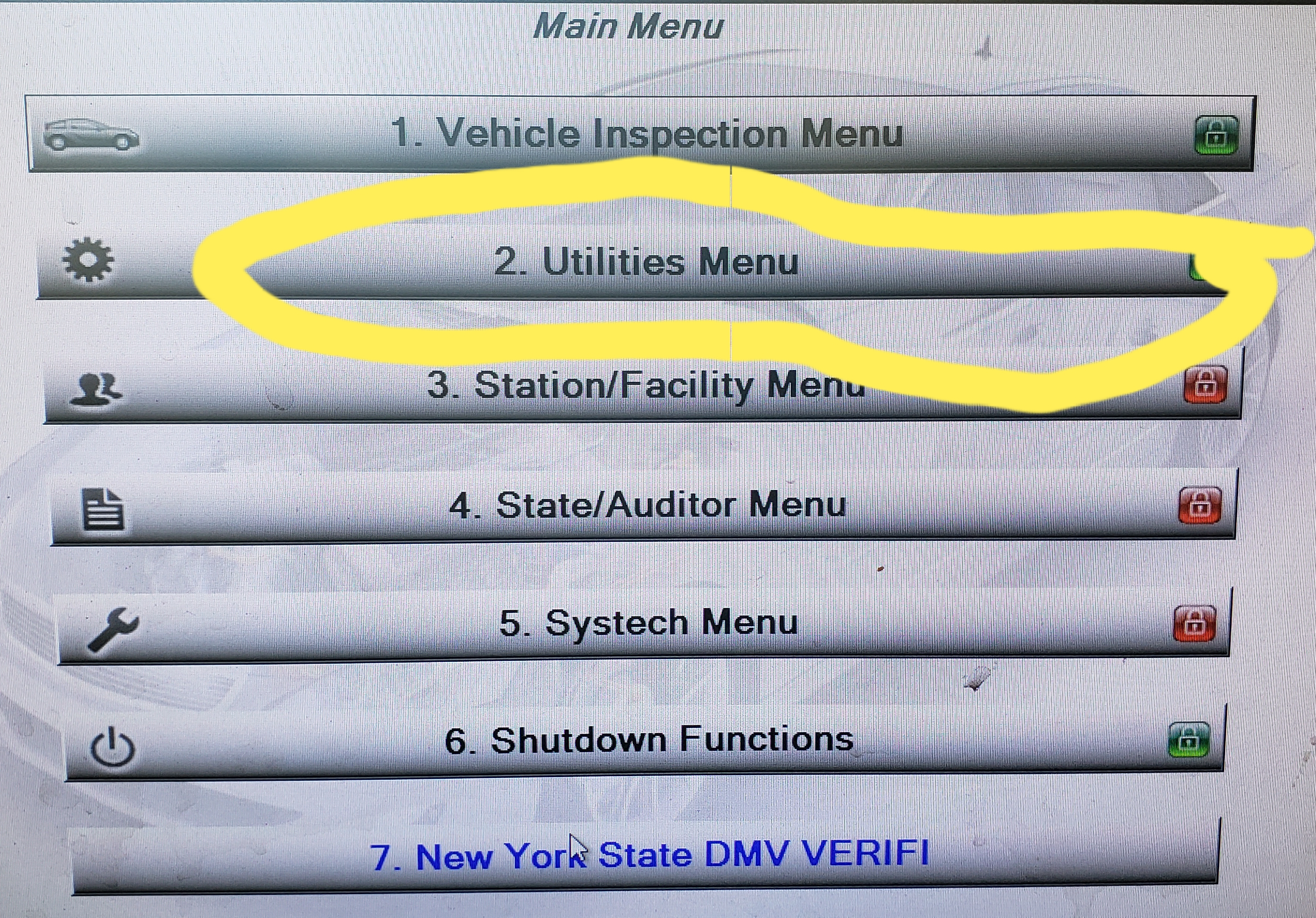

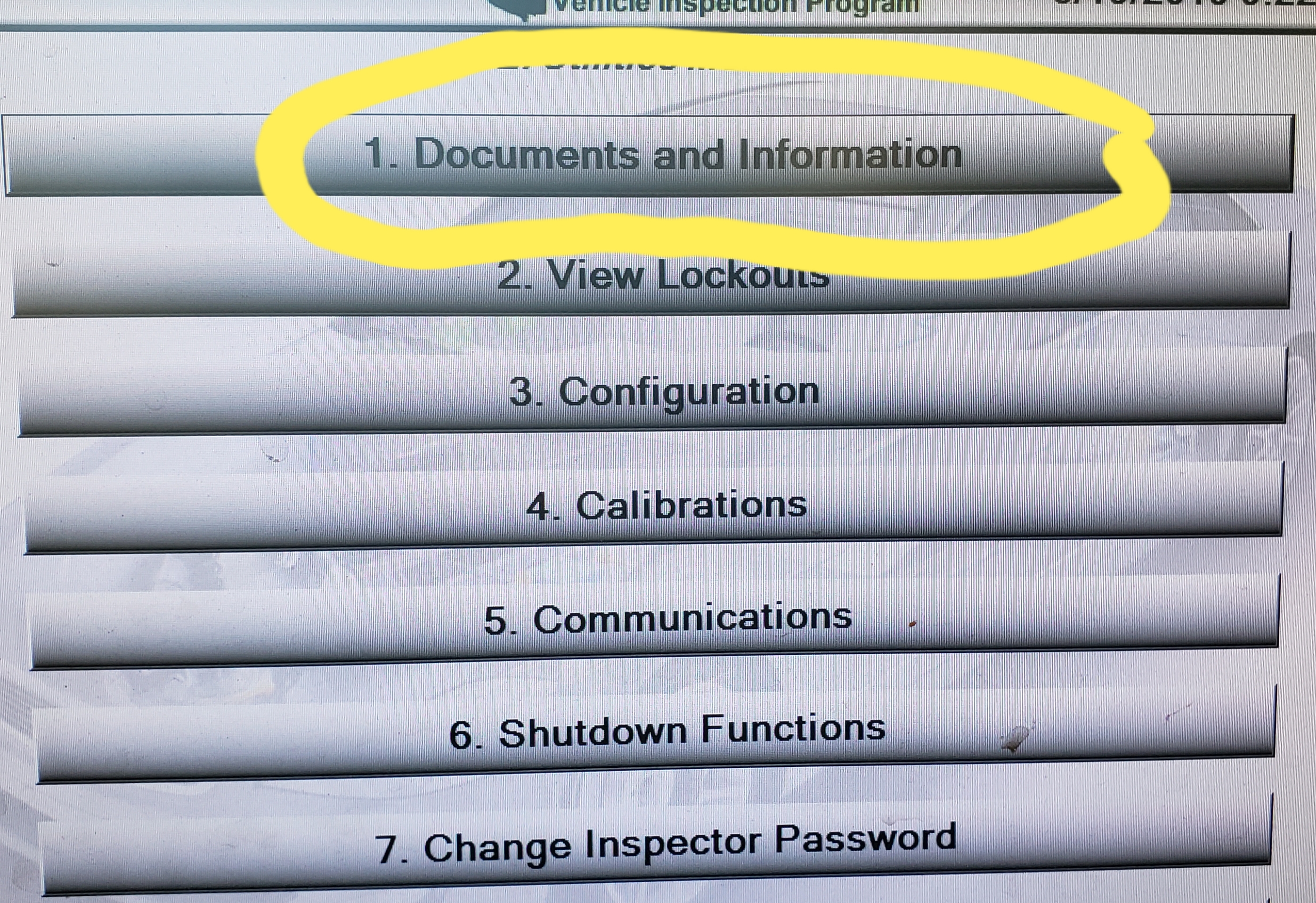

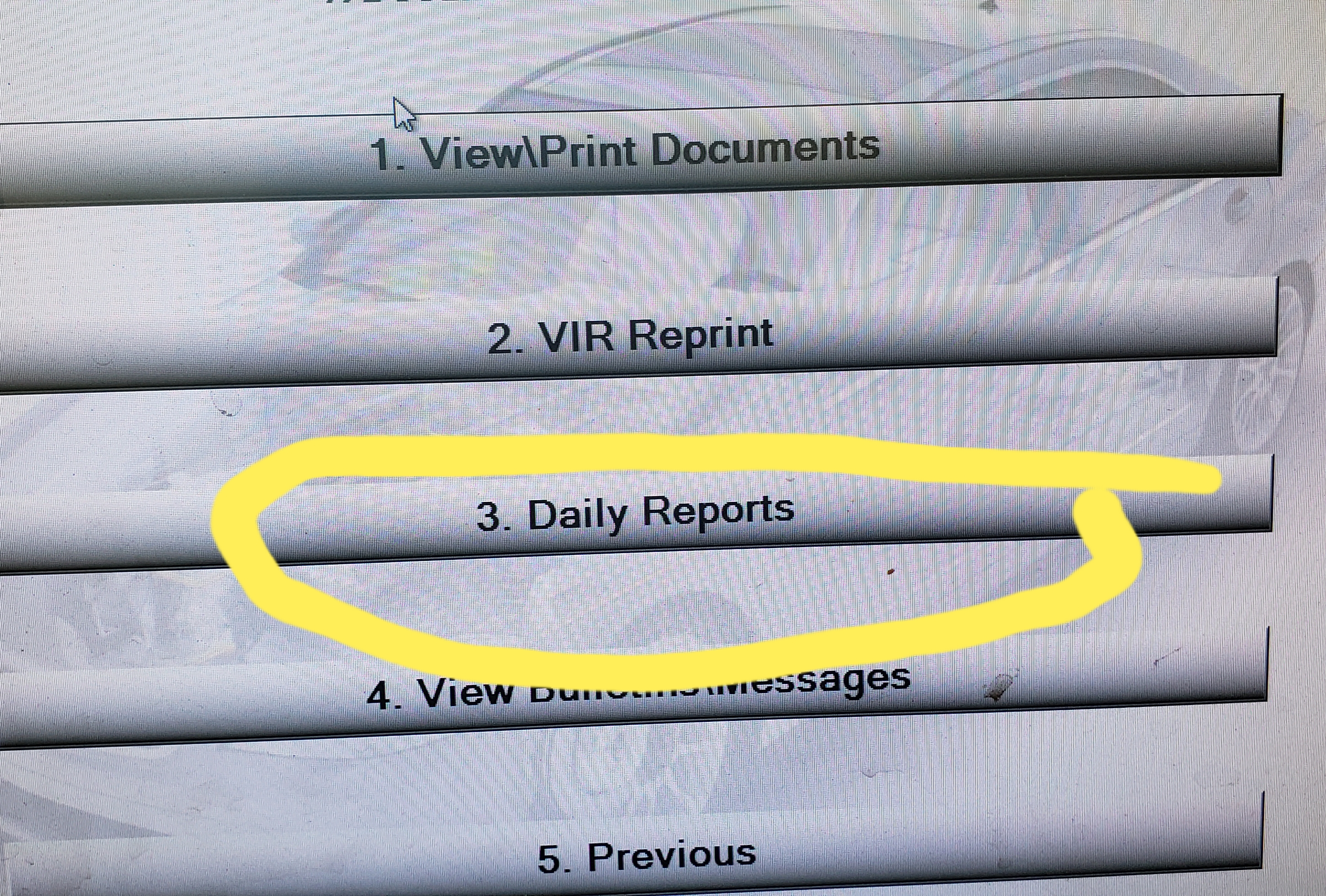

labor Rate

-

Main menu Step 1

-

Step 2

-

Step 3

-

Step 4

Collision

-

Check if you have a Collision Center

Estimating Area

-

Does the dealership post an official pink Appraisal Repair Shop sign?

-

Appraisal Sign

https://dmv.ny.gov/forms/vs47a.pdf -

Does the dealership post its labor rate specifying how it computes its LABOR CHARGE and is the sign at least 8.5x14 inches, as required by NYS law? NYS DMV (82.7c)

-

If the dealership operates an auto body shop and generates over 25 gallons of paint waste per month, is the facility properly registered?

-

Does each person who writes body shop estimates posses a VALID ESTIMATOR'S LICENSE, as required by NYS DMV?

-

Comments

Service Area

-

Are all ASTs/USTs properly labeled? (Waste - Purple Square) (State)

Required State and Federal HR Posters

NYS Posters

-

#1 Does the Dealership have The NYS Right to Know Poster posted as required by NYS.

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Right to Know Poster

https://www.health.ny.gov/environmental/workplace/right_to_know/docs/rtk.pdf -

#2 Discrimination sign BASED ON AGE, RACE, CREED, COLOR, NATIONAL ORGIN, SEXUAL ORIENTATION, MILITARY STATUS, SEX, DISABILITY OR MARITAL STATUS IS PROHIBITED, as required by the NYS Division of Human Rights? (DOHR 1990)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Discrimination Poster

http://www.dhr.ny.gov/sites/default/files/doc/poster.pdf -

#3 Does the dealership post a sign regarding MINIMUM WAGE INFORMATION, as required by the NYS DOL? (LS207) Curent Rate PER HOUR.

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Minimum Wage Poster NYS

