Information

-

Inspection Title. RMS Surveillance Checklist R11- Stormwater Drainage -Pipes ILC-MI-TP3-405-SC-R11-Pipes.

-

Project Name: Tabulam New Bridge.

-

Location: BRUXNER HIGHWAY TABULAM

-

Contractor

-

Prepared by

-

Conducted on

Work Activity Record

-

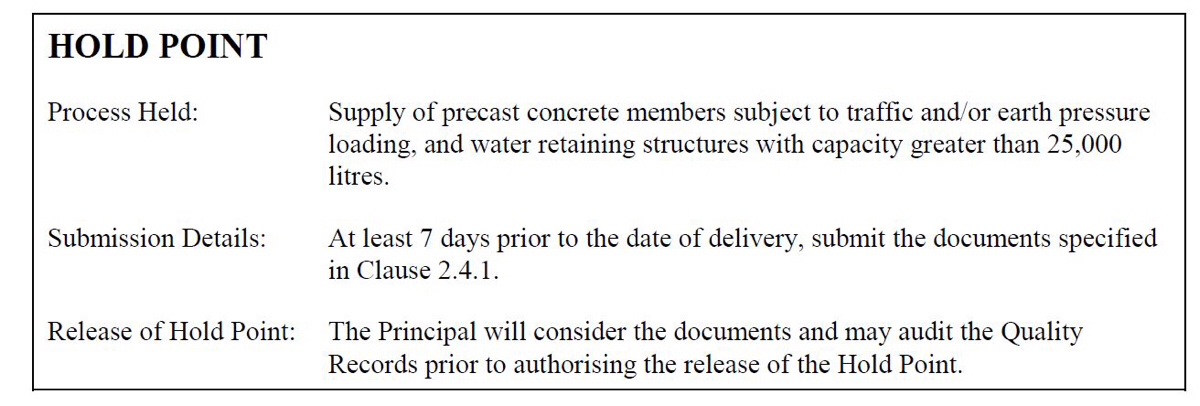

Cl 2.4.1

-

Has the hold point been released.

-

Cl 2.4.3 Are the precast pits manufactured specifically to suit the design.

-

Cl 2.4.4 Are the access covers and grates conforming. <br>Do grates include a fastening device which prevents their opening without the use of a tool.

-

Cl 2.4.5 Are ladders conforming.

-

Cl 2.5 Do the precast units have the correct markings on them.

-

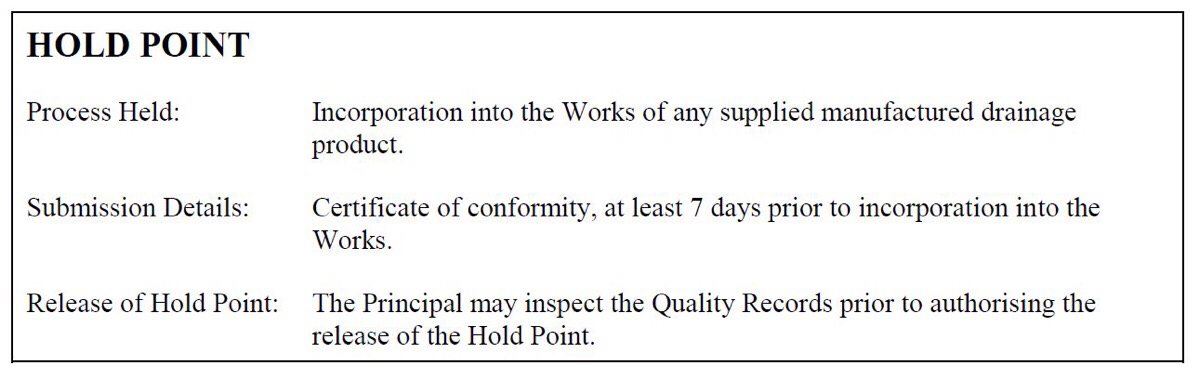

Cl 2.6

-

Cl 2.6 Has the Hold Point been released.

