Information

-

Audit Title. R44 - Earthworks - Embankment (Ed5 Rev 0) .

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

-

Cl 1.6.1 Has survey set out been installed for all Embankments

Cl 2.3 REMOVAL OF TOPSOIL.

-

Are erosion and sediment controls in place prior to commencing removal of topsoil?

-

Are all working areas maintained so as to ensure run-off of water without scouring or pounding.<br>

-

Has precautionary activities (such as sealing off) been implemented to minimise ingress of water into earthworks material.

-

Has the required action been taken to minimise the generation of generation of excessive dust.

-

Has the topsoil been left in place where bridging layers are to be used.?

-

Are topsoil stockpiles in a approved location.<br>Be free of subsoil and other excavated material.<br>Height not exceeding 2 metres.<br>Batters been track rolled or stabilised. <br>Been seeded within 7 days of completion of 500m2 of exposed batter face.

-

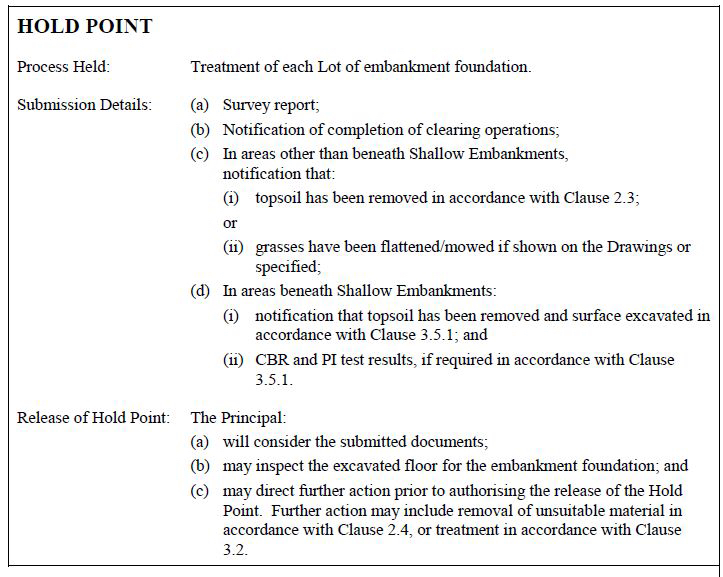

Has the hold point been released.

-

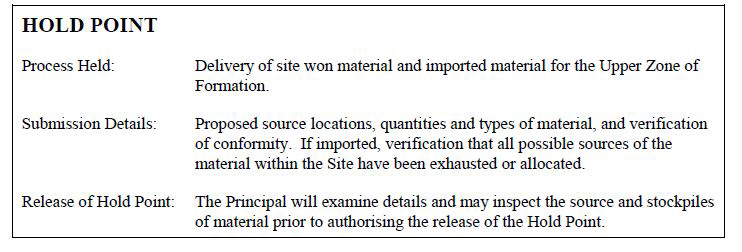

HOLD POINT Cl 2.3.3.

Cl 2.4 UNSUITABLE MATERIAL.

-

After the stripping of topsoil covering each embankment foundation , has the contractor allowed the inspection of the foundation.?<br>Has the contractor notified of any areas of the foundation or any layer of foundation that rut excessively, yield or show signs of distress or instability.? <br>Has any areas of unsuitable material (as defined in Cl 1.4) been found, such unsuitable material must be excavated to the extent directed by the Principle.?

-

Has the Principal inspected the excavation and released the hold point.

-

HOLD POINT 2.4.1.

-

Cl 2.4.2 and Has the unsuitable material been used in the embankment fill.

-

Cl 2.4.3 Has the unsuitable material been replaced with either \<br>(a) Suitable material in accordance with clause 5.1 <br>Or<br>(b) if directed, with a foundation treatment in accordance with clause 3 or as shown on the drawings.

Cl 2.8 MATERIAL IN UPPER ZONE OF FORMATION, VERGES AND SPILL THROUGH BRIDGE ABUTMENTS.

