Title Page

-

Conducted on

-

Prepared by

-

Location

-

Site Name

Site Security

-

Where the store is still trading - details which areas are live. Consider store staff and emergency exit

routes and consider any security risks. Make sure there are arrangements for communication with the

store staff in place.

Good Practice: A daily hazards and work taking place to day board placed in the staff rest/canteen areas.

Daily briefing with the store manager with notes in daily site diary. -

Is all or part of the site trading?

-

Is there a security guard appointed and at their post?

-

If there is a security guard make sure there are arrangements in place to cover rest and lunch breaks and

if out of hours make sure there is a lone working risk assessment in place if required and a work risk

assessment especially if required to walk around a live construction site. -

Is external access to site controlled by a suitable and sufficient barrier system to prevent public/staff access, separate pedestrians from traffic and allow emergency escape?

-

Consider: access up on to scaffolds by other (children), pedestrians walking under scaffolding,

segregation of scaffolder's from the public scaffolders must be in an enclosed work area just like any

other trade. Liaise with the site so that they can park as close as possible to the work area to avoid

walking tubes and board through public/staff accessible areas.

Key points:

Door ways, cash machines, displays, how can they be worked around safely.

Emergency exits that fall within our site

All segregation must be sufficient to prevent access.

Banksmen can only be used as a secondary measure -

Is there accurate and relevant H&S signage at site entry points and each fence or barrier line at perimeter of the site / work area?

-

Key points:

Plan the location and number of signs required

Where possible place signage at eye level

Consider wind loadings when placing signage on heras fencing. -

Are the Principal Contractors business details on display around the perimeterof the site, including the site contact details

-

For the general public

This must displayed in a prominent position and clearly legible.

This can be the office number as we have a 24hr call out service - however the call out service must be

able to contact the site manager in an emergency.

For deliveries and visitors (this can be at the site entrance/delivery point)

This should be the Site Managers mobile number and another person who is usually on site.

Signing In/Induction/Competency

-

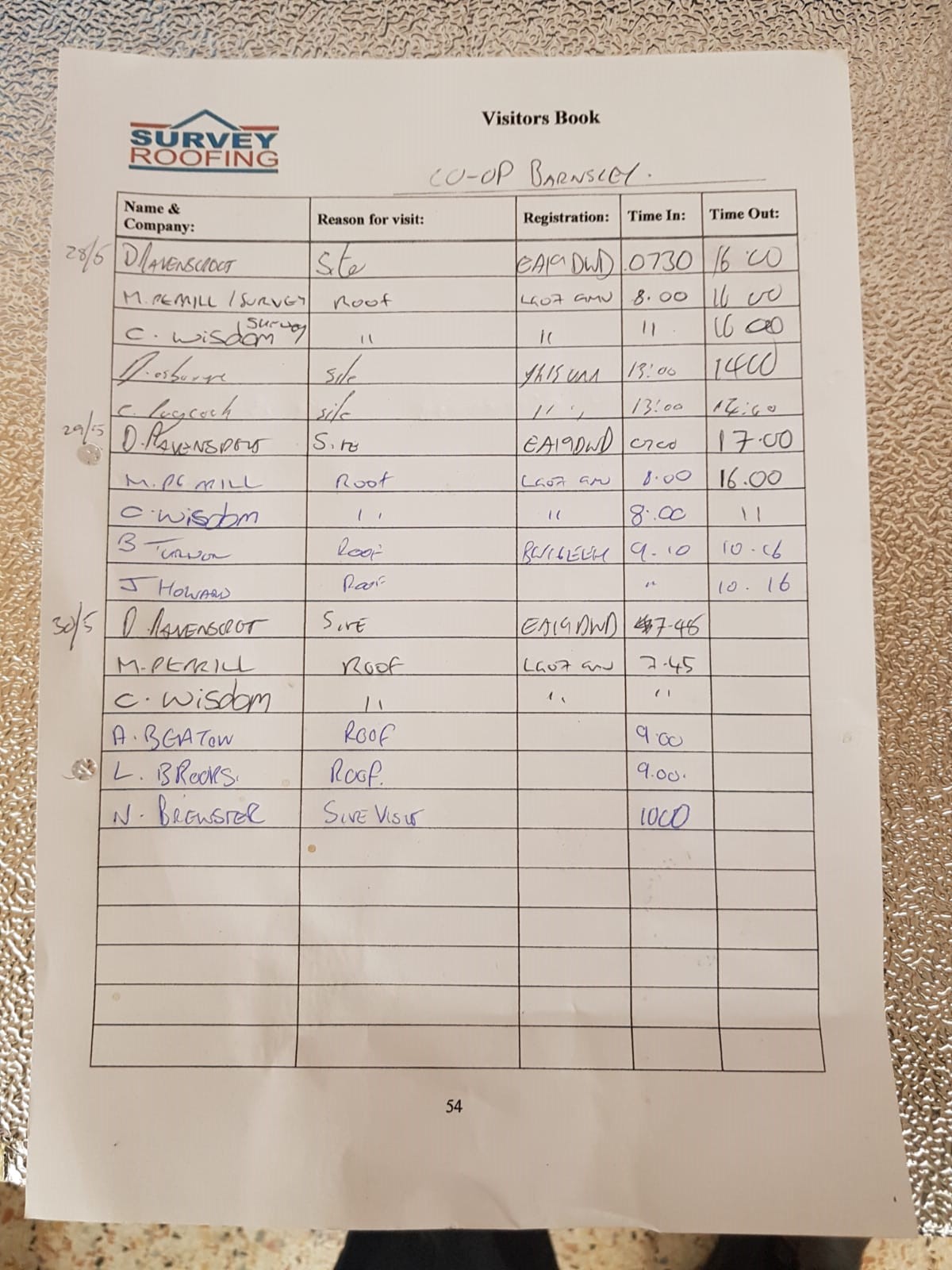

Is the signing in and out procedures enforced?

-

Complete a random check of 3 people on site to ensure they have signed in on the day of the visit. In Part - Where a couple of people have not signed inNo - Where 3 or more have not signed inPLEASE NOTE: If you find evidence of operatives NOT signing out on previous days but Site Management have evidence that they have addressed this (TBT, briefing, re-induction, yellow card etc.) do not mark them down for this

-

Where applicable, have FM contractors signed in at the store front end panel?

-

Have details of the site manger and supervisor been logged on the M+S training portal and are both compliant within their role requriements

-

Marks and Spencer sites only

Simple Compliance: Each person must have their own account set up and it is strictly forbidden to use

any one else's login. -

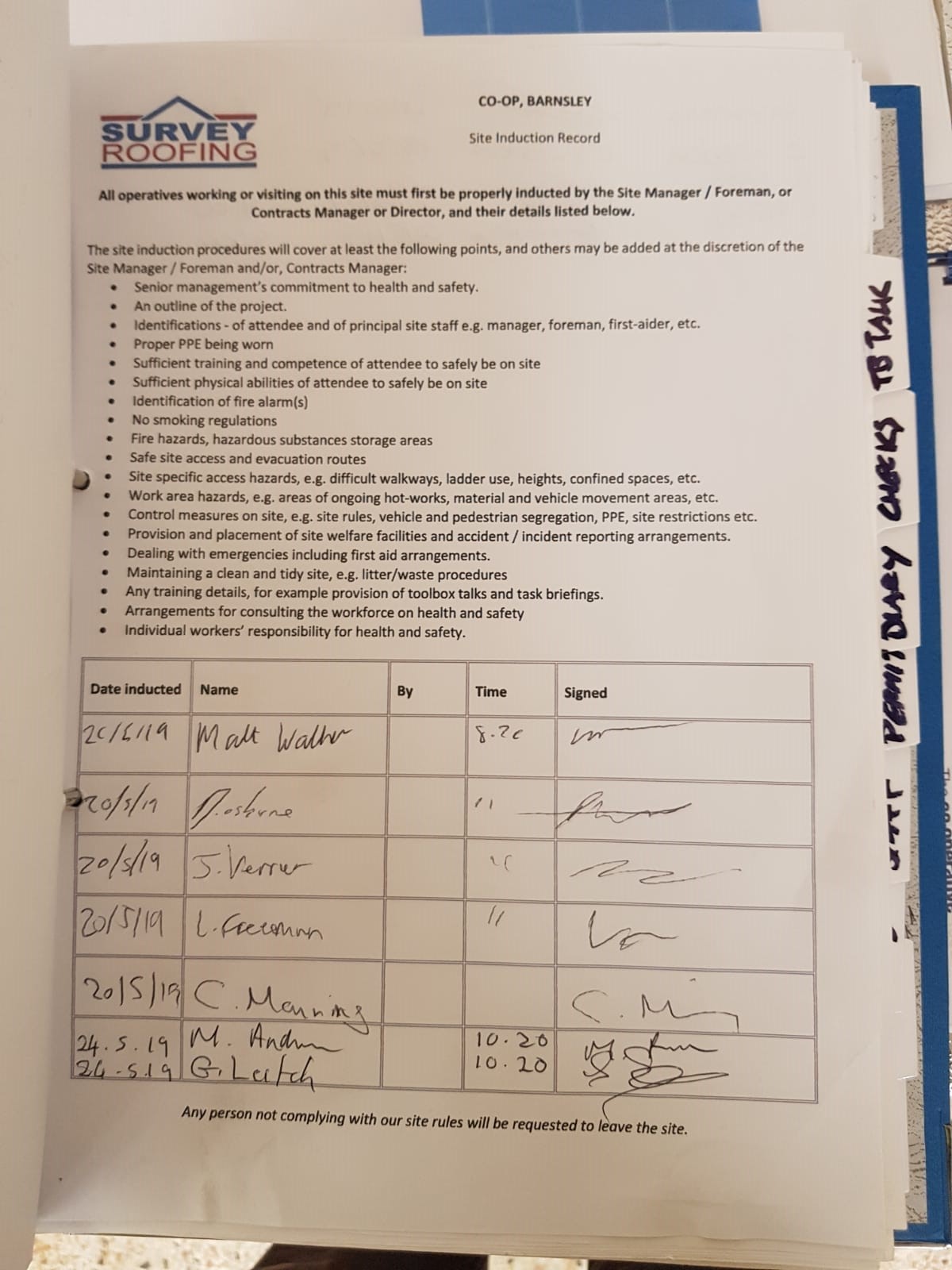

Is all relevant information included in the site induction?

-

An induction should include the following as a minimum: Buildings Asbestos content, Asbestos discovery/emergency procedures, evacuations procedures, traffic management, welfare facilities, site rules, PPE requirements, site rules and a description of works currently being undertaken: Use the Induction sign off template located V:\6.0 FORMS & TEMPLATES\001a NEW INDUCTION SIGN

OFF.docx

Fire and emergency plans must be site specific and if required make sure all plans have been

documented with the store.

GOOD PRACTICE:

Create a power point induction and make sure it is site specific and update as the site progresses -

Is the induction procedure being enforced

-

Complete a ramdom check of at least 3

-

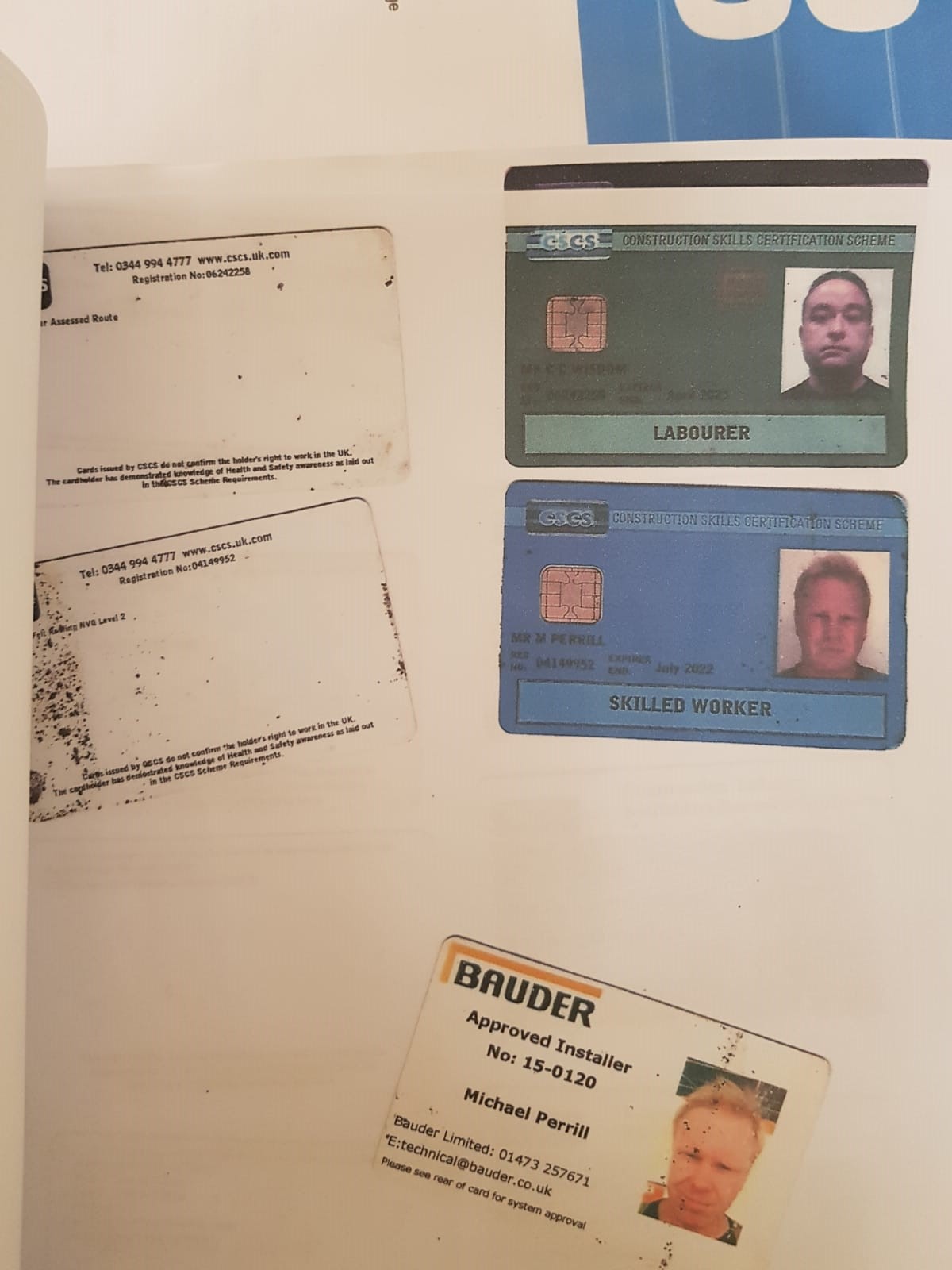

Are operatives competencies being recorded at the induction

-

Check the induction forms and ensure all sections are completed.

