Title Page

-

Site conducted

-

Conducted on

-

Location

-

Cable ID

-

Prepared by

-

Tick

- FOU - FO Cable Routing and Termination

-

Publication date: 01-02-2022

SOC Revision: 1

Document name: NS2244-ENG-00027

Complete file attached

Sub-Task #1 Preparation

-

1.1 Perform Toolbox talk

-

Check for a valid permit and review the required safety measures

Attached TRA M-00011431 -

1.2 Perform Radio communication check with ISV

-

1.3 Lift tools from ISV to EWP

-

Perform dropped object sweep, if found select "At Risk".

-

Report potential dropped object via HOC card to the vessel.

-

1.4 Check that accessories of the splice box and all material needed for the splicing are available. <br> Check that all tools required for the work is available and in good condition.

Sub-Task #2 FO Cable Routing & Termination

-

2.1 Route the submarine fiber optical cable to the splice box’s location to mark the bushing position on the cable.

-

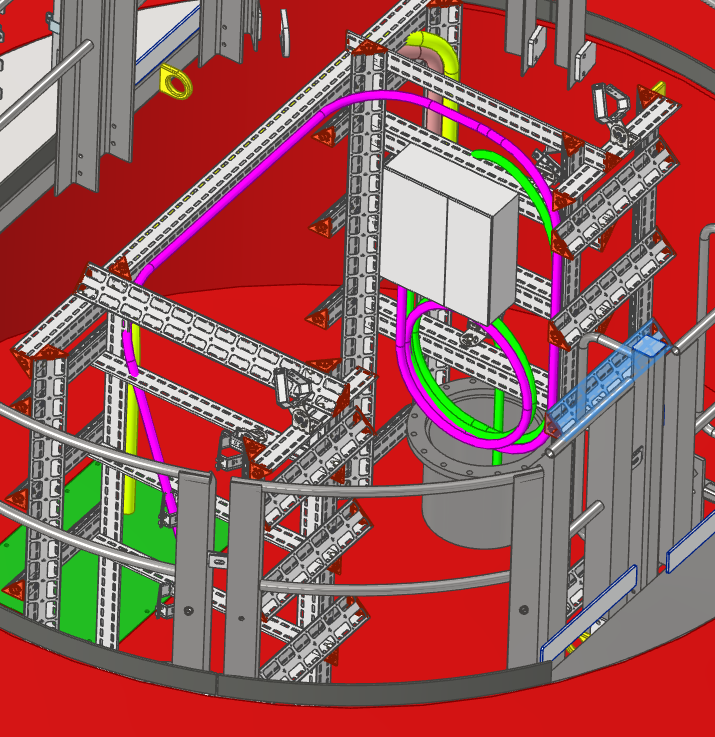

The FO splice box will be installed on the inner side of the cable racking above the hang-off, the box can be installed on either side, this being dependent upon which cable is pulled in first.

-

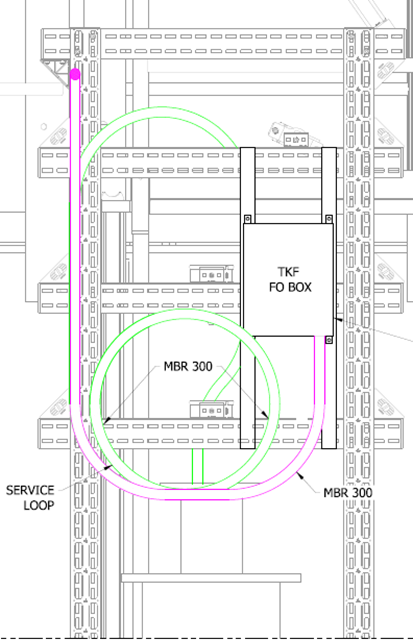

2.2 Refer to the FO cable routing sketch for more clarifications, NS2244-SKT-0035 [attachment-5]

-

2.3 Record the batch number and the meter length marking as embossed on the TKF Fibre Cables.

-

2.4 FO-Cables shall be guided below the interlink beam of the racking to have them protected from the stored power cores.

