Title Page

-

Client / Site

-

Conducted on

-

Location

-

Personnel

SLIDER BUNS

-

Slider Bun bags removed from the freezer are labeled with a 5-day discard date.

-

Slider Buns are thawed at room temperature on a bread rack for 12-hours. (Bags are not overlapped)

-

Sliders Buns are unbuttered and toasted cut-side up on the charbroiler bun belt.

-

During rush periods, multiple (up to 6) buns are toasted together to improve efficiency and speed of service.

-

Slider Buns are being held cut side down in pan. Hold time for unbuttered toasted buns is 5 minutes in a pan in the heatwell.

SLIDER CHEESE

-

Small American Cheese is cut in half.

-

Slider Cheese is separated and "Star Stacked" to reduce assembly time for Sliders and improve Speed of Service.

-

Slider Cheese is place into a pan on the cook line using the recommended placement on the Setup and Holding Chart. The 4-hour hold time is monitored.

SLIDER EGGS

-

Slider Eggs are folded in half and evenly cut in the center using the round tip breakfast spatula.

-

Slider Eggs are held separately from the Folded Eggs and have a 10-minute holding time.

SLIDER ASSEMBLY & PACKAGING

-

When observing employee behaviors while preparing the new products, Breakfast Sliders preparation and packaging is demonstrated to standard.

SUPPORT MATERIAL

-

Job-Aids are posted at the Cook Line Station.

-

Cashier Cards posted at the Cashier Station.

PERSON IN CHARGE

-

Person in Charge knows product sales projections (ADQs).

-

Person in Charge is Modeling- Coaching- Requiring. Praising good performance and correcting any operational issues.

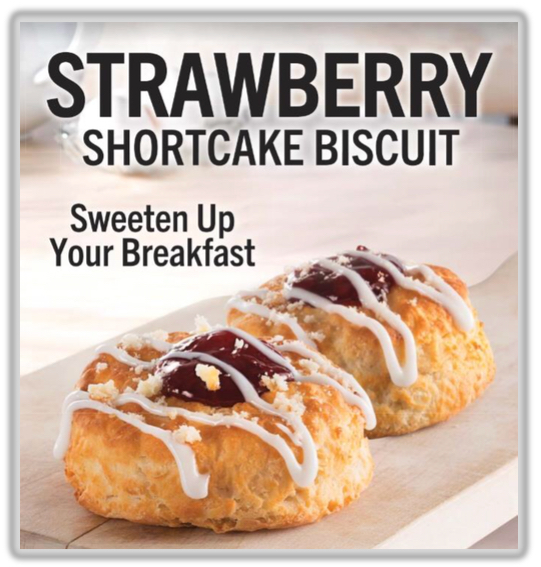

POP POSTING

-

The Breakfast Sliders POP is posted correctly and in a timely manner with correct pricing.