Take copies of all training certificates.

Every operative must be able to prove their basic H&S competence. This can be through the use of CSCS cards CCNSG Cards, SPA Passport or other passport schemes. Specific competence should also be provided for tasks that require it, such as JIB, IPAF, PASMA, SSSTS, asbestos awareness, CISRS etc. Should a specific skills card not be available for the given trade then contractors must be able to demonstrate to the PC that operatives have the individual skills, knowledge, experience and training the role requires. No - two or more card details missing and no other evidence of competencyMake a note of any competencies that expire during the project add them to the notes and discuss with the site manager -

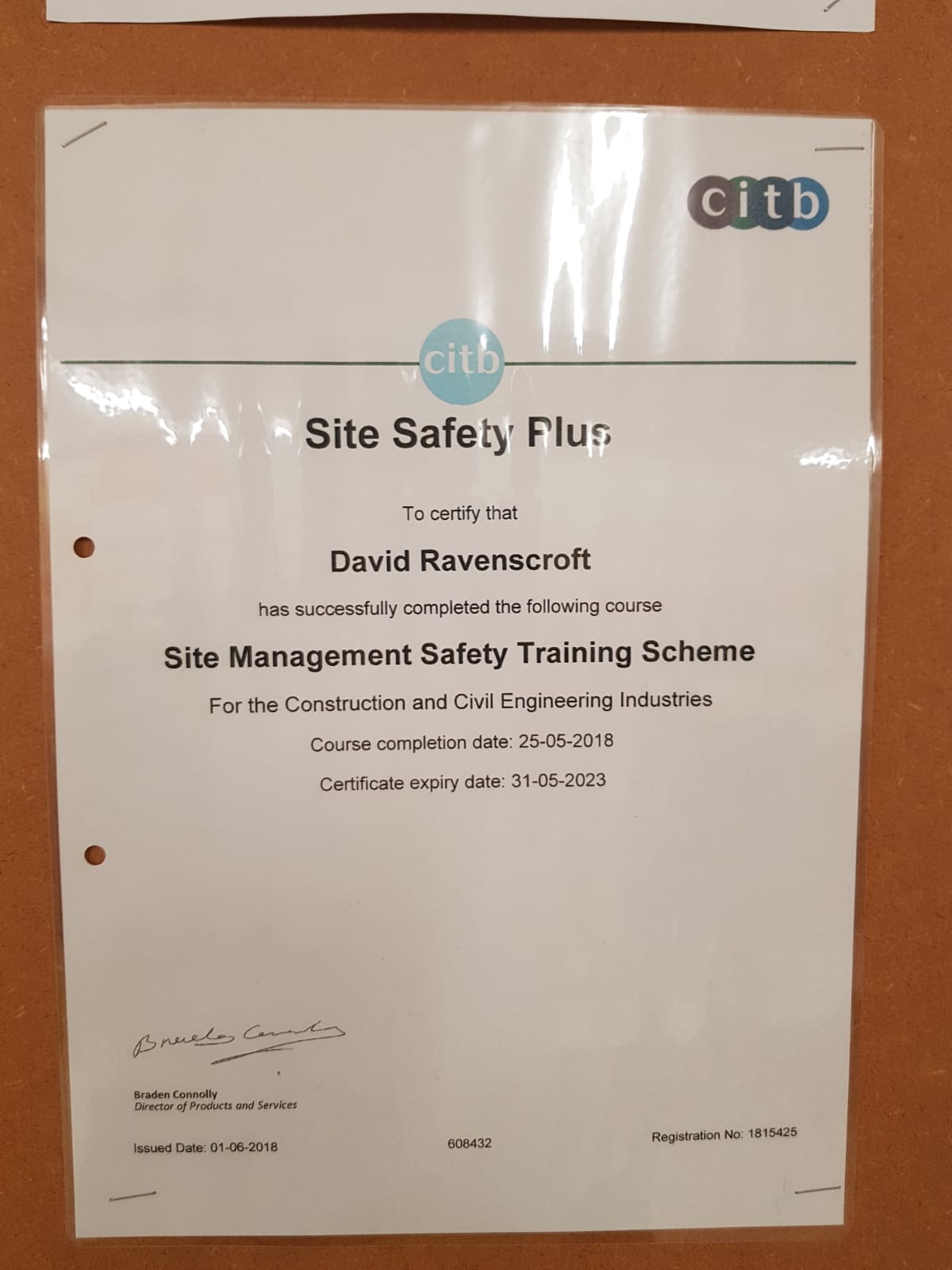

Is there a Site Manager or a competent responsible person on site and have evidence of competency

-

Site Managers SMSTS certificate must be available on site

Site Supervisors SSSTS must be available on site

GOOD PRACTICE: Display certificate along with photo in site office.

External Access

-

Are all materials stored within the confines of the site/work area and suitably segregated from the public?

-

All materials must be segregated, this includes when there are deliveries.

Never acceptable to leave in a publicly accessible area not even for 5 minutes.

Make sure there are adequate resources for deliveries.

Consider: scaffolding, and site set up deliveries.

It is extremely important that the fencing is one of the first things to be delivered to site and there must be

someone from SRG to take that delivery and set the fencing up. -

Is delivery of materials / equipment or removal of waste being managed effectively?

-

Can the contractors be identified on site?

-

All operatives and SRG staff must have branded high vis as a minimum.

All sub contract staff must have branded high vis and it must clean and the logo visible.

Health and Safety Display

-

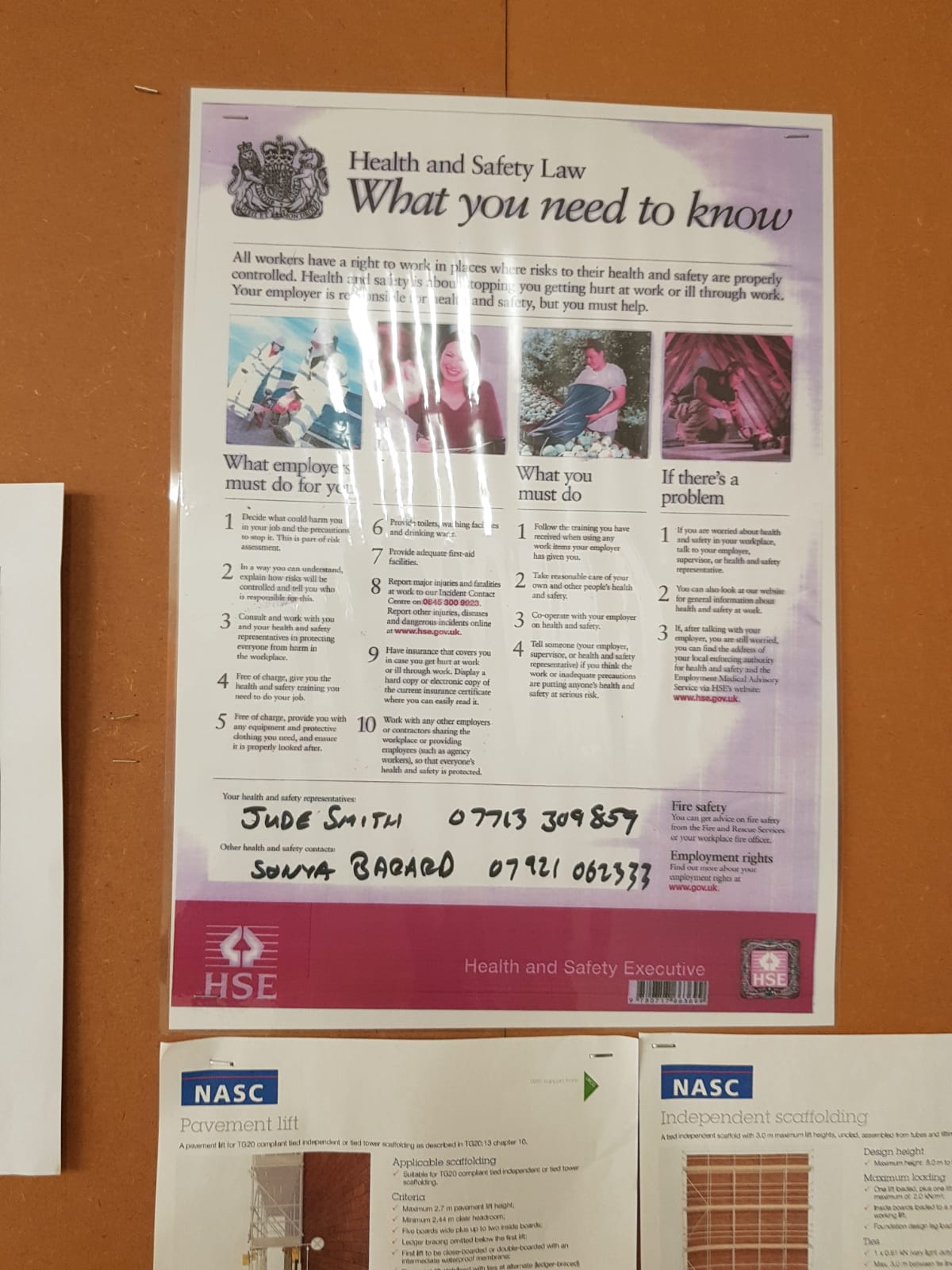

Is a valid 2009 H&S Law poster displayed?

-

Make sure the boxes are completed with the right peoples names and phone numbers

Checked as part of weekly H+S Walk through -

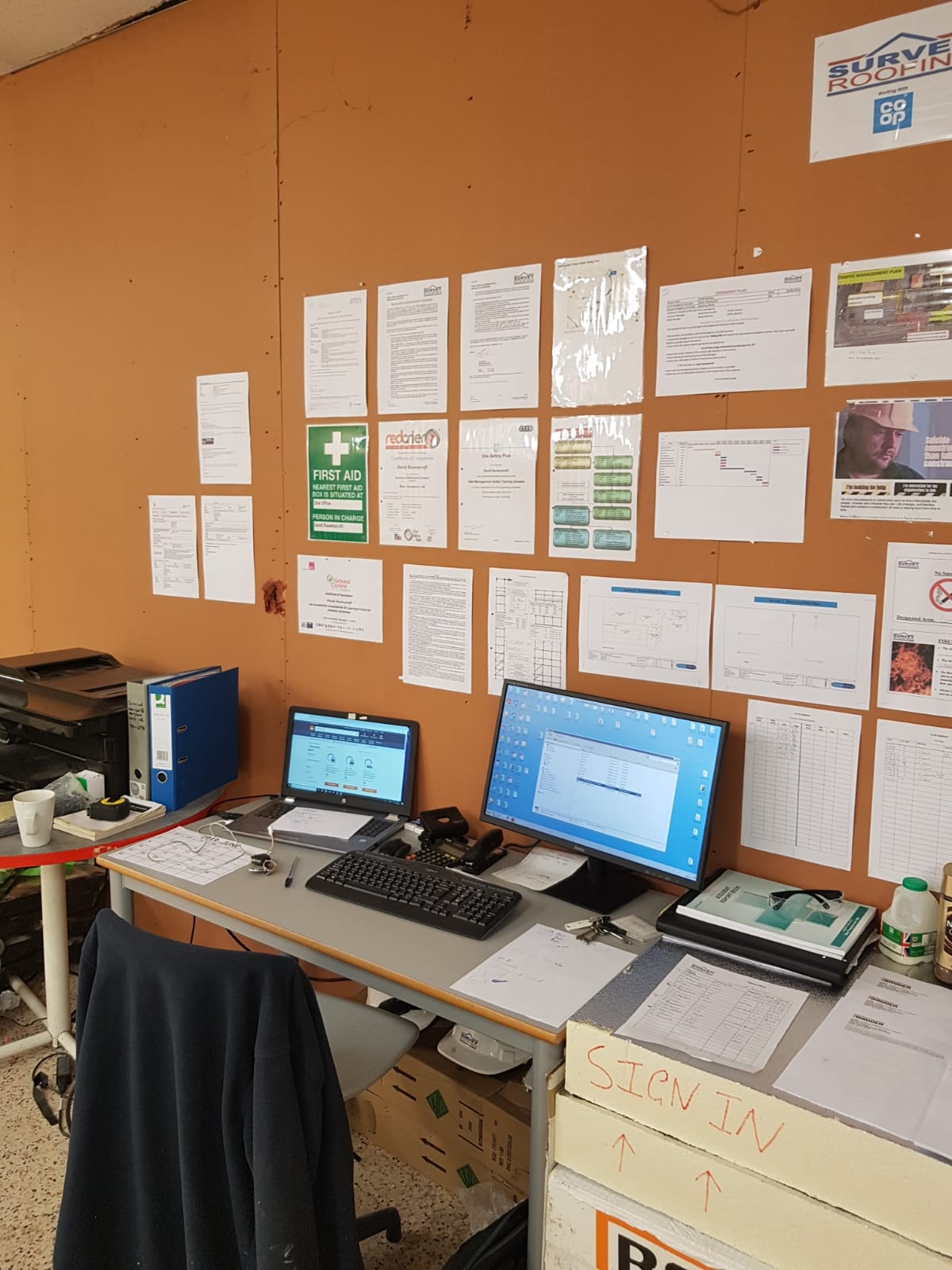

Is there a suitable area with relevant health & safety information displayed?

