Title Page

-

Site conducted

-

Conducted by

-

Date conducted

-

If more than one person is required to complete the inspection form, then this can be done by following the instructions attached. Division of areas may be required for large sites.

-

This fire inspection is being conducted in compliance with the First Bus Fire safety Policy P13.

-

During the inspection it may be necessary to raise actions. In this situation these must be created before the report can be closed. Actions raised during the inspection must be assigned to the relevant responsible person for the particular site where the inspection is being undertaken.

-

Please note that not all sections and/or questions will be relevant and is dependent on the site being inspected.

Means of Escape

-

Are fire action notices clearly displayed?

-

Fire action notices are usually located near MCP and final exits.

-

Example of sign.

-

Is the instruction and the information on the notice legible?

-

Are internal fire escape routes free from obstructions, combustible materials etc.?

-

Are external fire escape routes free from obstructions?

-

Are fire exits and routes clearly signed?

-

Do the fire exit doors open easily?

-

Are all exit routes suitably illuminated (internal & external)?

-

Is the fire assembly point clearly signposted?

-

Is the route to the assembly point clearly marked from all exits?

Fire Alarm System

-

Example of fire alarm panel (repeater panel will be similar, but may be a simpler version).

-

Is an automated fire alarm system installed in the premises?

-

Are all MCP clearly identified with no obvious visual defects?

-

Do all audio and visual alerts (strobes, sounders etc.) appear to be in good order with no visual defects?

-

Is the main fire alarm indicator panel displaying any faults?

-

Are fire alarm repeater panels installed?

-

Are the fire alarm repeater panels displaying any faults?

-

Are automatic door release devices fitted (these hold doors open and will release upon activation of the fire alarm)?

-

Do the the devices appear to be in good order with no visual defects?

Emergency Lighting

-

Look for red/green LED to indicate operation, condition of housing, brightness of light etc. In open areas emergency lighting may situated at high level and can only be observed from ground level.

-

Has all emergency lighting been tested (monthly test required for all EL units)?

-

Does all emergency lighting appear to be in good working condition with no obvious visual defects?

Fire Safety Equipment

Fire Extinguishers & Fire Blankets

-

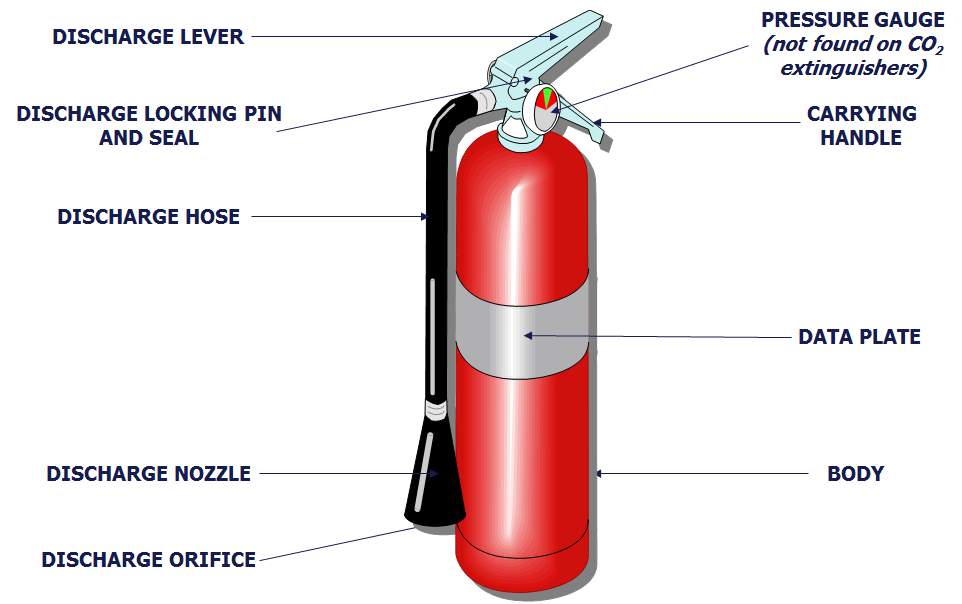

Fire Extinguisher Anatomy

-

Are all extinguishers clearly identified with appropriate signage?

-

Example of sign.

-

Are all extinguishers present in their identified location?

-

Are the extinguishers easily accessible?

-

Are extinguisher seals and pins fitted and intact?

-

Do the extinguisher fittings appear to be in good order with no missing parts i.e., horn attached

-

Where fitted is the gauge showing the pressure in the green zone?

-

Example of pressure gauge.

-

Where provided are external extinguishers in good condition with no sign of corrosion etc.?

-

Do fire blankets appear to be in good condition and accessible/close to the hazard they are intended for?

Fire Doors

-

Fire Door Components

-

Refer to the checklist to determine suitability and condition of all fire doors and fittings.

-

Do all fire doors conform to requirements of the checklist?

Hydrants

-

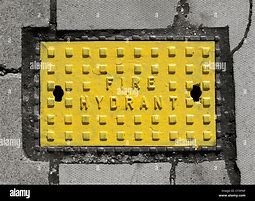

Example of fire hydrant below ground.

-

Does this site have fire hydrants?

-

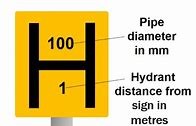

Is the location of the hydrants clearly indicated, including appropriate numbers on sign (signage and yellow hydrant cover)?

-

Example of sign.

-

Are the hydrants easily accessible and not obstructed?

-

Are the hydrants fit for use i.e., covers easily removable, valve area free from debris, no water ingress or leaks etc. Visual check only required.

Smoke Ventilation Systems

-

Inspections and testing are required at the following intervals: Weekly / Monthly / 6 & 12 Monthly. Six monthly and annual inspections and service must be conducted by an approved contractor. Internal testing must be conducted in accordance with approved procedures and recorded in the fire log book.

-

Typical smoke vent control.

-

Is an automated smoke ventilation system fitted (Automatic Opening Vent - AOV)?

-

Do the vent controls appear to be in good condition with no obvious visual defects?

Disabled Refuge Points

-

This sign (or similar) should be displayed in designated disabled refuge areas.

-

Are refuge points located in the building?

-

Are the areas free from debris, combustible material etc.?

-

If an evacuation chair is provided, is it accessible and in usable condition?

Communication

-

Example of communication system; green panel located in refuge area.

-

Is there a communication system present?

-

Is the communication system operational with no obvious visual defects?

Hose Reels

-

Example of fire hose reel.

-

Does this site have fire hose reels?

-

Is the location of hose reels clearly indicated?

-

Example of sign.

-

Are the hoses easily accessible?

-

Are the hoses stored on the reels?

-

Do the hoses have a suitable nozzle fitted?

-

Are there any signs of water leaks?

Wet & Dry Risers

-

Wet/dry risers are usually housed in a cabinet similar to the one shown below.

-

Are wet/dry risers installed at this location?

-

Is the location clearly indicated with appropriate signage?

-

Are the inlets accessible for the emergency services (fire engine needs to park close by to connect to riser system)?

-

Does the cabinet and hose connections look in good order and free from visual defects?

Sprinkler Systems

-

Inspections and testing are required at the following intervals: Weekly / Monthly / 6 &12 Monthly. Six monthly and annual inspections and service must be conducted by an approved contractor. Specific test criteria will be issued if required.

-

Are sprinkler systems fitted in any of the buildings?

-

Does the system look to be in good visual order with no obvious leaks etc.?

I, the undersigned, confirm this inspection took place and was completed accurately.

-

Name

-

Signature

-

Date & Time