Information

-

Audit Title. R71 Construction of Unbound and modified Pavement Course (Tabulam Bridge) (Ed4 Rev1) .

-

Project Name Tabulam New Bridge

-

Location: BRUXNER HIGHWAY TABULAM

-

Prepared by

-

Contractor

-

Conducted on

Work Activity Record

2 UNBOUND MATERIAL OR MATERIAL TO BE MODIFIED

-

Cl 2.1 does the proposed material to be used comply with Specification RMS 3051.

-

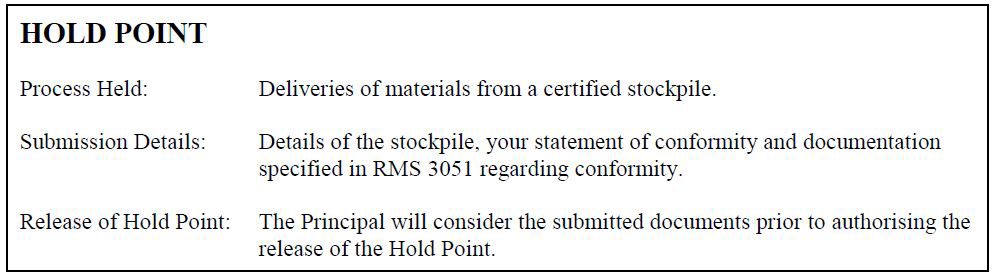

CL 2.2 Has the HOLD POINT been released.

-

Cl 2.2 HOLD POINT

-

Cl 2.2. No further material to be added to the stockpile after it has been certified. <br>

-

Cl 2.2 Each delivery docket must identify the certified stockpile

-

Cl 2.3 Install and maintain around the STOCKPILES appropriate erosion and sedimentation controls in accordance with G38 for the duration of the contract

-

Cl 2.3 Construct stockpiles in a manner which does not cause segregation. <br>.<br>. <br>. <br>Total height of the stockpile must not exceed 4 metres unless otherwise approved by the Principle.

-

Cl 2.3 Construct stockpiles in horizontal layers

-

Cl 2.3 The worked face of any stockpile must be the full face of the stockpile.

-

Cl 2.3 Keep stockpiles separated. <br>

-

Cl On completion of works; Clear the stockpile of all surplus material.<br>Re-vegetate the area in accordance with R178.

-

Cl 2.4 Transport any unbound material or Material To Be Modified in vehicles which are so constructed that loss of material does not occur.

-

Keep material suitably damp to prevent segregation or loss of fines during transit.

-

Material delivered which is unsuitable for reasons such as segregation, contamination or non-homogeneity is deemed to be nonconforming and must not be used in the Works.

Cl 6 CONSTRUCTION.

-

Cl 6.1 works to be carried out to prevent:<br>Segregation.<br>Slurrying the surface.<br>Meet the conformity requirements of clause 8

-

Cl 6.4 MOISTURE CONTENT.<br>Develop a work method and target moisture content to ensure;<br>Adequate moisture in the material to achieve specified compaction. <br>Pavement to be capable of taking traffic without shoving or ravelling on completion of compaction. <br>The field moisture content during placement and compaction must be within the target moisture range.

-

Cl 6.5 SPREADING, COMPACTING and TRIMMING.

-

Equipment and methods used must be as detailed in the PQP. <br>Works through to final finishing must proceed continuously until completion. <br>Each layer greater or equal to 100mm and less than or equal to 150mm. <br>Compact the full depth of the pavement over the entire area. <br>No roller marks to remain in the pavement surface after trimming.

-

Cl 6.6 PROTECTION of WORKS. <br>No water to pond on the surface. <br>Surface must be kept moist to stop dust being generated by traffic <br>

-

Cl 6.7. TREATMENT OF PAVEMENT PRIOR to PLACING WEARING SURFACE. <br> Contractor is to:<br>Rectify any deteriorated surface prior to placing wearing course at their cost. <br>Moisture content not to exceed 70% of OMC prior to placing wearing course. <br>Carry out Ball Penetration test in accordance with test method RMS 271 prior to placing wearing course.

