Title Page

-

Conducted on

-

Prepared by

-

Customer Name

-

Location

-

Task Number

-

Number of Units Included in Risk Assessment

-

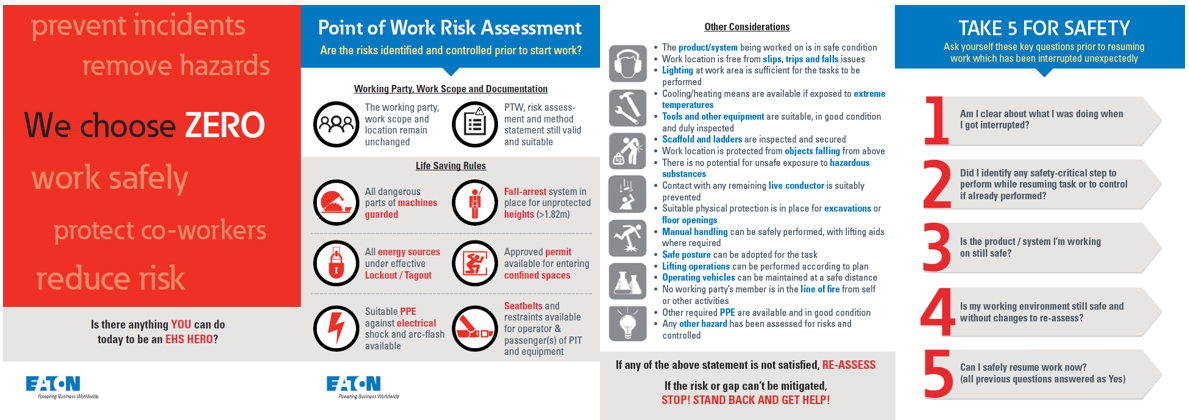

Please review the safety card as a reminder of safety actions that may be required before and during the task

-

Please review the PQ Predictive Risk Assessment to ensure you have applied all required controls

Assessment

-

Is there a site induction and have you and your team members been inducted

-

Do you know how to raise an alarm, call for help & evecuation procudure

-

Liaise with site contact to ensure you and your team are aware of emergency procedures for the site before you continue work.

-

Task type

-

Please describe type of work.

-

Please confirm there has NOT been any change in the scope of work. (You must also STOP WORK and obtain Management authorization to continue if at anytime the scope of work changes).

-

Stop Work. You must obtain authorization from Management before proceeding.

-

Is switching required for this task. (is the unit connected to a live electrical system or batteries)

-

Can you confirm there is NO Risk from stored Mechanical or Pressure Energy

-

Can it be Safely Secured

-

STOP WORK, Further Assessment Required to find safe system of work. Please continue with assessment to find further hazards that need control.

-

Document controls to ensure safety from stored mechanical or pressure energy

-

Will Manual Handling Operations be taking place and are control measures in place to ensure safe working (review RAMS)

-

Assess the manual handling operation and document a safe system of work before continuing. Consider - Can it be eliminated, can mechanical aids be used, can loads be split to make them lighter or less bulky, would assistance from a colleague reduce risk,

-

Document Manual handling Controls

-

If Working at Height operations are taking place, are adequate control measures also in place to ensure safe working (review RAMS)

-

Assess the working at height operation and document a safe system of work before continuing. Consider - Can it be eliminated, are fall prevention systems in place.

-

Document working at height controls

-

Do the RAM's adequatly identify all the Hazards and Controls for the task

-

Identify other hazards and controls to ensure a safe system of work is in place

-

Have all the Hazards and Controls been identified during the walk through and been highlighted to all the Team Members. Do all Team Members understand their role and critical safety controls to be in place before and during the job

-

Lead engineer must carry out a team brief and walk through to highlight the safety requirements for the job and ensure team members understand their roles in ensuring a safe system of work is in place.

-

Team leader to confirm job safety walk through with has taken place with team

-

Team Leader and all team members sign to agree they are fully aware and understand hazards and controls required to be in place and their individual roles to ensure a safe system of work

-

Team Leader to sign

-

Name and Signature

-

Name and Signature

-

Name and Signature

-

Team Leader and all team members sign to agree they are fully aware and understand hazards and controls required to be in place and their individual roles to ensure a safe system of work

-

Team Leader Signature

-

Name and Signature

-

Name and Signature

-

Name and Signature

-

Name and Signature

-

Name and Signature

Switching

-

Can the Rectifier Input be identified

-

Category 2 - STOP WORK until rectifier input is identified. When Rectifier input is Identified check box and continue.

-

Document position of Rectifier Input

-

Can it be locked off under your control

-

Is it in your sight with No Access without your Knowledge

-

Category 1 - Assess controls required to ensure rectifier input is not accessed without your knowledge and document a safe system of work.

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control rectifier input

-

Name of Eaton Manager who gave permission to continue

-

Category 0

-

Can it be locked off under your control

-

Is it in your sight with No Access without your Knowledge

-

Category 1

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control Rectifier input

-

Name of Eaton Manager who gave permission to continue

-

Category 0

-

Is this a single feed unit

-

Can the Bypass Input be identified

-

Category 2 - STOP WORK until bypass input is identified. When bypass input is Identified check box and continue.

