Information

-

Main Vehicle Fleet No.

-

Person responsible for this hire (The driver)

-

Staff ID #

-

Location

-

Conducted on

Main Vehicle

-

Tacho reading (Km)

-

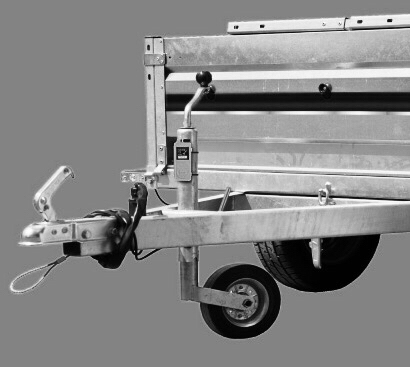

Is there a trailer or towed vehicle?

Trailer or Towed Vehicle (if applicable)

-

All checks must include the primary and secondary (towed) vehicle - use the dedicated Trailer Inspection app.

-

Fleet Number of trailer

-

Check that the tow vehicle and trailer are compatible e.g. Within acceptable towing limits.

Fluid Levels

-

Fuel Level

-

Fill tank (s) to FULL prior to leaving the depot

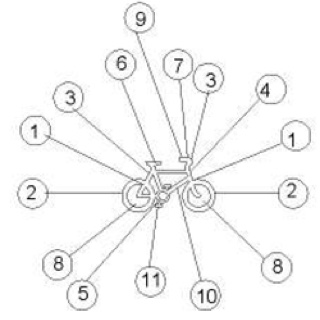

Tyres and Brakes

-

Check tyres for tread & studs all secure - include spare(s)

-

Check park brake(s) correct adjustment - remember to check any trailer brakes

-

Check the brakes and steering are operating correctly in a static location - remember to check the operation of any braked trailers to ensure brake bias is correct

-

Check brakes and steering are operating correctly in a SLOW SPEED environment and before the vehicle leaves the depot

Lights, Mirrors & Windows

-

Check all lights, indicators, hazard lights, hazard beacons and reverse warning beepers are operating correctly

-

Check mirrors/windows/washers are operating correctly

Horns

-

Check horn and any plant and equipment warning alarms and safety systems are operating correctly

Load Restraints and Seat belts

-

Check seat and seatbelts are in good working order

-

Check straps, chains and load restraints are in good working order and are not showing signs of wear that might jeopardise restraint capability

-

Check that there are no unrestrained loads on the vehicle including tools, materials etc. and that all cupboard doors are secure

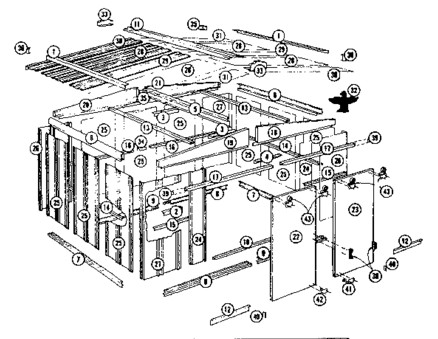

Plant and Equipment

-

Check: oil, brake fluid and water levels are adequate

-

Check that any buckets, cutting edges, teeth, ground engagement equipment and sweeping brushes associated with the operation of any carried plant, equipment or machinery are all serviceable

-

Check that any grease-able or oil lubricated joints are serviced as required

-

Explain reason for not lubricating this asset ..

Miscellaneous

-

Check fire extinguisher with Tag / Date

-

Check communications in good working order

-

Check Signs, labels and plates are in good order and clearly visible e.g. SWL, Long Vehicle, Hazchem etc.

-

Check exhaust system is operating correctly and is not too noisy

-

Ensure all the correct PPE and any road signage and cones are available and adequate for the job.

-

Check first aid kit available

Visual Check

-

Walk around the exterior of the vehicle (s) to check:<br><br>There is no damage that might affect the operation of the vehicle,<br>That it is clean and presentable,<br>That everything is operating correctly.

Any general comments ....

Inspection Completion

-

Are any items in this checklist that you have marked as being 'Defective' or 'unacceptable' ?<br><br>Or,<br><br>Is there anything that raises concern such that you are unable to use this vehicle ?

