Title Page

-

Site conducted

-

Conducted on

-

Location ID

-

Cable ID

-

Cable Type

-

String

-

Prepared by

Pre Task

-

Confirm a ToolBox Talk was completed

-

Confirm Pre Term testing has been completed

-

Confirm Cables are in final position

-

Procedure NS2244-ENG-00024 Cable Termination Power Cores FOU is available in digital or paper format and will be followed during the complete execution of the termination. The Below questions/Pictures are for QC Purposes and are *NOT* the detailed task plan also I Can confirm the procedure is available and will be followed during the termination works.

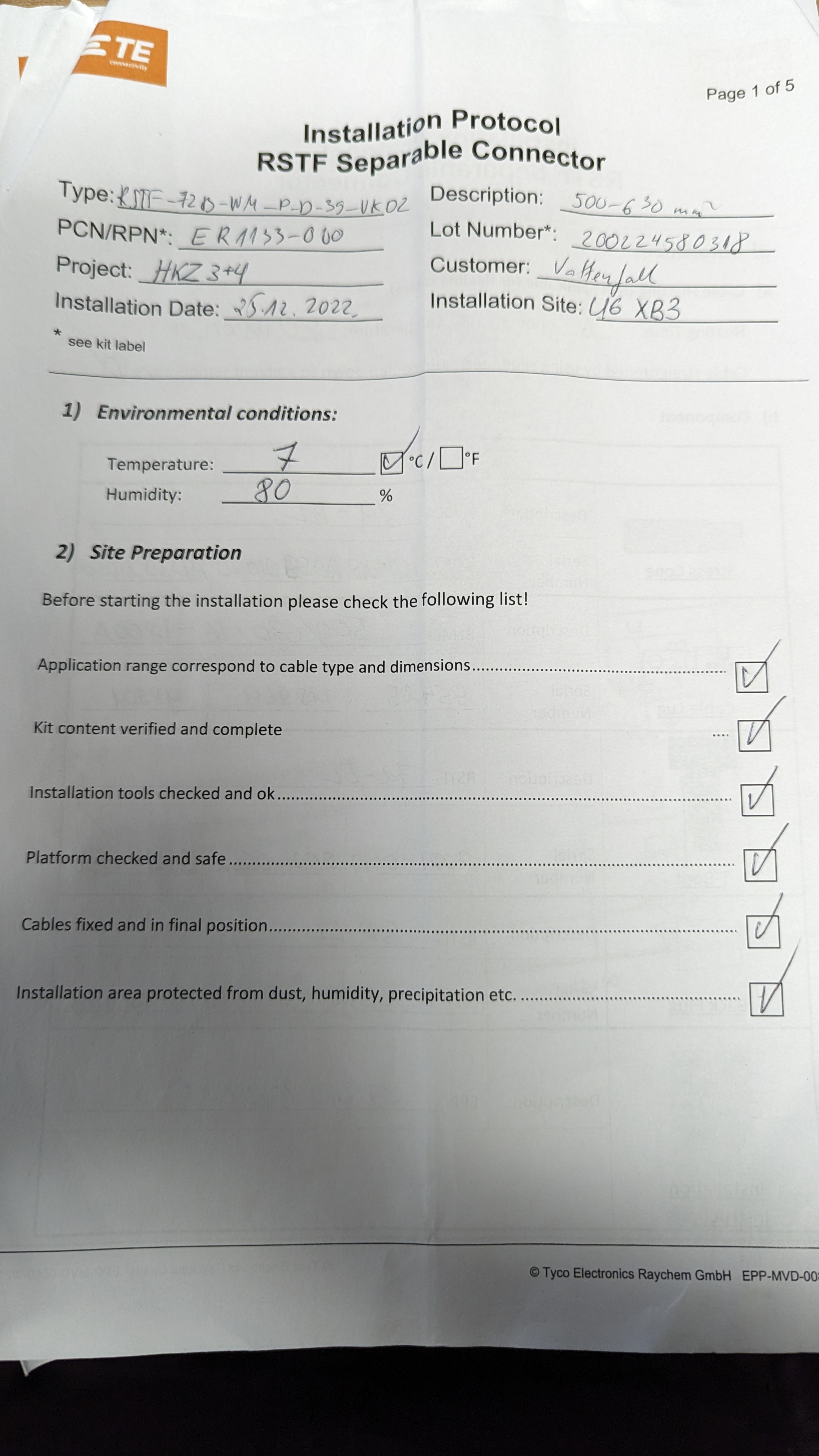

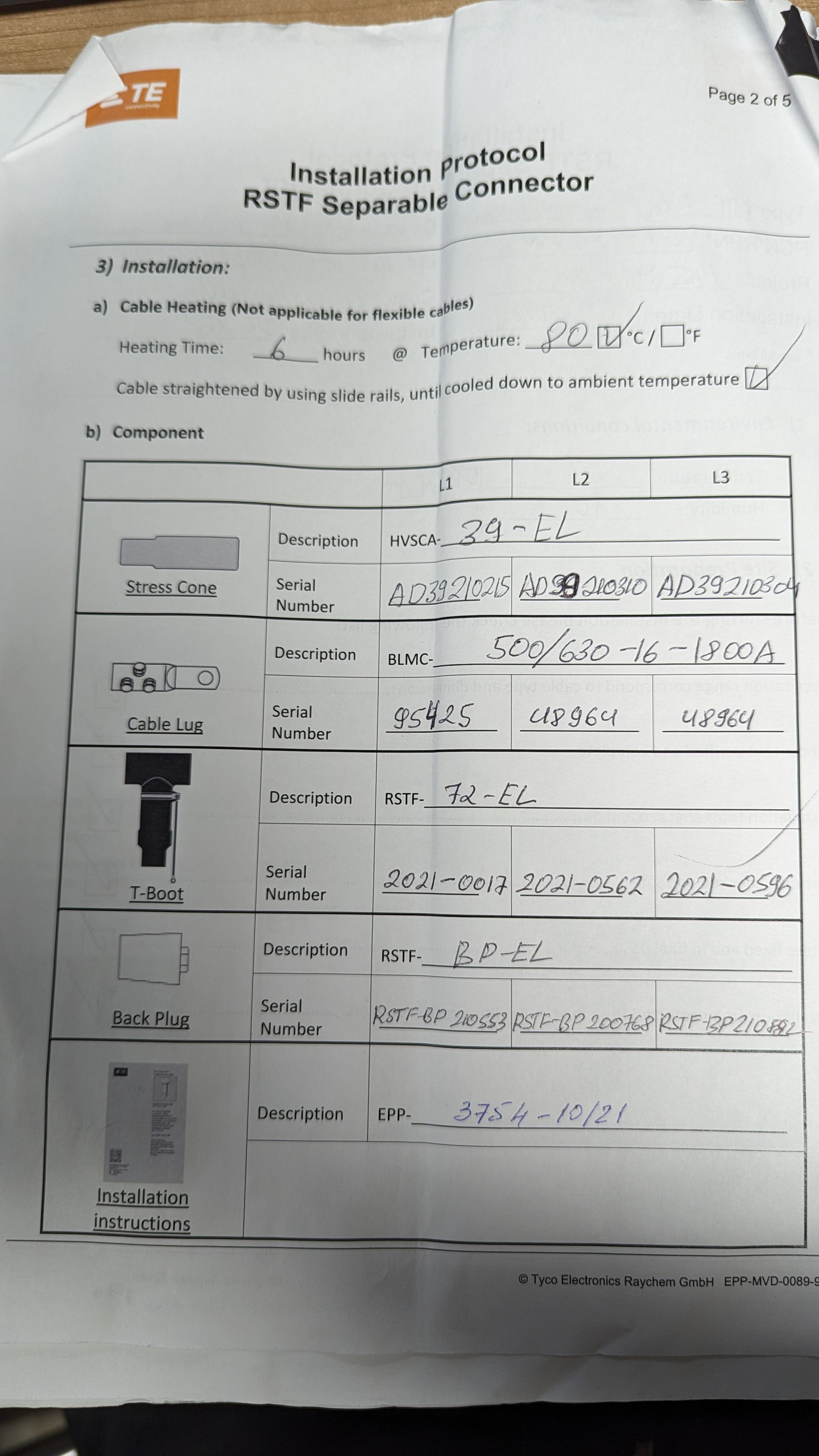

Connector Data/Serial Numbers

-

Confirm Kit is correct for cable size before install (Please note that all of the below information should be filled in while heat/Straighten Cables)