-

-

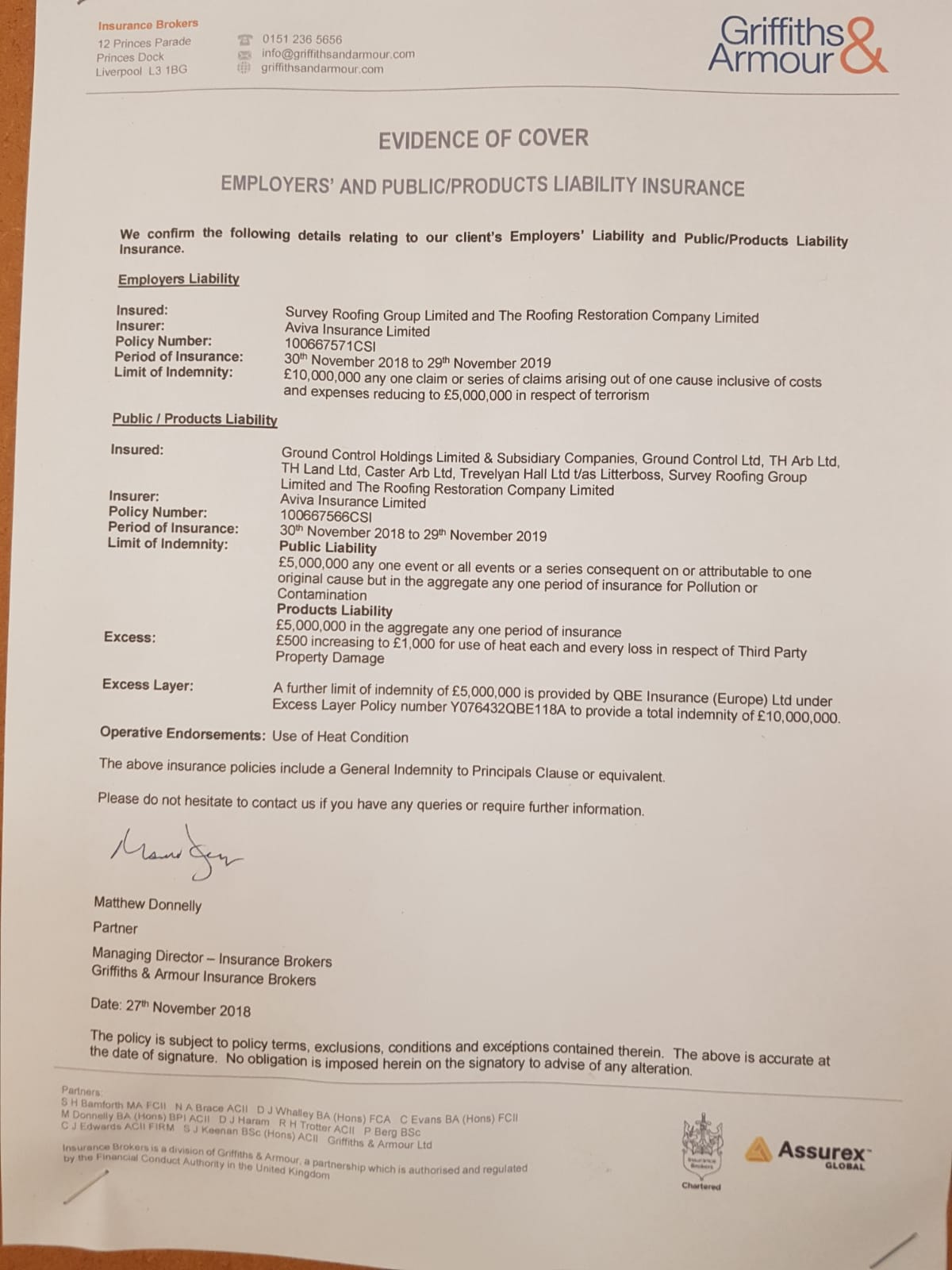

Is a valid copy of the Principal Contractors Civil Liability Insurance Certificate displayed?

-

This must be displayed

Check dates as part of H+S Weekly walk around and ensure a valid certificates is always displayed -

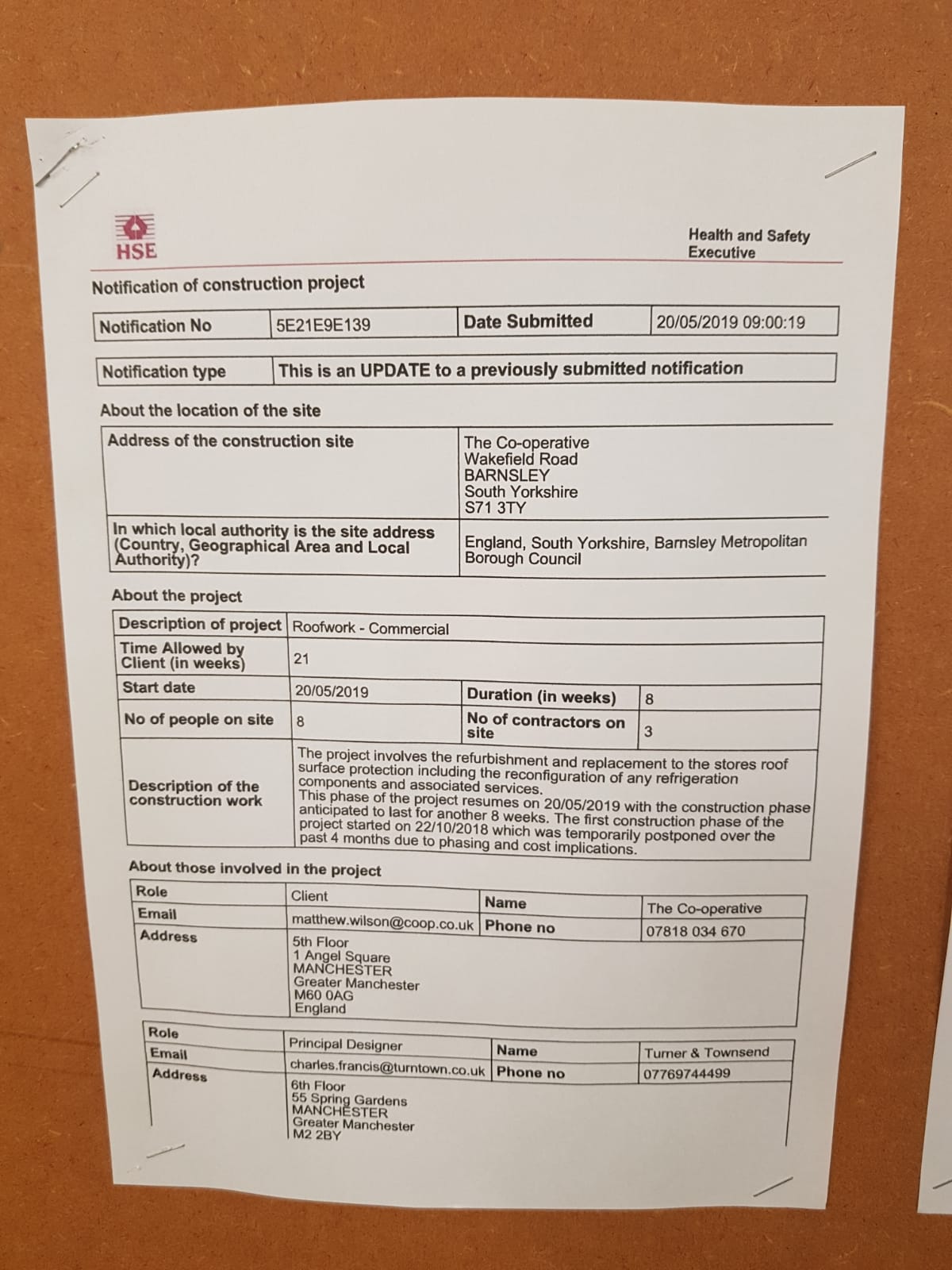

Is there a valid F10 Displayed?

-

On the weekly Health and Safety walk around check the details and make sure the F10 is in date with the

correct details.

If the form needs amending contact the SRG CM and request an update 2 weeks prior to expiry. -

Is a copy of the PC' Health and Safety policy displayed

-

A PDF copy of the Health, Safety and Welfare Policy can be found here:

V:\8.0 POLICIES\Health Safety and Welfare Policy Exp 16-01-2020

Check dates as part of weekly h+s walk around -

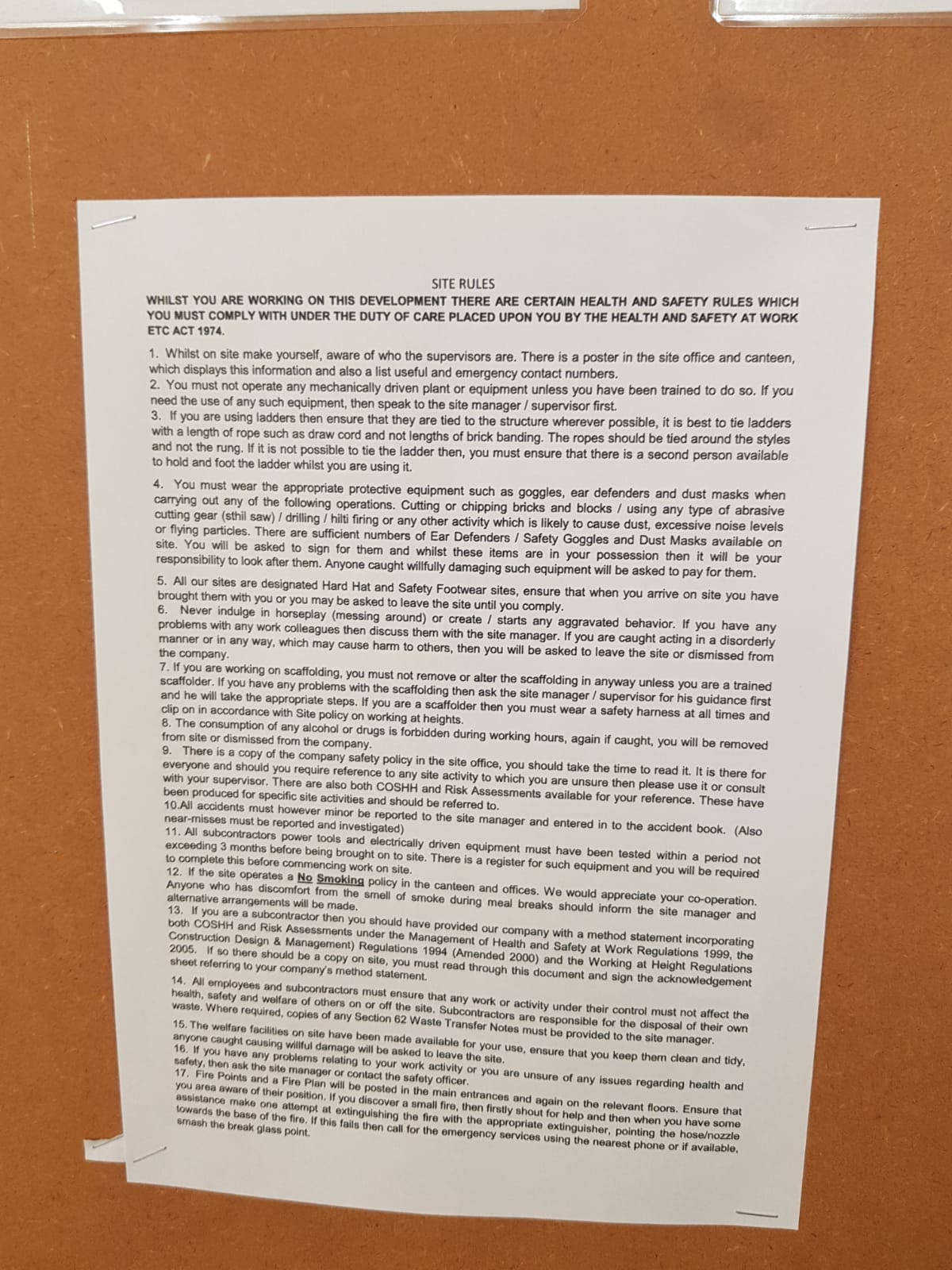

Are Principal Contractors site rules displayed or available for reference?