-

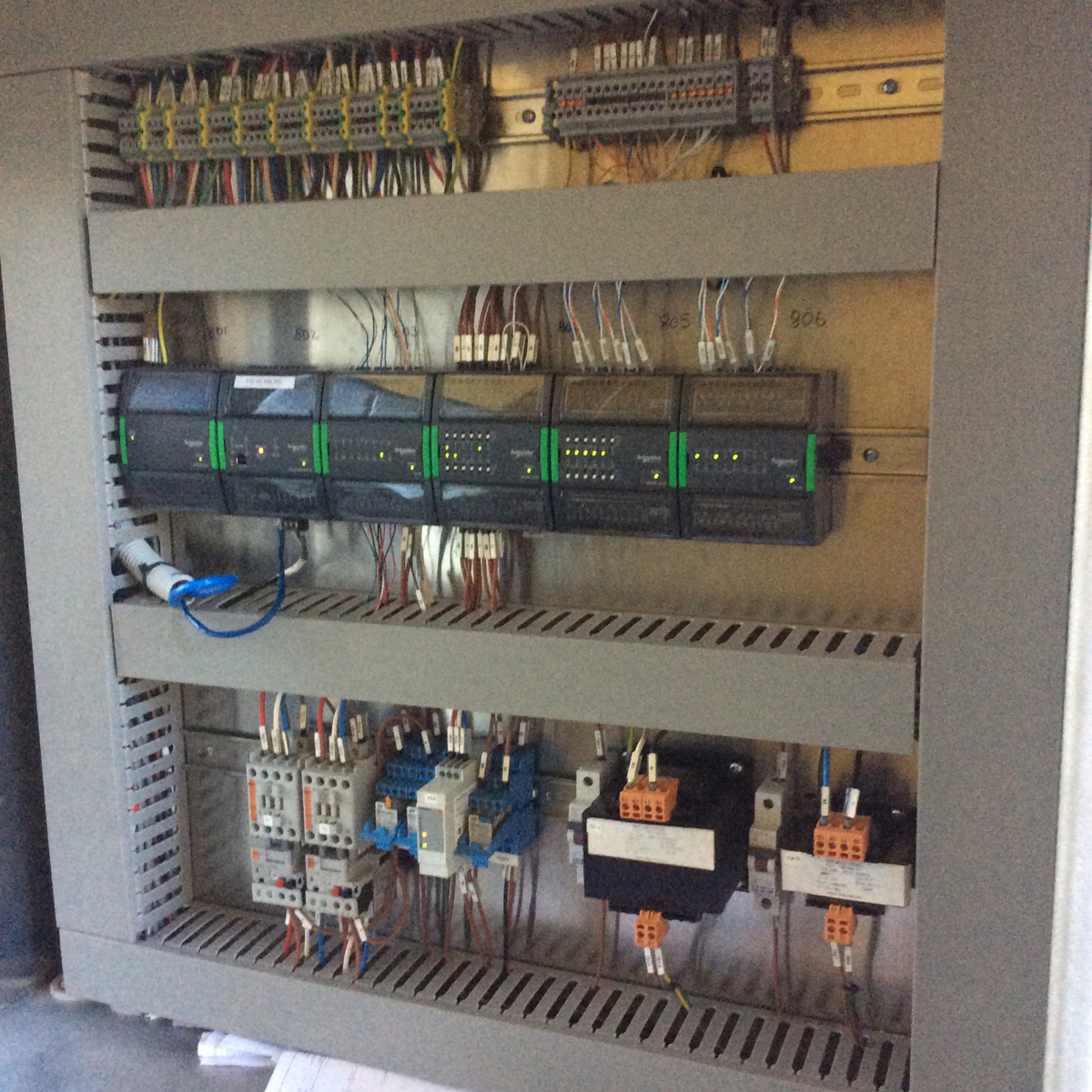

If there is a visual defect, please take a photo

-

Provide details here ....

-

Immediately report this to your supervisor and await further instruction. DO NOT USE OR MOVE THE VEHICLE, PLANT OR EQUIPMENT until notified otherwise.

-

You should be aware that by signing this inspection, you are acknowledging that you have fully completed this inspection

-

Signed by operator