Information

-

Technical Interview Assessment Paper

-

Candidate's Name

-

Date

-

Manager

-

Location

Materials

-

Materials section please attempt all questions

-

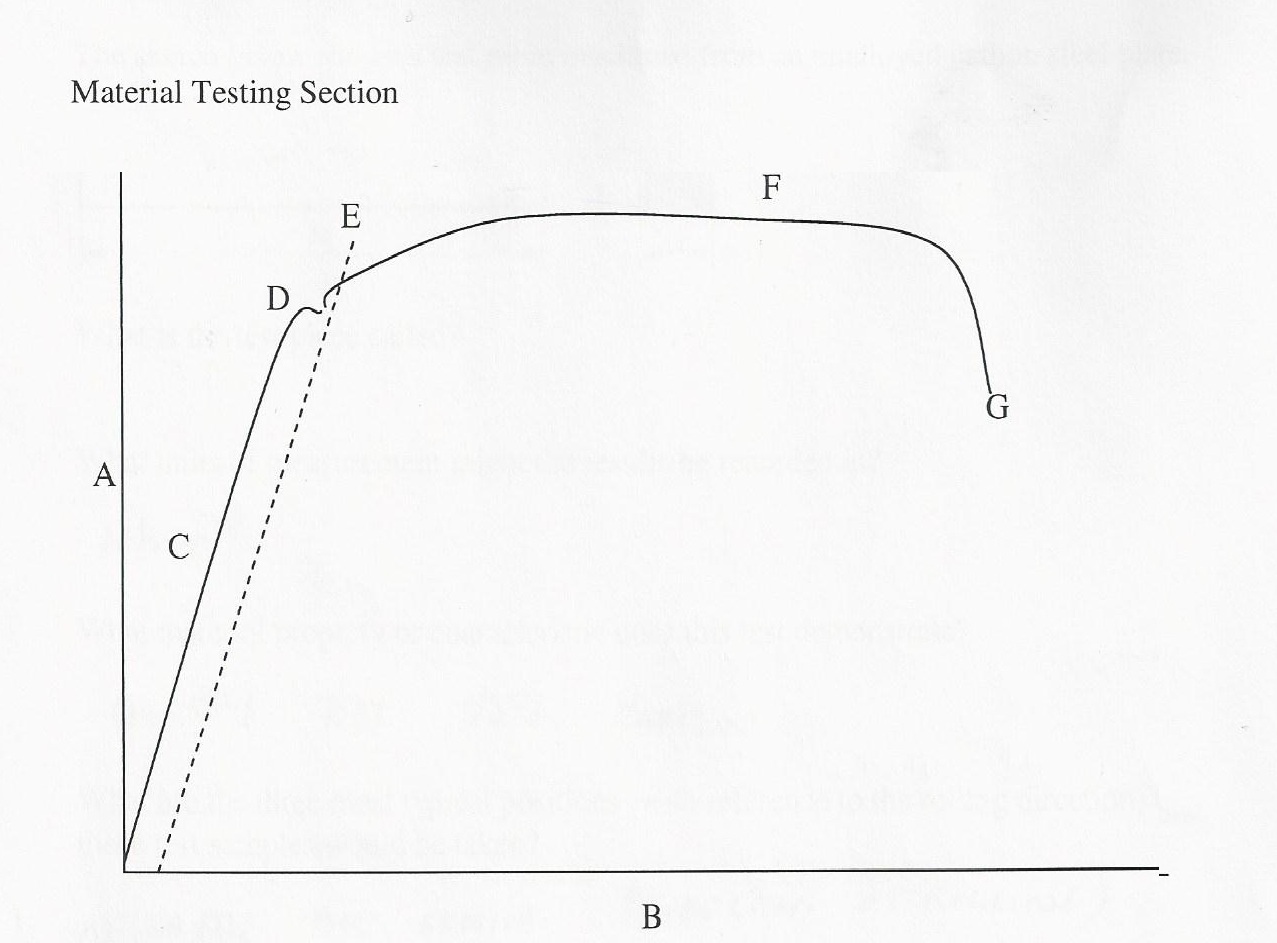

Diagram

-

What does position A indicate?

