Title Page

-

Terminals New Zealand Site Induction

-

Conducted on

-

Josh Aldridge

-

131 Hewletts Road Mt Maunganui

Introduction

-

-

Welcome to Terminals New Zealand Ltd

Gull imports fully refined fuel into its state of the art terminal situated in Mount Maunganui.

Initially called "impossible" by the oil giants, Gull went against the grain and opened our terminal on Hewletts road in 1999. It has a total storage capacity of 90 million litres and is significantly larger than the other Mount Maunganui terminals.

The terminal stores 91, 95, 98, diesel, bio-diesel, butane and ethanol. Gull Force 10 and Gull Force Pro are blended on site from base gasoline and ethanol. Because most of the ethanol we use is produced locally, we're supporting New Zealand's rural economy while reducing our dependency on imported fuel.

Our philosophy is to operate in an efficient ethical manner, to be decisive in our decision making to meet customer and consumer expectations. We provide a genuine alternative to major oil companies by offering high quality fuel in attractive, modern facilities at competitive prices.

Health, safety and environmental policy.

-

The management of the Gull Group of companies are committed to delivering and recognising excellence in health, safety and environmental performance.

It is line managements responsibility to promote a continual improvement approach to health safety and environmental performance through the delivery of our health, safety, environment and quality management system (HSEQ MS).

The Gull Group of companies will:

Ensure activities are conducted with full concern for the safety and health of customers, employees, contractors and members of the community and protection of the environment.

Annually review managers performance against measurable objectives and targets.

Comply with legislation, regulations, codes of practice, industry standards and safe operating procedures relevant to our business.

Provide a healthy and safe working environment by eliminating hazards or minimising the risks to acceptable levels.

Effectively respond to emergencies.

Hold managers and supervisors responsible for the health, safety, and environmental performance of those working under their direction.

Ensure management, employees and contractors are trained, competent, adequately informed and instructed on the hazards and controls associated with their work.

Require contractors to demonstrate the same level of commitment to excellence in health, safety and environmental management.

Promote a culture where employees are responsible for their own health and safety and those around them, both on and off the job.

Encourage accurate and timely reporting of health, safety and environmental incidents and undertake investigations to prevent their reoccurrence.

Develop and maintain operations to ensure health, safety and environmental considerations receive priority during design, operation, maintenance and change.

Promote early reporting of pain or discomfort and encourage the safe and early return to work of injured employees.

Engage with employees and committees in managing workplace health, safety and environmental issues.

Manage waste in an environmentally sound manner and pursue the efficient use of energy and other natural resources.

Safety Case

-

Terminals New Zealand Limited is classified as an Upper Tier Major Hazard Facility, under the Health and Safety at Work Act 2015, and have submitted a Safety Case to the Regulator. A Safety Case provides assurance to workers, emergency services, the community, the regulator, and others, that the potential for major incidents have been systematically assessed and that effective and suitable controls are, or will be, in place. A copy of this Safety Case can be accessed from Terminals New Zealand Limited’s office. Major Incident scenarios at Terminals New Zealand Limited include - Loss of containment of gasoline; butane; or ethanol. Full surface fire on gasoline storage tank; road tanker at the loading gantry; ethanol storage tank. Each Major Incident has been risk assessed and was used to identify Safety Critical Elements. Safety Critical Elements (SCE) are items of plant or equipment at a major hazard facility intended to be the last lines of defence against a major incident and its consequences. Any failure or issue with an SCE must be immediately raised with the Terminal Manager. Any proposed maintenance work on a SCE must be pre-approved in writing by the Terminal Manager. Person(s) working on a SCE must have their work independently assessed to ensure all requirements have been met.

Driver details

-

Driver name

-

Employer

-

Select date

-

Add signature

Terminal Representative

-

Induction log number

-

Terminal operators name

-

Add signature

-

Expiry Date

Terminal rules

-

The following site safety standards must be understood and complied with at all times. Failure to do so may result in disciplinary action or personnel being banned from site.

Only personnel who have completed a site induction will be permitted to operate equipment in loading bays.

Approved operators; only operators approved TNZ/TLL staff should operate equipment in the tank farm. This covers ethanol deliveries into F1 and D1.

Smoking is not permitted in the Terminal or surrounding property. This includes the areas outside the office blocks and MCC room. Smoking is only allowed on the grass behind the service station.

