Information

-

Surveillance Checklist. R107- Sprayed Bituminous Surfacing. (PMB) (ED 5 / Rev 1) .

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

2 MATERIALS

-

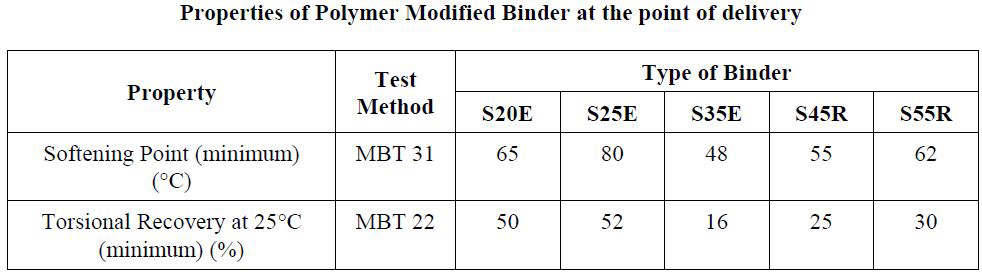

Cl 2.1.1 Is the binder to be used as specified in Annexure R107/AA and does it conform to spec RMS 3252.

Torsional recovery and softening point must conform to requirements Annexure R107/A1.2

Has the contractor provided.

Documented evidence f the binder conformity for each delivery.

Provide a sample of the binder from the delivery point to the principal. -

Cl 2.1.3 Has the binder been kept at or below the manufacture's written recommendations. <br>Do not use in the works: bitumen that has been overheated or stored in violation of the temperature and time combinations specified by the manufacture.

-

Cl 2.2 Does the precoating and adhesion agents used, comply to the required spec Precoat RMS 3268, Adhesion RMS 3269

-

Cl 2.4.1 Does the supply and deliver of aggregate conform to spec RMS 3151 <br>Have the test results been supplied prior to incorporating into the works.

-

Cl 2.4.2 Maximum stockpile lot size is 250m3 <br>Stockpiles on firm level ground.<br>Quantity and type of each stockpile signposted.

3 NOMINATED MATERIALS AND DESIGN OF BITUMINOUS SURFACING

-

Cl 3.1 has a design been carried out and the results submitted. (Texture testing for reseals, ball embedment tests for seals)