-

The Principal Contractor should display their site rules. Where there is no room to display must available in a folder and included in the induction

-

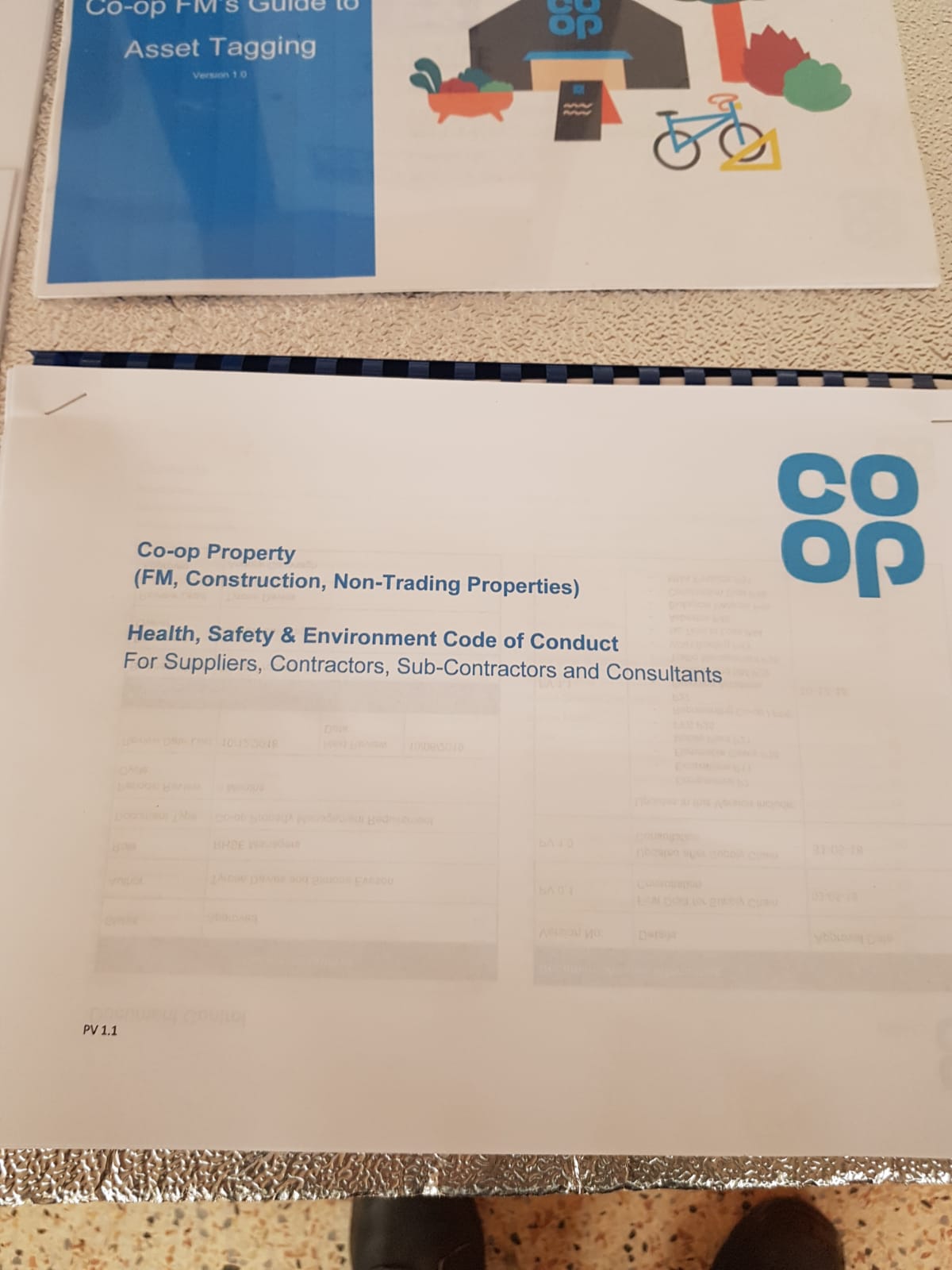

Is an up to date copy of the Co-op Code/client of Conduct displayed or available for reference?

-

-

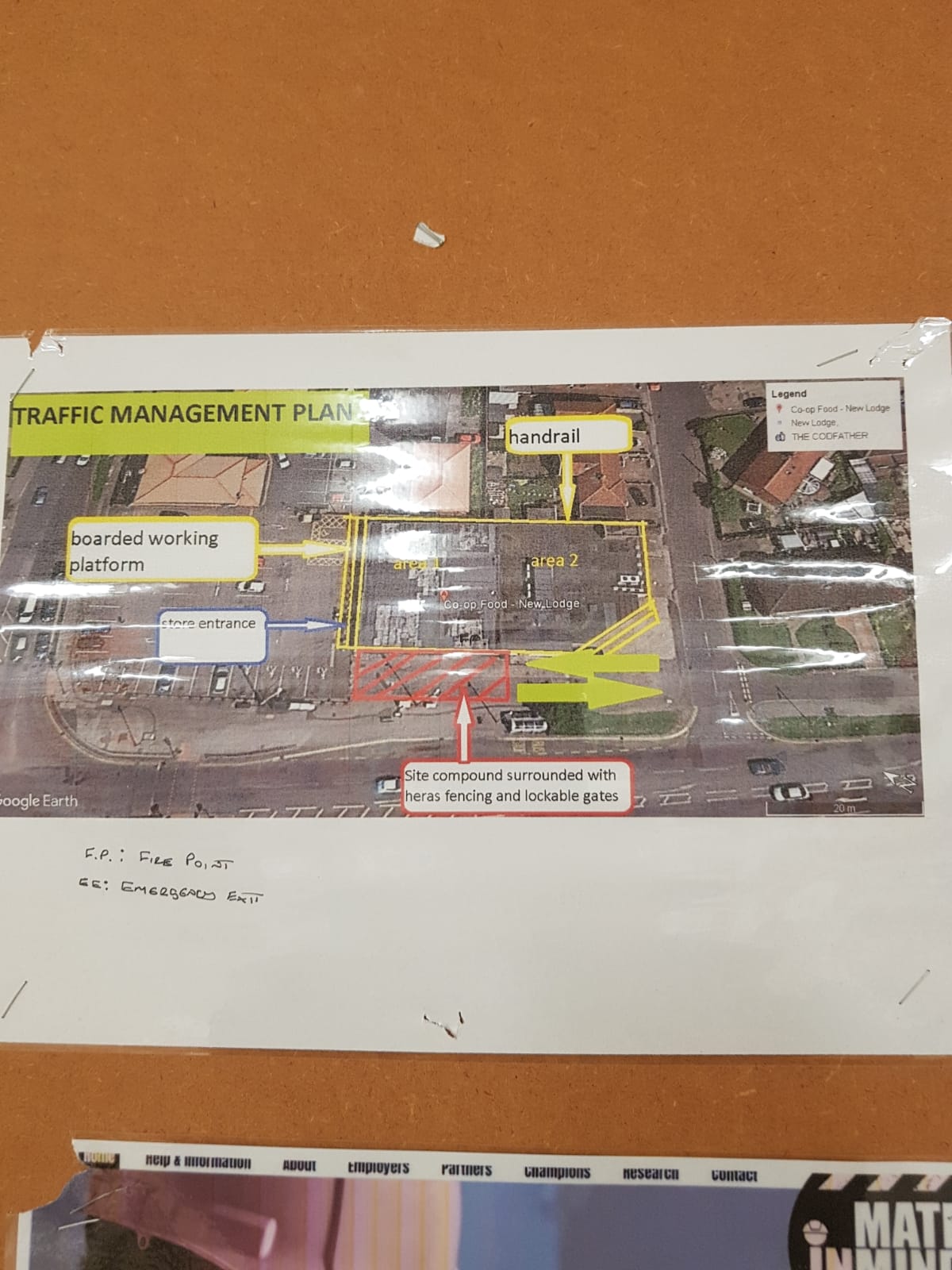

Is there a site layout plan showing, traffic management, fire points and exit routes etc?

-

The plans must clearly legible and must reflect what is on site.

Make sure any changes are documented and the plans are updated.

A plan that is wrong is useless and could be worse than not having one. -

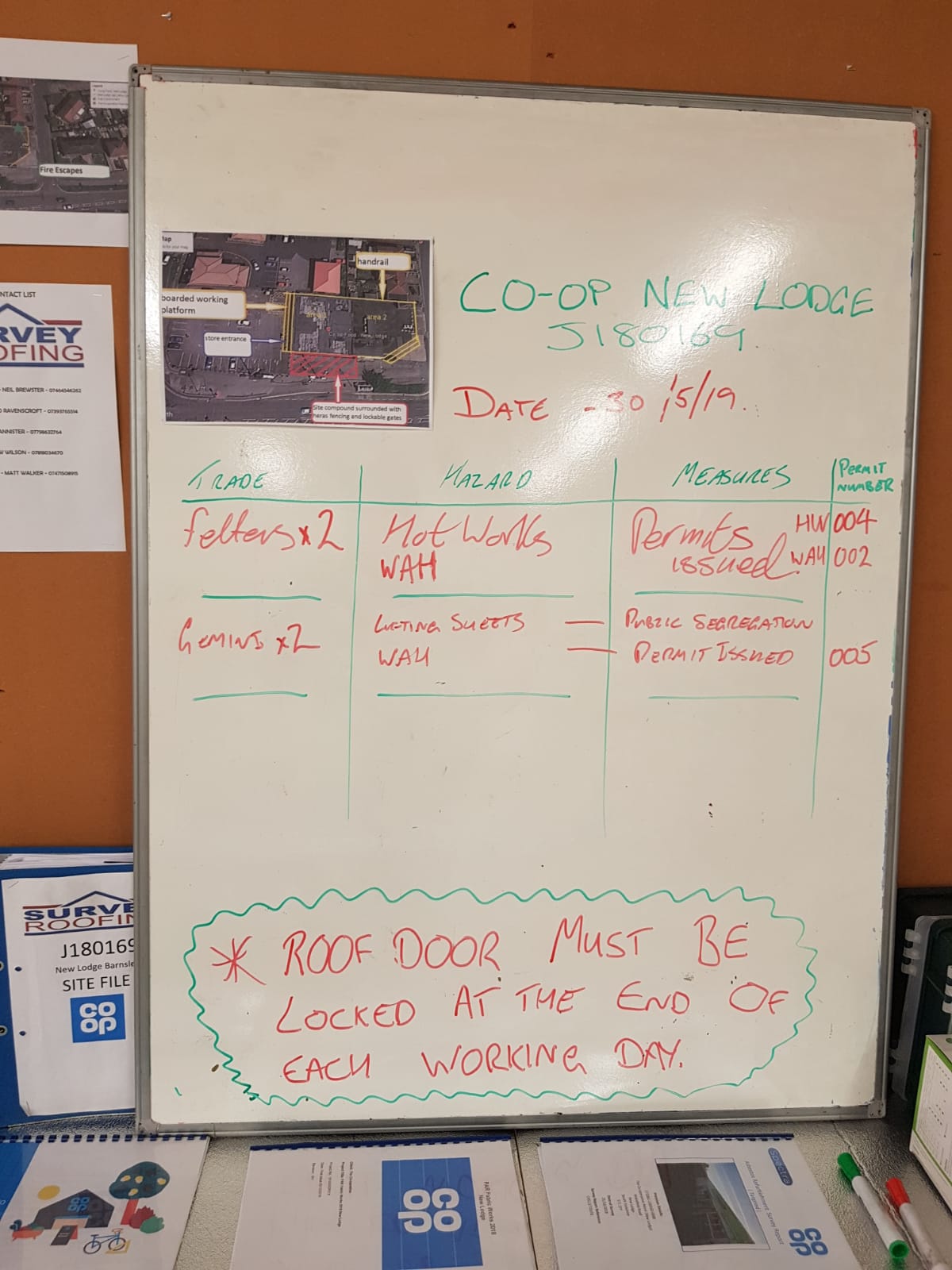

Are the Site Hazards for today clearly displayed on site?

-

This should be displayed in a prominent position and with evidence of it being up dated daily.

GOOD PRACTICE:

Lay out plan showing site

Updated daily with SM taking a picture and then up loading to weekly H+S Walk through.

Documentation

-

Does the Principal Contractor have an organised Site Management Filing System in place?

-

There must be at least on site binder folder on site. It must be separated out into sections and

information must be easy to find.

There must be an index and preferably labelled tabs

GOOD PRACTICE:

Electronic Folder filing system specific to site

Separate folder for RAMS, inductions,and training certificates.

