Information

-

Inspection Title. EXCAVATION FOR BRIDGE SITES B30 b Ed 4 /Rev 0 B30b

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

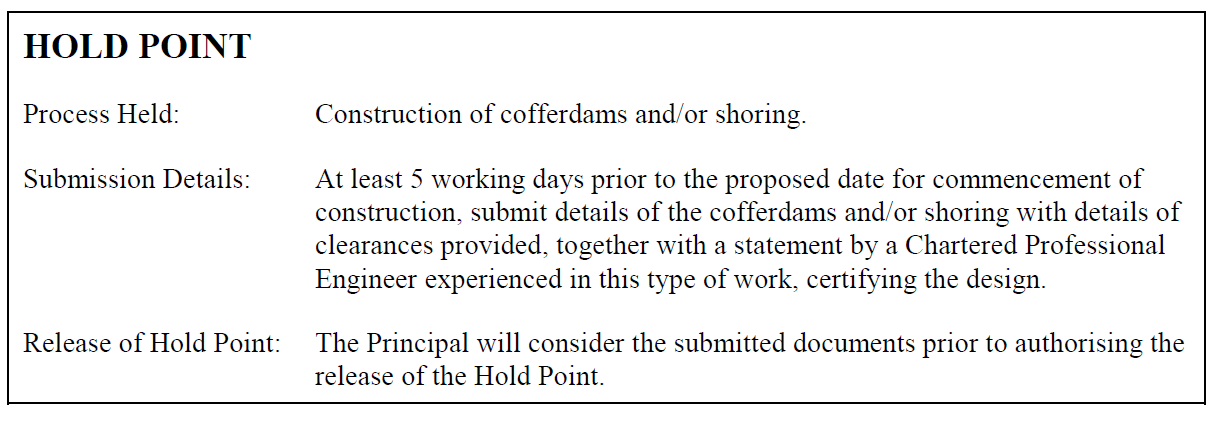

3 COFFERDAMS AND SHORING

-

-

Has the hold point been released for the Coffrdams / Shoring.

-

Do not incorporate material used in the construction of the cofferdam or shoring within the concrete of the finished structure, unless shown otherwise on the Drawings.

-

Remove any cofferdams and shoring, including temporary piles, to a minimum of 0.5 m below natural or finished surface, whichever is lower.

4 EXCAVATION

-

During excavation and backfilling, do not disturb any survey bench marks, survey or level peg, plug, pipe or marking.

-

If contaminated material is encountered during excavation, notify the Principal immediately and deal with the contaminated material in accordance with RMS R44.

-

Excavate for construction of structures to the depth and profile shown on the Drawings.

-

Avoid disturbing the material below the required excavation level shown on the Drawings.

-

Remove all loose material from within the excavation before placing concrete.

-

For foundations bearing on earth, backfill any over-excavation under the foundation member with Select Fill complying with Clause 6.2.2, or concrete of the same quality as the overlying concrete structure.

-

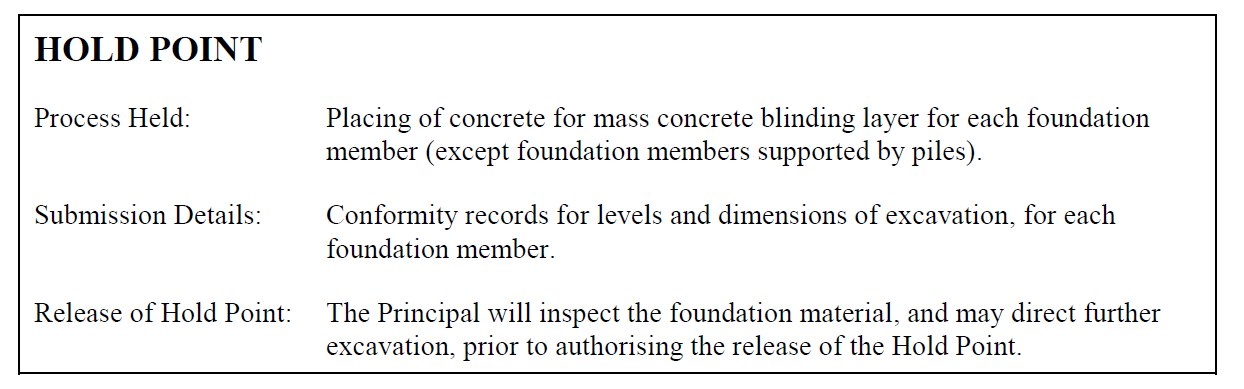

Prior to placing concrete for the mass concrete blinding layer, present the excavated foundation area for inspection by the Principal.

-

-

Where further excavation is directed, the above Hold Point will again apply after the completion of the excavation to the new levels or new dimensions.

5 MASS CONCRETE BLINDING LAYER

-

Do not place concrete in the presence of surface or seepage water.

-

The concrete for the blinding layer must be of the same quality as that of the overlying concrete structure, unless shown otherwise on the Drawings.

-

Allowed to harden sufficiently before any subsequent operation over it can take place, to avoid damage to the layer.

G22 Safety and G36 Environmental

G22 SAFETY

-

"Permit to Excavate" where applicable onsite before any work has commenced.

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Has a certified rigger checked that the structural members are secure before the load is released.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Are all accesses safe and sign posted.

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

G36 ENVIRONMENTAL

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Have nearby/adjacent waterways been protected from potential concrete, grout and curing compound spills

-

Has a concrete washout area been defined and used.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name