-

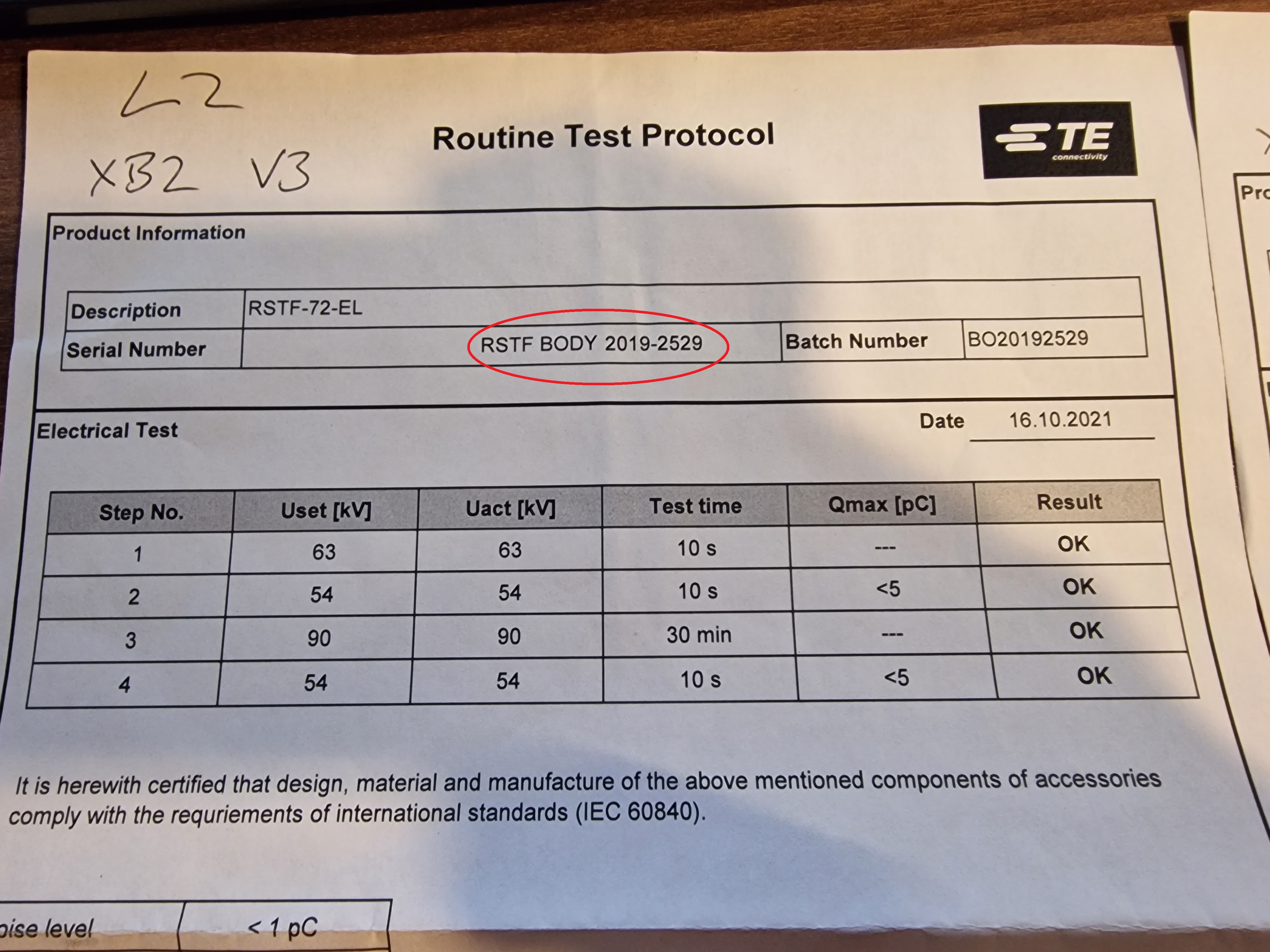

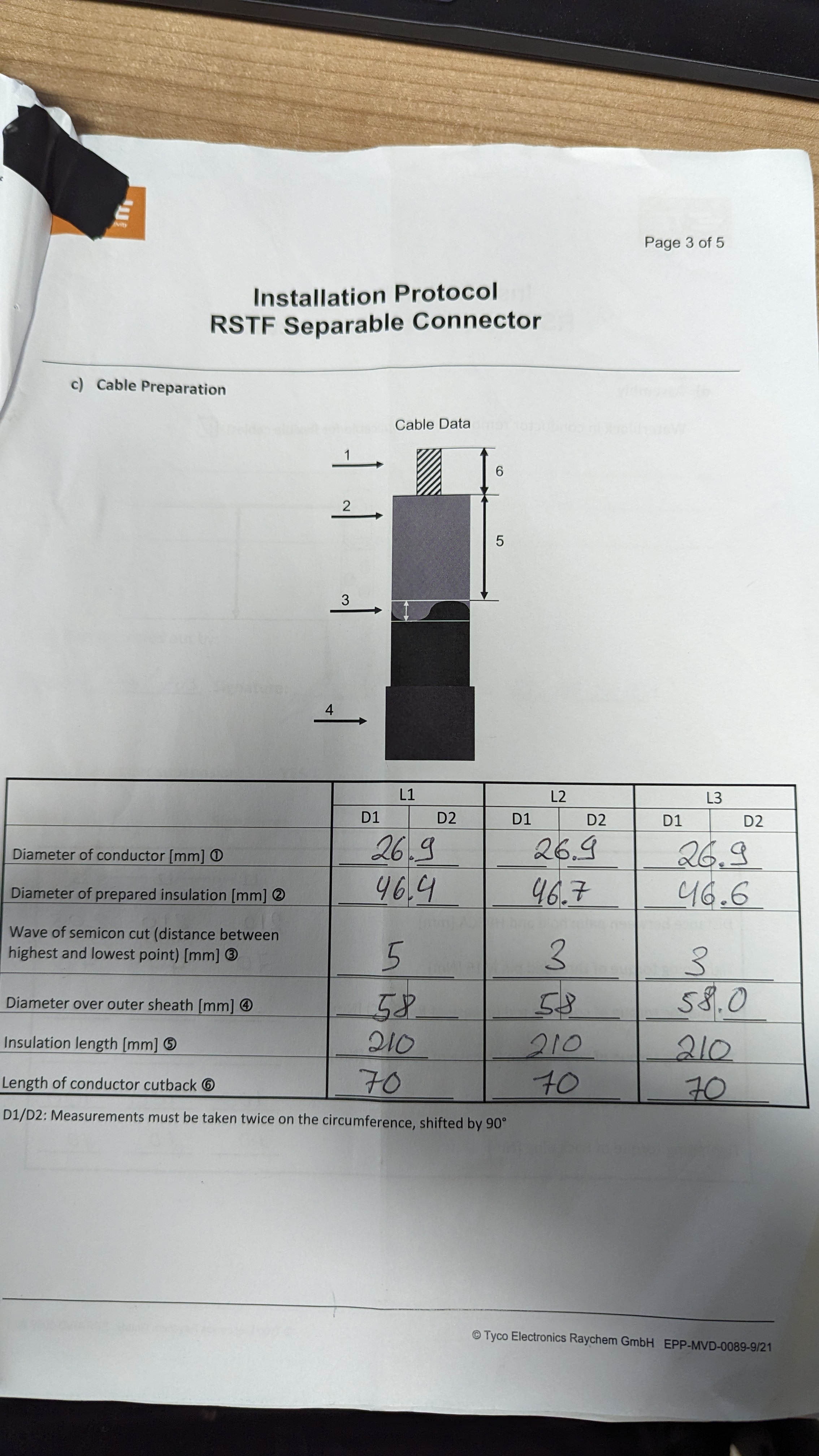

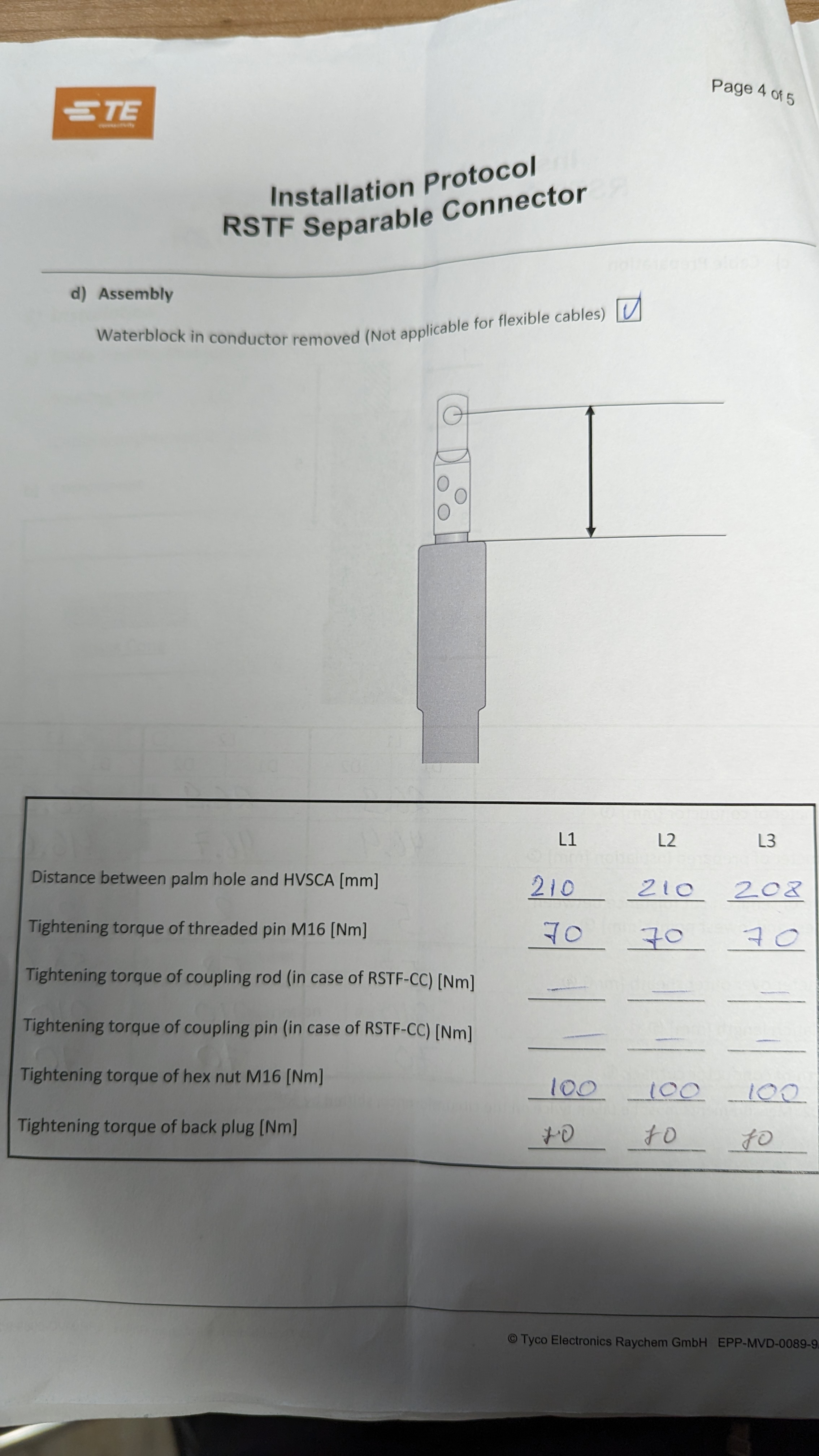

Ensure TE Documentation is filled out see example below

-

Ensure TE Documentation is filled out see example below

-

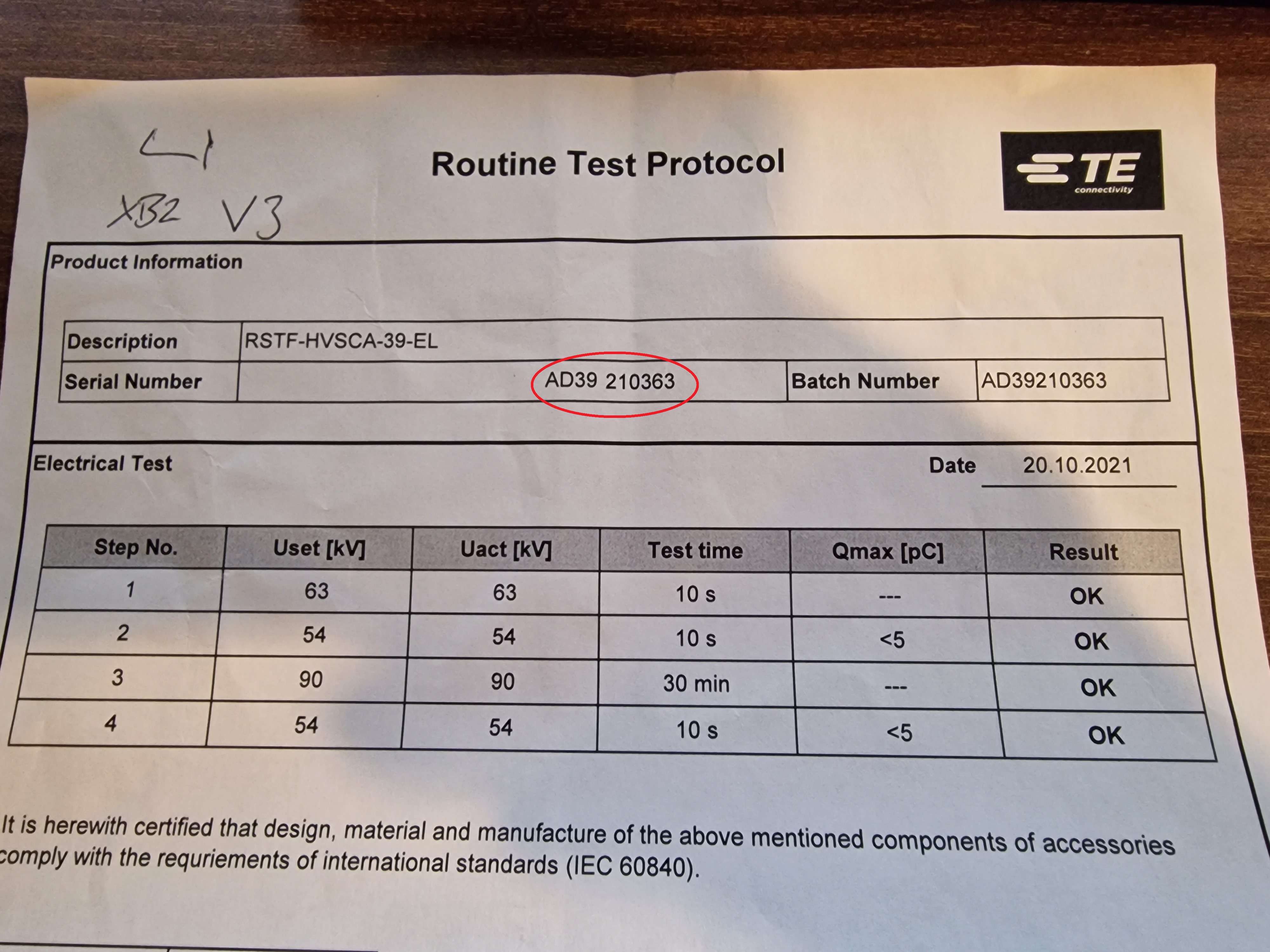

Stress cone serial number

-

L1 Stress cone

-

L1 Stress cone serial number

-