Contractors/ operatives filed in alphabetical order

I.E 1) AB PLUMBING

Andrews Paul

Bobbin Mark

2) GEMINI ROOFING

Lacy Gavin

Truet Mark

3) SAFETY WORKS -

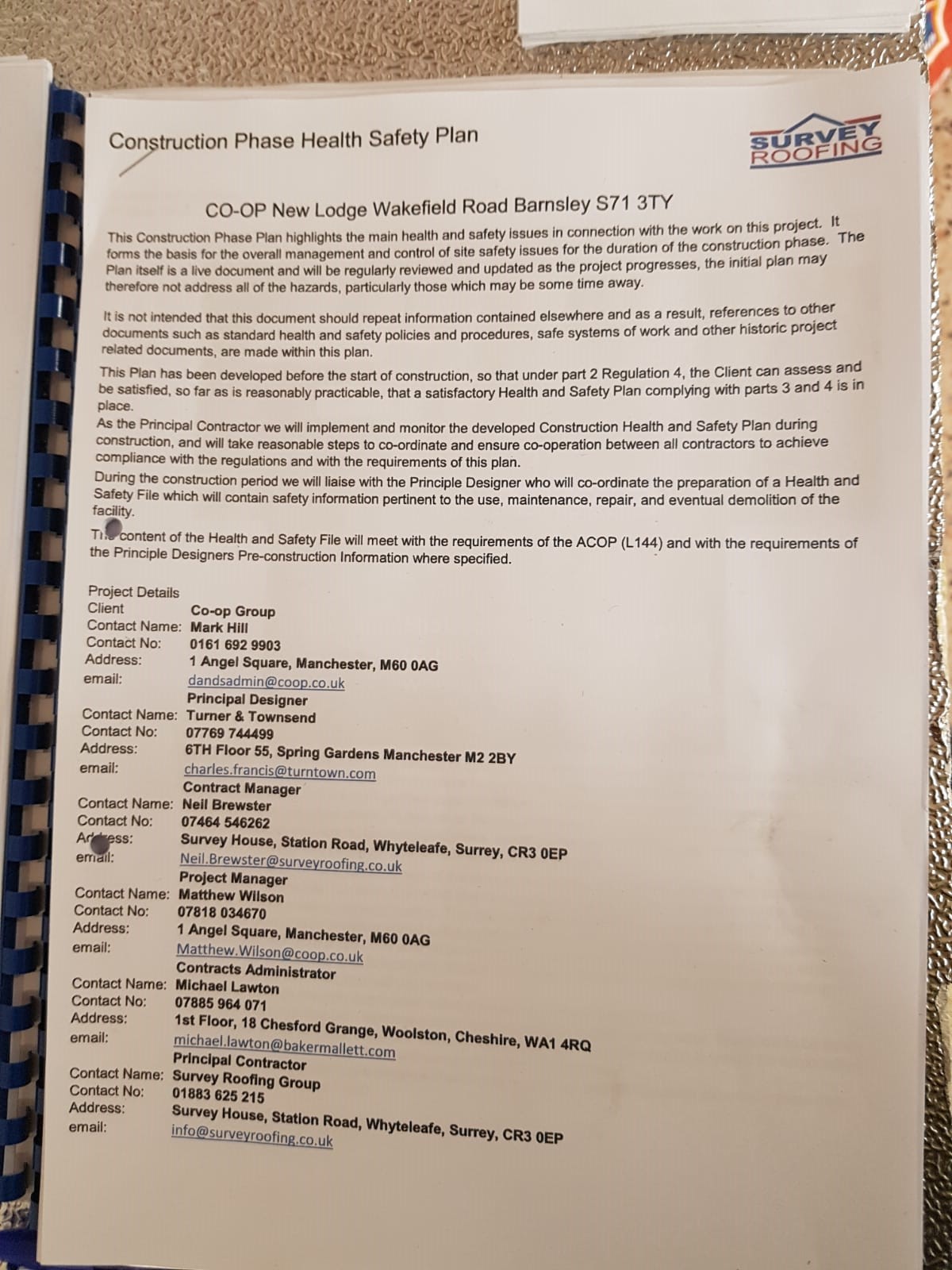

Is the Pre-construction information pack provided by the client filed on site?

-

Is the Construction Phase Plan available and updated where necessary including evidence that this has been approve by the CDM-A/PD?

-

Ensure the CPP is printed out and in the site file.

Read through the CPP and make sure its is up to date and current. This is a live document and can be

amended as the works progress

GOOD PRACTICE:

File the acceptance email from the CDM-A/PD - the SRG CM will be able to provide you with this.

Evidence that the CPP has been reviewed by SRG CM +SM -

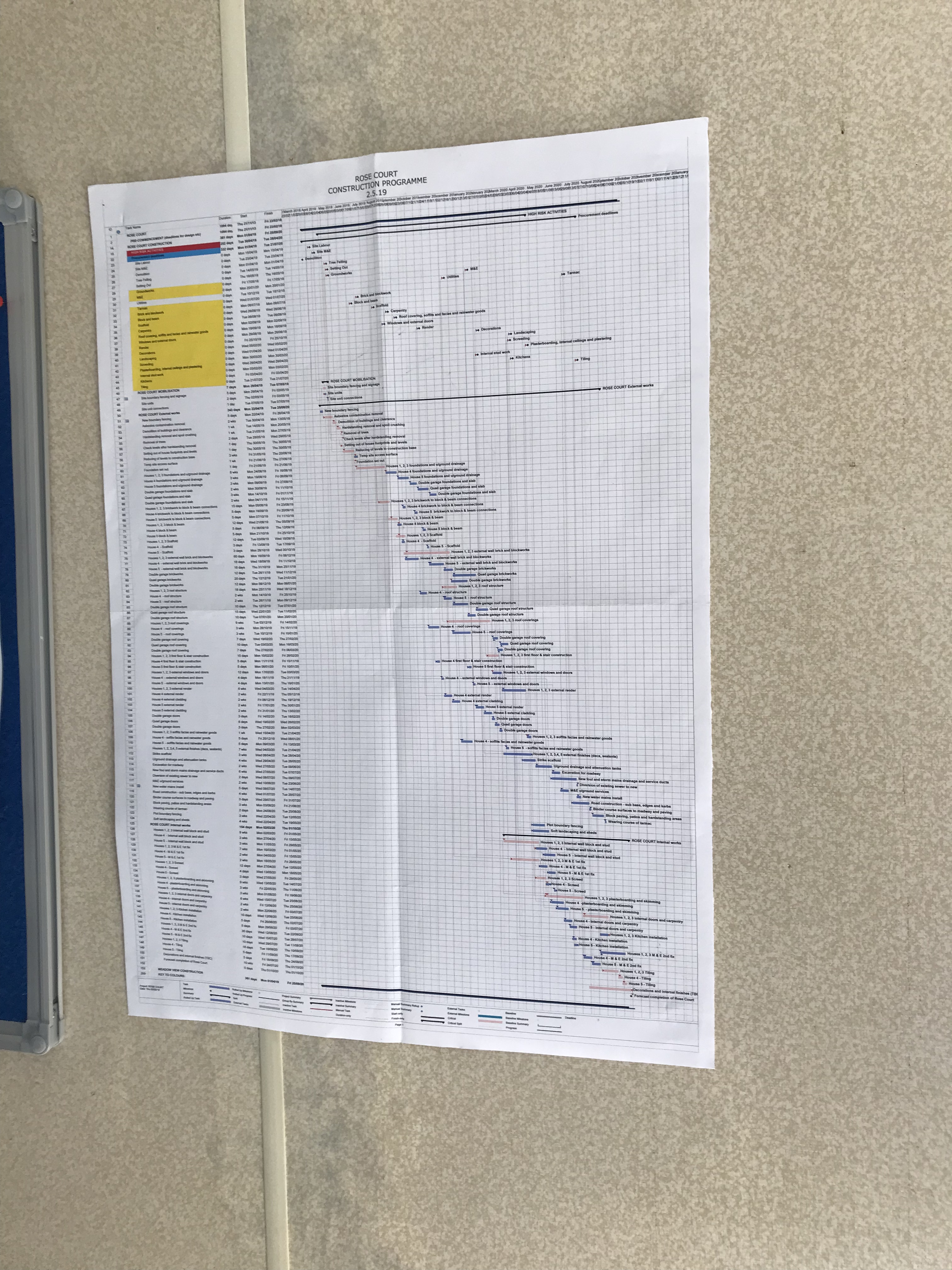

Is a current Project Programme of works available?

-

Display the programme in the site office

Where restricted space it can be in the folder and an electronic copy held. -

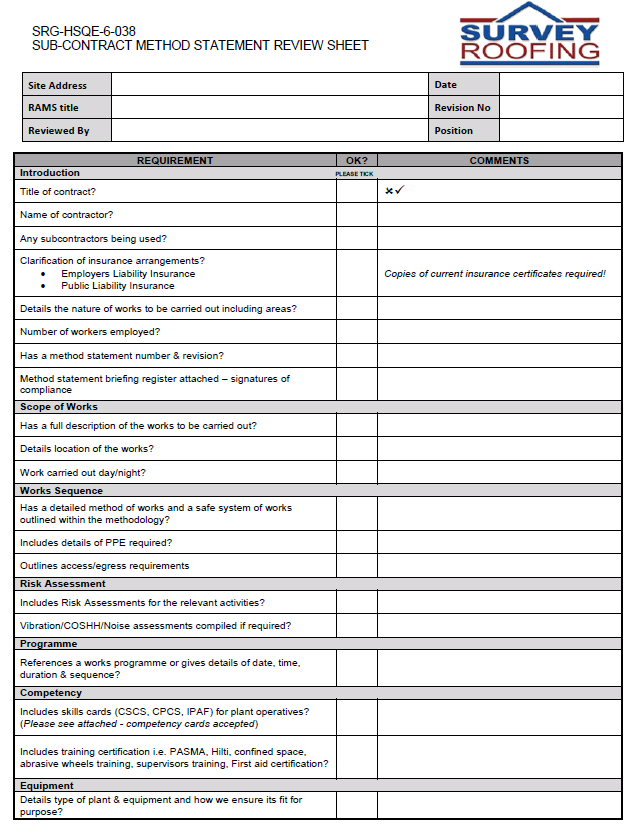

Is there evidence that the RAMs have been assessed and evaluated by the site manager/PC?

-

All RAMS must be reviewed by the CM and the SM.

Generic RAMS are not accepted

The template can be found at v:\6.0 FORMS & TEMPLATES\022 RAMS Review Sheet

GOOD PRACTICE:

Evidence that Review sheet is being used and RAMS are being amended with revision numbers.

RAMS are fully specific to the site with a good level of detail Ask the operatives to read the RAMS

GOOD PRACTICE:

SM to ask the operatives about the risk as associated with their works and what control measures are in

place.

Ask them to talk through the sequence of works specifically to the site and ask them to show where this

is documented in the RAMS. -

Have all the operatives involved signed and dated the RAMs or acknowledgement forms to indicate their acceptance and understanding of them?

-

Are there suitable and sufficient Risk Assessments and Method Statements (RAMs) on site all works including contractors?

-

READ THROUGH THE RAMS for everyone on site.

if you do not understand the works they are going to do after reading the RAMS then they are not good

enough!!

When reading the method of works think about the risks and check that they are in the risk assessment.

GOOD PRACTICE:

Evidence that the SM + CM have made notes on the method statement and checked the RA

NOTE: You will fail an audit if the operatives are not working to the RAMS. It is extremely important they

are accurate and reflex the works on site.

Any deviations must be documented Random check of 2 works RAMS. They must be site specific and reflect the work being undertaken.No - Where RAMs are missing - note contractor/task -

Do the people doing the work have access to the relevant documentation; specifications, permits, drawings etc

-

Is there evidence of accurate safety monitoring - Daily H&S Checks?

-

Evidence that daily inspections are taking place and recorded in the site folder.

A daily check sheet is in the site management packs - Tailor the questions to be site specific

GOOD PRACTICE:

SM to use iAuditor to complete daily checks with photos included.

Template SRG Daily Site Inspection

A daily H&S checklist should be available and completed at a random time each day, a minimal of site diary entries stating check have been completed. In Part - Where partially complete I.E. 1 or more days incomplete -

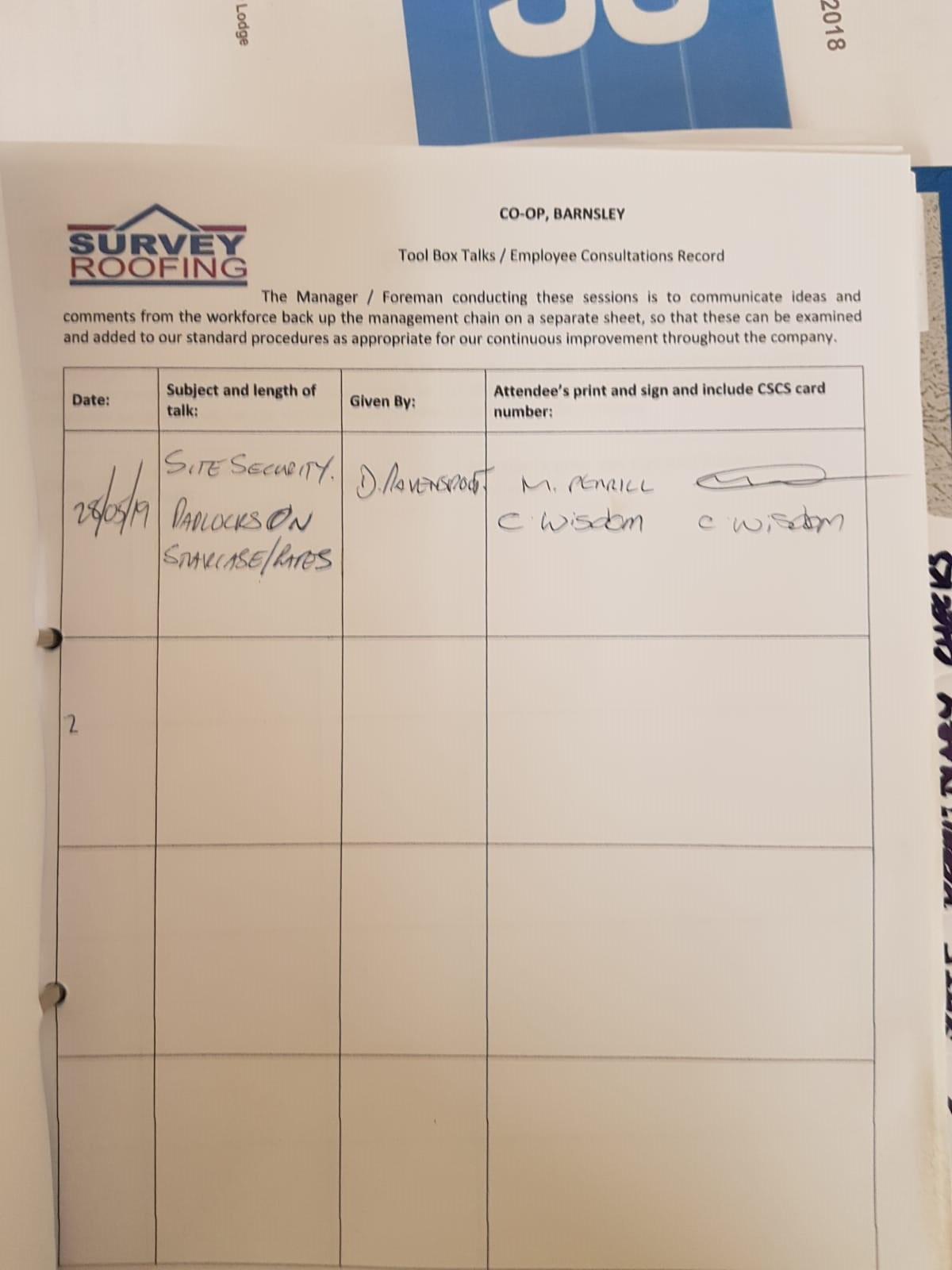

Has the Site Manager undertaken and recorded the completion of tool box talks?