-

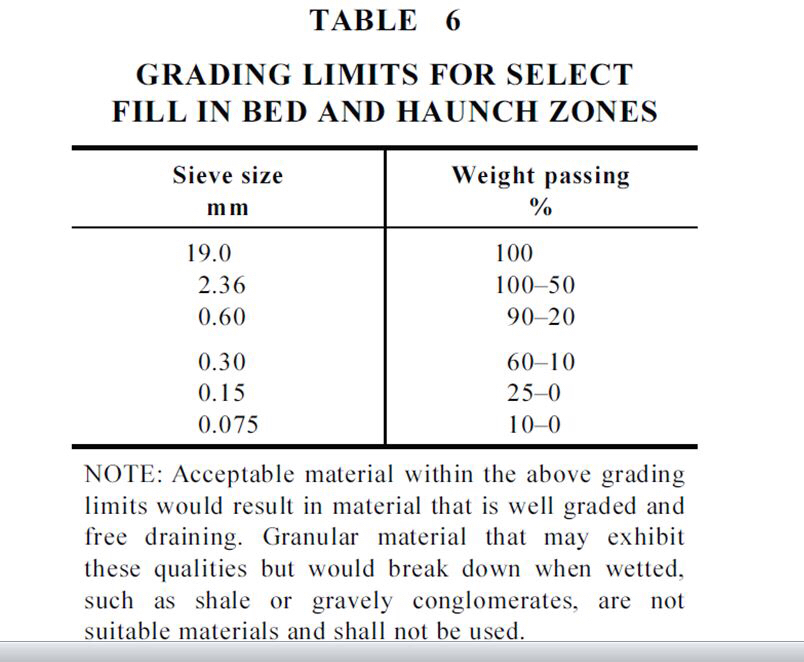

Cl 3.1.1 Does the type BH select fill for bedding and haunch zones have the following properties <br>(a) PI no greater than 6. <br>(b)PSD within the limits of Table 6 in AS 3725, (or Table 5.1 in AS. 1597.2) (see table section).

-

Cl 3.1.2 Does the type SO select fill for side and overlay zones have the following properties. <br>(a) Maximum particle size of 53mm.<br>(b) No more than 5% by mass passing the 9.5mm AS sieve.

-

Cl 3.2 Is the material placed adjacent to weep holes clean, graded, hard and durable crushed stone or river gravel, and have the following properties:<br>(a) maximum particle size of 53mm.<br>(b) No more than 5% by mass passing the 9.5mm sieve.

-

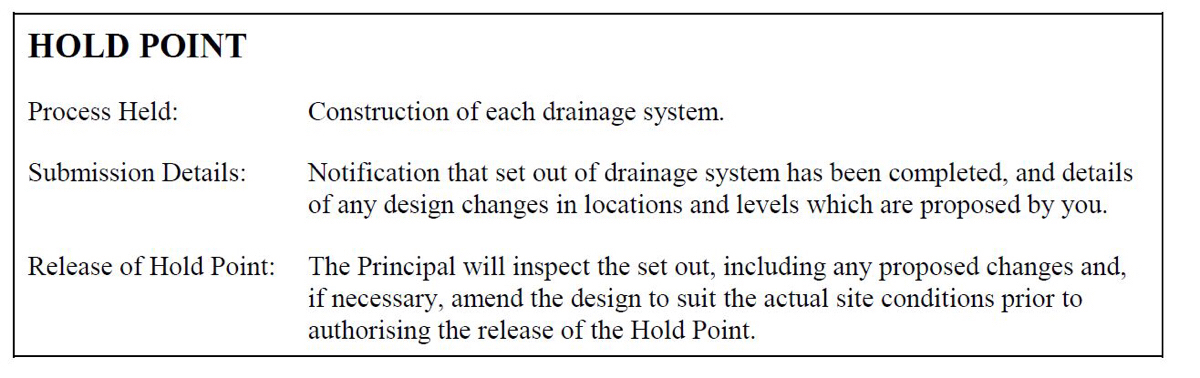

Cl 4.1.1

-

Cl 4.1.1 Has the Hold Point been released.

-

Cl 4.1.2 Have the required erosion and sediment control measures been implemented.

