Title Page

-

Business Name

-

Location

-

Date of Inspection

-

Inspector

Plans / Drawings

-

The approved plans / drawings are on-site or are available to the contractor.

Visual Inspection

-

Located within 100’ of a fire hydrant and is visible and accessible from the fire lane.

-

Piping, joints, and valves are uncovered.

-

Size and type of piping match approved plans.

-

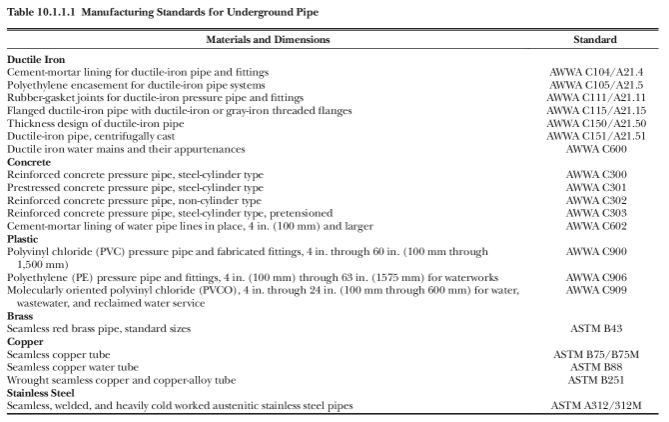

Piping is manufactured in accordance with NFPA 24, Table 10.1.1.1 (Manufacturing Standards for Underground Pipe).

-

Table 10.1.1.1 Manufacturing Standards for Underground Pipe

-

Piping is rated for the maximum system working pressure to which the piping will be exposed (not rated less than 150 psi).

-

Depth of piping is sufficient for protection from freeze and mechanical damage.

-

Depth of Piping (minimum 30" from top of the pipe to final grade; minimum of 36" under driveways/roads; minimum of 4' below railroad tracks or under large piles of heavy commodities or subject to heavy shock and vibrations).

-

Direction changes and thrust blocks or restrained joint systems match approved plans.

-

Corrosion resistance, such as coating and wrapping, is installed where necessary.

-

The tightness of bolted joints is verified by bolt torque or other methods approved by the manufacturer.

-

All bolted joint accessories are cleaned and thoroughly coated with asphalt or other corrosion retarding material after installation.

-

Where metal pipes of dissimilar metals are joined, they shall be insulated against the passage of an electric current using an approved method.

-

Bedding and backfill material on-site match the approved plans, do not exceed 3/4" particle size, and contain no ashes, cinders, refuse, organic matter, or other corrosive materials.

-

Backfill material is tamped in layers or in puddles under and around pipes to prevent settlement or lateral movement.

Hydrostatic Test

-

Trench is backfilled between joints.

-

The gauge is located at the lowest elevation or portion of the system being tested.

-

Starting pressure is minimum of 200 psi or 50 psi in excess of the system working pressure, whichever is greater.

-

Pressure pumps disconnected after initial pressurization.

-

The test lasted a minimum of two (2) hours; resulting in less than five (5) psi of pressure loss.

-

The pressure was relieved from the system and the gauge returned to zero (0) psi.

Line Flush

-

Flow through a minimum of 4" hose or pipe.

-

Hose or pipe is restrained prior to flowing water.

-

Observe flush or swab until clear of all debris.

Final Acceptance

-

12" x 12" x 4" concrete pad at the base of the FDC.

-

4' all-weather pathway from fire lane to remote FDC.

-

Signage that indicates which area, building, or address is served by the remote FDC.

-

The center of all hose outlets are located between 18 and 48 inches above final grade.

-

2-1/2" Siamese or 5" Storz connection provided.

-

Locking Knox Caps installed.

-

Check valve and ball drip installed at appropriate location.

-

Physical impact protection provided where appropriate.

Documentation

-

Contractor's material and test certificate(s) are received.

-

https://www.tdi.texas.gov/forms/sfmfireindustry/sf042sprundergd.pdf

Inspection Status

-

Inspection Status

-

Next Inspection

-

Owner / Representative

-

Phone #

-

Email Address