-

Toolbox talks must be recorded with dates, printed names and signatures.

GOOD PRACTICE:

Topics to be relevant to the site and topics that relate to issues picked up on SM walk through's.

Evidence of what has been discussed rather than just a title

Using the CITB Tool box box

NOTE Encourage discussion on the topic and get engagement from operatives. Ask them questions

about their knowledge of the topic before starting.

The Site Manager must complete at least 1 talk per weekYes - 1 or more Toolbox talk has been completedNo - No Toolbox talks have taken place within the last week -

Is there evidence of training for all people on site,

-

Copies of certification must be on site and must be filed so that it can be easily retrieved.

GOOD PRACTICE

Evidence that SM has checked Total view compliance for each operative

Each person to complete a training and competency that site with their induction paper work.

Contain information such as

NAME COURSE EXPIRY DATE

TRADE YRS OF EXPERIENCE

This is a quick way to check expiry dates. -

CSCS and asbestos awareness are mandatory for all

First Aid

-

Are there a sufficient number of first aiders on sie

- COMPLIANT

- NON-COMPLIANT

- RECTIFIED AT AUDIT

- OBSERVATION

- N/A

-

It is always recommended that there is a minimum of one first aider on site.

Where there are over 10 people on site it is recommended that there are is one first aider and one

appointed person

GOOD PRACTICE:

First aiders identified through photos and hard hats -

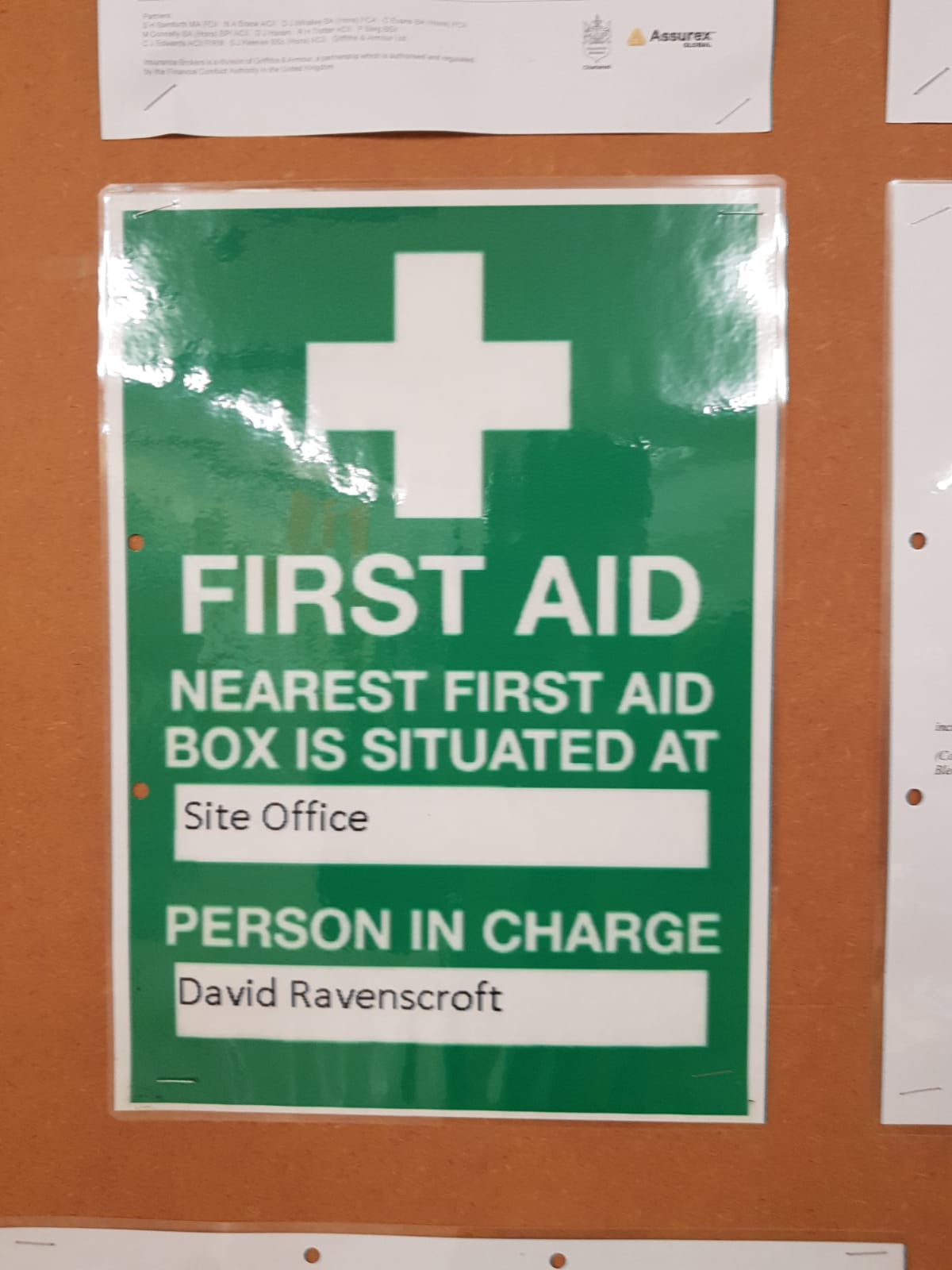

Are first aider details displayed in the H&S area?

-

A green first aiders sign must be displayed with name of first aider(s) on site and contact details. Good Practice would include a photograph

-

Does the first aider hold a 3 Day - First Aid at Work certificate?

-

Copy must be available on site

GOOD PRACTICE:

Displayed in the site office -

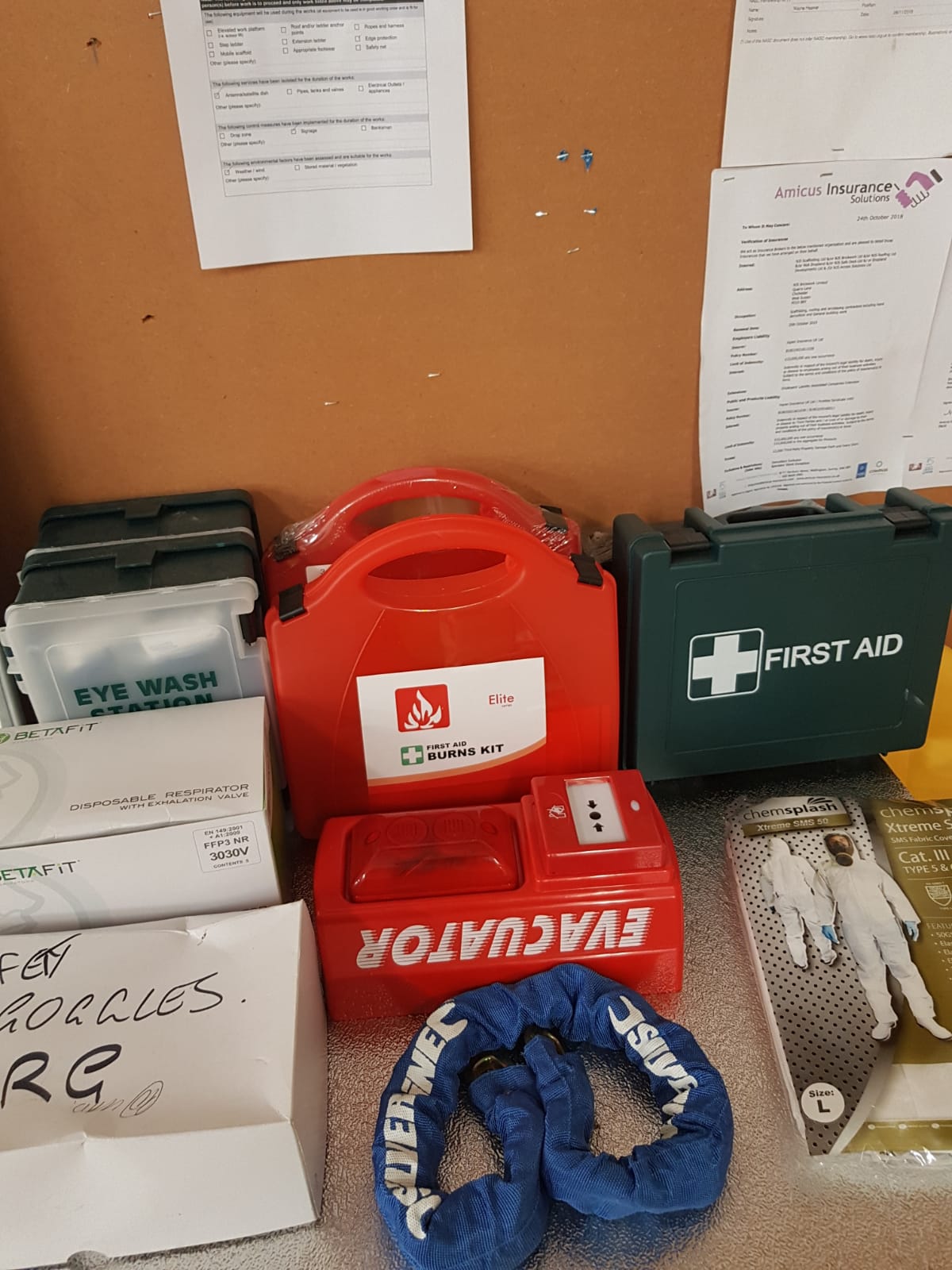

Are the first aid supplies suitable and sufficient for the work taking place?

-

As a minimum: 1x20 person kit including Eye wash where no water supply and a burns kit where hot works are planned. Ensure no medicines are stored in the box, and that all items are in date. In Part - Where part of kit missing or less than 20 person kitNo - Where items are out of date, none 1st aid items stored in kit

-

Is there a robust accident reporting process? I.E. accident book, report forms, or online submission form?

-

Is there an accident book on site

-

Is there a way of reporting near misses?

-

Actively encourage near miss reporting

Near miss reporting to be an induction topic

REQUIRED BY COOP

Don't Walk By Cards and a box for anonymous reporting

GOOD PRACTICE:

Evidence of the SM raising near misses

Evidence of operatives raising near misses

Tool box talk on the importance of near misses -

Have all accidents/incidents been reported to the client

-

COOP - All incidents to be report through i-Safety

M+S All incidents to be reported through Simple Compliance

Has any external authroity visited site (HSE, EA) and has client been -

Has any external authroity visited site (HSE, EA) and has client been informed

-

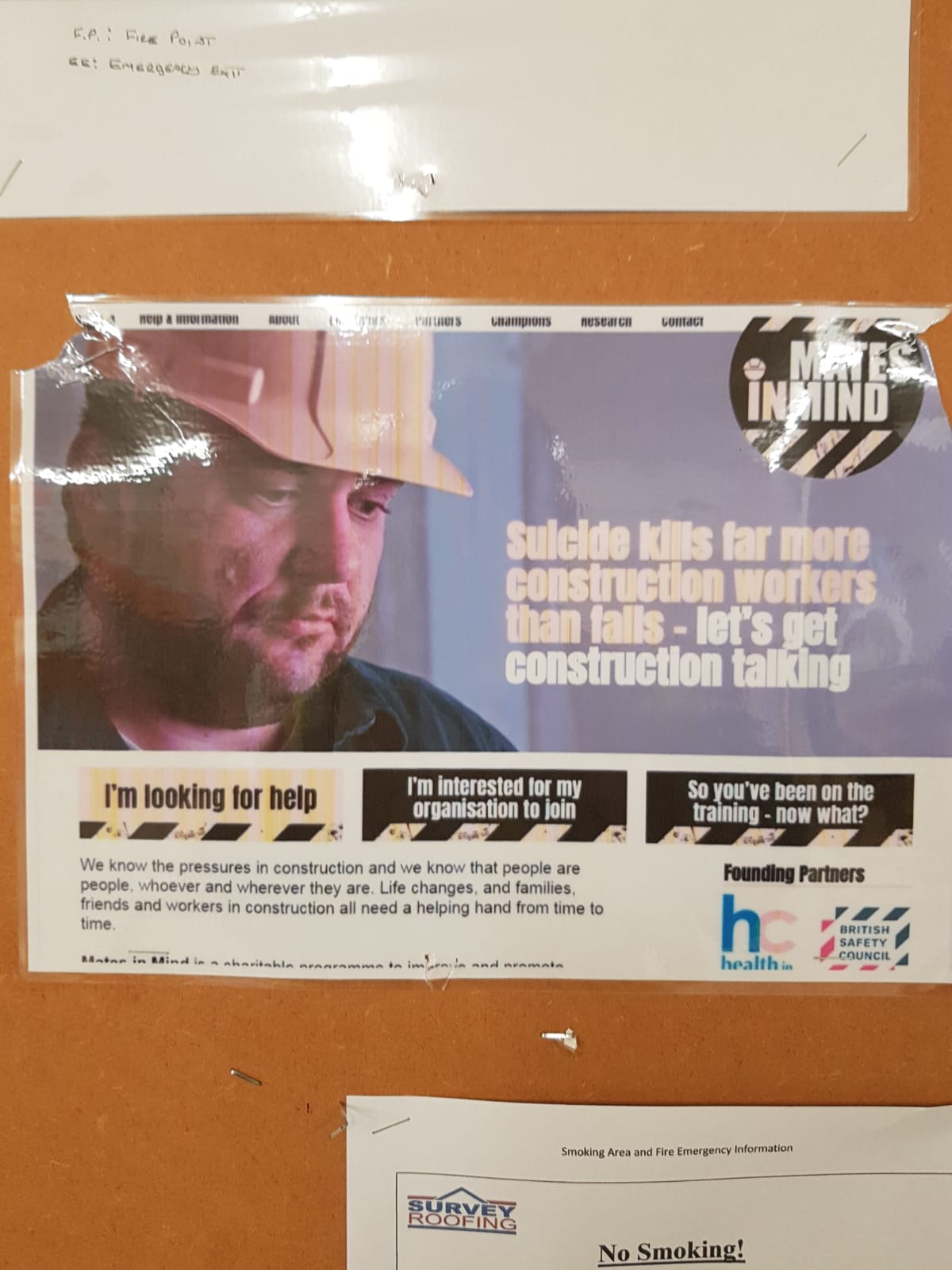

Is there a mates in Mind poster displayed

-

Welfare

-

Are adequate toilet and hand washing facilities provided?