-

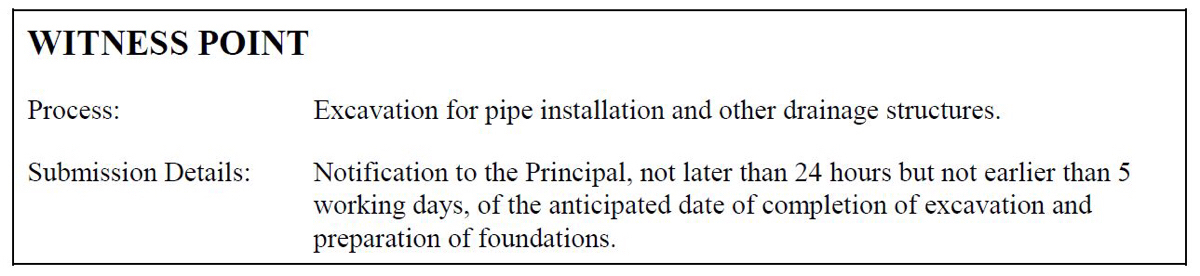

Cl 4.3

-

Has the contractor notified of the Witness point.

-

Cl 4.3.1 Is the trench excavated to the widths shown on RMS model drawing MD.R11A01.B and AS 3725.

-

Cl 4.3.1 For pipes under embankment, where "Embankment Condition" installation is specified:<br>Construct the embankment to a height of at least .7 times the external diameter of the pipe above the top of bed zone. <br>Where "Trench Condition" installation is specified:<br>Construct the embankment to the underside of SMZ.

-

Cl 4.3.1 Has a alternative flow channel been provided where appropriate.

-

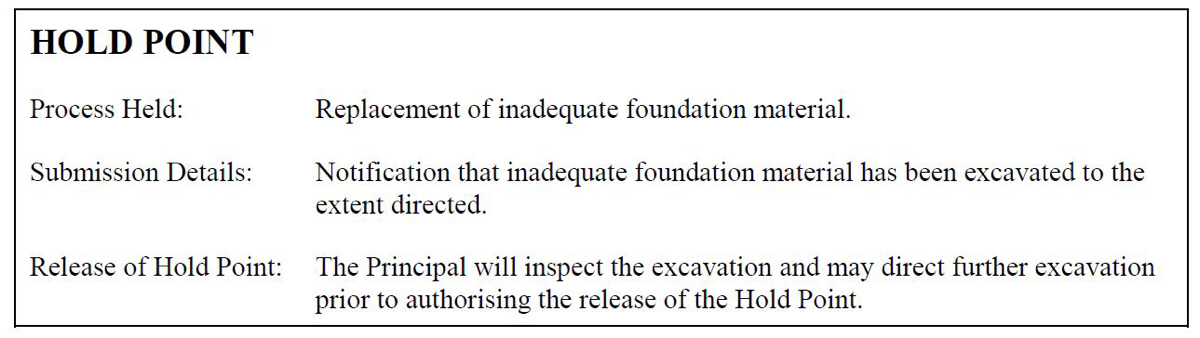

Cl 4.3.3 If inadequate foundation material is found:

-

Cl 4.3.3 Has the hold point been released by the Principal.

-

Cl 4.4.1 Is the correct pipe support type being used.

-

Cl 4.4.2 Are the pipes being handled and installed in accordance with the manufactures recommended practice.<br>Are the pipes being placed from the downstream end with the socket end upstream.

-

Cl 4.4.3 Have anchor blocks been installed at a maximum spacing of 3M and at bends or junctions for all pipes laid on a grade greater than 20% or where shown on drawings.

-

Cl 4.4.4 Have all lifting holes in the pipes, all flush holes or butt joints used to extend existing pipes been sealed.

-

Cl 4.4.5 Has a subsoil drainage pipe been installed at the discharge end of the pipes.

-

Cl 4.7.2 Have precast pits been installed on a minimum of 50mm thick DGB20 bedding material. <br>For drainage structures other than precast drainage pits been placed on a foundation of unreinforced concrete not less than 50mm thick.

-

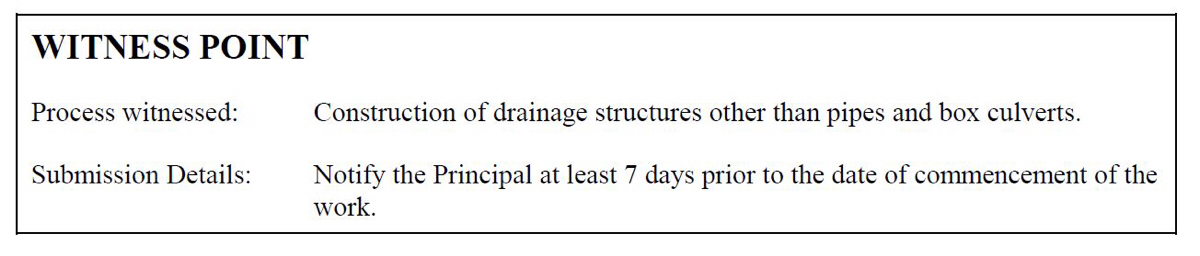

Cl 4.7.2

-

Cl 4.7.2 Has the contractor submitted the witness point.