-

Cl 2.8.2 Is the material used for Upper Zone Material, verge material and spill through abutment fill material being obtained from the borrow area. . <br>

-

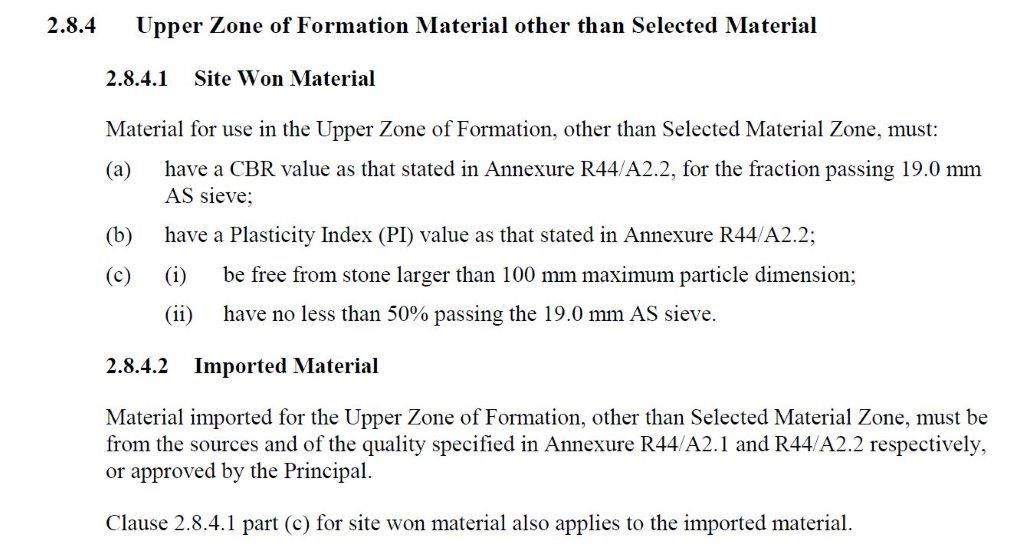

Cl 2.8.4

-

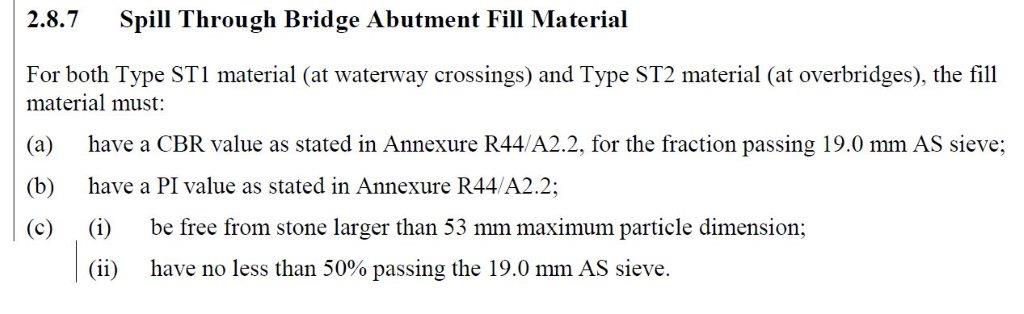

Does the fill material conform to clause 2.8.7.<br>)<br>Free of stone larger than 53 mm. <br>no less than 50% passing the 19mm sieve.<br> <br>Was the material stockpiled, sampled and tested in accordance with Cl 2.8.3.

-

Cl 2.8.7 Earth fill at spill through bridge abutments:

CBR min 8 (10Day),PI min 5 max 8 (R44 A2.2) -

Cl 3.2 Has the hold point been released.

-

Cl 3.2 Foundation Treatments.

-

Cl 3.2 Have further treatments been ordered.<br>Have these treatments been completed. <br>Material replacing unsuitable under embankments and foundation treatments for embankments (except E2 bridging layer and Type E5 drainage layer) CV 95

-

Cl 3.3 Is the embankment on a hillside if so:<br>Has terracing been carried out as per this clause.

-

CL 5.1.2 Materials for embankment construction must be :<br>Free from tree stumps, roots and refuse.<br>Must be obtained from within the site or borrow pit. (Unless authorised by the principal) <br>Programme and manage the works as detailed in the Earthworks plan.

Cl 5 EMBANKMENTS

-

Cl 5.1.3, 5.2.1, 5.2.2 <br>Embankment Construction the material to be placed:<br>In layers parallel to the grade line.<br>Compacted to achieve relative compaction over the full depth of the layer.<br>

-

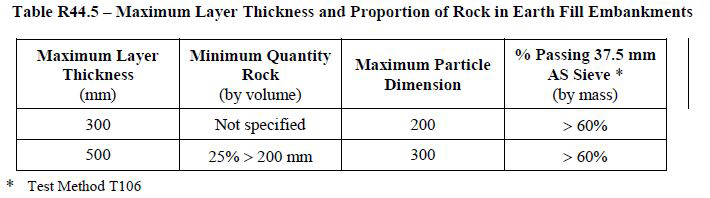

Cl 5.2.1 The particle size limitations and proportion of rock in earth fill material must be in accordance with

-

Cl 5.2.2 Layers (after compaction) must be not less than 100mm or more than given in table R44.5

-

Cl 5.2.3 Earth Fill at Spill Through Bridge Abutments.