https://www.labor.ny.gov/formsdocs/wp/LS207.pdf -

#4 Does the dealership post the NEW YORK CORRECTIONS Law Article 23-A?

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

NYS Corrections Laws

https://labor.ny.gov/formsdocs/wp/correction-law-article-23a.pdf -

#5 If the dealership employs minors, does it maintain and post a schedule of those MINOR EMPLOYEES' PERMISSIBLE WORK HOURS, LUNCH AND BREAKS, in accordance with the NYS DOL?

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Minor Employee Law

https://labor.ny.gov/formsdocs/wp/LS171.pdf

Dealer Specific Posters

-

Does the dealership have the PAID FAMILY LEAVE FOR EMPLOYEES poster as required by NYS. (PFL120)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Paid Family Leave Poster

https://www.ny.gov/sites/ny.gov/files/atoms/files/PFL120_NoticeOfCompliance.pdf -

Does the dealership post a WORKERS' COMPENSATION NOTICE OF EMPLOYEE RIGHTS? (C-105)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Sample of Workers Compensation Notice of Employee a Rights Poster

http://www.nyc.gov/html/dcla/downloads/pdf/cdf_sample_workerscomp_c_105_2.pdf -

Does the dealership post a notice regarding DISABILITY RIGHTS, as required by NYS Disability Insurance Law? (DB-120)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Sample of Disability Rights Poster (need form)

-

Does the dealership post a Sexual Harassment Prevention Policy Notice? (optional)

- Yes

- Replace (Missing Document)

- Updated Document

- N/A

- Reference

- No

- Missing

-

Sample of Sexual Harassment Prevention Policy Notice

https://www.ny.gov/sites/ny.gov/files/atoms/files/sexualharassmentpreventionposter_English_handfill.pdf -