-

No. toilets (T) and washbasins (WB) for mixed use (or women only):1-5 P = 1T 1WB, 6-25P = 2T 2WB, 26-50P = 3T 3WB Toilets and Urinals(U) used by men only:1-15P = 1T 1U, 16-30P = 2T 1UAre they clean, ventilated and lit?Do they have a plentiful supply of toilet paper? Hot water, soap and towels/hand dryer for washing hands?

-

Is hot and cold running water available in the toilets?

-

Ensure Hot and Cold running water is provided as per the construction phase plan and as stipulated in CIS 59

-

Is drinking water available?

-

Are food storage and preparation appliances available?

-

Are table(s) and adequate seating available?

-

Is there means of heating the welfare area?

-

Is there a suitable designated smoking area, is smoking taking place in the designated point?

Fire and Emergency

-

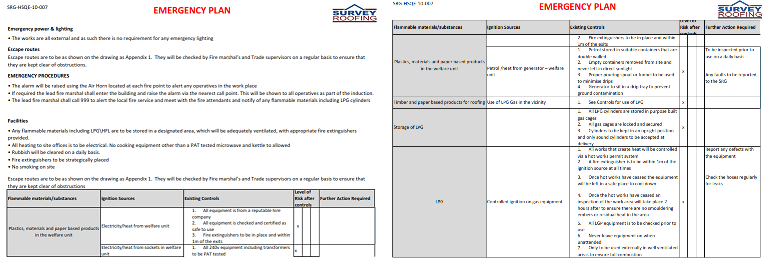

Is there a site specific fire risk assessment in place, has it been reviewed and signed by site manager?

-

There must be a specific fire risk assessment for the site

NOTE: This is not the fire plan. The fire risk assessments is part of the emergency plan and forms part of

the CPP.

Make sure you have a read the fire risk assessment and that it is site specific.

obtain a copy of the stores fire risk assessment and the review the two together.

GOOD PRACTICE:

SRG + Stores FRA on site

SRG Fire risk assessment refers to store FRA -

Has it been communicated to the client where applicable?

-

GOOD PRACTICE:

SRG SM + Store Fire Marshal/Store manage discuss FRA

Evidenced in site diary/ h+s daily checks -

Are all designated fire exit routes (internally and externally) unlocked, clear from obstructions and appropriately signposted?

-

GOOD PRACTICE:

Take photos of walkways to show good practice and if there are issues use the photo's to conduct

toolbox talk.

The route to the fire exit should be at least 750mm wide and clear from any obstructions. Also the escape distances in live stores should not be compromised by contractors work.Also check the external side of the fire exit to ensure it is free from obstructions and a relative place of safety can be reached.Appropriate Escape route signage is in place -

Has the Principal Contractor provided an adequate and appropriate number of fire points (Complete with suitable extinguishers and push button sounders)

-

Ensure that there is an adequate number of fire extinguishers available at each fire point. Push button sounders are to be used when the stores fire alarm system is disabled. Air horns and hand bells are not to be used as someone needs to remain and operate these in an emergency situation instead of evacuating

NOTE: Fire points extinguishers must not be removed for hot-works, there must be separate extinguishers.

Fire points to be located close to exit routes -

Is there evidence that these have been tested on a weekly basis?

-

-

Have the fire extinguishers been serviced in the last 12 months?

-

PLEASE NOTE: P50 Fire Extinguishers DO NOT require an annual service by an engineer as they are corrosion proof. Check pressure gauges

-

Are all temporary protective coverings to a Loss Prevention Certification Board Standard? (LPS 1207 internally or LPS1215 externally)

-

Are hot works being carried out?

-

NOTE:

GRINDING CAN CAUSE SPARKS AND MUST CONTROLLED VIA HOT WORKS PERMIT -

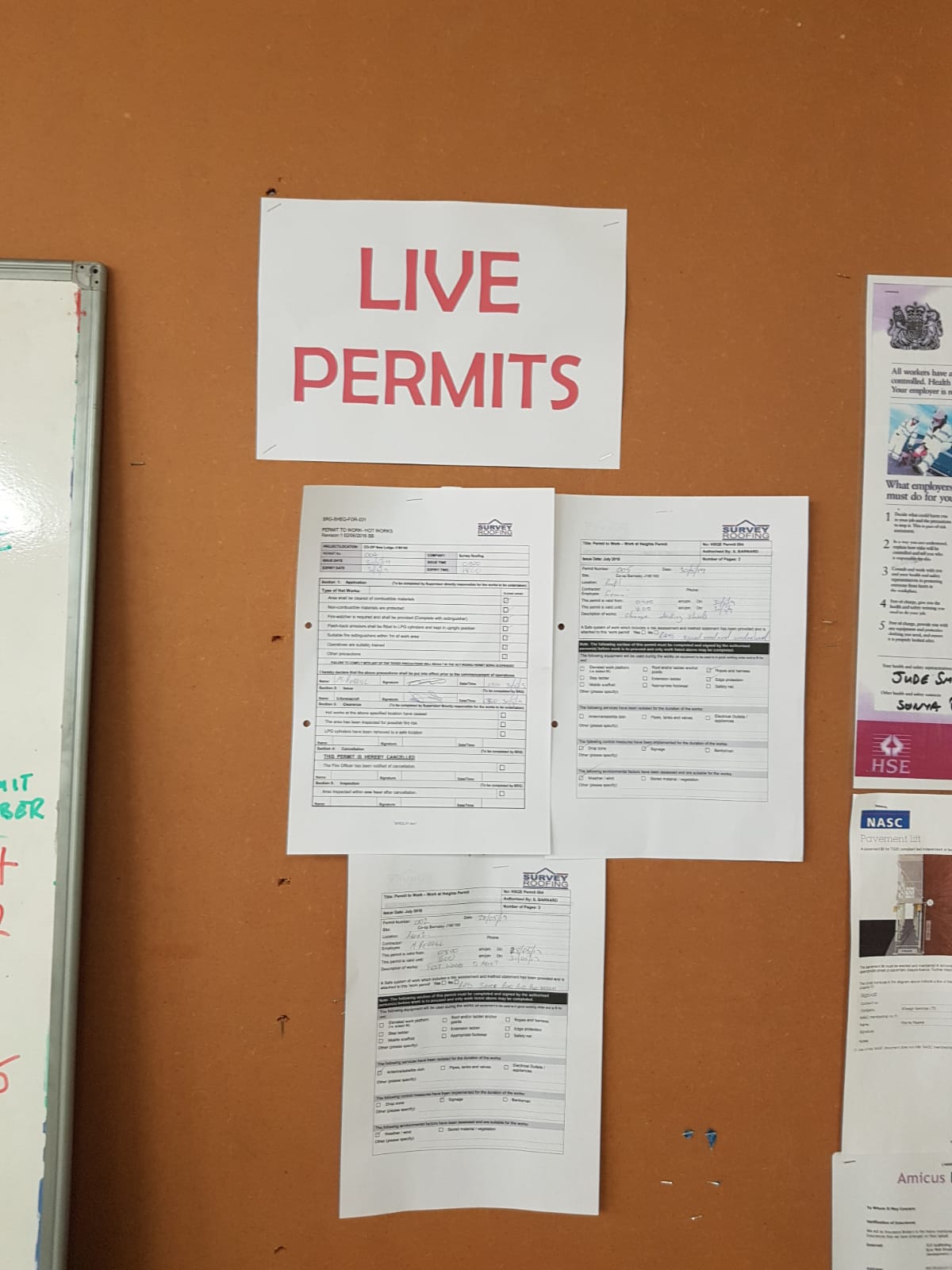

A Has a hot works permit been issued by the PC and accepted by the contractor?

-

Ensure that the HWP is completed in full and they must be sign off each day.

GOOD PRACTICE:

Live permit display which is monitored daily. -

Have all combustible materials been removed from the work area?

-

Are there 2 appropriate fire extinguishers to hand? (These should not be from the fire points)

-

NOTE: COOP Require 2 extinguishers to hand

-

Are all Highly Flammable Liquids (HFL's) being used, transported and stored correctly?

-

Are all gas cylinders being used, transported and stored correctly? (LPG / Oxy-Acetylene / Refrigeration)

-

LPG, Acetylene and Oxygen can be stored together in small quantities of up to 10 cylinders (total)provided storage is external, secure, ventilated (BGCA CoP 44)

-

Notes

Must be in a gas cage which is locked at all times and signed.

Must not be stored at roof level and consider any voids as LPG is heavier than air and will sink down into

drains and manholes etc

GOOD PRACTICE:

The site will have a gas monitor and bottles will be checked on a regular basis

Occupational Health

-

Are activities that create dust being undertaken? What are they?

-

Consider cutting wood, metal, brick work, tiles etc - what control measures are in place to help prevent,

minimise, collect and protect people from inhalation.

Check RAMS cover all dust creating activities

COSHH Assessments in place of the various types of dust. -

Is "On Tool" extraction or "On Tool" water suppression being used to control dust?

-

Are all extraction units Class M as a minimum standard?

-

Are all dust masks FFP3 as a minimum standard? (Half mask or disposable mask)

-

Check that all dust masks are FFP3 or higher. Check RAMS include details

NOTE: Any one who uses a dust masks must have it face fit tested and the test will only apply to that

particular make and model.

Ensure every one on site and contractors understand this.

Face fit testing can be arranged by SRG and can be done on site. -

Have face fit certificates been collated and filed on site? (Evidence of certs must be provided. Check relevant operatives wearing masks)

-

Are noisy operations being carried out?

-

Where engineering controls are needed, are they in use? (Explain fully in the notes why you feel engineering controls are necessary)

-

Have clearly marked and signed hearing protection zones been established if necessary?

-

Consider any staff/public that may be exposed to noise vibration through buildings

Ear plugs to be available to all staff and operatives

GOOD PRACTICE:

A frame hearing protection zone signage that can moved around if required. -

Are all operatives wearing the appropriate PPE as stipulated by their RAMs?

-

Is plant or equipment that produces Hand Arm Vibration being used on site?

-

Any one using equipment that causes vibration MUST record the vibration rating of the equipment, the

action levels, the trigger time for each person and each bit of equipment.

GOOD PRACTICE:

Health surveillance questionnaires for each operative every 3 months to monitor any

changes/deterioration

Detailed recording of vibration information for each individual

NAME

EQUIPMENT

VIBRATION RATING

ACTION LEVEL

DATE START TIME END TIME TOTAL -

Are individuals vibration exposure levels being monitored and recorded?

-

Have vibration levels been provided for each piece of plant and equipment?

-

Notes

https://www.hae.org.uk/Havs-data-hae/?Category=&Make=DeWalt&Model=DCP590

This is a link to the E Hire Assessment web page and most tools can be found here. Cut and paste this

link

Also Brandon tool hire have a list on their website.

GOOD PRACTICE:

evidence of At point vibration monitoring for individuals.

This kit is available for hire and GC have one that can requested through HSQE Department -

Do operatives have sufficient knowledge of the risks of Silica dust?

-

Ask 3 operatives to tell you about the risks of silica dust. They should be able to tell you were silica dust is found and the risk associated with inhalation.

NOTE: If not all of the operatives can tell you conduct a tool box on this.

You can use a straw to demonstrate restricted breathing. also there are some good HSE videos on

YouTube that can used.

Working at Height

-

Has a roof permit been issued for the works taking place

-

Notes

You must read the clients requirements for Permits - Some clients will relax the requirement for a roof

permit on a large project.

GET THIS IN WRITING from the PM

Ensure all live permits controls are met and that they are fully completed, signed on and off. -

Is the potential of falls from height adequately controlled?

-

SRG SM to walk the full perimeter of works area and take photos of all fall prevention equipment - including scaffold edge protection, fixed hand rails, parapet walls etc

-

Has the heirarchy of working at height been applied?

-

Is there an uncontroled fall risk greater than 600mm

-

Parapets or other edges 900mm or greater

-

Unsafe or incomplete edge protection

-

Have all roof lights, holes and voids been adequately protected

-

All rooflights, voids ad holes must be identifiable and be securely protected.

Any boarding must be secured down and must be step safe.

NOTE: Any temporary covering must be added to the temporary works register and must be approved for

loading by the Temporary Works Co-coordinator. -

Is the access to work at height equipment adequately controlled?

-

Are ladders being used on site

Ladders

-

Are steps the most appropriate means of working at height? Has a permit to use been issued?

-

Unsafe or damaged ladders

-

Unsafe positioning of ladders?

-

Ladder unsuitable for job (e.g. metal ladder used for electricla work)

-

Ladder not properly secured?