-

Document position of bypass Input

-

Can it be locked off under your control

-

Is it in your sight with No Access without your Knowledge

-

Category 1 - Assess controls required to ensure Input is not accessed without your knowledge and document a safe system of work.

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control bypass input

-

Name of Eaton Manager who gave permission to continue

-

Category 0

-

Can it be locked off under your control

-

Is it in your sight with No Access without your Knowledge

-

Category 1 - Assess controls required to ensure bypass input is not accessed without your knowledge and document a safe system of work.

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control rectifier input

-

Name of Eaton Manager who gave permission to continue

-

Category 0

-

Can the Output be identified

-

Category 2 - STOP WORK until Output is identified. When Identified check box and continue.

-

Document position of output

-

Can the output be locked off

-

Is it in your sight with No Access without your Knowledge

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Can it be locked off under your control

-

Category 0

-

Is it in your sight with No Access without your Knowledge

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Category 1 - Assess controls required to ensure Output is not accessed without your knowledge and document a safe system of work.

-

Is there a Battery installed on this unit

-

Can the Battery Isolation be identified

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Can it be locked off under your control

-

Category 0

-

Is it in your sight with No Access without your Knowledge

-

Category 1 - Assess controls required to ensure Battery isolation is not accessed without your knowledge and document a safe system of work.

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control

-

Name of Eaton Manager who gave permission to continue

-

Can you confirm that NO load sync is installed on this unit

-

Can the Load Sync Connector be Safely Removed

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control

-

Name of Eaton Manager who gave permission to continue

-

Category 0

-

Can you confirm that there are NO other electrical input greater than 50V on any of the Building Alarms / Contactor Auxillaries etc

-

Can the Connector be Safely Removed

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control

-

Name of Eaton Manager who gave permission to continue

-

Category 0

-

Does the work task involve / require lifting of the neutral?<br>Replacement of the unit or cable lugs for example.

-

Can you confirm that the neutral has been completely isolated by way of 4 pole breaker or neutral link removed?

-

Category 2 - STOP WORK - Liaise with customer and Eaton management to plan a safe system of work before continuing. Eaton Management must give permission to proceed. Tick box when permission is given to continue.

-

Document safe system of work to control

-

Name of Eaton Manager who gave permission to continue

-

Who is carrying out Switching

-

Obtain Switching Authority from site contact

-

Open Name & Signature Boxes with statement

-

Who is Proving Dead

-

Has a permit to work been issued

-

Record type and number of permit

-

Photo if possible

-

Are Adjacent live equipment / cabinets clearly marked

-

Are they obvious / is there NO chance you could enter them by mistake

-

Place signage on equipment to distinguish which is to worked on and which is not .

Live Work

-

Is Live Working with covers removed required

-

Full Arc Flash / Electrical PPE Required

-

Will you be working on Battery without safety links removed. Including removing or replaceing saftey links

-

Full Arc Flash / Electrical PPE Required

-

Name of safety person in attendance while proving dead or live testing

Final Check and Sign Off

-

Can you confirm there is NO Risk from stored Mechanical or Pressure Energy

-

Can it be Safely Secured

-

STOP WORK, Further Assessment Required to find safe system of work. Please continue with assessment to find further hazards that need control.

-

Document controls to ensure safety from stored mechanical or pressure energy

-

Will Manual Handling Operations be taking place and are control measures in place to ensure safe working (review RAMS)

-

Assess the manual handling operation and document a safe system of work before continuing. Consider - Can it be eliminated, can mechanical aids be used, can loads be split to make them lighter or less bulky, would assistance from a colleague reduce risk,

-

Document Manual handling Controls

-

If Working at Height operations are taking place, are adequate control measures also in place to ensure safe working (review RAMS)

-

Assess the working at height operation and document a safe system of work before continuing. Consider - Can it be eliminated, are fall prevention systems in place.

-

Document working at height controls

-

Do the RAM's adequatly identify all the Hazards and Controls for the task

-

Identify other hazards and controls to ensure a safe system of work is in place

-

Have all the Hazards and Controls been identified during the walk through and been highlighted to all the Team Members. Do all Team Members understand their role and critical safety controls to be in place before and during the job

-

Lead engineer must carry out a team brief and walk through to highlight the safety requirements for the job and ensure team members understand their roles in ensuring a safe system of work is in place.

-

Team leader to confirm job safety walk through with has taken place with team

-

Team Leader and all team members sign to agree they are fully aware and understand hazards and controls required to be in place and their individual roles to ensure a safe system of work

-

Team Leader to sign

-

Name and Signature

-

Name and Signature

-

Name and Signature

-

Team Leader and all team members sign to agree they are fully aware and understand hazards and controls required to be in place and their individual roles to ensure a safe system of work

-

Team Leader Signature

-

Name and Signature

-

Name and Signature

-

Name and Signature

-

Name and Signature

-

Name and Signature