Does the dealership post a sign regarding UNEMPLOYMENT INSURANCE BENEFITS, as required by NYS DOL? (IA133)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Sample of Unemployment Insurance Poster

https://labor.ny.gov/workerprotection/publicwork/PDFs/unemployment_insurance[1][1].pdf

Federal Posters

-

#6 Does the dealership have the JOB SAFETY & HEALTH PROTECTION SIGN posted, as required by OSHA? (OSHA 2203)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

OSHA Safety and Health IT'S THE LAW! Poster 8 1/2 x 14 approved

https://www.osha.gov/Publications/osha3165.pdf -

#7 Does the dealership have the FEDERAL MINIMUM WAGE SIGN posted, as required by the Labor Department? (Labor 1088)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Federal wage poster

https://www.dol.gov/whd/regs/compliance/posters/minwagep.pdf -

#8 Does the dealership have the EMPLOYEE POLYGRAPH PROTECTION ACT sign posted, as required by the Labor Department? (Labor 1462)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Employee Polygraph Protection Act Poster

https://www.dol.gov/whd/regs/compliance/posters/eppac.pdf -

#9 Does the dealership have a sign posted regarding the EQUAL EMPLOYMENT OPPORTUNITY LAW, as required by the Equal Employment Opportunity Commission? (EEOC 11/09)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Equal Employment Opportunity Law Poster

https://www.eeoc.gov/employers/upload/eeoc_self_print_poster.pdf -

#10 Does the dealership have the FAMILY AND MEDICAL LEAVE ACT requirements posted? (Department of Labor- over 50 employees within 75 miles)

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Family and Medical Leave Act Poster

https://www.dol.gov/whd/regs/compliance/posters/fmlaen.pdf -

#12 Does the dealership post the UNIFORMED SERVICES EMPLOYMENT AND REEMPLOYMENT RIGHTS ACT (USERRA)?

- Yes

- Replaced (Missing Document)

- Updated Document

- Reference

- No

- Expired

-

Uniformed Services Employment and Reemployment Rights Act Poster.

http://www.dol.gov/vets/programs/userra/USERRA_Private.pdf

Showroom

-

Does the dealership post WARRANTY PROVISIONS ON USED CARS, as required by Federal Trade Commission?

-

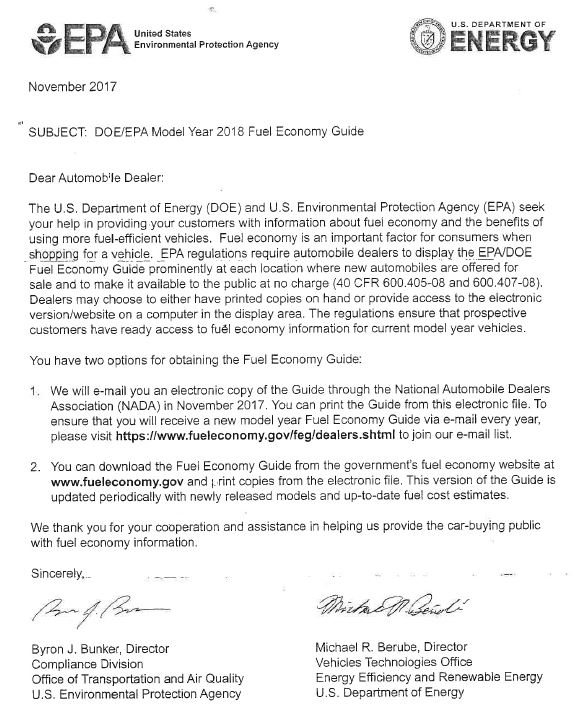

Do the dealership's customers have access to EPA MILEAGE GUIDES, in the showroom, as required by EPA?

-

EPA mileage guide

https://fueleconomy.gov/feg/dealers.shtml

Showroom

-

Check the box if you have a Showroom

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

Fire Safety

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

Floor

-

Are floor mats in place at all entrances?

-

Are they of sufficient length to accommodate at least 4 strides (2 steps for each foot)

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

- Yes

- No

- N/A

-

Does the department avoid daisy chaining extension cords/power strips?

-

Are ground fault circuit interrupters (GFCI) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

Other Location

-

Check the box if you have a Other Location

-

Location Name

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

Fire Safety

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

Floor

-

Are floor mats in place at all entrances?

-

Are they of sufficient length to accommodate at least 4 strides (2 steps for each foot)

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Are ground fault circuit interrupters (GFCI) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

-

Office

-

Check the box if you have an Office

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are floor mats in place at all entrances?

-

Are they of sufficient length to accommodate at least 4 strides (2 steps for each foot)

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

Fire Safety

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground fault circuit interrupters (GFCI) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

Service Writeup/Drive-lane

-

Check the box if you have a Service Writeup/Drive-lane

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are floor mats in place at all entrances?

-

Are they of sufficient length to accommodate at least 4 strides (2 steps for each foot)

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

Fire

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

- Yes

- No

- N/A

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground fault interrupters (GFCI's) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Is there a circuit panel box in this department?

-

Are all Panels Labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

Service Department

-

Check the box if you have a Service Department

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latched?

-

Are floor mats in place at all entrances?

-

Are they of sufficient length to accommodate at least 4 strides (2 steps for each foot)

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

FIRE SAFETY

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

-

Is there a "no smoking" sign posted on all portable battery chargers? (29 CFR 1910.178 (g) (10)

-

Will covers for flammable parts cleaning tanks (dip tanks, parts washer tanks) close automatically in a fire? if they are non flammable, please mark N/A (29 CFR 1910.108)

-

Are open flames and spark-producing equipment such as bench grinders kept away from flammable dip tanks? (29 CFR 1910.38)

-

Are oily, used rags properly stored in closed, non-flammable containers and properly disposed of or recycled by a laundry service? (DEC; fire regulaions)

-

Is gasoline stored in a approved metal safety can and properly labeled? (gasoline/flammable)

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

- Yes

- No

- N/A

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground circuit fault interrupters (GFICI's) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

PHYSICAL, SANITATION & HEALTH HAZARDS

-

Does the department prohibit the use of food preparation equipment (microwaves, coffee pots, toasters)?

-

Osha Standard1910.141(g)(2)

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.141 -

Standard Intepreatation

https://www.osha.gov/laws-regs/standardinterpretations/2009-12-03 -

Is food waste removed so to eliminate health hazards? (29 CFR 1910.141)

-

Does the department properly maintain and use the exhaust system to prevent the build-up of exhaust? (29 CFR 1910.1000)

-

Are all drain grates/floor openings (exhaust holes) in good condition? (29 CFR 1910.23)

-

If the dealership has open pits, does it have guards or rails around the open pit? (29 CFR 1910.22)

-

Are spilled materials cleaned up immediately?

-

Are the floors as dry as possible? (29 CFR 1910.22 (a)(2)

-

Are any fans that are within seven feet of floor totally enclosed? (29 CFR 1910.212)

-

Does the department maintain work areas and aisles free from trip hazards? (29 CFR 1910.176)

-

Are lights which may be hit, encased in protective shields or otherwise guarded to prevent breakage? (29 CFR 1910.303)

-

If the dealership conducts chemical rust proofing, does it provide proper ventilation and isolation from other areas/workers (curtain)? (29 CFR 1910.107)

-

Are bathrooms kept in a sanitary condition? (29 CFR 1910.141)

-

Are all containers of hazardous chemicals properly (29CFR 1910.1200 (f) (5) (i) )<br>Secondary units must be identified with the GHS label.