All potential ignition sources are not permitted within Terminal NZ boundary. All windows must be up upon entry into the terminal and doors must remain shut during loading in the gantry. Potential ignition sources include matches, lighters, music players, pagers, cell phones, cameras and tools which create heat or sparks etc. Drivers are allowed to carry cell phones to and from the terminal office and car park providing they are switched off.

Site speed limit is 5 km/hr. Pedestrians have right of way.

Vehicle access to the loading bays will be restricted to authorised vehicles permitted by the Terminal Manager; this includes approved road tankers with a current Safe Loading Pass. Prior to entry on site vehicles must turn off radios, music players, CB's, cellular phones, air conditioners and pagers. Vehicles must park in designated areas only. Whilst parked in the loading bays leave keys in the ignition and turn engine and master switch off. There is no tailgating through the entry or exit gate.

NOTE: NO access for any private vehicles in the gantry - diesel or petrol. Do not drive through the gantry with private vehicles.

A work permit is to be issued by a Terminal Operator for all non routine work.

First aid kit is located in the site portacom. Contact the Terminal Operator on call for assistance. All first aid incidents must be reported to the Terminal Manager and recorded in the first aid register.

The minimum level of personal protective equipment (PPE) must be worn upon entry to the Terminal. With the exception of arriving to work in your personal vehicle you must put your PPE on upon exiting your vehicle in the designated car park. If you have finished a shift and have parked your truck you must wear PPE back to your personal vehicle also.

Hazards have been identified and recorded on the Terminals NZ hazard register. New hazards will be communicated as required. You are required to notify the Terminal Manager of any unsafe conditions or practices immediately.

In the event of an incident make the area/situation safe and then report details to the Terminal Manager immediately. You will be required to complete an incident report form.

Ensure high standards of housekeeping must be maintained at all times. Keep the work place clean and tidy. Place rubbish in the dedicated bins. No product to ground policy - report all spills to TNZ staff.

Children or unauthorised personnel (passengers) are not permitted in the Terminal.

Anyone found under the influence of or in the unauthorised possession of alcohol or drugs on the premises will be required to leave the premises immediately and will be banned from any future entry.

Drug and alcohol testing may be undertaken following a significant incident.

Legislative requirements

-

Terminals NZ have an obligation to ensure compliance with a wide range of legislation, in particular the following:

* Health and safety at work act 2015

* Hazardous substance and new organisms act 1996

* Resource management act 1991

The purpose of these acts and relevant regulations is to ensure the facility and work place meets adequate safety and design standards to prevent any harm to people or the environment.

Security, access and vehicle parking

-

Normal business hours are 07:30 - 17:00 Monday to Friday. Parking for Tranzliquid drivers and Terminal Operator vehicles is available in the trailer park next to Hirequip. NOTE: exit via in-gate only - do not drive through the gantry with private cars. Once you have parked your car use the chained walkway along the boundary fence. Do not walk through the gantry.

Access to Terminals NZ is restricted to authorised personnel only. Where individuals have completed a site induction and have been approved they will be issued with a site access key. Drivers are not permitted to load a tanker until they have been load bay assessed.

In all other circumstances visitors and contractors must report to the main office and sign in on the Terminal visitor register.

Security patrols make regular, random inspections of the premises outside normal hours. Security cameras are installed and operating 24 hours, 7 days a week.

Facilities and amenities on site.

-

A toilet and shower is located in the office portacom. All personnel are expected to have high standards of hygiene and leave the facilities in a clean and tidy manor.

Hot water, tea, coffee etc will be available in the office portacom. Kitchen area must be left clean and tidy at all times. Use the toaster with caution (smoke detectors) and switch off after use. No food or drink to be consumed in the gantry.

Suppliers/contractors for vehicle maintenance activities

-

Emergency repairs: Terminals NZ recognise that in circumstances outside the control of the operator there may be a requirement to have repairs and maintenance performed on vehicles whilst at the Terminal. The preference would be to avoid this wherever possible, however should the occasion arise then the following will apply:

* Provide Terminals NZ manager with list of approved contractors.

* Suppliers/contractors will be required to complete a site induction.

* TNZ to supply work permit or manager approval as required.

* Work must only be performed in designated area outside the loading bays.

* The supplier/contractor must be supervised by the operator (TLL) at all times.