-

Do the steps comply to British Standard (BS) Class 1 ‘Industrial’(Max Load 175kg) or BS EN 131 for Commercial Use (Max Load 150 Kg)

-

Evidence that the equipment is being formally inspected before use/every 7 days

-

Are operatives using the ladder Safety?

-

If operatives are not using the stepladderer safely, please explain why and add photographs if possible

-

Are Step Ladders Being used?

Step Ladders

-

Are Step ladders being used?

-

Are steps the most appropriate means of working at height?

-

Is there a safe system of work in place to control step ladder use?

-

Is the ladder free from visible damage?

-

Do the steps comply to British Standard (BS) Class 1 ‘Industrial’(Max Load 175kg) or BS EN 131 for Commercial Use (Max Load 150 Kg)

-

Are operatives using the stepladders safely?

-

If operatives are not using the stepladderer safely, please explain why and add photographs if possible

-

evidence that equipment is being formally inspected weekly?

-

Is Fall Arrest/Fall restraint being used on site?

Fall Arrest/Fall Restraint

-

evidence that equipment is being formally inspected weekly?

-

Is fall restraint/arrest equipment being used correctly?

-

RAMS reflect the working techniques and detail the safe system of works

-

Correct type and length of lanyard in use

-

If working in fall arrest is there an adequate rescue plan and has it been briefed to the operatives

-

evidence that the equipment has been inspected prior to use

-

Evidence the equipment has been formally inspected every 6 months

-

evidence that the equipment has been inspected weekly

-

Are MEWPS being used?

MEWPS

-

-

Are the MEWPs being used on firm, stable ground free from holes and trenches?

-

Have all MEWPs been segregated to avoid others entering the work area?

-

Do all MEWP operators have IPAF cards or equivalent?

-

Are Cherry Picker operatives wearing certified / checked harnesses?

-

Does not apply to scissor lifts

-

Is there an emergency rescue plan in place for operatives wearing harnesses?

-

If operatives are not using the MEWP safely, please explain why and add photographs if possible

-

Are operatives using the MEWP safely?

-

Evidence that the pre start checks and weekly inspections are being carried out?

-

Are mobile access towers being used?

-

Are the towers on firm stable ground?

-

Have all 4 brakes been applied when in use?

-

Are all handrails and toe boards in place?

-

Are all hooks on the bracing fully engaged?

-

Does the person who erected and hold a valid PASMA qualification

-

Are operatives using the mobile tower safely?

-

Are podiums being used?

Podiums

-

Are the podiums being used on firm, level ground?

-

Have all the brakes been applied?

-

Is the podium free from physical damage?

-

Are the gates closed?

-

If operatives are not using the podium steps safely, please explain why and add photographs if possible

-

Are operatives using the podium safely?

-

evidence that equipment is being formally inspected weekly?

House Keeping

-

Is there adequate lighting in all work areas including task lighting?

-

Are walkways clear and free from debris and materials?

-

Are cables run at a high level or managed in a way to prevent trip hazards?

-

Are all holes / trenches / potholes covered?

-

Are all materials stored / stacked correctly?

-

Are all internal and external works clearly segregated from colleagues and the public?

Temporary Works

-

9.1 Has a temporary Works Co-ordinator been appointed and their details filed on site?

-

9.2 Is the Temporary Works Register up to date and filed on site?

-

9.3 Does the perimeter fencing / hoarding require a design and wind loadings?

-

9.3A Has the design / wind loadings for the perimeter fencing / hoarding been checked and filed on site?

-

9.4 Are formal checks for the perimeter fencing being carried out and up to date. (Every 7 days, after inclement weather, after collision etc)

-

Have permits to load/strike been issued where requried?

-

Is there scaffold erected on site?

-

Scaffold

-

Is the Site Manager competent and qualified to formally manage, review and accept the scaffolding on handover

-

Competent persons erecting scaffold, must hold CISRS cards

-

If the scaffold design is complex then an advanced scaffolder must be on site to over see and compelte the handover

-

Is there a design for the scaffold

-

Unless a scaffold is assembled to a generally recognised standard configuration, eg NASC Technical Guidance TG20 the scaffold should be designed by bespoke calculation, by a competent person, to ensure it will have adequate strength, rigidity and stability while it is erected, used and dismantled. Scaffolds that include the following need designs: Fans, cantilevers, loading bays, rubbish chutes, bridges, ramps, pavement gantries and crash decks. This list is not exhaustive

-

Has the scaffolding been built to the design?

-

Has a Hand Over Certificate been produced by the scaffolding contractor and accepted by the Site Manager?

-

Have formal scaffold inspections taken place- this must detail what has been inspected? (Every 7 days, after inclement weather, after collision etc)

-

Have pull tests been been carried out and recorded for anchor ties

-

No gaps greater than 100mm

-

No unprotected services including gas flues

-

All guard rails at correct height and toe-boards in place?

-

Falling materials adequately controlled?

-

Where a risk of falling materials controls such as brickguards, debris netting, or monoflex must be used

-

Does the scaffold provide suitable edge protection been installed to prevent contractors falling from height?

-

Full edge protection is required on all work areas of the scaffold (top rail, toe board, and intermediate protection) whenever the work requires access within 2 m of the roof perimeter. The working area and routes should be marked out with continuous physical barriers.PLEASE NOTE: This question is also asked in the roof work section of "Work at Height". Do not mark the contractor down twice for the same issue

-

Has the PC taken reasonable steps to prevent unauthorised access

-

Make sure that unauthorised access to the scaffolding is prevented e.g. by blocking or removing of ground level access ladders. Make sure appropriate warning signs are displayed on scaffolding

-

Are access ladders secured correctly, at the right angle and on firm level ground?

-

-

Are Acrow props or similar in use on site?

Acrow Props

-

9.6A Is there a propping design and calculations in place?

-

All planned work requires the input of a structural engineer. However, they may be instances where propping is used as an emergency before a structural engineer can attend site or give advice. In these instances this section should be marked as NA

-

Is the design site specific

-

-

Does the design have the necessary sign offs aligned to the TW classification?

-

Is there a handover or initial inspection which shows that thepropping was installed correctly and built exactly to the design?

-

Are formal checks of the propping being carried out and up to date

Lifting Operations

-

Are manual handling related risks controlled in accordance with site-specific risk assessment and regulatory requirements?

-

Is there evidence of manual handling training on site

-

Gin Wheels in use and compliant with SG9:15 requirements?

-

Lifting equipment has thorouhgh examination certificate with id no (this includes Gin wheels)

-

SWL clearly displayed on all lifting equipment

-

Have exclusion zones been set up under the lift radius and around the base of the lifting equipment?

-

Lifting plan in place where required

-

All persons undertkaking lifts are competent?

-

Has the PC issued a permit to lift or completed a checklist before the lift commences?

-

Permits to lift / lift checklists must be in place for crane lifts and when excavators are used as lifting equipment. Lorry loaders (Hiabs) are only expected to have been subject to permits / checklists if the lift is complex in terms of the load and environment

-

10.1A Has the ground stability been checked?

-

10.1B Have underground / overhead services been taken into account?

-

Asbestos

-

Have all staff completed the M+S e-learning asbestos awareness course

-

Is there a valid Asbestos Refurbishment & Demolition Survey onsite which covers all works areas in line with the scope of work? Or evidence that the building was constructed post 2000?

-

There MUST be an Asbestos Refurbishment & Demolition Survey available onsite if the building is Pre-2000. This document should be available in the Site Management File. Must have appropriate evidence if Post 2000 Build

-

Is access to the asbestos register available via simple compliance?

-

The site manager must have their own login and this cannot be through anyone elses

-

Has asbestos been removed from the building? (State if it was removed during this project or by a developer)

-

Is a copy of the ASB5 notification and plan of works on site for any notifiable Asbestos removal works? (State if the removal was non licensed work)

-

Where Asbestos removal has/is been undertaken during this project a copy of the ASB5 HSE notification should be available on site along with the Plan of works until the end of the project. NA if it was removed by the developer

-

Have clearance certificates or clean air tests and hazardous waste transfer notes been collated and filed on site?

-

If the building is Pre-2000, have asbestos awareness certificates been collated for relevant operatives? (Check 3 relevant operatives working on site)

-

Relevant operatives are those who are liable to disturb asbestos during their everyday activities. Trades include but are not limited to: Electricians, plumbers, plasterers, roofers, shop fitters, heating and ventilation engineers, refrigeration engineers, demolition workers, painting and decorators, joiners, telecommunication engineers, fire and burglar alarm installers. Please not that if the ground has been identified as contaminated with asbestos at the Pre Construction stage, then Ground workers should also have asbestos awareness training

-

If the building is Pre-2000, is there an emergency asbestos "Grab Pack" on site complete with instructions?

-

As a minimum the grab pack should contain: FFP3 Mask, Paper Overalls, Suitable Wipes, Plastic Bags for Contaminated Clothes and Instructions. The grab pack should be stored in a known, secure location ready to be used and accessible in cases of emergencies

-

Is there adequate segregation and separation between the asbestos works, contractors and staff?

-

Are the asbestos waste transit and waste removal routes being adhered to and are these routes demarcated appropriately?

-

Does the asbestos analyst and asbestos surveyor meet all role requirements on the Marks and Spencer training portal?

-

13.8 Can the site manager demonstrate that the store has been informed and engaged?

-

Did the site induction include information about Marks and Spencer asbestos policy and site specific arrangements?

-

Are there arrangements in place to deal with asbestos related emergencies and do these meet Marks and Spencer asbestos policy requirements?

-

COSHH

-

Are relevant COSHH assessments and material safety data sheets available on site and have they been signed by operatives

-

Check a minimum of 3

-

Are substances being used appropriately as per the relevant COSHH assessments?

-

Are substances being stored appropriately as per the relevant COSHH assessments?

-

Are suitable and sufficient emergency procedures in place to deal with incidents related to substances classified under COSHH (e.g. spillages, gas escape, and ingestion)?

Traffic Management

-

Are deliveries suitably managed and co-ordinated by the site manager with the store, landlord or centre management?

-

Has a site specific delivery route been identified and recorded in the traffic management plan?

-

Where banksmen are identified in the traffic management plan, is there evidence of this role being discharged appropriately and are banksmen suitably trained and managed?

-

PPE + Presntation

-

Are all site managers, operatives and visitors fully compliant with the Marks and Spencer PPE policy requirements detailed in the construction phase plan?

PPE and Presentation

-

Are operatives on site wearing 5 point PPE? (Hard hats, Hi Vis vests, Safety boots, suitable gloves and eye protection)

-

The requirement for eye protection is to be risk assessed by the PC. If the assessment finds that eye protection is not required this must be documented and form part of the induction process

-

Is PPE defined by risk assessments being worn?

-

Is it suitable and sufficient?

-

Is there evidence that operatives have been face fit tested

-

Are the operatives in SRG Branded high vis and hard hats?

-

Are harnesses in use?

-

Is the harness/lanyard/rope in good condition with no signs of damage?

-

Is the right type of equipment being used; fall arrest/fall restraint?

-

Is the equipment compatible?

-

All anchor points are safe to use?

-

Is there evidene that pre user and weekly inspections are being carried out?

Environmental

-

Are there segregated waste skips on site?

-

If there are site restrictions and there is only room for one skip, please mark as NA and mention this in the notes

-

Is there signage identifying the segregated waste?

-

NA if no segregation taking place

-

Is the waste stored correctly?

-

Are skips suitably barriered off and/or locked to prevent unauthorised used?

-

All Skips should be locked or barriered off from the public.Hazardous waste should be segregated from normal waste, check for any evidence of pollutants being introduced into drainage? Ensure hazardous waste has been segregated from normal waste - Examples of hazardous waste: lead acid batteries, fluorescent tubes, treated timber, concrete additives, asbestos, contaminated soils, preservative, adhesives, paint, varnish, solvents.Skips containing plasterboard should be appropriately covered? Damp plasterboard can leak pollutants into the environment therefore skips must be covered to ensure the boards can not get wet from rain etc

-

Where waste has been removed from site are Waste Transfer Notes / Hazardous Waste Consignment Notes available and completed in full?

-

All Waste Transfer Notes / Hazardous Waste Consignment Notes must available on site for inspection. This can be in paper or an electronic format. Please note how many skips have been used, The providers Company Name and the Carrier Licence Number.In Part - Where the WTN's are available, but not completed in full. NA - Where no waste has been collected

-

Is the waste carriers license certificate filed on site?

-

Are the details (Name and Address)of the waste transfer station held on site?

-

Are all fuels and other hazardous liquids stored appropriately?

-

Are they stored away from drains?Are small fuel containers of the correct type?Are plastic containers less than 10 litres in capacity? Are metal containers less than 20 litres capacity?Are the containers suitably labelled with ""Highly Flammable"" and ""Petrol""? Are they stored in a suitable cabinet away from direct sunlight?

-

Is there a secondary containment system in place with plant such as generators and compressors to prevent leaks and spillages

-

Secondary containment systems include double bunding, drip trays, plant nappies etc. If double bunding does not include all the base of the plant then another system may be required to prevent leaks of fuel or oil

-

Are drains within the site protected?

-

Are emergency spill kits available?

-

Is this a COOP site?

-

Are noisy works being carried out at the most appropriate times in liaison with the Co-op project representative and local authority (Especially where abatement notices are in effect)

-

Is there a requirement for noise monitoring to be taking place? (Explain the circumstances)

Electrical

-

Has a temporary electrical certificate been issued for the site cabins / welfare facilities?

-

Is all electrical equipment in good order and PAT tested

-

All equipment 110v or battery powered

-

Any uncontrolled risks of overhead power lines

Equipment

-

Is the equipment right for the task?

-

Equipment being used and stored in accordance with the RAMS

-

Gas guns in good working order

-

Hand tools in good working order