-

If employees use compressed air for cleaning parts or equipment, do they reduce compressed air to less than 30 PSI for cleaning parts or equipment? <br>NOTE; Compressed air should not be used to clean clothing, (29 CFR 1910.242)

-

Are shop reels installed or are hoses properly stored and kept out of aisles when not in use?

-

Are air hoses in good condition and not repaired with hose clamps, but with proper repair kit?<br>Air hose repair kit are available from NFADA or NAPA

-

(29 CFR 11910.243(b)(2) air hose. Hose and hose connections used for conducting compressed air to utilization equipment shall be designed for the pressure and service to which they are subjected.

Repair kit available NFADA (631-8510) part numbers 1699020002/1699021001 -

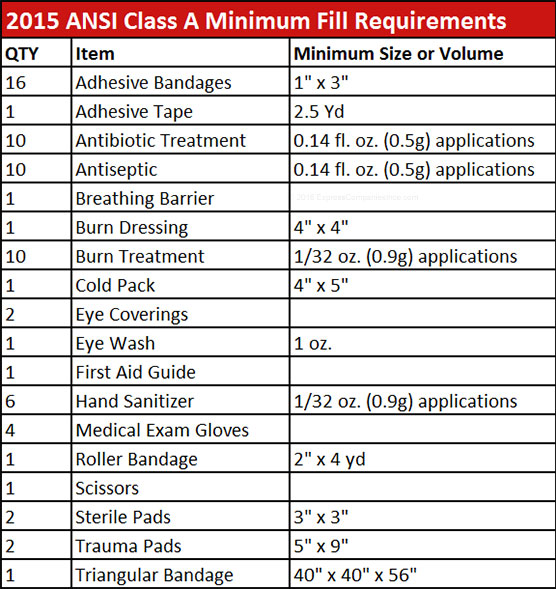

PERSONAL PROTECTIVE EQUIPMENT AND FIRST AID

-

Does the department provide personal protective equipment (e.g., googles, face shields, gloves, hearing protection) to all employees and is it kept in sanitary condition? (29 CFR 1910.132 (e))

-

Are eyewash units located within 55 feet of a potential hazard, and/or installed within 10 seconds of a hazard providing 15 minutes of a continuous flow of water? (29 CFR 1910.151 and ANSI Z358.1-2014)<br>

-

Does unit have unobstructed travel path?

-

Type of unit?

-

Is the unit full, clean, accessible, fluid changed when required by Manufacturer and documented?

-

Is clean, accessible and flushed weekly?<br>Water temp 60-100 degrees

GAS CYLINDERS/TORCHES

-

Do torches have a Flashback Arrestor (i.e., flash guard, or check valve)? (29 CFR 1910.253)

-

sample of Flashback Arrestor

https://static1.squarespace.com/static/510dbdc1e4b037c811a42c5a/t/548f3f3ae4b0273e692911dd/1418673982449/ -

Are they chained to a cart when moved? (29 CFR 1910.253(b) (2) (ii))

-

Are cylinders legibly marked? (29 CFR 1910.101)

-

Are torch gauges in good working condition?

-

Do the cylinders: (1) require a special wrench for each acetylene cylinder in order to quickly turn it off in event of an emergency, and (2) keep one on each cylinder? (29 CFR 1910.252)

-

Does the dealership store extra gas cylinders on-site

-

If the dealership stores extra gas cylinders on-site, do they meet all the following standards:

-

Chaining gas cylinders to a stationary object when they are not in use. (29 CFR 1910.253 (b) (2) (ii) )<br>

-

Storing them away from elevators, stairs, doors, doorways or anywhere they could be knocked over or damaged (falling objects)? (29 CFR 1910.253 (b) (2) (ii) )

-

Storing oxygen away from flammables (oil, grease or fuel gas) by at least 20 feet. (29 CFR 1910.253 (b) (4) (i) )

-

Store extra oxygen and acetylene gas cylinders at least 20 feet apart from one another (unless separated by non-combustible barrier at least 5 feet high? (29 CFR 1910.253)

MACHINES & EQUIPMENT

-

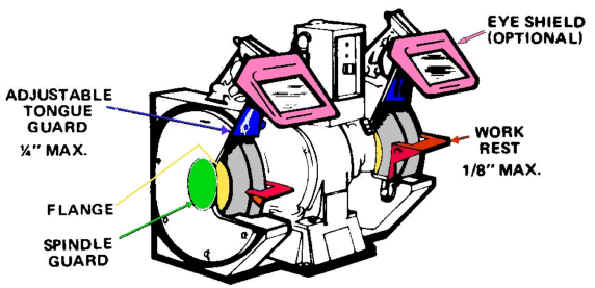

Does the dealership have a bench grinder?

-

OSHA website for reference

https://www.osha.gov/SLTC/machineguarding/new-grinder-checklist.html -

Bench Grinder

-

Is there a properly aligned and fastened with a tongue guard adjusted to within 1/4 inch of wheel, for each abrasive wheel of bench grinder?

-

Do you have a tool rest (i.e. work rest) for each abrasive wheel, and is each tool rest no more than 1/8 inch from each wheel?

-

Is each bench grinder properly grounded with a three prong plug?

-

Is each bench grinder securely attached and stable?

-

Does the department post a sign requiring employees to wear goggles or face shields when grinding, and supply this PPE to ensure adequate face protection? (29 CFR 1910.215) <br>Note: if wearing face shield safety glasses are still required!

-

Does each jack or jack stand have its load rating legibly displayed? (29 CFR 1910.244 (a) (1) (ii))

-

After raising load, do employees use safety precautions to prevent slippage using a chain or strap? (29 CFR 1910.244 (a) (2) (iii))

-

Are safety devices on lifts in working condition and is the lift mechanism free of tampering? (Reference ALI and OSHA 5 (a)(1) General duty clause)

-

Do all lifts include, the manufacturer's name, model, serial number and load rate?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

Secondary Service Shop

-

Check the box if you have a Secondary Service Shop

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

FIRE SAFETY

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

-

Is there a "no smoking" sign posted on all portable battery chargers? (29 CFR 1910.178 (g) (10)

-

Will covers for flammable parts cleaning tanks (dip tanks, parts washer tanks) close automatically in a fire? if they are non flammable, please mark N/A (29 CFR 1910.108)

-

Are open flames and spark-producing equipment such as bench grinders kept away from flammable dip tanks? (29 CFR 1910.38)

-

Are oily, used rags properly stored in closed, non-flammable containers and properly disposed of or recycled by a laundry service? (DEC; fire regulaions)

-

Is gasoline stored in a approved metal safety can and properly labeled? (gasoline/flammable)

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

- Yes

- No

- N/A

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground circuit fault interrupters (GFICI's) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

PHYSICAL, SANITATION & HEALTH HAZARDS

-

Does the department prohibit the use of food preparation equipment (microwaves,coffee pots,toasters)?

-

Does the department properly maintain and use the exhaust system to prevent the build-up of exhaust? (29 CFR 1910.1000)

-

Are all exhaust holes or floor openings covered? (29 CFR 1910.23)

-

If the dealership has open pits, does it have guards or rails around the open pit? (29 CFR 1910.22)

-

Are spilled materials cleaned up immediately ?