-

Cl 4.7.3 Has a curtain wall been installed on the outer edge of the apron in accordance with RMS model drawings.

-

Cl 4.7.4 Do all pits which are deeper than 600mm have step irons installed.

-

Cl 4.9.1 Side and overlay zones to be backfilled with Type SO Select Fill.<br>Material to be compacted in 150mm compacted thickness.<br>Material to be compacted from structure out.

-

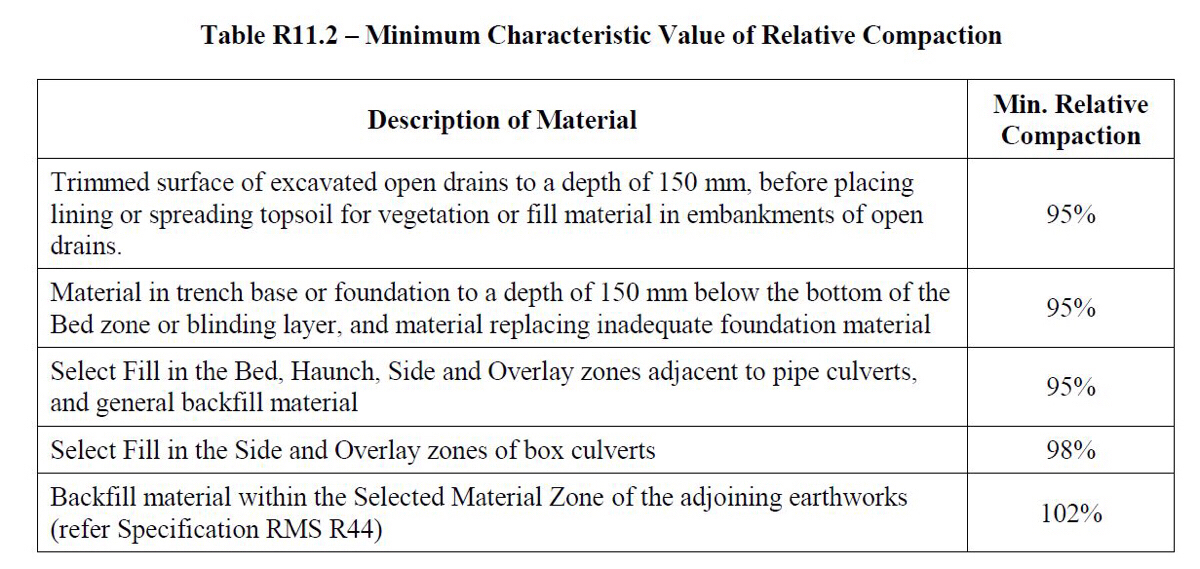

Cl 4.9.2 Compact the foundation and fill material to achieve the minimum CV as shown in Table R11.2

-

Cl 4.9.3 Have surplus material be disposed of in accordance with RMS R44.

