Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Introduction

-

Skill

-

Date

-

Operator Name

-

Clock Number

-

Assessor Name

Following the SOP

-

Select correct tape if it is not kitted for you, and thread onto tape machine. Cut tape at an angle to thread through binder.

- Pass

- Fail

- N/A

-

Selecting Tape

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Adjust tape machine head height and adjust tension for different tapes. Remove plastic tags on tufted mattresses before taping.

- Pass

- Fail

- N/A

-

Adjusting machine.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Place lid and border into binder and begin taping. Turn flywheel on tape head to lower needle & hold lid / border in place.

- Yes

- No

- N/A

-

Placing matt in machine.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Tape line must be straight, not puckered and there should be no shoulders. Tape in 15mm of border and lid and ensure the poly corner cards are also sewn in.

- Yes

- No

- N/A

-

Tape must be straight.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Begin taping at fire ticket end. Run at constant speed to ensure smooth tape line.

- Yes

- No

- N/A

-

Begin taping.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Run on 50mm for tape join and trim all loose threads. Tape join must be neatly folded under with no wings. No tape joins allowed in the label third of the mattress

- Yes

- No

- N/A

-

Tape run on.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Turn the mattress over and repeat process for other side (unless waterfall mattress). Follow the SSOW procedure at all times (3 man handling for 180cm 2000 & 2800 count pocket mattresses). Ensure consistent border depth along entire mattress by taping in 15mm. Readjust tape head for second side. Pull borders up at corners to stop border slipping from binder.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

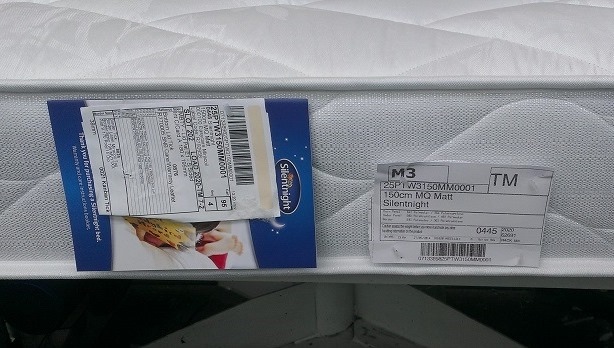

Inspect the finished mattress, scan work ticket at appropriate time and ensure it matches the thermal ticket then attach both labels to mattress, check name and size of mattress also match.

- Yes

- No

- N/A

-

Inspect matt.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Mattress should be clean with no big stitches or tape bursts. Trim off any loose threads. Pattern straight - border even.

- Yes

- No

- N/A

-

Matt requirements.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Inspect the finished mattress. Select the correct care leaflet and tag it along with the thermal through the holes at the centre of one side of the mattress (straight and within the tape lines).

- Yes

- No

- N/A

-

Inspect finished mattress.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Tag the other thermal ticket over the fire ticket (as shown)

- Yes

- No

- N/A

-

Tag ticket.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Ensure the correct corner cards are used (as per ticket details). Corner cards must cover both tape lines, be centralised and tag as close to the tape line as possible.

-

Corner cards.

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Examples of unacceptable taping.

SSOW

-

Safety Signs (identify any PPE requirements)

-

Before operating this equipment you must always do a pre use check to ensure that all stop, emergency stop, isolator switches are all working, all guards are fitted, secure and in place, electrical cabinets are locked and pressure mats are working

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must inform your manager immediately if you discover any faults or defects likely to cause harm or injury.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must (where installed) us T180 units & motorised conveyors to transfer and turn mattresses.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must follow the SSOW for manual handling, compressed air, conveyor belts, tag guns, cutting tools, vacuum cleaners and aerosols.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must rotate daily between jobs where practical to reduce upper limb disorders and report any persistent pains to your manager.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must wear eye protection when operating the tape edge machine.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must ensure the machine is switched off before carrying out any autonomous maintenance, cleaning tasks, threading cotton, changing needles or making any adjustments.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must ensure the area around the machine is clear of obstructions and other personnel.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must use a 3 person handling method for manually turning 150cm and 180cm (1400, 2000 and 2800 spring count) pocket spring mattresses, as detailed in the S.O.P.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must ensure you have a firm footing, keep control of the clutch and move backwards in time with the moving carriage.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must dispose of used tape edge and tag gun needles in a sealed puncture proof container.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must keep fingers away from the path of the needle point when sewing or using a tag gun.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must keep clear of the machine when it is set in auto return mode.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must keep clear of the T180 flipper when it is in operation.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

You must keep the work area clean & tidy at all times by adopting a 'clean as you go' policy.

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Observation Sheet

-

The trainer observes the operator carrying out their normal work and completes the observation. The assessor must explain the procedure before the test starts but must not help the operator during the test. Not all tasks will take place during the test so the assessor may ask the operator to demonstrate how they would carry out certain tasks in order to complete the test. An operator has successfully completed the test when the trainer verifies that they have consistently followed the SSOW. Unsatisfactory observations must be explained to the trainee at the end of a test and a retest taken a week later.

General Observations

-

Work are clean and tidy?

- Yes

- No

- N/A

-

If failed, take pictures to justify failure.

-

Sensible forward worn?

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Hands/arms appear free from skin problems?

-

If failed, what are the reasons for this and identify planned actions going forward.

Machinery / Equipment / Tools

-

Check all machinery, equipment and tools at start of shift?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Does the Operator know the procedure for reporting faults?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Airline use

-

Pointed away from self and others?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Eye protection worn?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Airline tidied away after use?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Scissor / knife use

-

Cuts away from self and others?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Stored safely when not in use?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Personal Protection Equipment

-

Using relevant PPE?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Stored in a clean place?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Is in good, clean condition?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Manual Handling

-

Uses handling aids?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Gets help when required?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Holds the weight close to the body?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Bends knees when handling a load below waste height?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Stacking is kept below 1.8m?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Sliding rather than lifting is used where possible?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Staple Gun use

-

Air supply is connected before loading staples?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Air supply is disconnected when clearing gun jams?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Jammed staples are removed before any maintenance is carried out?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Gun is being used on the correct job as intended in a safe manner?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Gun is kept square when in use?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Operations and Quality

-

Correct sequence of operations?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Recognises minimum quality standards?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Knows how to repair faults?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Knows how to read a work ticket/load sheet?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Correct selection and identification of materials?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

-

Correct content of operations?

- Yes

- No

- N/A

-

If failed, what are the reasons for this and identify planned actions going forward.

Comments and Sign off

-

Additional Comments?

-

I, the assessor, agree the trainee has successfully completed the skills verification programme.

-

I, the operator, have received suitable and sufficient training to enable me to work to the standards of the latest issue of the Standard Operating Procedure(s) Safety Elements Of Training and the Safe Systems Of Work.