-

Are the floors as dry as possible? (29 CFR 1910.22 (a)(2)

-

Are any fans that are within seven feet of floor totally enclosed? (29 CFR 1910.212)

-

Does the department maintain work areas and aisles free from trip hazards? (29 CFR 1910.176)

-

Is residue and debris disposed of a timely manner? (29 CFR 1910.22)

-

Are lights which may be hit, encased in protective shields or otherwise guarded to prevent breakage? (29 CFR 1910.303)

-

If the dealership conducts chemical rust proofing, does it provide proper ventilation and isolation from other areas/workers (curtain)? (29 CFR 1910.107)

-

Is food waste removed so to eliminate health hazards? (29 CFR 1910.141)

-

Are bathrooms kept in a sanitary condition? (29 CFR 1910.141)

-

Are all containers of hazardous chemicals properly (29CFR 1910.1200 (f) (5) (i) )<br>Secondary units must be identified with name of product and target organ, and hazard warning

-

If employees use compressed air for cleaning parts or equipment, do they reduce compressed air to less than 30 PSI dor cleaning parts or equipment? <br>NOTE; Compressed air should not be used to clean clothing, (29 CFR 1910.242)

-

Are shop reels installed and properly positioned to keep cords and hoses off the shop floors?

-

Are air hoses in good condition and not repaired with hose clamps,but with proper repair kit?<br>Air hose repair kit are available from NFADA or NAPA

-

(29 CFR 11910.243(b)(2) air hose. Hose and hose connections used for conducting compressed air to utilization equipment shall be designed for the pressure and service to which they are subjected.

Repair kit available NFADA (631-8510) part numbers 1699020002/1699021001 -

PERSONAL PROTECTIVE EQUIPMENT AND FIRST AID

-

Does the department provide personal protective equipment (e.g., googles,face shields gloves,hearing protection) to all employees and is it kept in sanitary condition? (29 CFR 1910.132 (e))

-

Are eyewash units located within 55 feet of a potential hazard site, and/or installed within 10 seconds of a hazard providing 15 minutes of a continuous flow of water? (29 CFR 1910.151 and ANSI Z358.1-2009))<br>

-

Does unit have unobstructed travel path?

-

Type of unit?

-

Is the unit full, clean, accessible, fluid changed when required by manufacturer and documented?

-

Is clean, accessible and flushed weekly?<br>Water temp 60-100 degrees

GAS CYLINDERS/TORCHES

-

Do torches have a Flashback Arrestor (i.e., flash guard, or check valve)? (29 CFR 1910.253)

-

sample of Flashback Arrestor

https://static1.squarespace.com/static/510dbdc1e4b037c811a42c5a/t/548f3f3ae4b0273e692911dd/1418673982449/ -

Are they chained to a cart when moved? (29 CFR 1910.253(b) (2) (ii))

-

Are cylinders legibly marked? (29 CFR 1910.101)

-

Are torch gauges in good working condition?

-

Do the cylinders: (1) require a special wrench for each acetylene cylinder in order to quickly turn it off in event of an emergency, and (2) keep one on each cylinder? (29 CFR 1910.252)

-

Does the dealership store extra gas cylinders on-site

-

If the dealership stores extra gas cylinders on-site, do they meet all the following standards:

-

Chaining gas cylinders to a stationary object when they are not in use. (29 CFR 1910.253 (b) (2) (ii) )<br>

-

Storing them away from elevators, stairs, doors, doorways or anywhere they could be knocked over or damaged (falling objects)? (29 CFR 1910.253 (b) (2) (ii) )

-

Storing them away from flammables (oil, grease, or fuel gas) by at least 20 feet. (29 CFR 1910.253 (b) (4) (i) )

-

Store extra oxygen and acetylene gas cylinders at least 20 feet apart from one another (unless separated by non-combustible barrier at least 5 feet high? (29 CFR 1910.253)

MACHINES & EQUIPMENT

-

Does the dealership have bench grinder?

-

OSHA website for reference

https://www.osha.gov/SLTC/machineguarding/new-grinder-checklist.html -

Bench Grinder

-

Is there a properly aligned and fastened with a tongue guard adjusted to within 1/4 inch of wheel, for each abrasive wheel of bench grinder?

-

Do you have a tool rest (i.e. work rest) for each abrasive wheel, and is each tool rest no more than 1/8 inch from each wheel?

-

Is each bench grinder properly grounded with a three prong plug?

-

Is each bench grinder securely attached and stable?

-

Does the department post a sign requiring employees to wear goggles or face shields when grinding, and supply this PPE to ensure adequate face protection? (29 CFR 1910.215) <br>Note: if wearing face shield safety glasses are still required!

-

Does each jack or jack stand have its load rating legibly displayed? (29 CFR 1910.244 (a) (1) (ii))

-

After raising load, do employees use safety precautions to prevent slippage using a chain or strap? (29 CFR 1910.244 (a) (2) (iii))

-

Are safety devices on lifts in working condition and is the lift mechanism free of tampering? (Reference ALI and OSHA 5 (a),(1) General duty clause)

-

Do all lifts include, the manufacturer's name, model, serial number and load rate?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

QuickLane Shop

-

Check the box if you have a Quicklane Shop

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

FIRE SAFETY

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

-

Is there a "no smoking" sign posted on all portable battery chargers? (29 CFR 1910.178 (g) (10)

-

Will covers for flammable parts cleaning tanks (dip tanks, parts washer tanks) close automatically in a fire? if they are non flammable, please mark N/A (29 CFR 1910.108)

-

Are open flames and spark-producing equipment such as bench grinders kept away from flammable dip tanks? (29 CFR 1910.38)

-

Are oily, used rags properly stored in closed, non-flammable containers and properly disposed of or recycled by a laundry service? (DEC; fire regulaions)

-

Is gasoline stored in a approved metal safety can and properly labeled? (gasoline/flammable)

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground circuit fault interrupters (GFICI's) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

PHYSICAL, SANITATION & HEALTH HAZARDS

-

Does the department prohibit the use of food preparation equipment (microwaves,coffee pots,toasters)?

-

Does the department properly maintain and use the exhaust system to prevent the build-up of exhaust? (29 CFR 1910.1000)

-

Are all exhaust holes or floor openings covered? (29 CFR 1910.23)

-

If the dealership has open pits, does it have guards or rails around the open pit? (29 CFR 1910.22)

-

Are spilled materials cleaned up immediately ?

-

Are the floors as dry as possible? (29 CFR 1910.22 (a)(2)

-

Are any fans that are within seven feet of floor totally enclosed? (29 CFR 1910.212)

-

Does the department maintain work areas and aisles free from trip hazards? (29 CFR 1910.176)

-

Is residue and debris disposed of a timely manner? (29 CFR 1910.22)

-

Are lights which may be hit, encased in protective shields or otherwise guarded to prevent breakage? (29 CFR 1910.303)

-

If the dealership conducts chemical rust proofing, does it provide proper ventilation and isolation from other areas/workers (curtain)? (29 CFR 1910.107)

-

Is food waste removed so to eliminate health hazards? (29 CFR 1910.141)

-

Are bathrooms kept in a sanitary condition? (29 CFR 1910.141)

-

Are all containers of hazardous chemicals properly (29CFR 1910.1200 (f) (5) (i) )<br>Secondary units must be identified with name of product and target organ, and hazard warning

-

If employees use compressed air for cleaning parts or equipment, do they reduce compressed air to less than 30 PSI dor cleaning parts or equipment? <br>NOTE; Compressed air should not be used to clean clothing, (29 CFR 1910.242)

-

Are shop reels installed and properly positioned to keep cords and hoses off the shop floors?