-

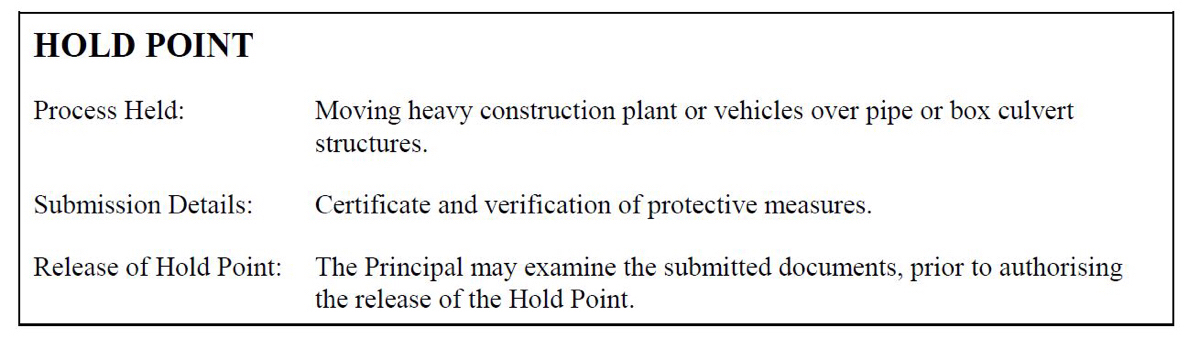

Cl 4.10 Where you propose to move heavy construction plant and vehicles over pipe or box structures. Design and provide protective measures for each crossing.

