Title Page

-

Site conducted

-

Conducted on

-

Location ID

-

Cable Type

-

String

-

Cable ID

-

Prepared by

Pre Task

-

Confirm a ToolBox Talk was completed

-

Confirm Cables have been marked to final position and there is no damage present

-

Confirm Pre Term testing has been completed

-

Ensure kit size is correct before install

-

Procedure NS2244-ENG-00026 Cable Termination Power Cores OSS is available in digital or paper format and will be followed during the complete execution of the termination. The Below questions/Pictures are for QC Purposes and are *NOT* the detailed task plan also I Can confirm the procedure is available and will be followed during the termination works.

Pfisterer install before plug-in/Test

-

Ensure that the cable and Switchgear are disconnected from any voltage source and earthed.

-

Ensure there is a valid Permit in place before starting works

-

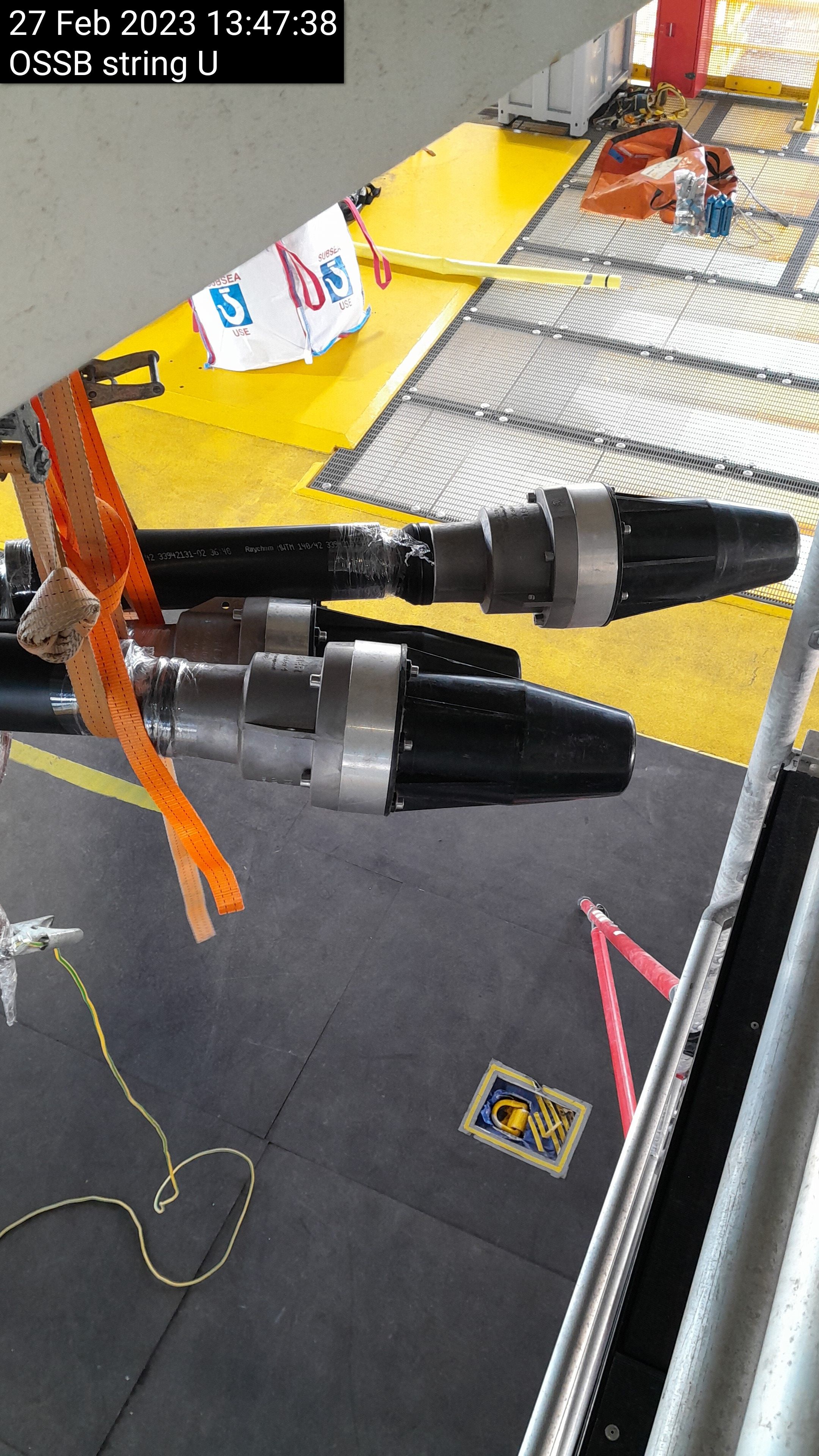

Take a picture showing the cables up and measured in the final position

-

Picture showing the cables up into position and measured in the final position

-

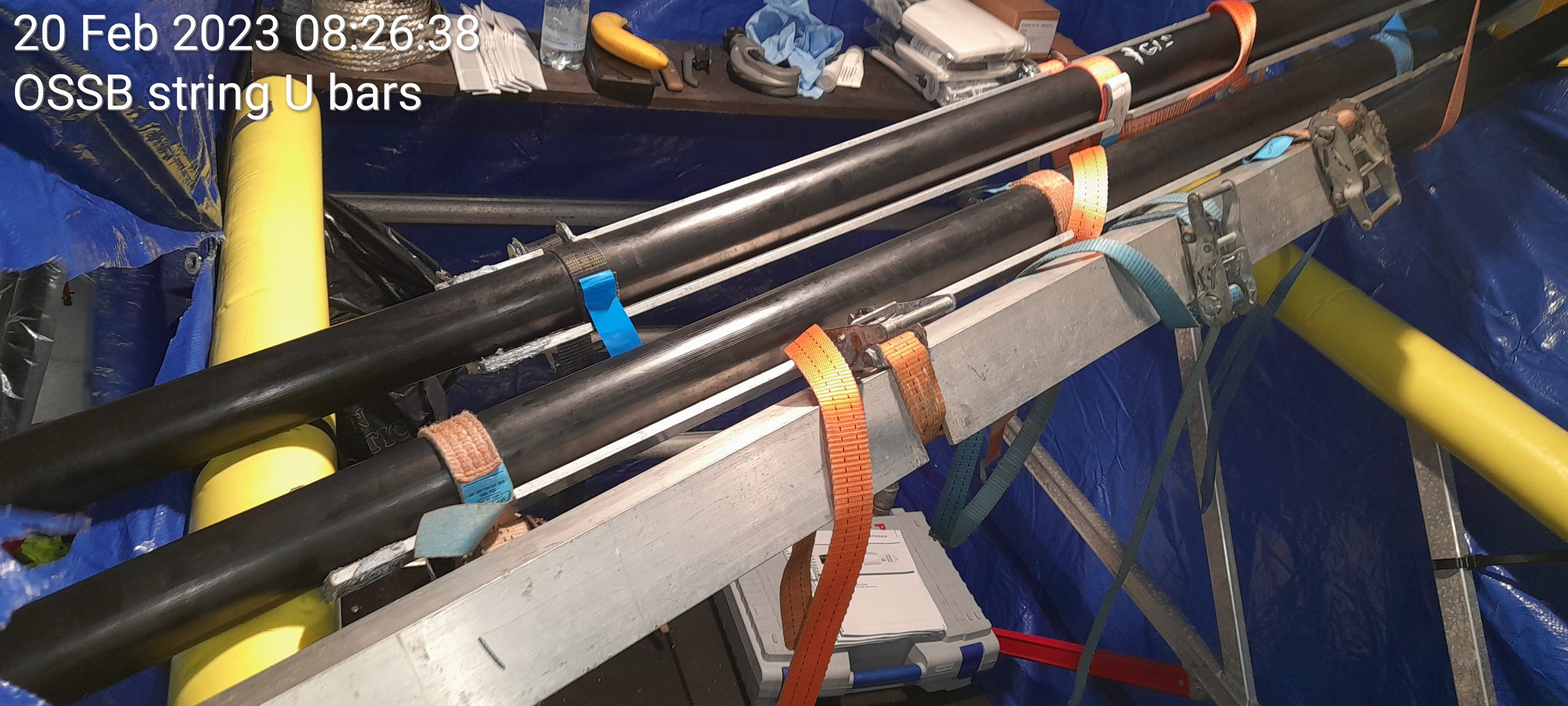

Take a picture showing straighten bars installed ensure there is excess length for screens

-

Picture showing bars installed

-

Length of time cables heated for

-

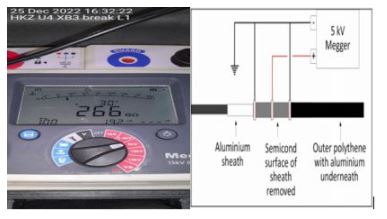

MOC-TT-007 Break Test diagram for reference 5KV for 1min (Picture required showing megger display showing result over 100MΩ)

