Title Page

-

Surveillance Checklist R44 - Earthworks Selected Material Zone (SMZ) (ED5 Rev0)

-

Project Name.

-

Location:

-

Prepared by

-

Contractor

-

Conducted on.

6 STRUCTURAL TREATMENTS

-

R44 CL 6.1 Has survey set out been installed for Selected Material Zone (SMZ)

-

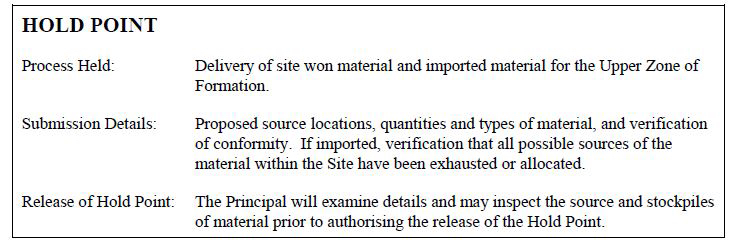

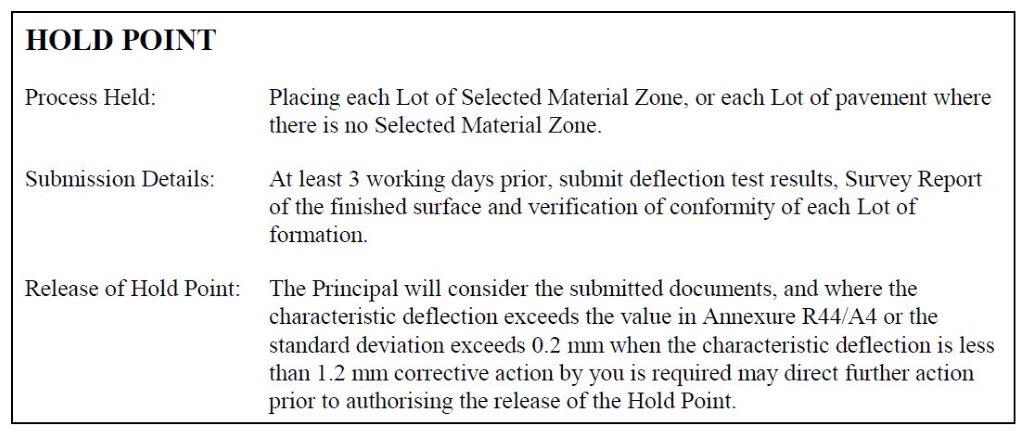

Cl 6.1.1 HOLD POINT.

-

Cl 6.1.1 Has the HOLD POINT been released.

-

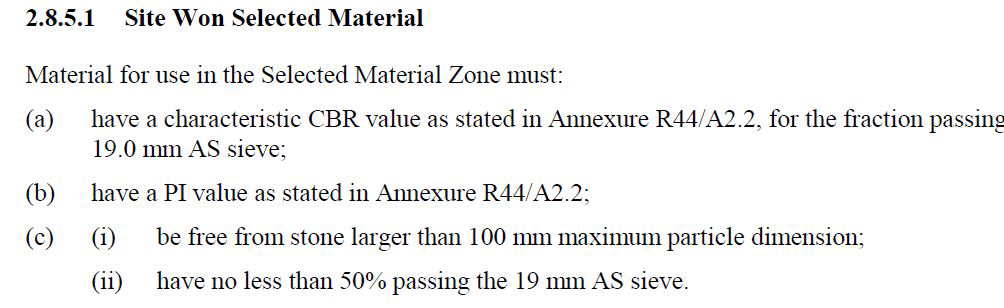

Site won selected material. Cl 2.8.5.1

Does selected material meet the requirements -

If any selected material layer has a CBR value less than specified above, has hydrated lime at a rate of 2% by mass or equivalent, been used for modification.