-

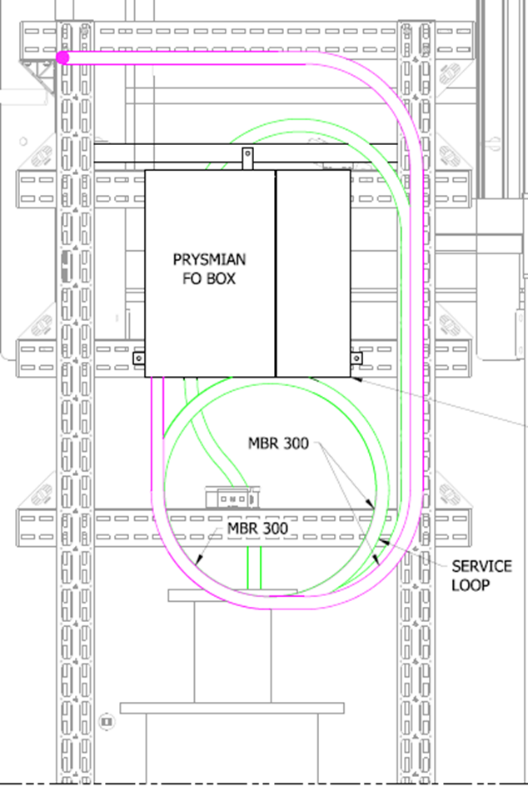

2.5 Create a service loop of the submarine FOC near the FO splice box

-

No service loop is necessary for the far reach submarine FOC.

-

2.6 Make sure that the FOC MBR is not breached!

-

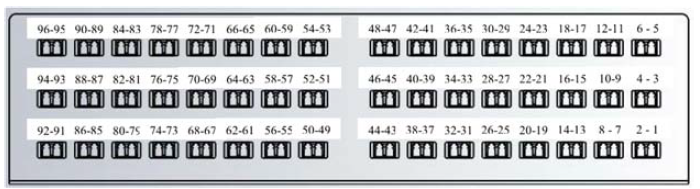

TKF FOC

Diameter of the service loop has to be at least 1.9 meters.

MBR: 300 mm

PPL FOC

Diameter of the service loop has to be at least 1.9 meters.

MBR: 300 mm -

2.7 Measure and record the diameter of the maintenance loops.

-

2.8 Fix the cable to the structure with two cable ties forming an X at least every meter over the cable.

-

2.9 Photographs including date/time stamp shall be taken showing the routed cable.

-

2.10 Get the splice box and place it on a table to have a convenient work place.

-

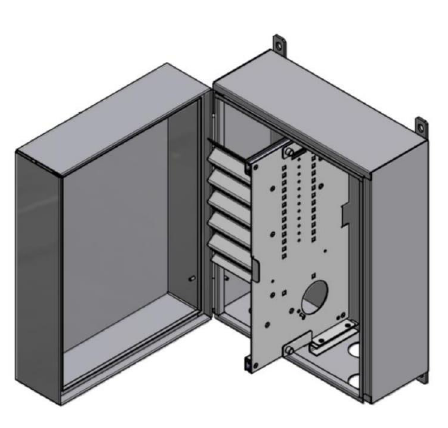

TKF FO Box

-

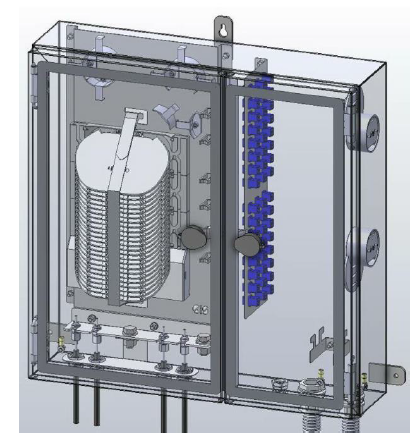

PPL two door FO Box

-

2.11 Install the pre-manufactured adaptor identification labels to the TKF cabinet as per the Splice Plan.

-

-

2.12 Ensure the adaptor labelling within the Prysmian patch panel have been pre-installed.

-

-

2.13 Add 2.5 meters to the mark of the bushing location, if there is any excess cable, extend the maintenance loop or lose the excess in the cable route

-

*Do not cut the fibre cable*.