-

L1 Picture showing Megger display proving no breakdown result over 100MΩ

-

L2 Picture showing Megger display proving no breakdown result over 100MΩ

-

L3 Picture showing Megger display proving no breakdown result over 100MΩ

-

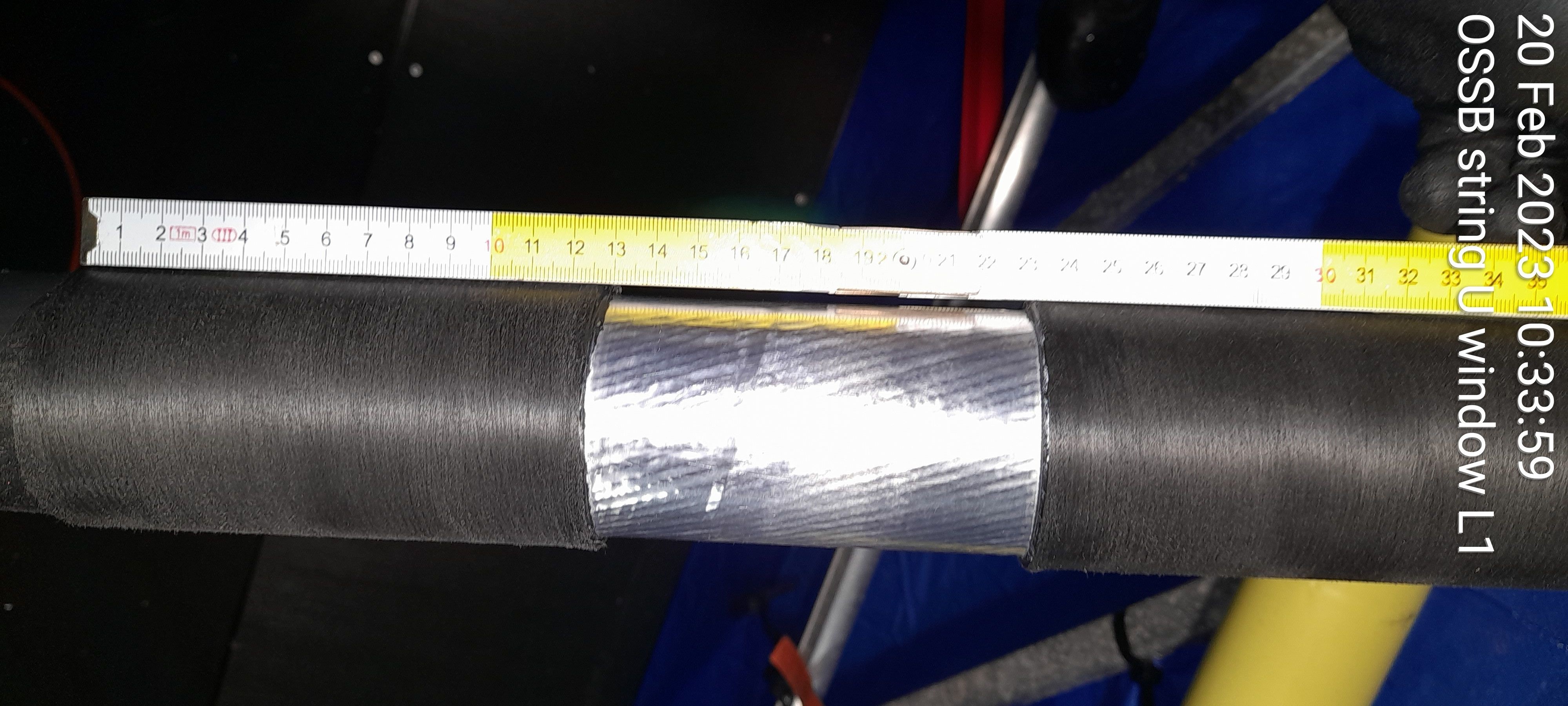

Take a picture showing clean window

-

L1 picture showing window clean from 4 angles

-

L2 picture showing window clean from 4 angles

-

L3 picture showing window clean from 4 angles

-

Take a picture showing mesh applied/Control Mark

-

L1 picture Showing mesh/Control mark applied

-

L2 picture Showing mesh/Control mark applied

-

L3 picture Showing mesh/Control mark applied

-

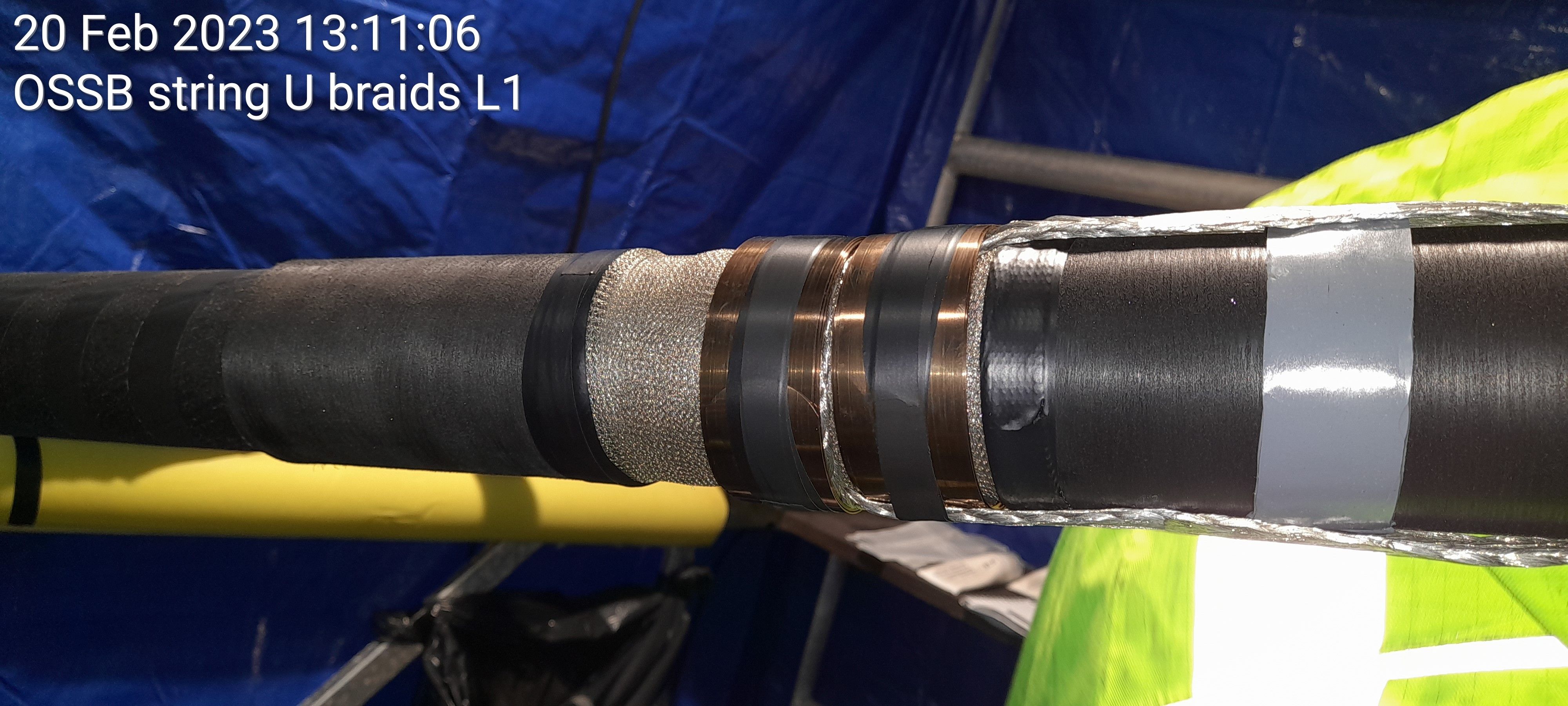

Take a picture showing braids installed

-

L1 picture showing braids installed

-

L2 picture showing braids installed

-

L3 picture showing braids installed

-

Take a picture of CR display off contact resistance between window and braids