-

Imported Selected Material. Cl 2.8.5.2 <br>Does imported selected material meet the requirements of RMS material <br>Specification. 3071 <br>Size distribution as per Annexure 3071/A3<br>Max Size 53mm or less <br>PSD as per table 3071/A1(type B)<br>CBR 30 or greater for top 150mm (4day)<br>CBR 30 or greater for bottom 150mm (4day)<br>PI greater than 2 less than 15.

-

If any selected material layer has a CBR(4day) of less than 30, has the top 150mm of material in this zone been modified with a binder (usually lime)

-

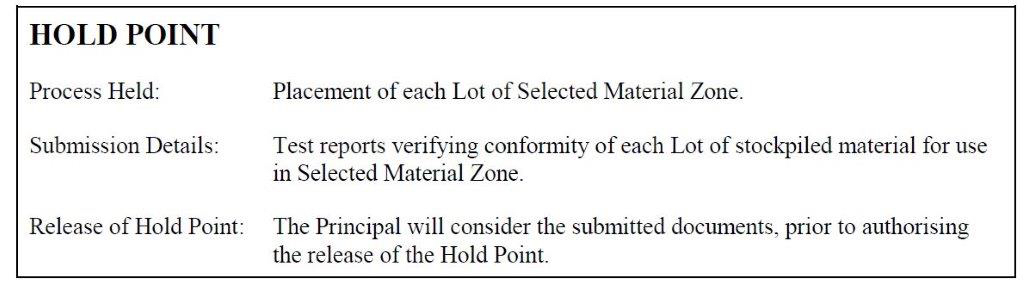

Cl 6.1.2 HOLD POINT

-

Cl 6.1.2 Has the HOLD POINT been released.

-

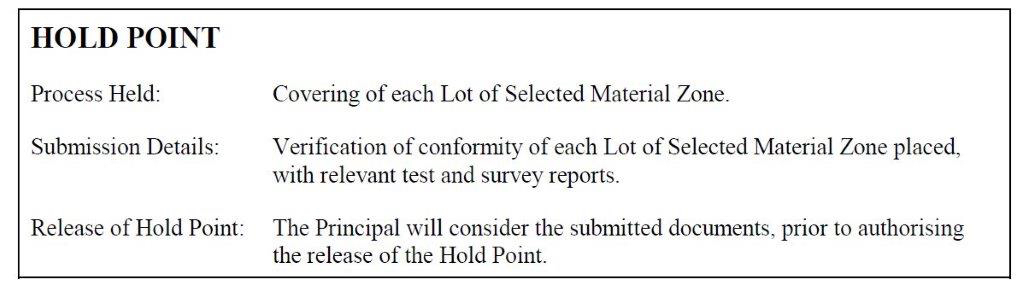

Cl 6.1.2 HOLD POINT (b)

-

Has the HOLD POINT been released.

-

Is each SMZ layer thickness not exceeding 150mm.