* Entry and exit from site must be controlled by the operator at all times.

* Restrict work to minor maintenance work to enable vehicle to be safely driven to regular maintenance facility.

* Under no circumstance must any hot work be performed in the terminal boundary without authorisation from a terminal operator and the issue of a hot work permit.

* All truck breakdowns in the gantry must be towed. No jump starts or battery changes allowed.

* Incase of emergency related to above - notify Terminal Manager to discuss options and actions required.

Personal protective equipment (PPE) standards

-

All Terminals NZ employees, tanker operators, contractors and visitors are required to wear appropriate PPE upon entry to the Terminal. There are no exceptions. Refer to the site safety signage.

Loading tankers

-

Before loading, or entering the loading bay any person in the loading bay must comply with the following minimum PPE standards:

PPE for loading trucks:

* Overalls only - no exceptions.

* Clothing must be of natural fibre (cotton).

* Approved safety shoes or boots must be worn. (Exposed steel caps are not permitted).

* Safety glasses with side splash protection, these must be AS/NZS stamped 1337.1

* Protective gloves must be worn when handling hoses/product.

PPE for rest of terminal:

* Full cover clothing from neck to toe must be worn, such as overalls or long trouser and long sleeved shirts with hi-vis.

* Enclosed footwear or approved safety shoes or boots must be worn.

* Safety glasses are to be worn in all areas of operation.

Tanker truck must be positioned correctly before loading. The loading arms should be at a 90 degrees (straight up and down) while loading. If you have pulled in to the gantry and are too far away from the arms you must exit the Terminal, do a loop around the block and re-enter the gantry. If you have pulled in to the gantry and parked too far forward of the arms you can reposition your truck up to 1 meter. To pre-load a truck and leave it in the Terminal truck park you must have permission from the Terminal Manager. No distracting other drivers in the gantry while they are loading. There should only be one driver per truck unless there is training in place or an assessment being done.

Other activities

-

Gantry entry:

Upon entry to the Terminal check the Online/Offline board. This tells you whether or not the product(s) you need to load are available.

Gantry exit:

It is important to keep the loading bay exit (parking in front of the office) clear at all times. This is necessary to enable trucks that are loading to exit the terminal in an emergency. Once you have completed loading tag the BOL tag reader with your truck key, get your B.O.L from the office, tag the exit gate tag reader, hop into truck and exit terminal.

Yellow line:

Please do not cross the yellow line to pass a parked truck or jump the queue it is unsafe to do so. This applies to the entry and exit of the gantry.

Hose trays (Tranzliquid only):

Drain product from the hose tray into a bucket supplied and pour down the gantry centre sump for processing. Product to ground - by using a bucket it will eliminate any product onto the gantry floor that can cause operators to slip and fall. Good housekeeping - we would expect everyone to keep the terminal tidy and the gantry area free from any product and combustible materials.

Washing:

There is a designated area for washing truck lights, mirrors and windows only. No truck washing allowed throughout the rest of the terminal. Any person using the wash station must remain on the ground, NO standing on the bund wall.

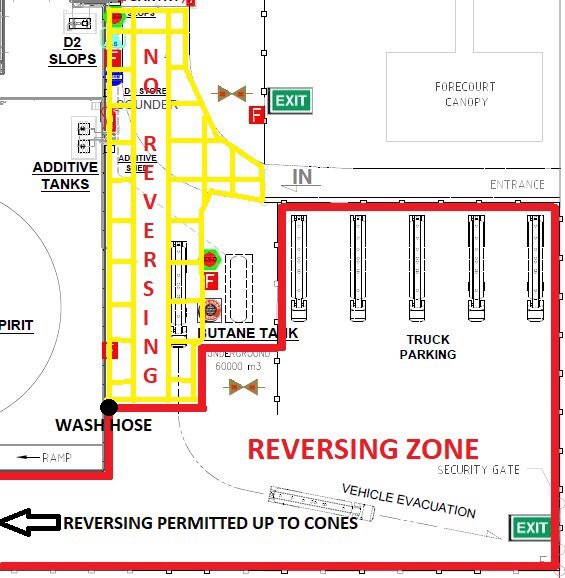

Reversing:

You must never reverse in the no reverse zone without an authorised person to guide you back, see picture below. Authorised personnel are Terminal Operators and TLL management. Reversing out of the gantry should only be done after denaturing ethanol. Reversing short distances for load bay truck alignment is allowed.