-

L1 picture showing CR display of contact resistance between window and braid

-

L1 CR measurement

-

L2 picture showing CR display of contact resistance between window and braid

-

L2 CR measurement

-

L3 picture showing CR display of contact resistance between window and braid

-

L3 CR measurement

-

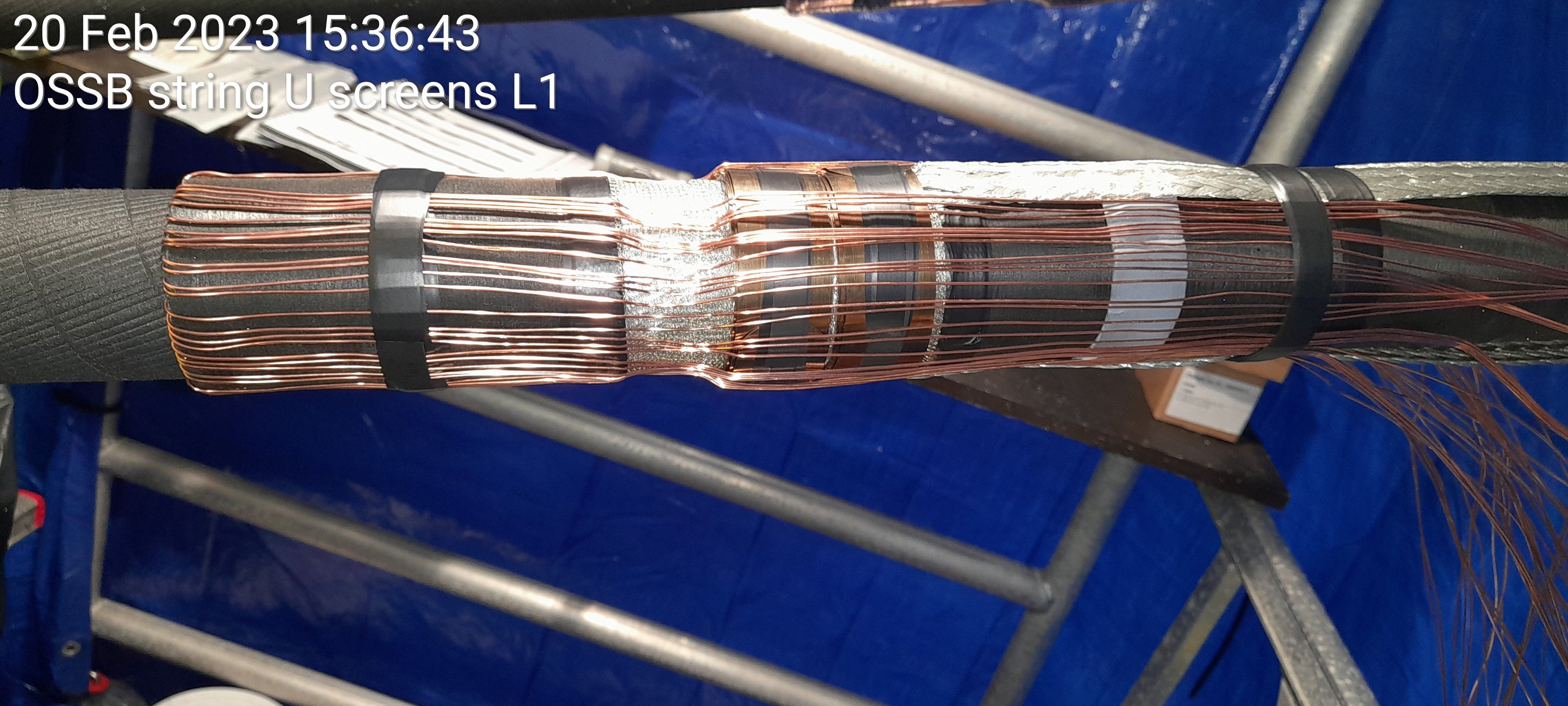

Take a picture showing screens down

-

L1 picture Showing screens down

-

L2 picture showing screens down

-

L3 picture showing screens down

-

Take a picture showing core Length

-

L1 picture showing core Length with a ruler

-

L1 core length measurement

-

L2 picture showing core Length with a ruler

-

L2 core length measurement

-

L3 picture showing core Length with a ruler

-

L3 core length measurement

-

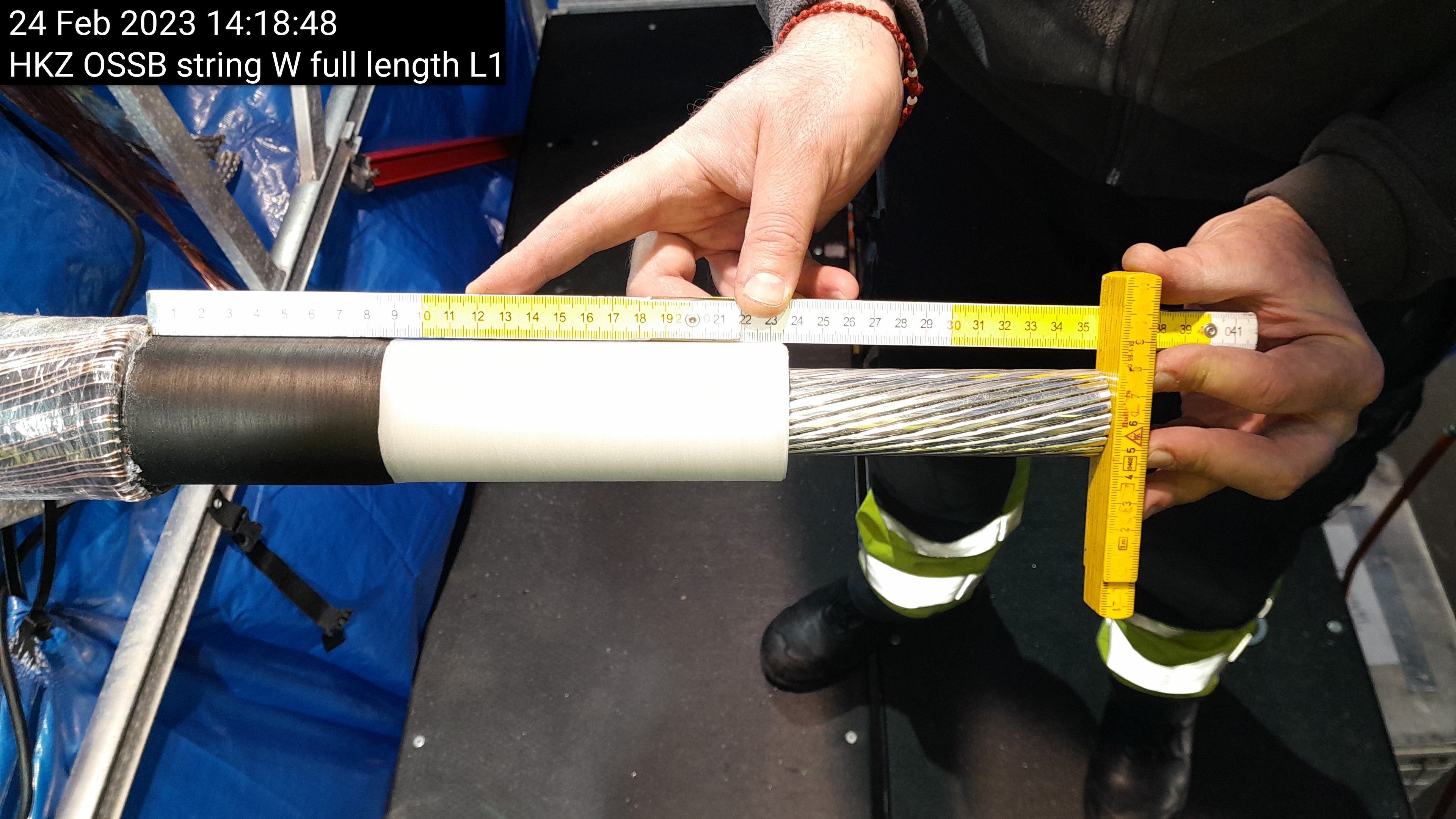

Take a picture showing full length

-

L1 Full length of prepared end with a ruler