L2 Stress cone

-

L2 Stress cone serial number

-

L3 Stress cone

-

L3 Stress cone serial number

-

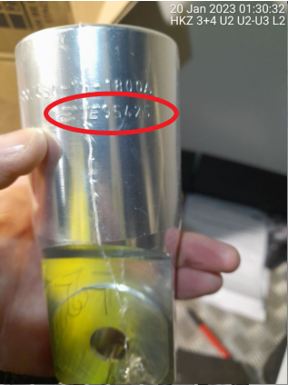

Cable Lug Serial Number

-

L1 Cable Lug

-

L1 Cable Lug serial number

-

L2 Cable Lug

-

L2 Cable Lug serial number

-

L3 Cable Lug

-

L3 Cable Lug serial number

-

T-Boot Serial Number

-

L1 T-Boot

-

L1 T-Boot serial number

-

L2 T-Boot

-

L2 T-Boot serial number

-

L3 T-Boot

-

L3 T-Boot serial number

-

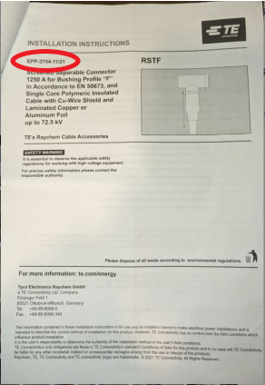

Jointing instructions EPP

-

Picture showing jointing instruction EPP

-

Jointing Instruction EPP serial number

HV Terms/Cable Preperation

-

Ensure that the cable and switchgear are disconnected from any voltage source and earthed.