-

Are air hoses in good condition and not repaired with hose clamps,but with proper repair kit?<br>Air hose repair kit are available from NFADA or NAPA

-

(29 CFR 11910.243(b)(2) air hose. Hose and hose connections used for conducting compressed air to utilization equipment shall be designed for the pressure and service to which they are subjected.

Repair kit available NFADA (631-8510) part numbers 1699020002/1699021001 -

PERSONAL PROTECTIVE EQUIPMENT AND FIRST AID

-

Does the department provide personal protective equipment (e.g., googles,face shields gloves,hearing protection) to all employees and is it kept in sanitary condition? (29 CFR 1910.132 (e))

-

Are eyewash units located within 55 feet of a potential hazard site, and/or installed within 10 seconds of a hazard providing 15 minutes of a continuous flow of water? (29 CFR 1910.151 and ANSI Z358.1-2009))<br>

-

Does unit have unobstructed travel path?

-

Type of unit?

-

Is the unit full, clean, accessible, fluid changed when required by Manufacturer and documented?

-

Is clean, accessible and flushed weekly?<br>Water temp 60-100 degrees

GAS CYLINDERS/TORCHES

-

Do torches have a Flashback Arrestor (i.e., flash guard, or check valve)? (29 CFR 1910.253)

-

sample of Flashback Arrestor

https://static1.squarespace.com/static/510dbdc1e4b037c811a42c5a/t/548f3f3ae4b0273e692911dd/1418673982449/ -

Are they chained to a cart when moved? (29 CFR 1910.253(b) (2) (ii))

-

Are cylinders legibly marked? (29 CFR 1910.101)

-

Are torch gauges in good working condition?

-

Do the cylinders: (1) require a special wrench for each acetylene cylinder in order to quickly turn it off in event of an emergency, and (2) keep one on each cylinder? (29 CFR 1910.252)

-

Does the dealership store extra gas cylinders on-site

-

If the dealership stores extra gas cylinders on-site, do they meet all the following standards:

-

Chaining gas cylinders to a stationary object when they are not in use. (29 CFR 1910.253 (b) (2) (ii) )<br>

-

Storing them away from elevators, stairs, doors, doorways or anywhere they could be knocked over or damaged (falling objects)? (29 CFR 1910.253 (b) (2) (ii) )

-

Storing them away from flammables (oil, grease, or fuel gas) by at least 20 feet. (29 CFR 1910.253 (b) (4) (i) )

-

Store extra oxygen and acetylene gas cylinders at least 20 feet apart from one another (unless separated by non-combustible barrier at least 5 feet high? (29 CFR 1910.253)

MACHINES & EQUIPMENT

-

Does the dealership have bench grinder?

-

OSHA website for reference

https://www.osha.gov/SLTC/machineguarding/new-grinder-checklist.html -

Bench Grinder

-

Is there a properly aligned and fastened with a tongue guard adjusted to within 1/4 inch of wheel, for each abrasive wheel of bench grinder?

-

Do you have a tool rest (i.e. work rest) for each abrasive wheel, and is each tool rest no more than 1/8 inch from each wheel?

-

Is each bench grinder properly grounded with a three prong plug?

-

Is each bench grinder securely attached and stable?

-

Does the department post a sign requiring employees to wear goggles or face shields when grinding, and supply this PPE to ensure adequate face protection? (29 CFR 1910.215) <br>Note: if wearing face shield safety glasses are still required!

-

Does each jack or jack stand have its load rating legibly displayed? (29 CFR 1910.244 (a) (1) (ii))

-

After raising load, do employees use safety precautions to prevent slippage using a chain or strap? (29 CFR 1910.244 (a) (2) (iii))

-

Are safety devices on lifts in working condition and is the lift mechanism free of tampering? (Reference ALI and OSHA 5 (a),(1) General duty clause)

-

Do all lifts include, the manufacturer's name, model, serial number and load rate?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

Truck Shop

-

Check the box if you have a Truck Shop

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

FIRE SAFETY

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

-

Is there a "no smoking" sign posted on all portable battery chargers? (29 CFR 1910.178 (g) (10)

-

Will covers for flammable parts cleaning tanks (dip tanks, parts washer tanks) close automatically in a fire? if they are non flammable, please mark N/A (29 CFR 1910.108)

-

Are open flames and spark-producing equipment such as bench grinders kept away from flammable dip tanks? (29 CFR 1910.38)

-

Are oily, used rags properly stored in closed, non-flammable containers and properly disposed of or recycled by a laundry service? (DEC; fire regulaions)

-

Is gasoline stored in a approved metal safety can and properly labeled? (gasoline/flammable)

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground circuit fault interrupters (GFICI's) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

PHYSICAL, SANITATION & HEALTH HAZARDS

-

Does the department prohibit the use of food preparation equipment (microwaves,coffee pots,toasters)?

-

Does the department properly maintain and use the exhaust system to prevent the build-up of exhaust? (29 CFR 1910.1000)

-

Are all exhaust holes or floor openings covered? (29 CFR 1910.23)

-

If the dealership has open pits, does it have guards or rails around the open pit? (29 CFR 1910.22)

-

Are spilled materials cleaned up immediately ?

-

Are the floors as dry as possible? (29 CFR 1910.22 (a)(2)

-

Are any fans that are within seven feet of floor totally enclosed? (29 CFR 1910.212)

-

Does the department maintain work areas and aisles free from trip hazards? (29 CFR 1910.176)

-

Is residue and debris disposed of a timely manner? (29 CFR 1910.22)

-

Are lights which may be hit, encased in protective shields or otherwise guarded to prevent breakage? (29 CFR 1910.303)

-

If the dealership conducts chemical rust proofing, does it provide proper ventilation and isolation from other areas/workers (curtain)? (29 CFR 1910.107)

-

Is food waste removed so to eliminate health hazards? (29 CFR 1910.141)

-

Are bathrooms kept in a sanitary condition? (29 CFR 1910.141)

-

Are all containers of hazardous chemicals properly (29CFR 1910.1200 (f) (5) (i) )<br>Secondary units must be identified with name of product and target organ, and hazard warning

-

If employees use compressed air for cleaning parts or equipment, do they reduce compressed air to less than 30 PSI dor cleaning parts or equipment? <br>NOTE; Compressed air should not be used to clean clothing, (29 CFR 1910.242)

-

Are shop reels installed and properly positioned to keep cords and hoses off the shop floors?

-

Are air hoses in good condition and not repaired with hose clamps,but with proper repair kit?<br>Air hose repair kit are available from NFADA or NAPA

-

(29 CFR 11910.243(b)(2) air hose. Hose and hose connections used for conducting compressed air to utilization equipment shall be designed for the pressure and service to which they are subjected.

Repair kit available NFADA (631-8510) part numbers 1699020002/1699021001 -

PERSONAL PROTECTIVE EQUIPMENT AND FIRST AID

-

Does the department provide personal protective equipment (e.g., googles,face shields gloves,hearing protection) to all employees and is it kept in sanitary condition? (29 CFR 1910.132 (e))

-

Are eyewash units located within 55 feet of a potential hazard site, and/or installed within 10 seconds of a hazard providing 15 minutes of a continuous flow of water? (29 CFR 1910.151 and ANSI Z358.1-2009))<br>

-

Does unit have unobstructed travel path?