-

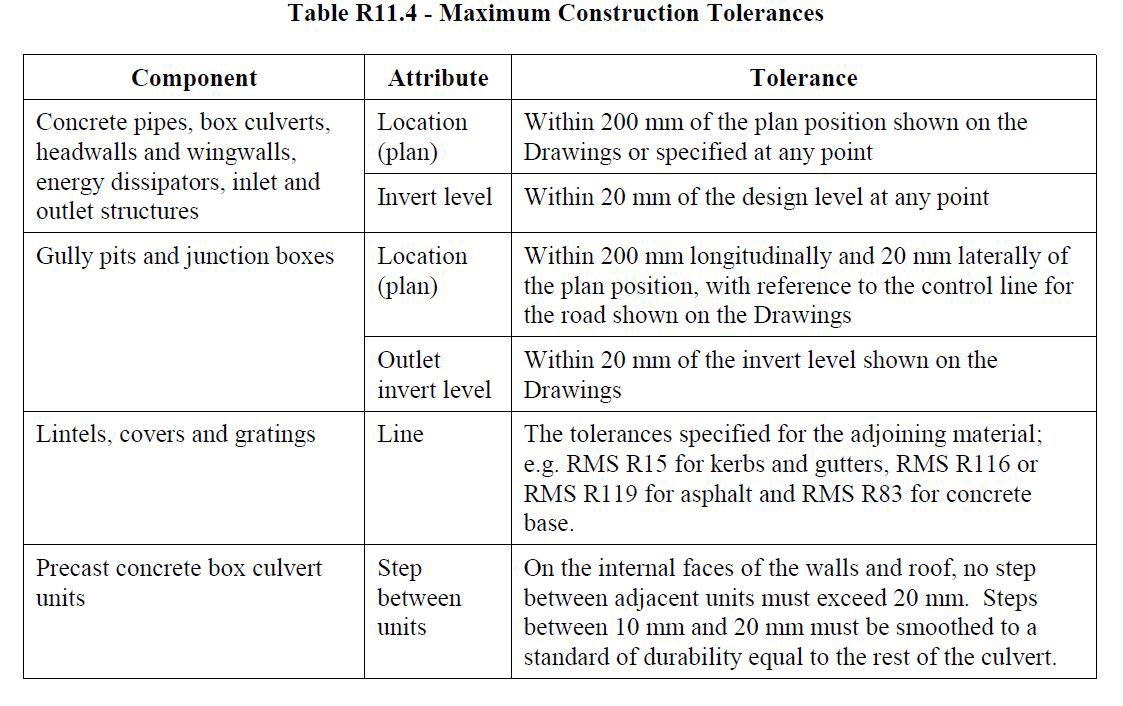

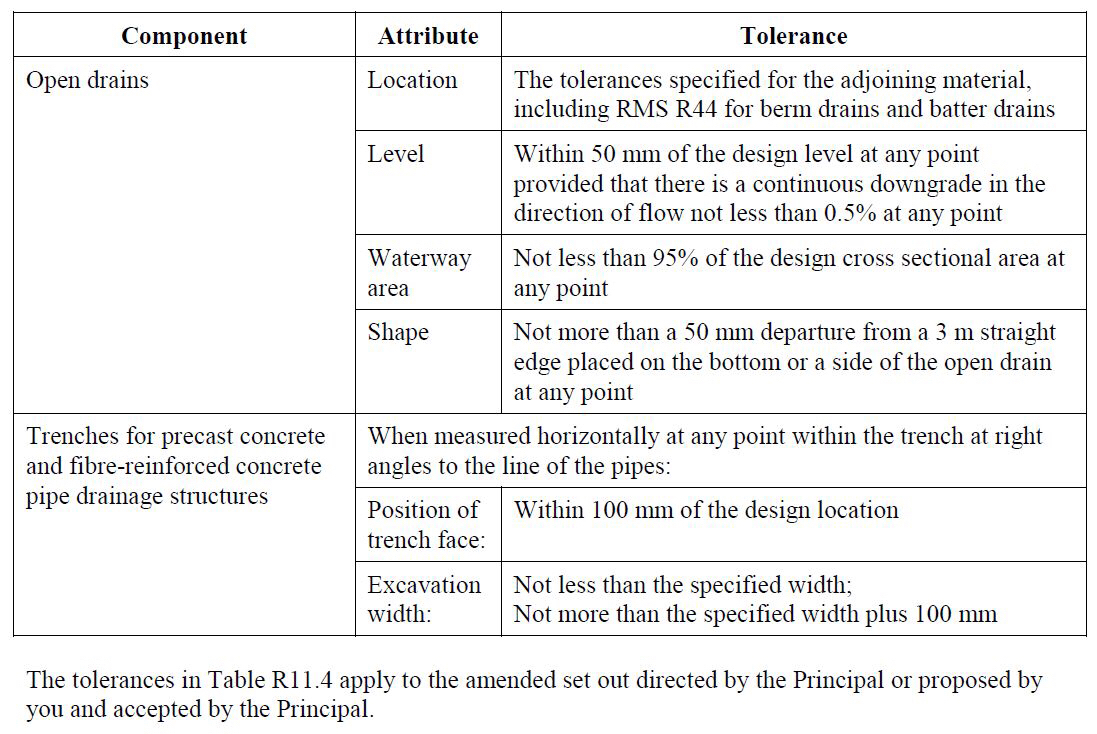

Cl 5.1 Has the stormwater drainage system been constructed so that water flows through the system without unintended ponding, and within the construction tolerances in Table R11.4 (see table section)

-

Cl 5.2 Has CCTV inspection of all pipe and box culvert with dimensions that restrict human access, to verify that the works have been constructed within the specified tolerances.:<br>(a) On completion of the subject drainage structure and prior to commencement of the overlying pavement <br>(b) No more than 14 days prior to completion.

G22 Safety and G36 Environmental

-

G22 SAFETY

-

Has a safe work and technical criteria been implemented for the connection of existing pipes to new pipes that have the same or grater size.

-

Have operators demonstrated their competence to operate the plant/equipment to the satisfaction of the contractor. <br>

-

Has a SWMS been developed.

-

Is each and every item of plant being used for its designated and intended purposes.

-

Have the attachments for plant and processes been approved and used in accordance with their design and purposes.

-

Is the correct PPE being worn

-

Has a certified rigger checked that the structural members are secure before the load is released.

-

Have all slings been inspected and tagged.

-

Is the laser used approved for use.

-

Has a exclusion zone been established where a load is being lifted or suspended.

-

Is all lifting plant fitted with approved hooks/lugs and its SWL marked.

-

Was the item inspected for irregularities before being lifted.

-

Has safe entry/ exit been provided to excavations.

-

Has the excavation been battered/benched if depths greater than 1.5m, or if there is a possibility of collapse.

-

Has spoil been placed away from the excavation.

-

Were any unsafe practices observed. <br>

-

Good safe practices observed.

-

G36 ENVIRONMENTAL

-

R44 Cl 1.7 Were erosion and sediment controls in place prior to the removal of any topsoil.

-

Are Erosion and Sediment controls measures being installed prior to works commencing and are they being maintained.

-

Has mud been prevented from being deposited on roadways.

-

Have any environmental incidents or potential incidents been observed.

-

Good environmental procedures observed.

Compliance and Follow-up action.

-

Is the activity compliant.

-

Surveillance Officer

-

NCPN or memo number.

-

Follow up action

-

Product Non Conformance

-

System Non Conformance

-

Contractor generated NCR

-

Contractor generated a CAR

Matters arising

-

NCPN no

-

Contractors NCR no

-

CAR no

-

Closed out.

-

RMS representative's name

Tables

-

Table 6 AS 3725.

-

Cl 5.1 Table R11.4

-

Cl 5.1 Table R11.4 Part 2