-

Check for a Valid E-Permit with isolation measures detailed

-

Ensure you leave enough length for earth screens

-

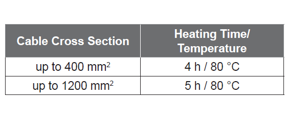

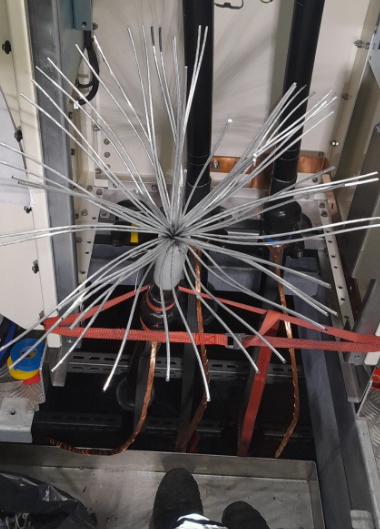

Heat/Straighten Cables ensure cable is allowed cooling after removing blankets

-

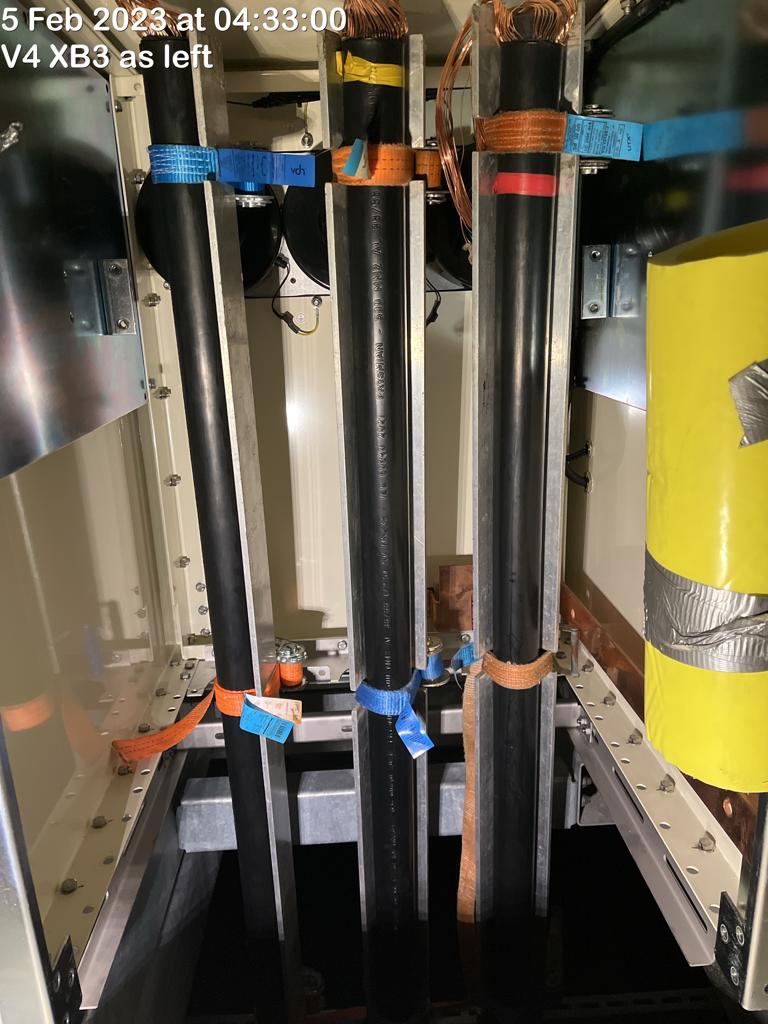

Example picture showing bars installed ensure you have extra length for screens

-

Picture Showing the Bars installed after heating

-

Length of time cables heated for

-

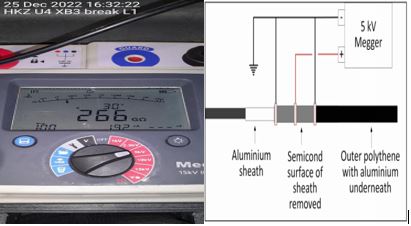

MOC-TT-007 Break Test diagram for reference 5KV for 1min (Picture required showing megger display showing result over 100MΩ)

-

L1 Picture showing Megger display proving no breakdown result over 100MΩ

-

L2 Picture showing Megger display proving no breakdown result over 100MΩ

-

L3 Picture showing Megger display proving no breakdown result over 100MΩ

-

Take 4 pictures off the window showing all angles

-

L1 Clean Window 4 pictures off the window showing all angles

-

L1 Window measurement

-

L2 Clean Window 4 pictures off the window showing all angles

-

L2 Window measurement

-

L3 Clean Window 4 pictures off the window showing all angles

-

L3 Window measurement

-

Take Pictures of the Ali Foil bend over the support ring as shown

-

L1 Ali Foil Bend over support ring

-

L2 Ali Foil Bend over support ring

-

L3 Ali Foil Bend over support ring

-

Take Pictures Before tape is applied

-

L1 Before Tape on window

-

L2 Before Tape on window

-

L3 Before Tape on window

-

Picture showing CR display off contact resistance between window and braid

-

L1 CR Display off contact resistance

-

L1 CR measurement

-

L2 CR Display off contact resistance

-

L2 CR measurement

-

L3 CR Display off contact resistance

-

L3 CR measurement

-

Take Pictures After Tape is applied and screens are down

-

L1 After tape is applied and screens are down

-

L2 After tape is applied and screens are down

-

L3 After tape is applied and screens are down

-

Picture Showing the heatshrink installed from different angles

-

L1 After heatshrink install

-

L2 After heatshrink install

-

L3 After heatshrink install

-

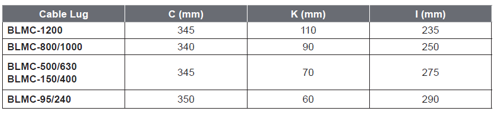

Table Showing measurements depending on cables sizes/Kits (Ensure Core is longer for removing waterblock)

-

Picture Showing the core opened and clean see example below

-

L1 Core opened and clean

-

L2 Core opened and clean

-

L3 Core opened and clean

-

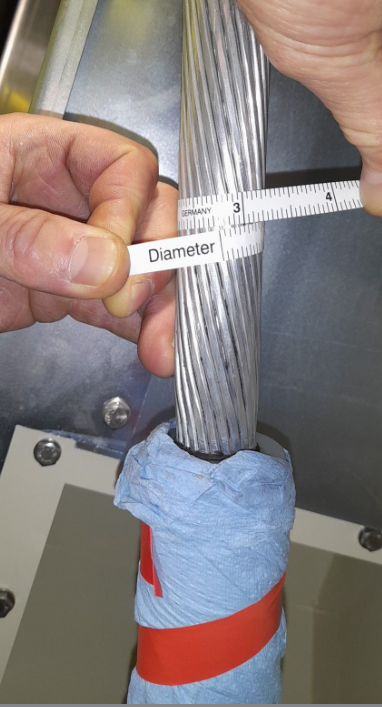

Picture showing the core back together see example below(Must be within 1mm off original Diameter)

-

L1 Core back together after clean

-

L2 Core back together after clean

-

L3 Core back together after clean

-

Picture showing the Diameter in 3 points as displayed in pictures below for each phase after sanding

-

L1 Showing 3 diameter measurements

-

L1 diameter measurement

-

L1 diameter point two measurement

-

L1 diameter point three measurement

-

L2 Showing 3 diameter measurements

-

L2 diameter measurement

-

L2 diameter point two measurement

-

L2 diameter point three measurement

-

L3 Showing 3 diameter measurements

-

L3 diameter measurement

-

L3 diameter point two measurement

-

L3 diameter point three measurement

-

Picture Showing core length with a ruler see example below

-

L1 Core Length

-

L1 core length measurement

-

L2 Core Length

-

L2 core length measurement

-

L3 Core Length

-

L3 core length measurement

-

Picture Showing the whole length of the Prepared cable with a ruler see example below