-

Type of unit?

-

Is the unit full, clean, accessible, fluid changed when required by Manufacturer and documented?

-

Is clean, accessible and flushed weekly?<br>Water temp 60-100 degrees

GAS CYLINDERS/TORCHES

-

Do torches have a Flashback Arrestor (i.e., flash guard, or check valve)? (29 CFR 1910.253)

-

sample of Flashback Arrestor

https://static1.squarespace.com/static/510dbdc1e4b037c811a42c5a/t/548f3f3ae4b0273e692911dd/1418673982449/ -

Are they chained to a cart when moved? (29 CFR 1910.253(b) (2) (ii))

-

Are cylinders legibly marked? (29 CFR 1910.101)

-

Are torch gauges in good working condition?

-

Do the cylinders: (1) require a special wrench for each acetylene cylinder in order to quickly turn it off in event of an emergency, and (2) keep one on each cylinder? (29 CFR 1910.252)

-

Does the dealership store extra gas cylinders on-site

-

If the dealership stores extra gas cylinders on-site, do they meet all the following standards:

-

Chaining gas cylinders to a stationary object when they are not in use. (29 CFR 1910.253 (b) (2) (ii) )<br>

-

Storing them away from elevators, stairs, doors, doorways or anywhere they could be knocked over or damaged (falling objects)? (29 CFR 1910.253 (b) (2) (ii) )

-

Storing them away from flammables (oil, grease, or fuel gas) by at least 20 feet. (29 CFR 1910.253 (b) (4) (i) )

-

Store extra oxygen and acetylene gas cylinders at least 20 feet apart from one another (unless separated by non-combustible barrier at least 5 feet high? (29 CFR 1910.253)

MACHINES & EQUIPMENT

-

Does the dealership have bench grinder?

-

OSHA website for reference

https://www.osha.gov/SLTC/machineguarding/new-grinder-checklist.html -

Bench Grinder

-

Is there a properly aligned and fastened with a tongue guard adjusted to within 1/4 inch of wheel, for each abrasive wheel of bench grinder?

-

Do you have a tool rest (i.e. work rest) for each abrasive wheel, and is each tool rest no more than 1/8 inch from each wheel?

-

Is each bench grinder properly grounded with a three prong plug?

-

Is each bench grinder securely attached and stable?

-

Does the department post a sign requiring employees to wear goggles or face shields when grinding, and supply this PPE to ensure adequate face protection? (29 CFR 1910.215) <br>Note: if wearing face shield safety glasses are still required!

-

Does each jack or jack stand have its load rating legibly displayed? (29 CFR 1910.244 (a) (1) (ii))

-

After raising load, do employees use safety precautions to prevent slippage using a chain or strap? (29 CFR 1910.244 (a) (2) (iii))

-

Are safety devices on lifts in working condition and is the lift mechanism free of tampering? (Reference ALI and OSHA 5 (a),(1) General duty clause)

-

Do all lifts include, the manufacturer's name, model, serial number and load rate?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

Other

-

Check the box if you have a Other Dept.

-

Department Name:

EXIT ROUTES (29 CFR 1910.37)

-

Are exit clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latched?

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

FIRE SAFETY

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

-

Is there a "no smoking" sign posted on all portable battery chargers? (29 CFR 1910.178 (g) (10)

-

Will covers for flammable parts cleaning tanks (dip tanks, parts washer tanks) close automatically in a fire? if they are non flammable, please mark N/A (29 CFR 1910.108)

-

Are open flames and spark-producing equipment such as bench grinders kept away from flammable dip tanks? (29 CFR 1910.38)

-

Are oily, used rags properly stored in closed, non-flammable containers and properly disposed of or recycled by a laundry service? (DEC; fire regulaions)

-

Is gasoline stored in a approved metal safety can and properly labeled? (gasoline/flammable)

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground circuit fault interrupters (GFICI's) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

PHYSICAL, SANITATION & HEALTH HAZARDS

-

Does the department prohibit the use of food preparation equipment (microwaves, coffee pots, toasters)?

-

Osha Standard1910.141(g)(2)

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.141 -

Standard Intepreatation

https://www.osha.gov/laws-regs/standardinterpretations/2009-12-03 -

Is food waste removed so to eliminate health hazards? (29 CFR 1910.141)

-

Does the department properly maintain and use the exhaust system to prevent the build-up of exhaust? (29 CFR 1910.1000)

-

Are all drain grates/floor openings (exhaust holes) in good condition? (29 CFR 1910.23)

-

If the dealership has open pits, does it have guards or rails around the open pit? (29 CFR 1910.22)

-

Are spilled materials cleaned up immediately?

-

Are the floors as dry as possible? (29 CFR 1910.22 (a)(2)

-

Are any fans that are within seven feet of floor totally enclosed? (29 CFR 1910.212)

-

Does the department maintain work areas and aisles free from trip hazards? (29 CFR 1910.176)

-

Are lights which may be hit, encased in protective shields or otherwise guarded to prevent breakage? (29 CFR 1910.303)

-

If the dealership conducts chemical rust proofing, does it provide proper ventilation and isolation from other areas/workers (curtain)? (29 CFR 1910.107)

-

Are bathrooms kept in a sanitary condition? (29 CFR 1910.141)

-

Are all containers of hazardous chemicals properly (29CFR 1910.1200 (f) (5) (i) )<br>Secondary units must be identified with the GHS label.

-

If employees use compressed air for cleaning parts or equipment, do they reduce compressed air to less than 30 PSI for cleaning parts or equipment? <br>NOTE; Compressed air should not be used to clean clothing, (29 CFR 1910.242)

-

Are shop reels installed or are hoses properly stored and kept out of aisles when not in use?

-

Are air hoses in good condition and not repaired with hose clamps, but with proper repair kit?<br>Air hose repair kit are available from NFADA or NAPA

-

(29 CFR 11910.243(b)(2) air hose. Hose and hose connections used for conducting compressed air to utilization equipment shall be designed for the pressure and service to which they are subjected.

Repair kit available NFADA (631-8510) part numbers 1699020002/1699021001 -

PERSONAL PROTECTIVE EQUIPMENT AND FIRST AID

-

Does the department provide personal protective equipment (e.g., googles, face shields, gloves, hearing protection) to all employees and is it kept in sanitary condition? (29 CFR 1910.132 (e))

-

Are eyewash units located within 55 feet of a potential hazard, and/or installed within 10 seconds of a hazard providing 15 minutes of a continuous flow of water? (29 CFR 1910.151 and ANSI Z358.1-2014)<br>

-

Does unit have unobstructed travel path?

-

Type of unit?

-

Is the unit full, clean, accessible, fluid changed when required by Manufacturer and documented?

-

Is clean, accessible and flushed weekly?<br>Water temp 60-100 degrees

GAS CYLINDERS/TORCHES

-

Do torches have a Flashback Arrestor (i.e., flash guard, or check valve)? (29 CFR 1910.253)

-

sample of Flashback Arrestor

https://static1.squarespace.com/static/510dbdc1e4b037c811a42c5a/t/548f3f3ae4b0273e692911dd/1418673982449/ -

Are they chained to a cart when moved? (29 CFR 1910.253(b) (2) (ii))

-

Are cylinders legibly marked? (29 CFR 1910.101)

-

Are torch gauges in good working condition?