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

What does position B indicate?

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

What does position C indicate?

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

What does position D indicate?

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

What does position E indicate?

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

What does position F indicate?

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

What does position G indicate?

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

Points D, E and F are typically measured in numerical values, please identify what units of measurement you would typically see. Imperial and metric are acceptable.

Welding

-

Welding section (please attempt all questions)

-

What do the following process acronyms stand for?

-

TIG

- Stress

- Strain

- Ultimate tensile strength

- Breaking load

- Linear Elastic Region

- 0.2% Offset

-

MIG

- Tungsten inert gas

- Metal inert gas

- Manual Metal Arc Welding

- Sub-Merged Arc Welding

- Flux-Cored Arc Welding

- Pulsed Arc Welding

- Oscillating Arc Welding

-

MAG

- Tungsten inert gas

- Metal inert gas

- Manual Metal Arc Welding

- Sub-Merged Arc Welding

- Flux-Cored Arc Welding

- Pulsed Arc Welding

- Oscillating Arc Welding

-

MMAW

- Tungsten inert gas

- Metal inert gas

- Manual Metal Arc Welding

- Sub-Merged Arc Welding

- Flux-Cored Arc Welding

- Pulsed Arc Welding

- Oscillating Arc Welding

-

SAW

- Tungsten inert gas

- Metal inert gas

- Manual Metal Arc Welding

- Sub-Merged Arc Welding

- Flux-Cored Arc Welding

- Pulsed Arc Welding

- Oscillating Arc Welding

-

FCAW

- Tungsten inert gas

- Metal inert gas

- Manual Metal Arc Welding

- Sub-Merged Arc Welding

- Flux-Cored Arc Welding

- Pulsed Arc Welding

- Oscillating Arc Welding

-

PAW

- Tungsten inert gas

- Metal inert gas

- Manual Metal Arc Welding

- Sub-Merged Arc Welding

- Flux-Cored Arc Welding

- Pulsed Arc Welding

- Oscillating Arc Welding

-

O-AW

- Tungsten inert gas

- Metal inert gas

- Manual Metal Arc Welding

- Sub-Merged Arc Welding

- Flux-Cored Arc Welding

- Pulsed Arc Welding

- Oscillating Arc Welding

-

Name two internationally recognised standards for weld procedure testing of metallic materials

-

Name two internationally recognised standards for weld qualification testing of welders

-

In order to determine the heat input in a fusion weld, what are the main parameters that would have to be measured during the test?

Welding 2

-

Welding page 2

-

Detail the testing for a 15mm thick carbon steel procedure qualification test plate in accordance with the recognised BSEN standard. Tick the testing applicable in the multiple choice answers please.

- Face Bends x2

- Side bends x4

- Root bends x 2

- Face bends x 4

- Side Bends x 2

- Transverse tensile tests x 2

- Macro test

- Hardness Survey

- Radiographic testing

- Utrasonic testing

- MPI

- DPI

- Drop Test

- Impact testing

- Through thickness testing

- Side bends can be substituted for thickness over 12mm

Destructive Testing

Destructive testing section

-

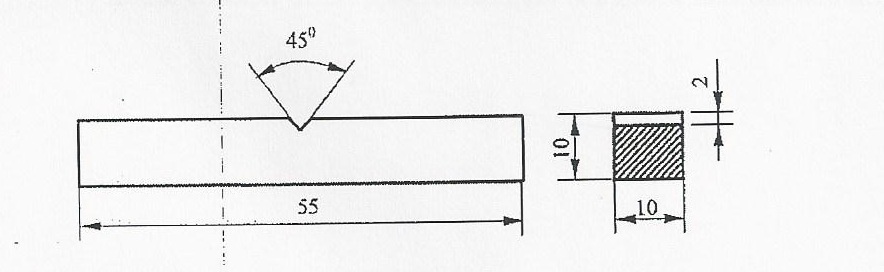

Diagram

-

What is the test piece called

-

What material properties does this test demonstrate?

