Title Page

-

Site conducted

-

SOP 11-1B: Internal Plant Audit for Manufacturing Facilities

-

Conducted on

-

Inspector

-

Factory

-

Location

-

Each question has to be classified and scored in any of the following categories: Yes (1) - No (0)

A company standard of 90% is considered a passing score. A score below 90% is considered a Fail.

This Internal Plant Audit is based on the "Maintenance and Operation of Establishment Checklist" provided by the Canadian Government to comply with the Safe Food For Canadians Regulation:

http://www.inspection.gc.ca/DAM/DAM-aboutcfia-sujetacia/STAGING/text-texte/regs_safe_food_regulations_preventative_ctrl_plan_temp_domestic_food_exp_1_1525967054048_eng.pdf

Guidance on the justification statements was provided by the Canadian Government to comply with the checklist:

http://www.inspection.gc.ca/food/general-food-requirements-and-guidance/preventive-controls-food-businesses/regulatory-requirements/eng/1524581767630/1524581834894?chap=0#s4c4 -

For non-conformances with immediate corrective actions, describe corrective action/s taken. Person responsible for corrective action/s must sign/initial.

-

For non-conformances requiring work/service orders or maintenance to be scheduled, assign an Action to the Plant Manager with a description, priority level, and a target completion date.

SFCR Sections 50 - 54: Sanitation, Pest Control and Non-Food Agents, Conveyances and equipment used in the establishment

-

Instructions:

1. Select “Yes” for compliance and “No” for non-compliance.

2. If “No,” specify the non-conformance under “Notes” and add photos under “Photo” of the non-compliant item.

3. If “No,” select the appropriate corrective action and specify the corrective action/s taken under notes and/or attach photos of the corrective action/s.

For special/unique cases, select “Other Corrective Action/s” and specify in the notes.

SFCR 50 - Sanitation

-

Requirement: The establishment, and any conveyances or equipment used in it are clean and in a sanitary condition. Cleaning and sanitizing activities do not contaminate food

-

Establishment, conveyance or equipment are free from accumulation of dust, dirt, food residue, grease, and other debris

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

No contamination of chemicals on food, food-contact surfaces, and food-packaging materials

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

I.e., no spray bottles or chemical buckets on tables where food is being produced; no open chemical dispensers

-

Food-contact surfaces & equipment are cleaned as frequently as needed and away from food preparation

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

I.e., Observe cleaning of sushi robot during changeovers; cleaning of knives and cutting boards as necessary. Observe that they are following Wash-Rinse-Sanitize procedures

SFCR 51 - Animal and Pest Control

-

Requirement: The establishment (the facility and surrounding area) is protected against entry of animals. No animals / companion animals are permitted in the facility. Any measures taken to prevent the presence of animals (ie. bait stations) do not contaminate food.

-

Roof, foundation, walls, floors, and doors prevent the entry of pests and animals

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

I.e., Animals, such as insects, rodents, birds or other vermin - Check that there are no gaps / holes between door to floor, on walls, etc. that may allow pest entry

-

Bait stations are installed and in good condition to prevent pest and animal entry. Visual verification indicates no evidence of pests.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 52 - Non-Food Agents (i.e. cleaning chemicals)

-

Chemical concentrations are verified (SOP 2-3)

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Chemicals are clearly labelled and used according to their intended use.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

If sanitizers or non-food chemical agents are transferred into different containers (i.e., spray bottle), each container must be clearly identified with the name and/or purpose of use of the chemical.

SFCR 52 - Conveyances and Equipment used for Food

-

Conveyance or equipment

(Véhicule ou matériel)

In general terms, "conveyance or equipment " when used in Part 4 – Preventive Controls of the SFCR, refers to anything that is used within the establishment to transport or manufacture, prepare, store, package, or label food or slaughter a food animal. (I.e. Utensils, containers, thermometers and devices, Tables, ovens, mixers, equipment used in cleaning systems such as Clean-In-Place (CIP)) -

Requirement: Conveyances and equipment used for food:

- Designed, constructed and maintainable to prevent contamination of food

- Equipment parts are made of materials that are corrosion-resistant, durable, cleanable and non-toxic

- Equipped with the necessary measuring instruments (e.g., recording thermometer)

- Functions as intended

- Cleanable and accessible for sanitation

- Used, maintained, and calibrated as per manufacturer's instructions and in a way that does not contaminate food

- Food contact surfaces are smooth, free from pitting, cracks or flakes, and non-absorbent -

All equipment, utensils, containers, and controlling and measuring devices are appropriate for the food and activity.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Check items that they are: used only for the intended purpose; calibrated or verified for calibration

-

All equipment, utensils, containers, and controlling and measuring devices are designed, constructed and maintainable to prevent contamination of food.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Check items that they are: designed to be corrosion-resistant and smooth; in good repair (no rust, peeling paint, leaking lubricants); cleanable; and properly stored.