-

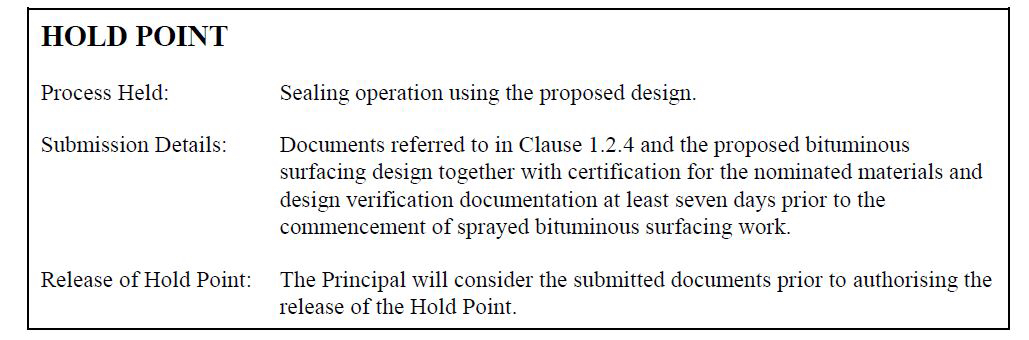

Cl 3.2.3 HOLD POINT

-

Has the Hold Point been released

-

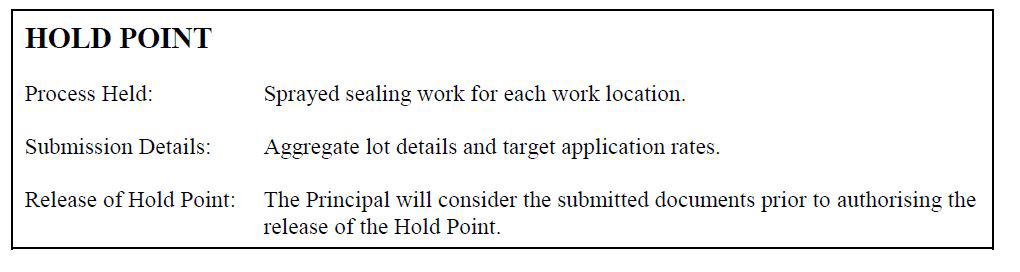

Cl 3.3 HOLD POINT

-

Has the Hold Point been released.

4 PROCESS CONTROL

-

Cl 4.1 Has the sampling and testing been carried out in accordance with: <br>As per relevant material specs. <br>Complies with Annexure R107/L

-

Cl 4.2 Has the binder been sprayed to achieve: <br>Uniform binder application and aggregate cover. <br>

-

Cl 4.2 Effective binder bond with aggregate

-

Cl 4.3 Have process control charts been used for works where 10 or more sprayer runs greater than 1000lts are required. <br>If used, does it show specific tolerances and plot the differences between individual results. <br>Has action been taken if any point is between 2% and 5% (inclusive) above or below the target over 5 successive runs.

-

Cl 4.4 Have details of the works been recorded using Form RMS 500E. <br>Details of binder and aggregate applied must be recorded immediately after every sprayer run. <br>Is the principal going to be supplied with a copy of the completed form.

5 CONDITION FOR COMMENCEMENT

-

Cl 5.1 Has the aggregate been precoated:<br>Has it provided a complete light, uniform, effective cover of all aggregate. <br>. <br>.<br>

-

Cl 5.1 Has the stockpile been covered to prevent precoat agent being washed off

-

Cl 5.1 Settlement of dust and penetration of moisture

-

Cl 5.2 Has the pavement been swept at least 300mm beyond the edge of the sprayed area. <br>

-

Cl 5.2 Has all loose and foreign material been removed

-

Cl 5.2 Have raised pavement markers been masked or removed

-

Cl 5.3 Has the pavement temperature been above 20 degC for at least an hour prior to sealing

-

Cl 5.3 Has the pavement temperature been recorded at regular intervals. <br>. <br>. <br>

-

Cl 5.3 Spraying has not been done when pavement was wet, rain was imminent, or during strong winds or dust storms

-

Cl 5.4 Have all necessary precautions been taken to prevent binder or other material from sticking to road fixtures.

6 APPLICATION OF SPRAYED BITUMINOUS SURFACING

-

Cl 6.1 Has the sprayer got a current certificate (RMS Form 354).<br>

-

Cl 6.1 Is the spreading equipment use capable of achieving a uniform spread rate

-

Cl 6.1 Are rollers achieving mechanical interlock between aggregate without breaking down or crushing the aggregate

-

Cl 6.2 Do the runs start and finish on suitable paper. <br>

-

Cl 6.2 Are longitudinal overlaps 50mm if end jets used, 300mm for other jets

-

Cl 6.2 Is a constant road speed by the sprayer being maintained throughout each run

-

Cl 6.2 Is spraying stopped when defects develop or nozzle blockage occurs

-

Cl 6.2 Specified tolerance for spraying PMB +-10%(scrap rubber) +-5% otherwise. <br>Is the sprayer stopped if the actual application rate for 3 continuous runs differs more than 5%. (IF so the sprayer is not to be used until a new sprayer certificate is obtains

-

Cl 6.3 Is the binder being keep within the temperature range recommended by the manufacture. <br>

-

Cl 6.3 Is there 2 or more fully charged pressurised chemical fire extinguishers conveniently placed near the heaters while the heating is in

-

Cl 6.3 If the PMB cannot be sprayed for any reason and no adhesion agent or cutter oil has been added it can be stored at the manufacture's recommended storage temperatures for up to 3 days