-

What are the three most typical positions (with reference to the rolling direction) that these test samples would be taken?

-

How many test pieces are typically required to provide one set?

-

If the test were performed at room temperature and then again at minus 50 degrees C, what would the results typically be?

-

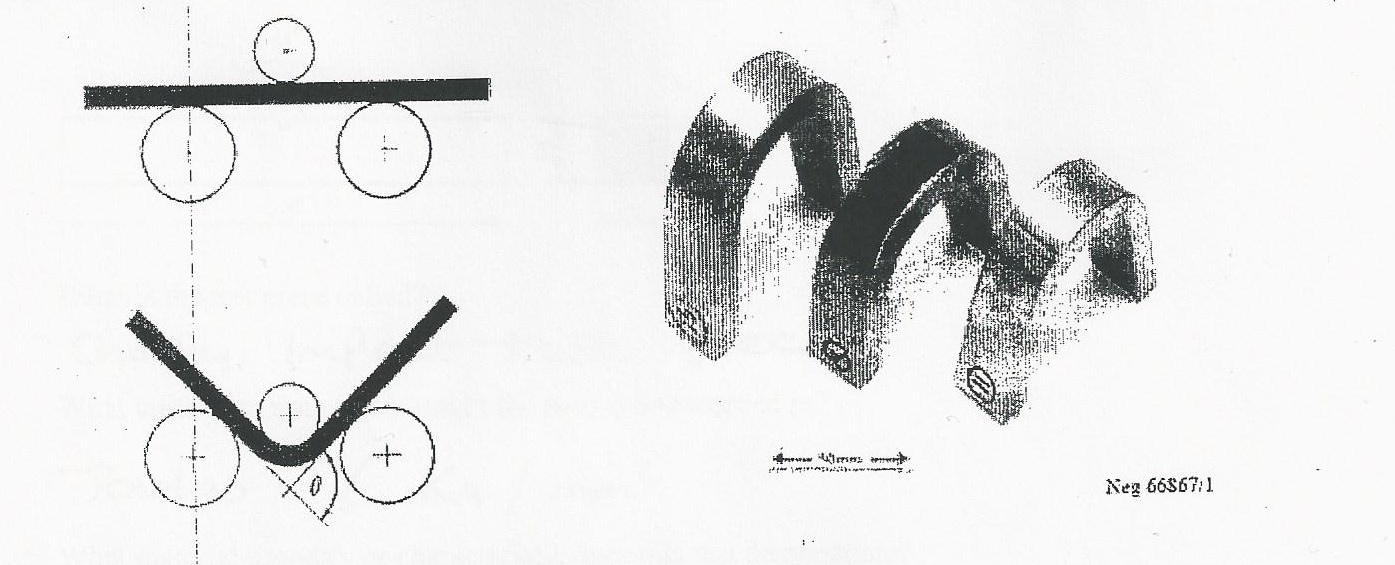

Diagram

-

What is this test called?

-

What material property or characteristic does this test indicate?

-

If the test was to break or tear apart what might this indicate?

-

With reference to the rolling direction of the plate, in what direction would you expect this test to be cut?