-

L1 full length measurement

-

L2 Full length of prepared end with a ruler

-

L2 full length measurement

-

L3 Full length of prepared end with a ruler

-

L3 full length measurement

-

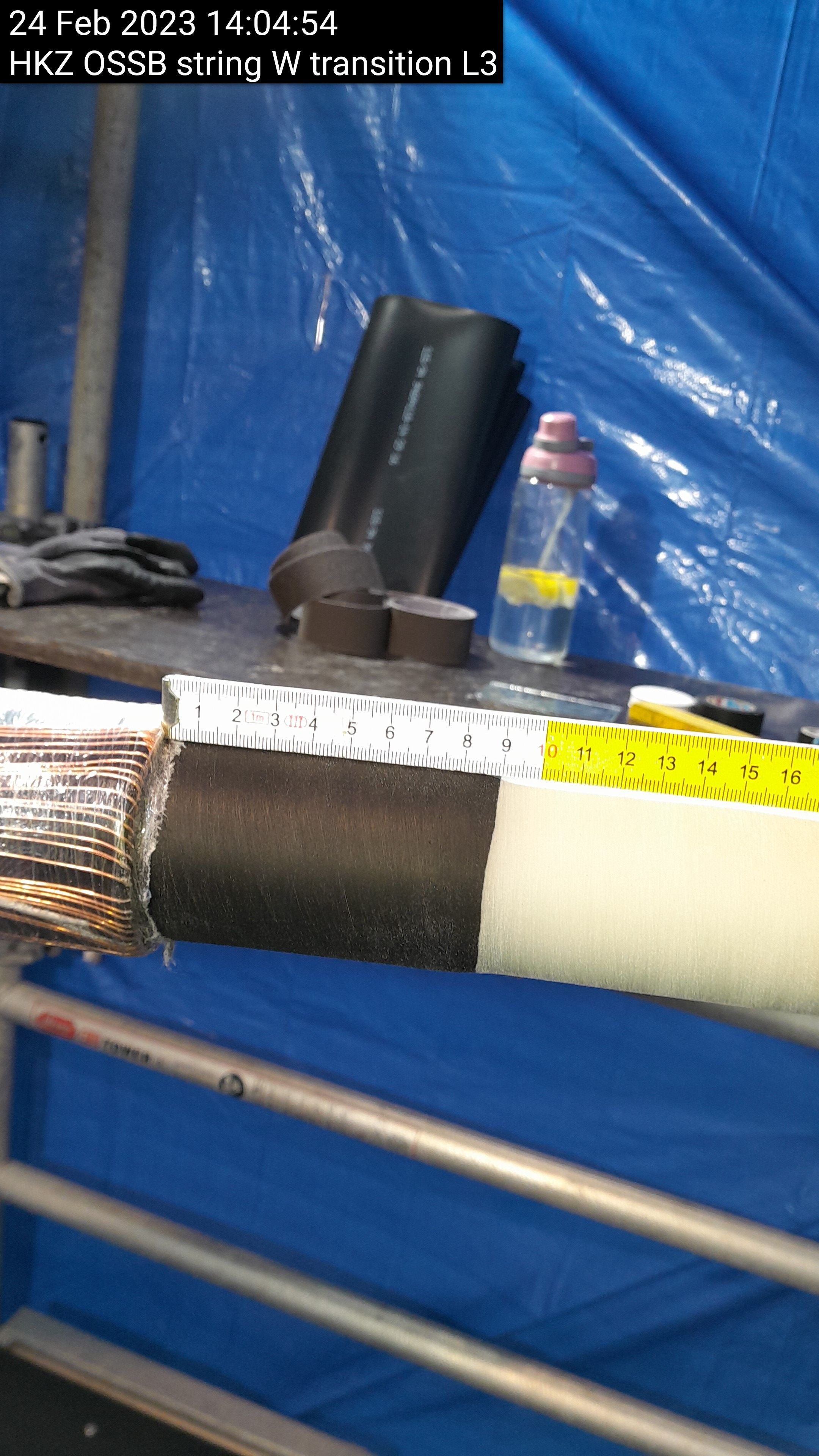

Take a Picture of the sheath to transition with a ruler

-

L1 Picture of the sheath to transition with a ruler

-

L2 Picture of the sheath to transition with a ruler

-

L3 Picture of the sheath to transition with a ruler

-

Take a picture of these diameters 3 measurements are required per phase

-

L1 Pictures showing the above diameters (3 pictures)

-

L1 diameter measurement

-

L1 diameter point two measurement

-

L1 diameter point three measurement

-

L2 Pictures showing the above diameters (3 pictures)

-

L2 diameter measurement

-

L2 diameter point two measurement

-

L2 diameter point three measurement

-

L3 Pictures showing the above diameters (3 pictures)