-

Cl 6.4 Has the geotextile (if ordered) been applied: <br>After the tact coat has been applied (up to .6 L/m2 cold of C170 bitumen).<br><br>

-

Cl 6.4 Has it been placed smoothly and without wrinkle

-

Cl 6.4 Has it a minimum of 200mm overlap

-

Cl 6.4 Joining fabric in the longitudinal direction under wheel paths must be minimised

-

Cl 6.5 Is the traffic management is accordance with spec RMS G10 and the TCWS manual. <br>Have necessary steps been taken to minimise delays and inconvenience to road users. <br>

-

Cl 6.5 Have all vehicles been controlled to travel at a sufficiently low speed to prevent displacement of aggregate

-

Cl 6.5 Where early traffic of the seal is needed:<br>Has the initial rolling been completed.

-

Cl 6.7 If flux oil, adhesion agent or cutter oil is to be added to hot bitumen circulate at a rate of 700 lts a minute for 15 minutes before spraying. <br>

7 APPLICATION OF POLYMER MODIFIED BINDER

-

Cl 7.1 Has the area sprayed been limited to an area that can be covered aggregate at the target application spread rate within 15 minutes.

-

Cl 7.2 Do not spray PMB over a prime until at least 48 hours have elapsed after spraying the primer or such longer periods as required for the primer to completely dry. <br>

-

Cl 7.2 Do not spray PMB over a primer seal until at least 12 months after spraying unless hardness testing of the primer seal is less than 2.5mm

-

Cl 7.3 Is the class and grade of the binder sprayed as specified in Annexure R107? A1. <br>Has the application rates been adjusted using RMS form 500E when adhesion agent and/or cutter oil have been added to the binder.

8 APPLICATION AND INCORPORATION OF AGGREGATE

-

Cl 8 Have only precoated aggregates been used. <br>. <br>. <br>. <br>.

-

Cl 8 Was the aggregate free of surface moisture and/or free surface water

-

Cl 8 Was the aggregate evenly spread

-

Cl 8 Was the binder covered within 5 minutes of it being sprayed

-

Cl 8 Has the aggregate been rolled with not less 8 passes with a roller

-

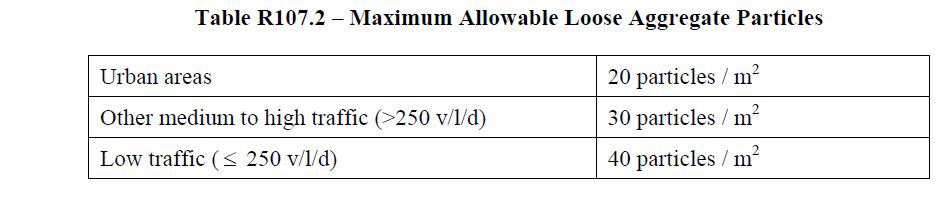

WITNESS POINT: Process witnessed. Final sweeping and loose aggregate measurement prior to opening to traffic. Has the test location been agreed with the Principal. <br>Are the number of loose aggregate particles less than the maximum allowable in Annexure R107/A <br>20 particles M2 for 7mm, 10mm and 14mm aggregate.<br>

9 SWEEPING AND LOOSE AGGREGATE REMOVAL (10 mm AND 14 mm SEALS/ RESEALS ONLY)

-

Cl 9 Table R107.2

-

Cl 9 SWEEPING and LOOSE AGGREGATES REMOVAL. (10mm and 14mm seals only).

-

Any areas open to traffic exceeding 60 kph before final sweeping. Must have loose stone and slippery warning signs erected and temporary 60 speed zoning in place until maximum allowable loose aggregate requirement is met. <br>

G22 Safety and G36 Environmental

G22 SAFETY

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

G36 ENVIRONMENTAL

-

Are Erosion and Sediment controls measures being installed and maintained.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name