-

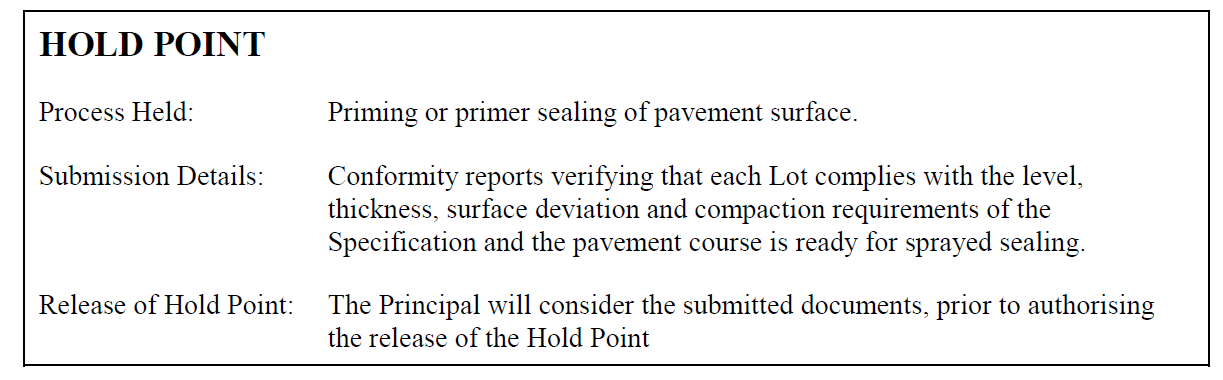

Cl 6.8 Has the Hold point been released<br>

-

Cl 7 SURVEY.

-

Cl 7.1 Carry out survey in accordance with RMS G71 to determine levels at the top of:<br>Underlying layer (surface over which the pavement is to be placed) <br>Finished surface of the pavement course

-

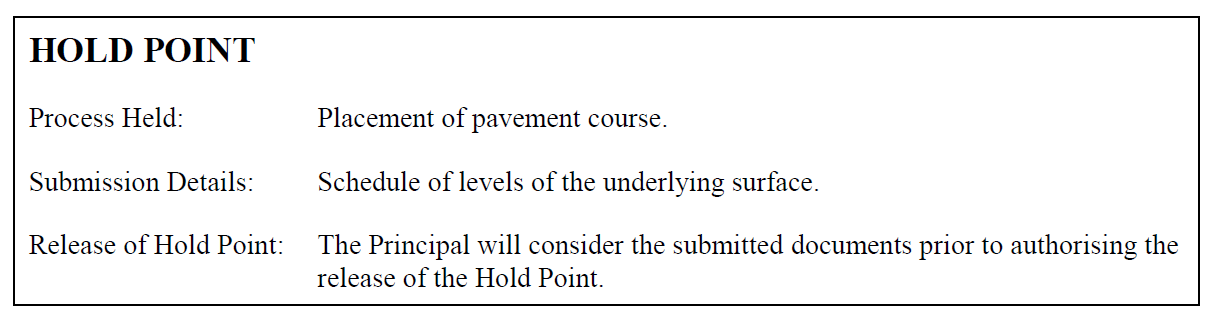

7 working days prior to programmed commencement of work the contractor is to present:<br>Schedule of levels of the underlying surface highlighting all locations where the actual levels are higher than the design levels. <br>The Principal may redesign the pavement finished levels. The will advise of any such redesign within 5 working days of receipt of the schedule. <br><br>Has the Principal released the hold point.

-

Has the Hold point been released

-

-

Cl 7.3 Survey for Pavement Course Finished Surface Levels. <br><br>Contractor to supply finished surface levels within 6 working days of completion of final trimming. <br>Highlight in the schedule all levels which area non conforming.<br>Tolerance: <br>Base Course -0mm , +10mm<br>Subbase Course -10mm, +10mm

-

Cl 7.4 Survey for Thickness <br>Contractor to submit a schedule of calculated thickness of pavement course for each lot within 6 working days of completion of final trimming. <br>Determine the survey points on Random basic. <br>Required accuracy of +- 5mm. <br>Point must be recoverable in the horizontal plane to within +-50mm. <br>At each survey point determine;<br>Underlying surface prior to placing the base and subbase material.<br>Pavement course after completion of compaction and trimming.