-

L3 diameter measurement

-

L3 diameter point two measurement

-

L3 diameter point three measurement

-

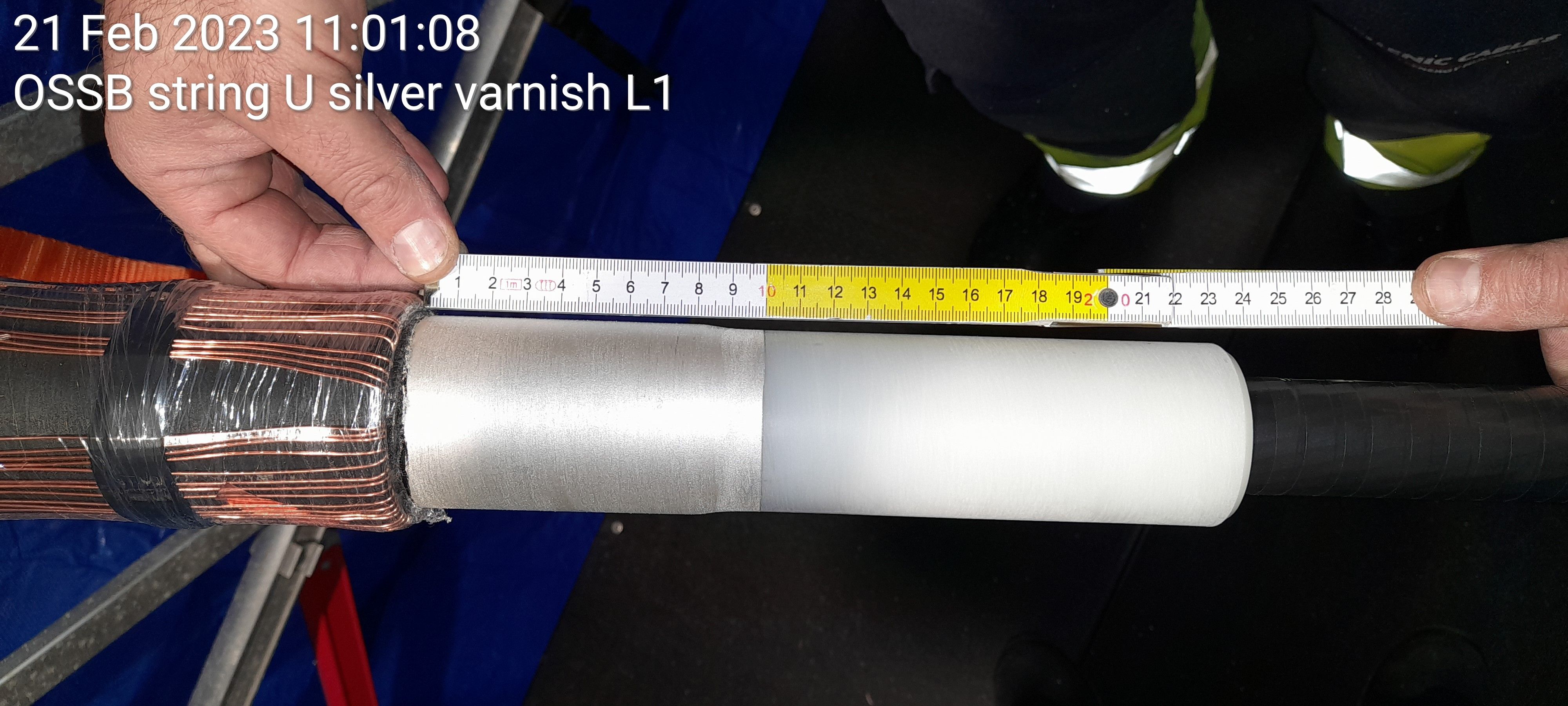

Take a picture showing silver varnish applied with a ruler

-

L1 Picture of the silver varnish with a ruler against it

-

L2 Picture of the silver varnish with a ruler against it

-

L3 Picture of the silver varnish with a ruler against it

-

Take a picture showing mesh installed

-

L1 Picture showing Mesh installed

-

L2 Picture showing Mesh installed

-

L3 Picture showing Mesh installed

-

Take a picture showing installed heatshrink

-

L1 Picture showing heatshrink installed

-

L2 Picture showing heatshrink installed

-

L3 Picture showing heatshrink installed

-

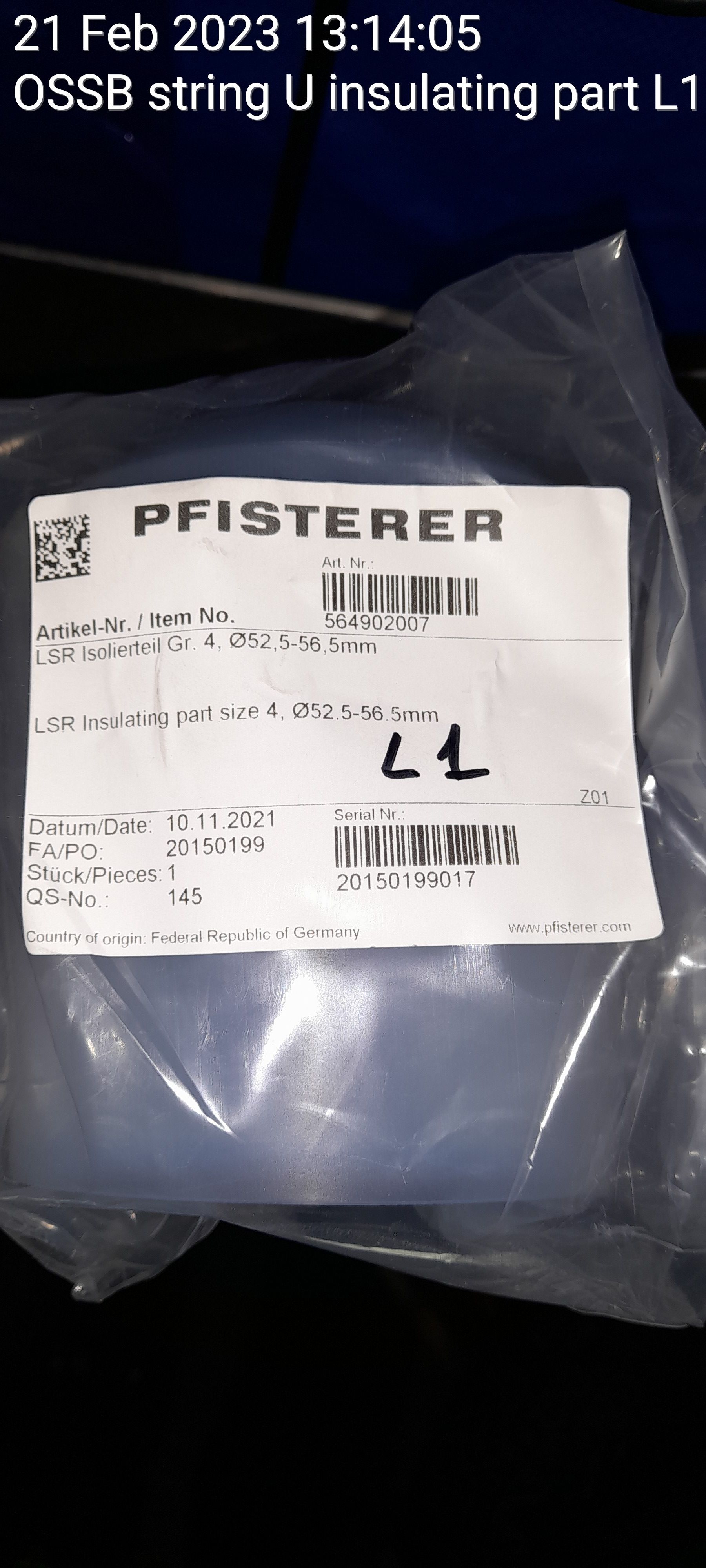

Take picture of insulating part serial number for each phase

-

L1 Picture showing insulating part serial number

-

L1 insulating part serial number

-

L2 Picture showing insulating part serial number

-

L2 insulating part serial number

-

L3 Picture showing insulating part serial number

-