Loading / refuelling:

Never leave your truck unattended when loading or refuelling. Multitasking is not permitted in the loading gantry. Do not distract other drivers while they are loading.

Gantry alarms:

It is very important to notify the terminal staff if there is an Omega alarm as this can affect product quality and result in off-specification product. Low additive - usually indicates not enough additive blend in the product. High additive - usually indicates there is too much additive blend in the product.

Trailer park:

Reversing is permitted in the truck park, see the below picture for reversing and non reversing areas. No maintenance allowed, see Terminal Manager for emergency repairs.

No reversing site plan

Disciplinary procedures

-

Where an individual refuses to follow Terminals NZ site requirements, or has been observed conducting an unsafe act or not following the correct operational procedures, the three strike rule will apply.

Incident reporting

-

ALL accidents and incidents must be reported to the Terminal Manager immediately. An incident report will need to be completed. An accident or incident is any event which causes harm, or had the potential to cause harm (near miss events). The purpose of reporting accidents/incidents is to prevent reoccurrence or serious harm.

Drug and alcohol testing may be undertaken following a significant incident.

Hazard identification

-

All hazards which have been identified are recorded on the Terminals NZ hazard register. When any hazard is observed or identified it must be reported to the Terminals NZ Manager who will then take appropriate action to implement the necessary controls to eliminate/isolate/minimise the hazard to prevent harm.

Site walk around

Site walk around checklist

-

FIRE PROTECTION: * Emergency stop buttons are located at the entrance and exit of the load bay and at the rear door into the office. * Emergency shower and eye wash units located at the entrance and exit of the loading bay. * Emergency call points are located (1) near the entrance and exit of the loading bay (2) at the boundary exit gate (3) at the entrance to the portacom. * Foam deluge points are located adjacent to the fire alarm call points located near the entrance and exit of the loading bay. * Portable dry powder fire extinguishers are available at the entrance to the loading bay and adjacent to the loading control panel and office. * Fire alarm testing occurs monthly.

-

STATIC ELECTRICITY: * Because of the possible generation of static electricity, do not remove any item of clothing in the loading bay. * Wear natural fibre clothing when loading. * Always ensure vehicles are earthed via the overfill protection system (scully plug), and when draining product earthing straps are used on buckets.

-

CLOTHING SOAKED IN PRODUCT: * Go directly to emergency shower and stay under shower fully clothed until clothing is completely washed and free of product. * Remove contaminated clothes under shower first, then go to the office for another shower with soap which is provided. Use spare pair of overalls.

-

FIRST AID: * First aid facilities are available in the lunch room in the portacom. * A list of first aiders is displayed in the first aid kit. * Depending on nature of injury appropriate first aid action will be taken. * All first aid incidents must be recorded in the first aid register.

-

SPILLS: Less than 5 litres. * Stop loading immediately, do not move the vehicle from the loading bay. * Use absorbent materials provided to soak up as much product as possible. More than 5 litres. * Press emergency stop button and stop loading immediately. * Do not move the vehicle from the loading bay. * Notify any other personnel in the loading bay of the spill. * Ensure the area is safe. Evacuate loading bay. * Notify the Terminal Manager. * Terminal Manager will instruct action to take.

-

ELECTRICAL STORM: * Stop loading immediately. Do not move the vehicle from the loading bay. * Make the area safe. * Go to the portacom and wait for the storm to pass.

-

EVACUATION: * Upon hearing the fire alarm you must evacuate the terminal. * All personnel must assemble at the assembly point located in the car park behind the service station. * If loading or unloading in the gantry area, if it is safe to do so, immediately stop loading disconnect then drive out of the terminal unless told otherwise. * Follow instructions and park vehicle in a safe location.

Questionnaire

-

What is the speed limit within the terminal?

-

What PPE is required while loading a tanker truck?

-

Where is the assembly point in case of alarm sounding?

-

Can you drive your personal vehicle through the gantry?

-

Are you allowed to wash your truck in the gantry?

-

Are you permitted to reverse a tanker truck out of the gantry?

-

How do you respond to a spill in the gantry that is less than 5 litres?

-

If you are involved in an incident, what must you do?

-

If you get covered in product what must you do?

-

Where are the fire extinguishers located?

-

Where are the emergency stop buttons located?