-

L1 Whole prepared cable length

-

L1 full length measurement

-

L2 Whole prepared cable length

-

L2 full length measurement

-

L3 Whole prepared cable length

-

L3 full length measurement

-

Picture Showing Transition with ruler against it see example below

-

L1 Showing Transition with ruler against it

-

L1 Transition measurement

-

L2 Showing Transition with ruler against it

-

L2 Transition measurement

-

L3 Showing Transition with ruler against it

-

L3 Transition measurement

-

Picture of the transition wave with a ruler aginst it see example below showing lowest to highest point

-

L1 Showing Wave measurement

-

L1 Wave measurement

-

L2 Showing Wave measurement

-

L2 Wave measurement

-

L3 Showing Wave measurement

-

L3 Wave measurement

-

Ensure TE Documentation is also filled out

-

Confirm TE Documentation is completed up to required stage

-

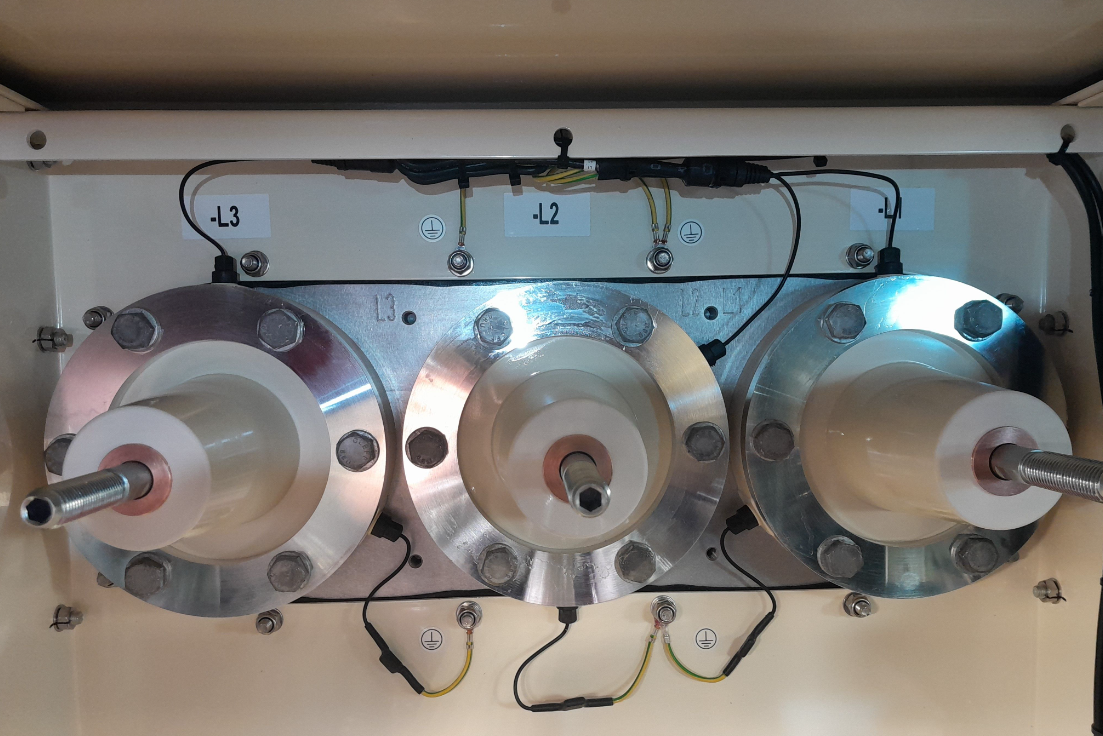

Picture Showing the bushing before T-Boots installed with threads installed (The thread should be installed hand tight as far as possible)

-

The thread should be installed hand tight as far as possible in final position then torqued (Please report this to the HV Supervisor if not)

-

Confirm Thread torqued to 70NM

-

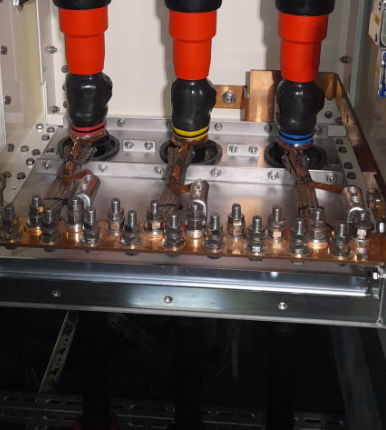

All Three bushing shown clearly before T-Boots installed

-

Picture Showing the lug installed with ruler against it see example below

-

L1 Lug Measurement after install

-

L1 lug to stress cone measurement

-

L2 Lug Measurement after install

-

L2 lug to stress cone measurement

-

L3 Lug Measurement after install

-

L3 lug to stress cone measurement

-

Confirm T-Boots torqued to 100NM

-

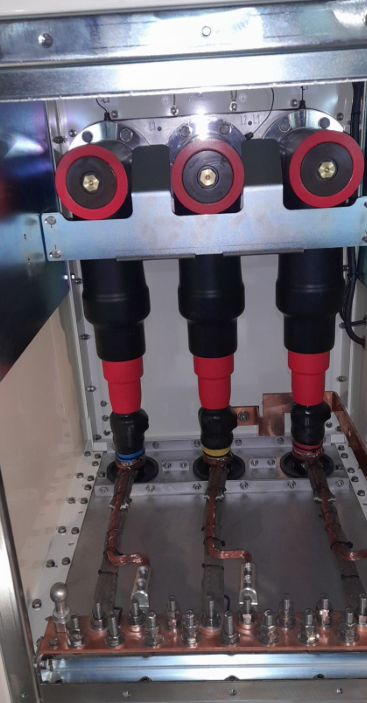

Picture stepped back showing insulation plugs installed when all 3 are installed

-

Picture stepped back showing insulation plugs installed when all 3 are installed

-

Confirm Back Plugs torqued to 70NM

-

Picture Showing the T-Boot installed completed/Cabinet Complete see example below