SFCR 53 - Conveyances and Equipment for Food Waste

-

Requirement: Conveyances and equipment for food waste:

- Conveyances and equipment that are used to handle, and that come in contact with, contaminated materials, waste or inedibles are dedicated for this purpose and identified as such.

- Designed, constructed and maintained to prevent contamination of food (ie. leak proof, covered)

- Function as intended.

- Cleanable and accessible for sanitation. -

Conveyances or equipment used for handling contaminated material or allergens are identified for that purpose by labeling and/or colour coding

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Employees are practicing the system used to identify equipment reserved for handling materials, waste, or other inedible things.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

I.e., All food waste and inedible waste should be disposed in the designated waste bin and not using other food containers

SFCR Sections 56-71: Conditions of the establishment

SFCR 56 - Land and Location

-

Requirement:

- The surrounding land does not pose a risk of contamination to food (e.g., free of debris, refuse, pooling water, and pest harbourages).

- The establishment is not located near anything that is a source of contamination to food. -

Land surrounding the establishment is free of debris, refuse, or dead vegetation so as not to pose a risk of contamination to food.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

External waste containers are clean and equipped with tight fitting lids that are resistant to animals and pests.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 57 - Interior Facility (Building) or Conveyance

-

Interior facility is of sanitary design to prevent the accumulation of contaminants and allow for effective maintenance and sanitation

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Building should be of adequate size and layout to ensure space between equipment, employees and various activities

-

Floors, walls, and ceilings are: cleanable (smooth, non-absorbent); in good repair (no rust, peeling paint, no cracks, joints sealed)

-

Floors permit good drainage (floors are properly sloped)

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 59 - Movement

-

Requirement: The movement of persons and things within, into and out of the facility or conveyance is controlled to prevent contaminating food

-

The flow of incoming ingredients, persons, chemicals, packaging materials and equipment does not pose a risk of contamination to the food

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

I.e., the ingredients, finished food and packaging material are not at risk of contamination when they are moved from one area to the next

SFCR 60 - Separation of Incompatible Activities

-

Requirement: You use physical or other effective means to separate incompatible activities in order to prevent contamination of the food

-

Cleaning and sanitizing activities are separated from food preparation activities.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Shipping of finished products are separated from the receiving of incoming ingredients

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Storage of inedible products and waste are separated from food preparation areas and prevent cross-contamination

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

There is no cross-contamination from staff handling food with allergens and food without allergens

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

When staff are changing tasks, especially when handling food without allergens after handling food with allergens, they wash hands and put on new PPE such as disposable sleeves, aprons, and gloves.

SFCR 61 - Separation of Food

-

Requirement: You use physical or other effective means to separate food from anything that presents a risk of contamination to the food

-

Food with allergens are separated from food without allergens and/or other allergens

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Sanitizers and non-food chemical agents are separated from food, food-contact surface, or food-packaging materials by physical or other effective means

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 62 - Arrival of Certain Food at Establishment

-

Food that has been subject to a recall or considered “defective” due to hazards are identified, rejected (SOP 5-1: Material Receiving Log), and/or placed on hold (SOP 5-4: Hold & Release Form)

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 63 - Lighting

-

Requirement: Any light fixtures in the establishment where you manufacture, prepare, store, package or label food or slaughter a food animal can withstand repeated cleaning and, if necessary to prevent contamination of a food, repeated sanitizing.

-

Using a LUX meter, measure the light intensity (LUX) in the following areas:

-

After taking the cap off the lux meter sensor, simply place it on a surface where a task is carried out such as the centre of a desk. It is important the sensor is placed on the surface as this is where the light is reflected into the user eye and represents the true level of light they receive. Holding the light meter above the surface would produce potentially inaccurate readings. The lux reading should then be displayed on the display.

-

Standard:

538 LUX - processing area or where employee is working

215 LUX - hand-washing, warewashing, equipment and utensil storage -

Processing Area

-

Rice Cooking Room / Kitchen

-

Cooler

-

Freezer

-

Shipping / Receiving Area

-

Warehouse

-

Offices

-

Placement and intensity of lighting in the establishment is appropriate to effectively produce food and conduct inspection of food

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Specify in the "Notes" the Rooms and LUX readings that are non-compliant. Also specify the non-conformance (i.e., burnt out lights, broken / cracked lights resulting in dim room)

-

Light fixtures are shielded with covers to protect against breakage or lights are shatter-proof

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 64 - Ventilation System

-

Ventilation System

- Ventilation provides sufficient air exchange and can be maintained and cleaned to prevent unclean air from affecting the food. -