-

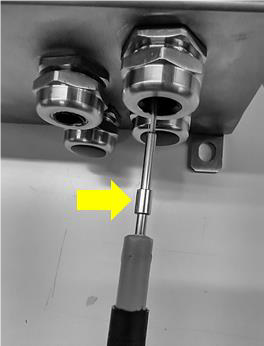

2.14 Pull the bushing assembly over the cable, feed the cable through the box and strip the outer sheath, the stainless-steel tube to access the fibres. <br><br>Follow the instruction manual of the splice box for the required lengths.

-

2.15 For TKF FOC, follow the FO Splice box installation manual

-

-

TKF: Fibre Box Installation Manual - Doc. No. 34014-IIN-OF0260994

-

2.16 For PPL FOC, follow the FO Splice box installation manual

-

-

Prysmian: Fibre Box Installation Manual - Doc. No. PPL18301-SE-PRO-005

-

2.17 Assemble the cable bushing and the earthing kit according to the splice box manual. <br> Coil the spare fibre length in the splice cassette. <br> Make sure that at any sharp edges the fibers are protected

-

2.18 Photographs including date/time stamp shall be taken showing the earthing of the fibre optic cable steel tube.

-

2.19 Clean and separate the fibres, care should be taken while carrying out this task.

-

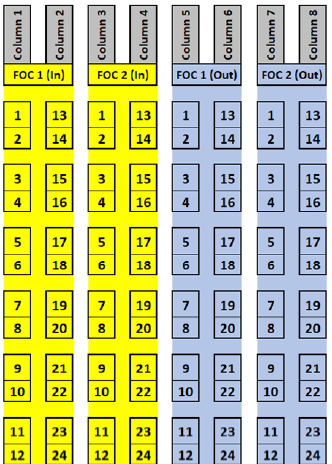

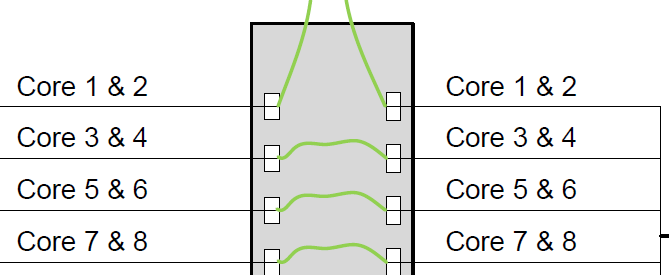

2.20 Start to splice the fibres according to SOC fibre Optic Cable Splicing Instruction GEN-SUP-0707 and the splice plan.

-

All splices are to be installed with a splice protector.

-

Arrange the completed fibers in the splice cassette.