8 CONFORMITY

-

Cl 8.4.1 Each lot must be visually homogeneous. <br>All test holes must be reinstated with similar material to an equivalent compaction level.

-

Cl 8.4.4 RELATIVE COMPACTION;<br>Determine the sampling locations for each lot in accordance with RMS Q. <br>All test holes must be reinstated with similar material<br>Repair method to be as detailed in the PQP. <br>Compaction requirements as per table R71.1. CV 102%. Standard. <br>Submit test results daily.

-

The pavement course thickness at any point must not very from that specified in Annexure R71A by more than:<br>Base course automatic level -0mm +10mm, Non automatic level +10mm, +30mm. <br>Sub base course +-10mm. <br>

-

Cl 8.4.5 Field moisture content to be determined at each density test location. <br>Determine the moisture content over the full depth of the base. <br>Field moisture content must not exceed 70%of OMC prior to bituminous seal.

-

Cl 8.6 After final trimming all surfaces, the pavement surface must be parcel to the finished surface. <br>Tolerance <br>(A) base course: -0mm, +10mm<br>(B) subbase course: -10mm, +0mm

-

Cl 8.7Surface must not deviate from a 3 metre straight edge laid in any direction on the pavement by more than 5mm. <br>No abrupt change of levels in the transition from the pavement to fixed structures such as a bridge deck.

-

Cl 8.9 The width of the pavement must not be less than the shown on the drawings or specified in Annexure R71/A

-

Cl 8.10 Ball penetration value to be determined at the surface of the base course in accordance with Test Method RMS T271.<br>Test location to be where insitu density test was performed. <br>The average ball penetration value is to be less than 3mm.<br>The CV of the lot to be less than 2.5mm.

-

Cl 8.11 Contractor to submit to the principal a weekly signed certificate verifying conformity with the requirements of clause 8. <br>Submit with the certificate a summary of the test results. <br>Submit daily a summary of moisture results and relative density results.

-

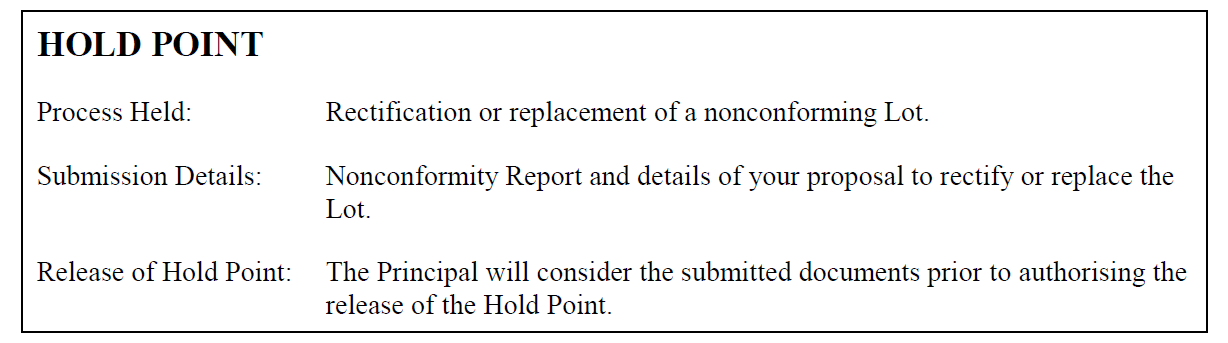

Cl 8.12 Has the Principal released the hold point.

-

G22 Safety and G36 Environmental

Closed out.

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Were any unsafe practices observed. <br>

-

Good safe work practises observed.

G36 ENVIRONMENTAL

-

R44 Cl 1.7 Were erosion and sediment controls in place prior to the removal of any topsoil.

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

Matters Arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

Select date

-

RMS Representatives name