The ventilation system prevents the accumulation of heat, steam, condensation or dust

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Check for condensation that could contaminate the food (i.e., dripping on food or food-contact surfaces)

-

The ventilation system is equipped with filters to prevent the entry of dust, smoke, steam, odours, and contaminated air.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 65 - Temperature and Humidity

-

Requirement: You maintain the temperature and humidity in the facility or conveyance where you manufacture, prepare, store, package or label food at a level that is appropriate to the food and the activities being conducted

-

Environmental temperatures are maintained according to standards

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Processing Area: ≤10°C (50°F)

Coolers: ≤4°C (39.2°F)

Freezer: ≤-18°C (-0.4°F) -

Refrigerated areas are equipped with a recording thermometer

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Refrigeration facilities are operated in a manner that prevents frost build-up

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 66 - Waste Disposal

-

Waste Disposal

- There is means for removing and disposing of contaminated materials and waste.

- Drainage, sewage, and plumbing systems function as intended.

- Removal and disposal is conducted at a frequency and in a manner that does not contaminate food. -

Drainage and sewage systems are equipped with traps and vents to prevent backflow

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Visually inspect. Review maintenance records. Check to make sure Grease Trap Service Reports are filed and that service was done according to frequency per month.

-

Waste and contaminated materials are removed at a set frequency by designated employees, or more often if necessary

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Check that there are no overflowing garbage bins

SFCR 67 - Employee Facilities

-

Requirement: Employee facilities are available to permit the necessary hygienic practices and and prevent conditions which may result in the contamination of food

-

There are sufficient hand washing stations, lavatories, showers, drinking water stations, lunch rooms, and change rooms are properly located, designed and maintained. Hand-washing notices are posted at the hand washing stations and in lavatories.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Hand washing stations are equipped with warm water, non-hand operated taps, liquid soap, non-hand operated paper towel dispenser, and garbage bin

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Washrooms are located separate from production, maintained in good operating order and equipped with toilet paper

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Sanitizing chemicals for hands are not expired and foot dip sanitizing solutions are at the appropriate chemical concentration for their intended purpose and are food-grade (SOP 2-3)

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 70 - Water, Steam, and Ice - contact with food

-

Requirement: Any water that may contact food is potable, unless there is no risk of contamination of the food if it is not potable. Any water is protected against contamination

-

Municipal water that come in contact with food or food-contact surfaces are bacteriologically acceptable

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Check that test results were performed as per schedule and/or available in binder.

-

Hoses or taps have back-flow prevention devices

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 71 - Water, Steam, and Ice - supply and treatment

-

Requirement: The water you use is sufficient to prepare food, such as washing, rinsing, growing and harvesting. The water is sufficient to clean and sanitize the facility or conveyance.

-

Water is supplied in adequate quantity, temperature, and pressure for processing, cleaning, hand-washing, etc.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Check that running water reaches 38°C

SFCR Sections 72 - 74: Loading, Unloading and Storage

-

Conveyance

(Véhicule)

The Safe Food for Canadians Act defines "conveyance" as meaning "a vessel, aircraft, train, motor vehicle, trailer or other means of transportation, including a cargo container."

SFCR 72 - Conveyances used to transport food

-

Requirement: Any conveyance that is used to carry food to or from your establishment, and that is loaded or unloaded at the establishment is designed, constructed and maintained to prevent contamination of the food

-

Conveyances are designed, constructed, and maintained to prevent contamination of the food

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Before you load or unload the food, you make sure that there are no defects or damaged parts that may present a risk of contamination to the food

-

Conveyances are equipped with thermometers and temperatures are recorded. Conveyances are capable of maintaining refrigerated food at a temperature between 0°C and 4°C

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 73 - Unloading and Loading

-

Lot numbers or expiration dates of each item received is recorded and a receiving date is applied onto the items received

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Refrigerated or frozen food temperatures are checked for compliance to the receivable temperatures as per SOP 5-1

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Refrigerated or frozen foods are moved directly to the appropriate storages 30 minutes after unloading

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Receiving is done only in the designated Receiving Area and food is received separately from non-food chemical agents

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR 74 - Storing

-

"First-In, First-Out" stock rotation principle is followed

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Check that all items have receiving date sticker and verify FIFO - packaging, dry food items, frozen food items, WIP items

-

Food and non-food items are stored in a way that does not contaminate food

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Food are placed on pallets off the floor or on shelves.

There is no food stored that has passed its expiration date.

Unused equipment, sanitizers, and chemical agents are stored in designated locations that are clean and away from production area.

SFCR Section 75: Competency / Process Control

-

Competencies and qualifications: Employees have the necessary technical knowledge to perform their specific duties.