-

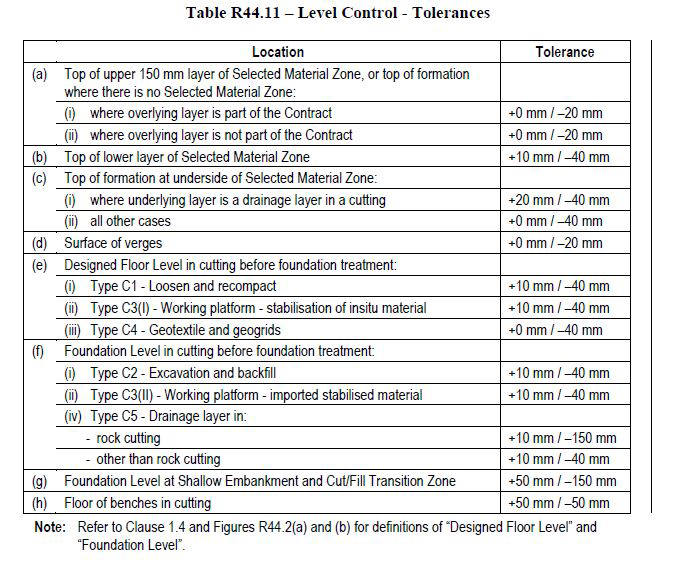

Cl 6..1.2 Has the top of the SMZ been trimmed to required tolerance

7 ADDITIONAL CONFORMITY REQUIREMENTS

-

Cl 7.3.2 A lot must contain only areas of work that are essentially homogeneous

-

Have any areas that failed to meet homogeneity criteria been excluded from the lot and another lot been opened to be tested

-

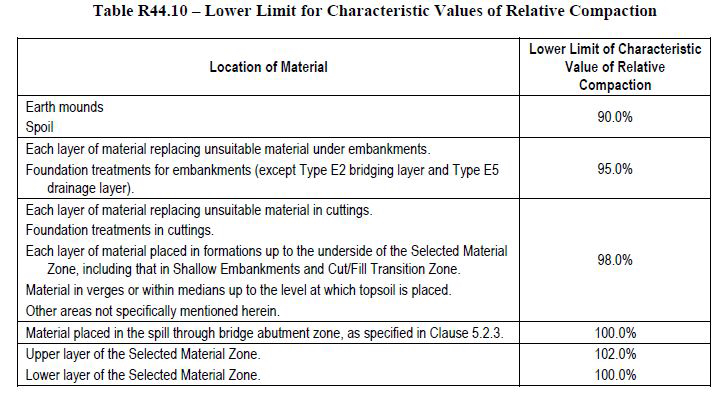

Cl 7.1 Has all layers been compacted uniformly over the full area and depth of the layer to achieve the relative compaction specified before the next layer is commenced

-

Cl 7.3.4 have tests within a particular lot been conducted using a single test method

-

Cl 7.3.7 Have the test holes been repairs as detailed in the PQP.

-

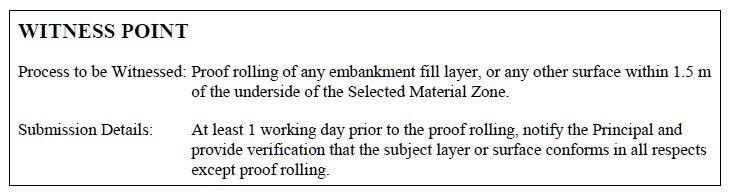

Cl 7.6.1 WITNESS POINT. PROOF ROLLING

-

Has the proof rolling for the underside of SMZ formation been witnessed.

-

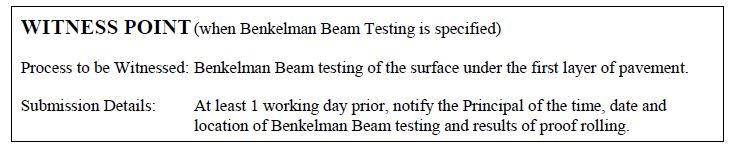

Cl 7.6.2 WITNESS POINT benkelman beam testing

-

Cl 7.6.2 has the benkelman beam testing been witnessed. R4

-

CL 7.6.2 HOLD POINT

-

CL 7.6.2 Has this HOLD POINT been released

G22 SAFETY and G36 ENVIRONMENTAL.

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor.

-

Has a SWMS been developed for the activity.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with its design and purposes.

-

Safe work practices observed.

-

Is correct PPE being worn.

-

Were any unsafe practices observed.

G36 ENVIRONMENTAL

-

Are erosion and sediment control measures being installed and maintained.

-

Has mud been prevented from being deposited on the roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental practices been observed.

Compliance and Follow-up action

-

Is the activity compliant.

-

NCPN or memo number

-

Add signature

-

Follow up Action

-

Product nonconformance

-

System Non Conformance

-

Contractor generated an NCR.

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors' NCR no

-

CAR no

-

Closed out

-

Add signature