-

Cl 5.2.3 Is the zone the correct dimensions. Is the material being placed in Max 300mm layers when compacted.

-

Do the finished batters conform to the tolerences in table R44.8

-

Cl 5.6.2. Is the material being placed adjacent retaining walls and bridge abutments of the type and to the extent in accordance with spec RMS B30. <br>

-

Cl 5.6.3 is the material being placed adjacent to culverts and other drainage structures of the type and to the extent in accordance with spec RMS R11<br>

-

Has the Principal released the hold point.

-

Cl 6.1.1 HOLD POINT

-

Cl 6.1.1 Before placing any imported Upper Zone Material:<br>Carry out a survey to determine the surface levels at sufficient locations to latter determine the volume of compacted imported material placed in the works.

7 ADDITIONAL CONFORMITY REQUIREMENTS

-

Cl 7.1 Has the layer been trimmed prior to and during compaction.

-

Cl 7.2 Is the moisture content within the range specified.<br>Annexure R44/A5 Moisture Range 60-90%.

-

Cl 7.3.2 Is the lot homogeneous.

-

Cl 7.3.4 Is only a single test method being used for the lot.

-

Cl 7.3.7 Are test holes being repaired as detailed in the contractors Project Quality Plan.

-

Has the layer been compacted to the required limits Table R44.10 CV 98%<br>Has the surface been trimmed to required tolerance Table R44.11 +0mm/-40mm

-

Cl 7.4 Has the layer been compacted to the required limits:

-

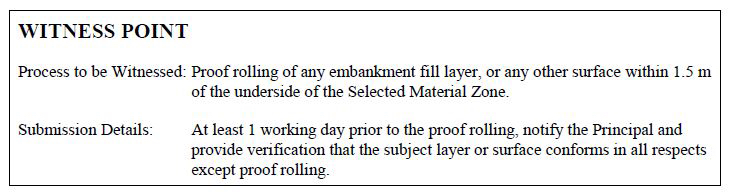

Has the proof roll been requested by the contractor and was the proof roll witnessed.

-

Cl 7.6.1 Proof Rolling Witness point.

-

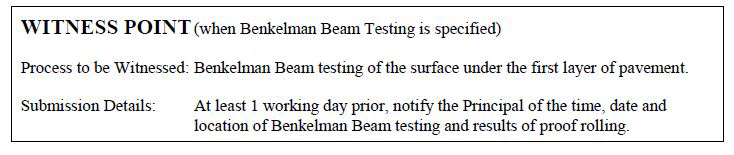

Has the contractor notified of the time, date and location of the benkelman beam testing and results of proof rolling. <br>Was the testing witnessed.

-

Cl 7.6.2 WITNESS POINT Process to be witnessed: Benkelman beam testing of the underside of SMZ

-

Cl 7.6.2 Benkelman Beam Witness point (if applicable)

-

Cl 7.6.2 Was the testing Witnessed.

-

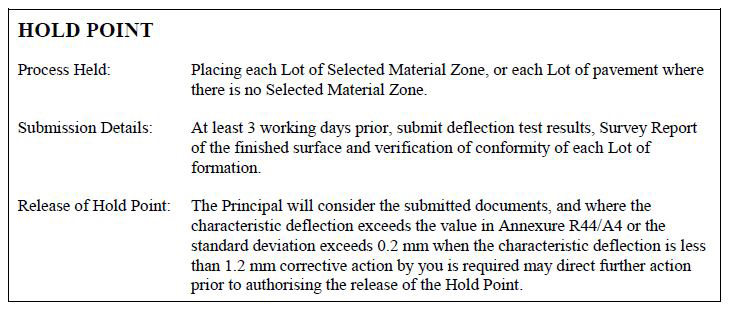

Cl 7.6.2 Benkelman Beam. HOLD POINT. (If applicable)

-

Cl Has the HOLD POINT been released.

G22 Safety and G36 Environmental

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Were any unsafe practices observed. <br>

-

Safe work practices observed.

G36 ENVIRONMENTAL

-

R44 Cl 1.7 Were erosion and sediment controls in place prior to the removal of any topsoil.

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

NCPN or memo number.

-

Surveillance Officer

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name