Monitoring critical control points (CCPs): CCP 1

-

The pH should be between 3.8 to 4.2. If pH > 4.2, add more vinegar. If pH < 3.8, add more rice and re-check. If this cannot be achieved, product should be discarded. Reference: SOP 4 Regulations

-

Batch/Bin#

-

Rice pH

Rice Temperature

-

Spot-check of rice pH matches pH recorded by rice cooker and verifier

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

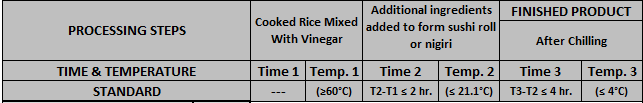

Monitoring critical control points (CCPs): CCP 2

-

Reference: SOP 4 Regulations

-

Batch/Bin#

-

Specify the in-process product roll name/s under "Notes"

-

Time 1

Temperature 1

-

Time 2

Temperature 2

-

Time 3

Temperature 3

-

CCP 2 temperatures are monitored from Time 1 to Time 3 and is met.

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

In-Process and Finished Product Weight Control

-

In-process Weight

-

Finished Product Weight

-

Random weight check of sushi matches weight recorded

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

-

Note in-process and finished product item under "Notes"

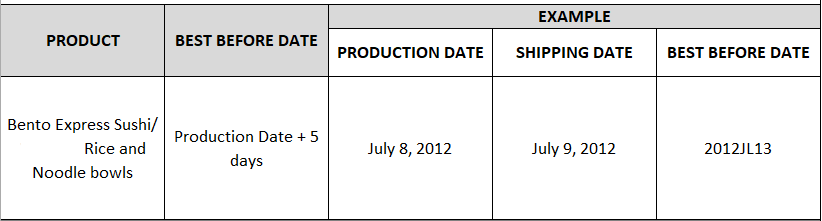

Date and Finished Product Label Control

-

Reference: SOP 9 Regulations - 2. Date Coding / Best Before Date

-

Spot-check indicates application of correct label and "Best Before Date"

-

Corrective Action/s

- Removed

- Washed, Rinsed, and Sanitized

- Re-trained Personnel

- Maintenance / Work Order Scheduled

SFCR Sections 76 - 81: Hygiene

SFCR 76 - Clothing, Footwear, and Protective Coverings

-

Requirement:

- Anyone in a food handling area wears appropriate clothing and, if there is exposed food or food-contact surfaces, hairnets, beard nets, gloves, etc.

- Protective coverings are worn and maintained in a sanitary manner. -

Employees wear protective clothing (i.e. uniform, boots, disposable aprons, sleeves, hair nets, beard nets, etc.) that are clean and suitable for the tasks they perform.

-

Employees' foot wear are clean and sanitary and employees use foot dip/foam if appropriate

-

Protective clothing removed immediately upon leaving a processing area and stored in a manner that prevents contamination.

SFCR 77 - Personal Cleanliness

-

Requirement:

- Anyone in a food handling area maintains an appropriate degree of personal cleanliness and takes the necessary precautions, such as cleaning and sanitizing their hands if there is exposed food or food-contact surfaces. -

Personal cleanliness are maintained as per SOP 1

-

Employees are washing and sanitizing hands upon entering production area; after using the washroom; at a frequency appropriate for the food and the activity being conducted.

SFCR 78 - Personal Conduct

-

Requirement:

- Anyone in a food handling area does not contact the food unnecessarily and refrains from acts that could contaminate food, such as spitting, smoking, and eating -

No smoking, spitting, eating, or chewing gum in process areas

-

Employees are not acting in a way that presents a risk of contamination of the food

SFCR 79 - Personal Objects and Substances

-

Requirement: Anyone in a food handling area refrains from wearing or using any object or substance that could contaminate food, such as jewellery.

-

No jewellery or personal adornments that could become incorporated into fish being processed

-

Substances that may present a risk of contamination to the food such as hand cream, nail polish, or topical medicinal creams are not used

SFCR 80 - Reporting of Health Condition

-

Requirement: Anyone who works in a food handling area and who has a disease or illness, symptoms of a disease or illness or an open or infected lesion is required to report their condition to a responsible person at the establishment

-

There is a documented mechanism in place for employees to report their disease or illness, symptoms of a disease or illness, or presence of an open or infected lesion to management

-

Employees returning to work from an illness have submitted a Doctor's Note verifying that they are safe to work with food

SFCR 81 - Communicable Disease and Lesions

-

Requirement: Anyone suffering from a condition that could contaminate food is excluded from food handling areasAnyone suffering from a condition that could contaminate food is excluded from food handling areas

-

No known carriers of conditions that could contaminate food

-

No open or infected wounds, skin infections or sores / Open wounds on exposed areas of the skin are adequately covered with waterproof dressing

Verification

-

Inspector

-

Verified by