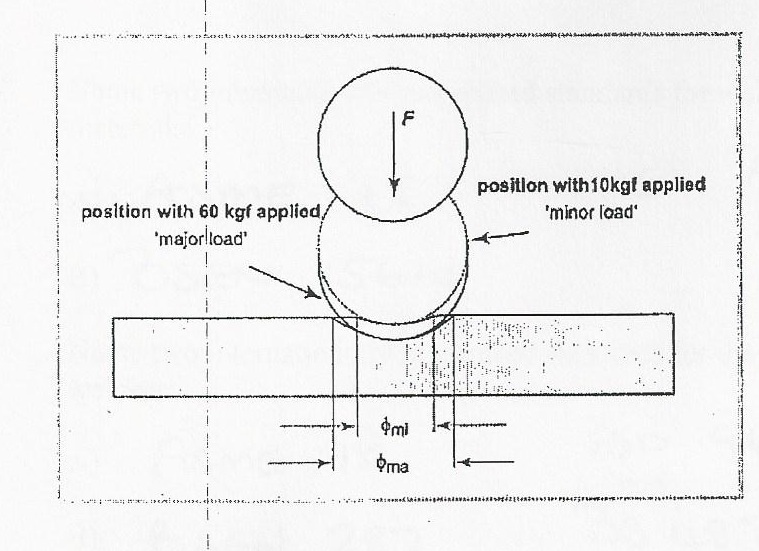

Destructive page 2

Destructive Testing

-

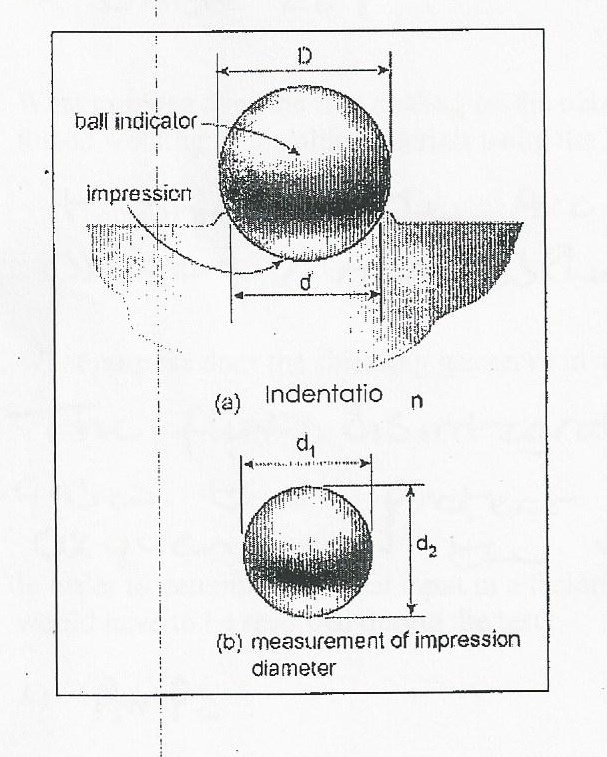

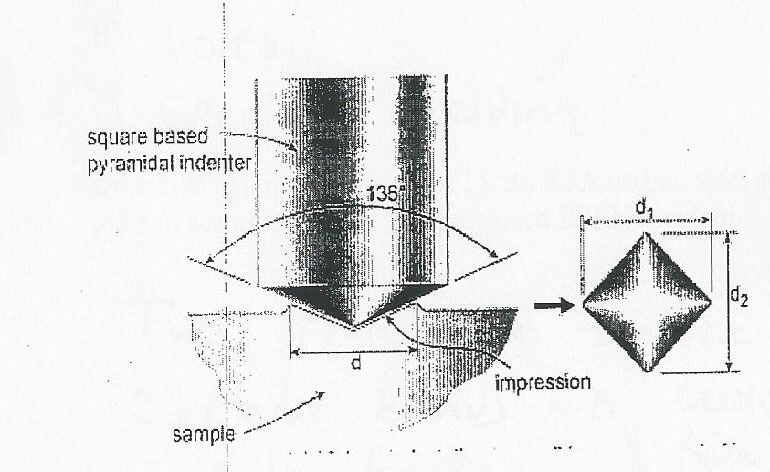

Identify the test

-

What test is this called?

-

Identify the test

-

What test is this called?

-

Identify the test

-

What test is this called?

Directives

Directives

-

Do you know what the acronym PED stands for

-

Do you know what the acronym TPED stands for?

-

Do you know what a harmonised standard is?

-

Do you know what ASME stands for?

NDE

NDE Section

-

Please identify the acronyms

-

PT

- Penetrant Testing

- Magnetic Particle Testing

- Radiographic Testing

- Ultrasonic Testing

- Visual Inspection

- Radiographic Intepretation

-

MT

- Penetrant Testing

- Magnetic Particle Testing

- Radiographic Testing

- Ultrasonic Testing

- Visual Inspection

- Radiographic Intepretation

-

RT

-

UT

-

RI

-

VI