-

SOC fibre Optic Cable Splicing Instruction GEN-SUP-0707

-

HKZ 1&2 - Splice Plan

-

HKZ 3&4 - Splice Plan

-

2.21 Photographs including date/time stamp shall be taken showing every splice cassette.

-

2.22 Photographs including date/time stamp shall be taken showing the complete FO splice box with the bushings visible.

-

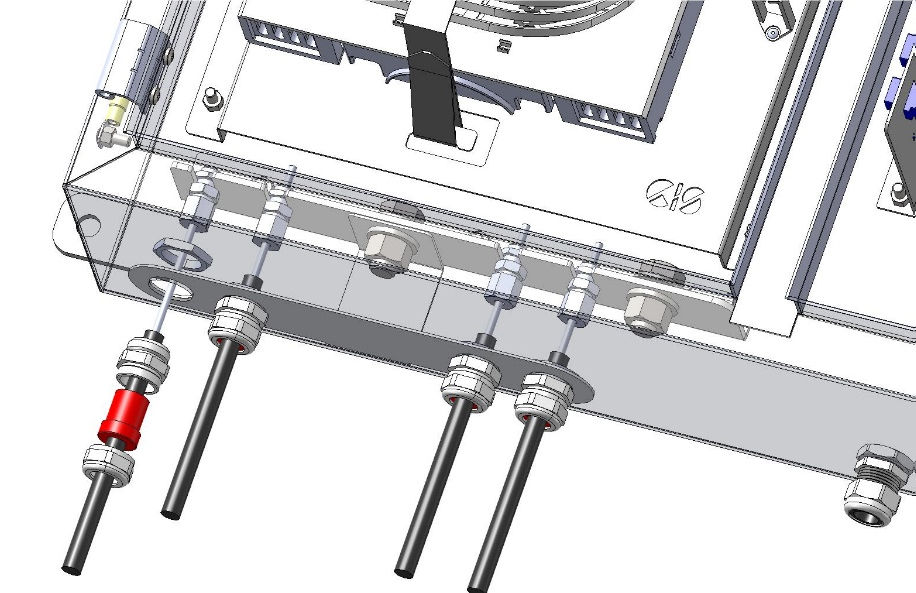

2.23 Close the splice box and install it to the structure according to the splice box manual

-

Prysmian FO Box

-

2.19

-

2.24 The smaller TKF splice box should to the right side of the racking to get the FO Cable straight into the box maintaining the FO-Cable MBR

-

2.25 Reroute and fix the service loop (if applicable) close to splice box

-

2.26 Photographs including date/time stamp shall be taken showing the finally installed splice box.

-

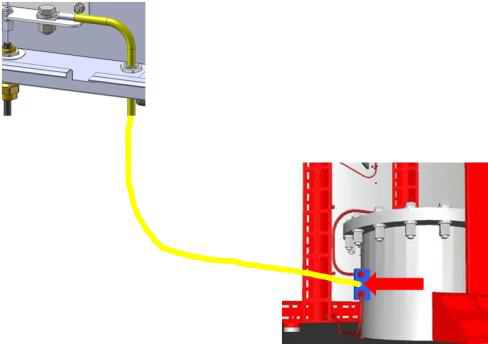

2.27 Route and connect the earthing cable to the nearest earthing point on the structure.

-

-

2.28 Photographs including date/time stamp shall be taken showing the splice box external earthing.

-

2.29 Attach the cable identification label to the fibre optic cable above the hang off.

-

2.30 Photographs including date/time stamp shall be taken showing the cable identification label installed in Step 2.29.

-

2.31 Attach the cable identification label to the fibre optic cable just below the fibre optic box.

-

2.32 Photographs including date/time stamp shall be taken showing the cable identification label installed in Step 2.31.

-

2.33 Following post-termination testing install the patch leads interconnecting the incoming subsea cable with the outgoing subsea cable as detailed in the Splice Plan.

-

2.34 Photographs including date/time stamp shall be taken showing the patch leads installed in Step 2.33.

-

Sample Patch

-

HKZ 1&2 - Splice Plan

-

HKZ 3&4 - Splice Plan

Sub-Task #3 Completion

-

Are you performing this Sub-Task

-

3.1 Normalize any structures removed

-

3.2 Collect all tools and waste and pack them for protection. Clean any stains caused

-

3.3 Lift off tools using the crane of the ISV (if no other works to be done).

-

3.4 Leave Structure.

Sign off

-

Client present?

-

No Client present

-

Client Representative

-

Comment if applicable

-

SOC Tower Team Leader

-

Comment if applicable