-

Picture Showing All T-Boots installed

-

Ensure TE Documentation is also filled out

-

Confirm TE Documentation is completed

-

Picture Showing Earths installed see example below

-

Picture showing completed Earths

-

Picture showing closed switchgear door see example below

-

Picture of the Switchgear Closed

-

Picture Showing installed labels above the hang-off and under the switchgear see examples off the required pictures below

-

X2 Pictures Showing labels above the Hang-Off and also below the switchgear

-

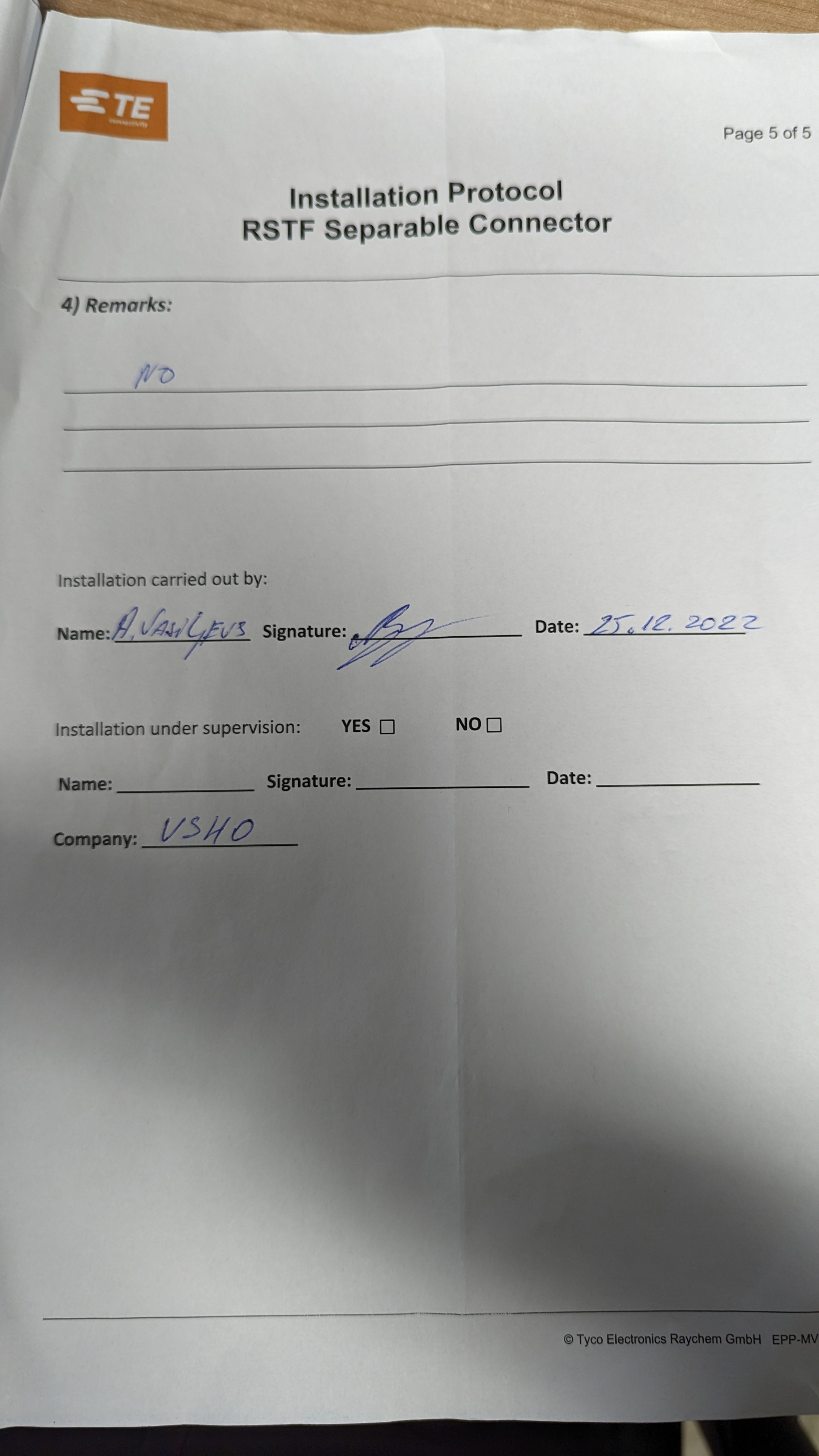

Ensure TE Documentation is filled out and signed

-

Confirm TE Documentation is fully completed (Hand the completed document to HV Supervisor)

-

Pictures showing all of the pages from the TE documentation completed

Sign Off

-

I Can confirm the termination has been executed according to NS2244-ENG-0024 Cable Termination Power Cores FOU Procedure.

-

Client Rep Present

-

Client Rep Signature

-

V&SH Tower team Lead (Add notes if full termination wasn't done by one jointer showing which points where done)

-

SOC HV Supervisor to review and confirm installation work carried out satisfactory meeting the specified requirements and tick complete.

-

SOC HV Supervsior

-

Comment if applicable