L3 insulating part serial number

-

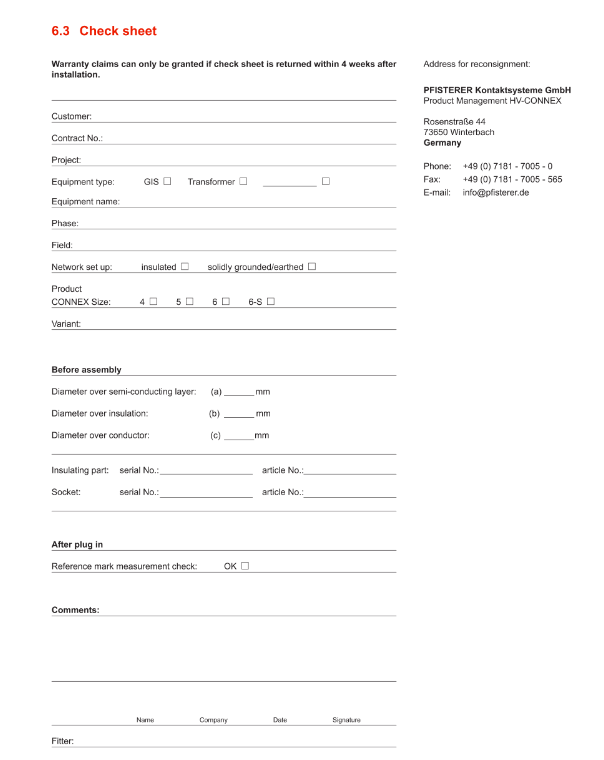

Ensure checksheet is filled out

-

Confirm document has been filled out

-

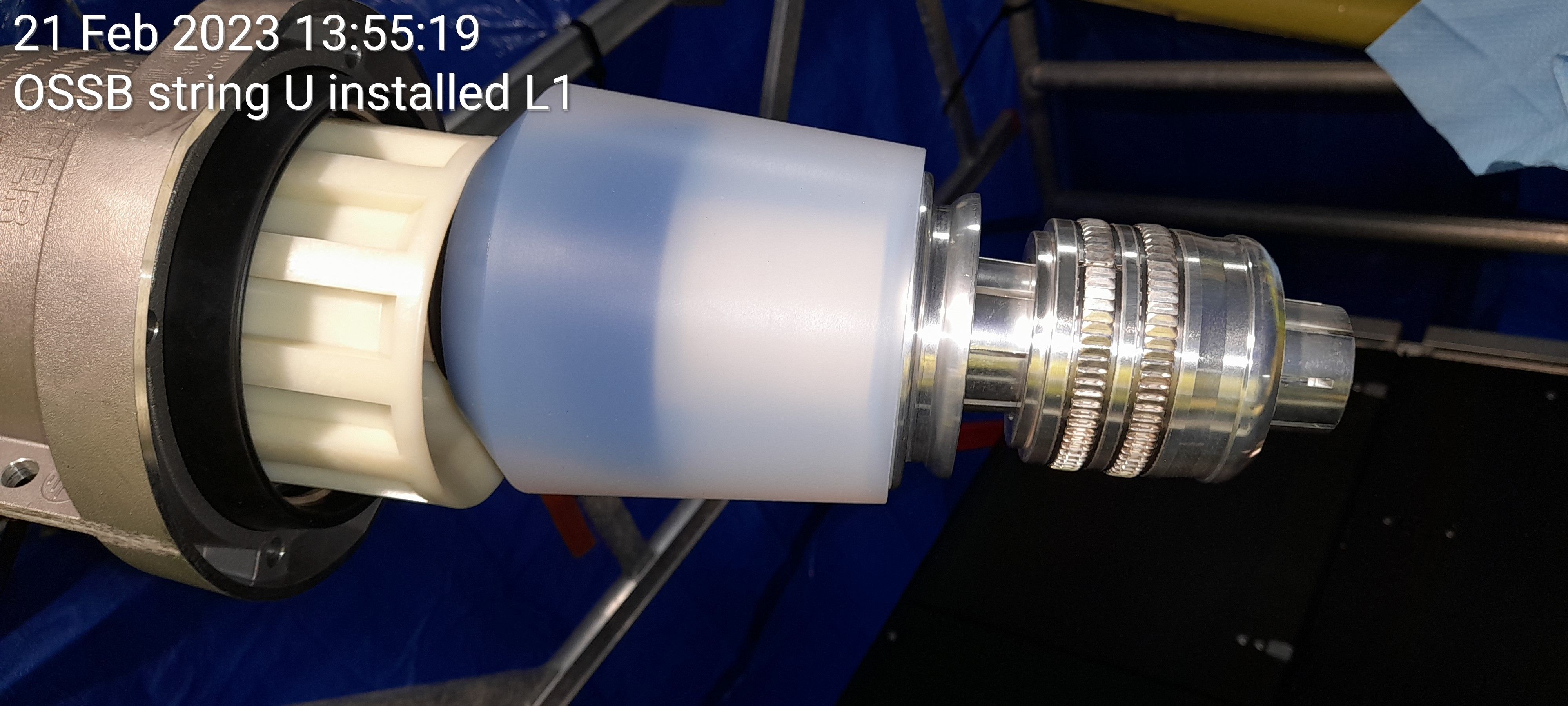

Take a picture of cone insulation part installed

-

L1 picture showing insulation part installed

-

L2 picture showing insulation part installed

-

L3 picture showing insulation part installed

-

Take a picture showing cable end completed after compression

-

L1 picture showing cable end completed after compression

-

L2 picture showing cable end completed after compression

-

L3 picture showing cable end completed after compression

-

For information purposes next page is for test box/protective cap/plug-in pictures

Test/Plug-in

-

Take a picture showing cable in test boxes and dummy plugs installed and ready to test

-

L1 picture showing cable in test boxes and dummy plugs installed and ready to test

-

L2 picture showing cable in test boxes and dummy plugs installed and ready to test

-

L3 picture showing cable in test boxes and dummy plugs installed and ready to test