-

Do the cylinders: (1) require a special wrench for each acetylene cylinder in order to quickly turn it off in event of an emergency, and (2) keep one on each cylinder? (29 CFR 1910.252)

-

Does the dealership store extra gas cylinders on-site

-

If the dealership stores extra gas cylinders on-site, do they meet all the following standards:

-

Chaining gas cylinders to a stationary object when they are not in use. (29 CFR 1910.253 (b) (2) (ii) )<br>

-

Storing them away from elevators, stairs, doors, doorways or anywhere they could be knocked over or damaged (falling objects)? (29 CFR 1910.253 (b) (2) (ii) )

-

Storing oxygen away from flammables (oil, grease or fuel gas) by at least 20 feet. (29 CFR 1910.253 (b) (4) (i) )

-

Store extra oxygen and acetylene gas cylinders at least 20 feet apart from one another (unless separated by non-combustible barrier at least 5 feet high? (29 CFR 1910.253)

MACHINES & EQUIPMENT

-

Does the dealership have bench grinder?

-

OSHA website for reference

https://www.osha.gov/SLTC/machineguarding/new-grinder-checklist.html -

Bench Grinder

-

Is there a properly aligned and fastened with a tongue guard adjusted to within 1/4 inch of wheel, for each abrasive wheel of bench grinder?

-

Do you have a tool rest (i.e. work rest) for each abrasive wheel, and is each tool rest no more than 1/8 inch from each wheel?

-

Is each bench grinder properly grounded with a three prong plug?

-

Is each bench grinder securely attached and stable?

-

Does the department post a sign requiring employees to wear goggles or face shields when grinding, and supply this PPE to ensure adequate face protection? (29 CFR 1910.215) <br>Note: if wearing face shield safety glasses are still required!

-

Does each jack or jack stand have its load rating legibly displayed? (29 CFR 1910.244 (a) (1) (ii))

-

After raising load, do employees use safety precautions to prevent slippage using a chain or strap? (29 CFR 1910.244 (a) (2) (iii))

-

Are safety devices on lifts in working condition and is the lift mechanism free of tampering? (Reference ALI and OSHA 5 (a)(1) General duty clause)

-

Do all lifts include, the manufacturer's name, model, serial number and load rate?

Miscellaneous

-

General housekeeping

-

Do you have any other actions that need to be addressed in this department?

Detail

-

Check the box if you have Detail Department

EXIT ROUTES (29 CFR 1910.37)

-

Are exits clearly marked with approved signs? (6"x3/4" letters)

-

If Battery Backup, does the sign illuminate when tested?

-

Emergency Lighting if equipped, Is it working?

-

Are the directions to exits, when not immediately apparent, marked by visible signs?

-

Are doors which could be confused with emergency exits marked "not an exit" or otherwise identified? <br>(29 CFR 1910.37)

-

Free of locks and easily opened (e.g. Crash Bars) to allow emergency egress from the building? (29 CFR 1910.36 (d) (1) and or (d) (2)

-

Is the path to exit and discharge free from obstruction?

-

If there is an elevation differential between exit doors and the ground, is there a "step down" or "step up" sign posted on the door? (29 CFR 1910.37)

-

Does the department have fire doors?

-

Fire door free from kick down stops?

-

Fire door fire rating label legible?

-

Fire door closed/positively latch?

-

Are there rolling fire doors present in department?

-

Rolling fire door path clear from obstructions?

-

Rolling fire door fusible link free from paint?

FIRE SAFETY

-

Are Fire Extinguisher readily accessible, mounted, identified with signs and inspected every 30 days?

-

Is there a clothes dryer in detail

- Yes

- No

- N/A

-

Is the dryer properly vented? (bucket method must have sufficient water in bottom of bucket to trap lint)

-

Is there "no smoking" sign posted on all portable battery chargers? (29 CFR 1910.178 (g) (10)

-

Is gasoline stored in a approved metal safety can?

ELECTRICAL SAFETY

-

Are electrical outlets or boxes secured with no openings? (29 CFR 1910.303 (b)(8)(i))

-

Are cords, wiring and plugs in good condition and grounded? (29 CFR 1010.303 (h)(3))

-

Does the department avoid taping flexible cords which are frayed or missing insulation? (29 CFR 1910.305)

-

Does the department prohibit use of multiple plug adapters? (29 CFR 1910.303)

-

Does the department only use extension cords for temporary work? (max 90 days) (29 CFR 1910.305)

-

Are extension cords that are used for temporary work properly grounded with a three-prong plug? (29 CFR 1910.304 and 305)

-

Are ground fault interrupters (GFCI's) installed near electrical equipment which has the potential for contact with moisture? (29 CFR 1910.394)

-

Does the department avoid daisy chaining extension cords/power strips?

-

Is there a circuit panel box in this department?

-

Are all circuits labeled properly? (29 CFR 1910.303)

-

Is there 3 feet of clerance around circuit panel boxes?

-

Are all spaces in panel filled with breakers or blanks?

-

Are vacuum cleaners located in wet areas properly grounded with a three prong plug and a GFI or are they double insulated? (29 CFR 1910.304 (f) (4) )

PERSONAL PROTECTIVE EQUIPMENT AND FIRST AID

-

Does the department provide personal protective equipment (e.g., googles,face shields gloves,hearing protection) to all employees and kept in sanitary condition? (29 CFR 1910.132 (e))

-

Are eyewash units located within 55 feet of a potential hazard site, and/or installed within 10 seconds of a hazard providing 15 minutes of a continuous flow of water? (29 CFR 1910.151 and ANSI Z358.1-2009))<br>

-

Does unit have unobstructed travel path?

-

Type of unit?

-

Is the unit full, clean, accessible, fluid changed when required by Manufacturer and documented?

-

Is clean, accessible and flushed weekly?<br>Water temp 60-100 degrees

PHYSICAL, SANITATION & HEALTH HAZARDS

-

Does the department prohibit the use of food preparation equipment (microwaves,coffee pots,toasters)?

-

Does the department properly maintain and use the exhaust system to prevent the build-up of exhaust? (29 CFR 1910.1000)

-

Are all exhaust holes or floor openings covered? (29 CFR 1910.23)

-

If the dealership has open pits, does it have guards or rails around the open pit? (29 CFR 1910.22)

-

Are spilled materials cleaned up immediately ?

-

Are the floors as dry as possible? (29 CFR 1910.22 (a)(2)

-

Does the department maintain work areas and aisles free from trip hazards? (29 CFR 1910.176)

-

Are any fans that are within seven feet of floor totally enclosed? (29 CFR 1910.212)

-

Is residue and debris disposed of a timely manner? (29 CFR 1910.22)

-

Are lights which may be hit, encased in protective shields or otherwise guarded to prevent breakage? (29 CFR 1910.303)

-

If the dealership conducts chemical rust proofing, does it provide proper ventilation and isolation from other areas/workers (curtain)? (29 CFR 1910.107)

-

Is food waste removed so to eliminate health hazards? (29 CFR 1910.141)

-

Are bathrooms kept in a sanitary condition? (29 CFR 1910.141)

-

Are all containers of hazardous chemicals properly (29CFR 1910.1200 (f) (5) (i) )<br>Secondary units must be identified with name of product and target organ, and hazard warning

-

If employees use compressed air for cleaning parts or equipment, do they reduce compressed air to less than 30 PSI dor cleaning parts or equipment? <br>NOTE; Compressed air should not be used to clean clothing, (29 CFR 1910.242)

-

Air pressure Blowguns and OSHA Complliance