-

Take a picture of the protective caps installed

-

L1 picture showing protective caps installed

-

L2 picture showing protective caps installed

-

L3 picture showing protective caps installed

-

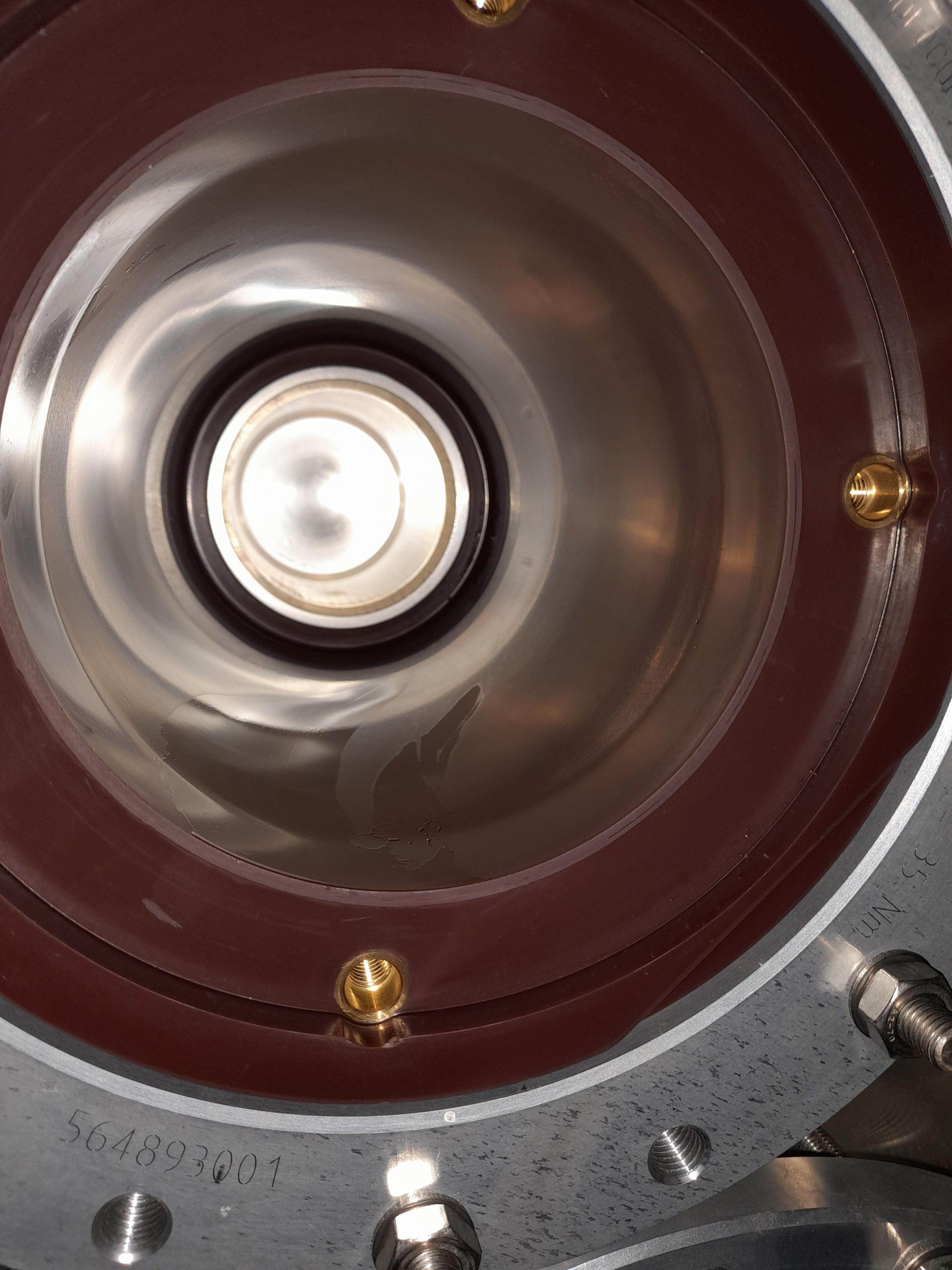

Take a picture inside socket before plugging-in ensure there is no marks/damage

-

L1 picture of inside socket before plugging-in ensure there is no marks/damage

-

L2 picture of inside socket before plugging-in ensure there is no marks/damage

-

L3 picture of inside socket before plugging-in ensure there is no marks/damage

-

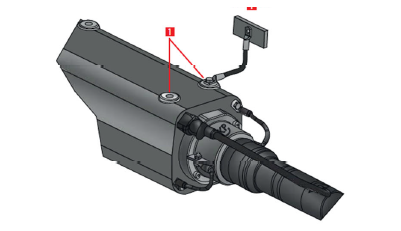

Picture with cable into position ready for plug-in sat under the socket as shown in the example

-

L1 picture showing cable ready to plug-in sat under the socket

-

L2 picture showing cable ready to plug-in sat under the socket

-

L3 picture showing cable ready to plug-in sat under the socket

-

Take a picture when cable is plugged-in/heatshrink installed showing the torqued and marked pfisterer bolts

-

L1 picture showing cable plugged-in/heatshrink installed showing the torqued and marked pfisterer bolts

-

L2 picture showing cable plugged-in/heatshrink installed showing the torqued and marked pfisterer bolts

-

L3 picture showing cable plugged-in/heatshrink installed showing the torqued and marked pfisterer bolts

-

Take a picture showing earthing completed and connected to the earthbar

-

L1 Picture showing earthing complete connected to the earth bar

-

L2 Picture showing earthing complete connected to the earth bar

-

L3 Picture showing earthing complete connected to the earth bar

-

Take a picture showing the bellhouse earthing straps installed

-

L1 picture showing bellhouse earthing straps installed

-

L2 picture showing bellhouse earthing straps installed

-

L3 picture showing bellhouse earthing straps installed

-

Take a picture showing the cable straight until the first cleat

-

L1 picture showing cable straight until first cleat

-

L2 picture showing cable straight until first cleat

-

L3 picture showing cable straight until first cleat

-

Take a picture showing roxtec plate reinstalled from above

-

Picture showing roxtec plate reinstalled from above

-

Take a picture showing installed labels where required (example pictures only)

-

Picture showing the installed labels where required

Sign off

-

I Can confirm the termination has been executed according to NS2244-ENG-00026 Cable Termination Power Cores OSS Procedure.

-

Client Rep Present

-

Client Signature

-

V&SH Tower team Lead (Add notes if full termination wasn't done by one jointer showing which points where done)

-

SOC HV Supervisor to review and confirm installation work carried out satisfactory meeting the specified requirements and tick complete.

-

SOC HV Supervsior

-

Comment if applicable