Title Page

-

Conducted on

-

Prepared by

-

Location

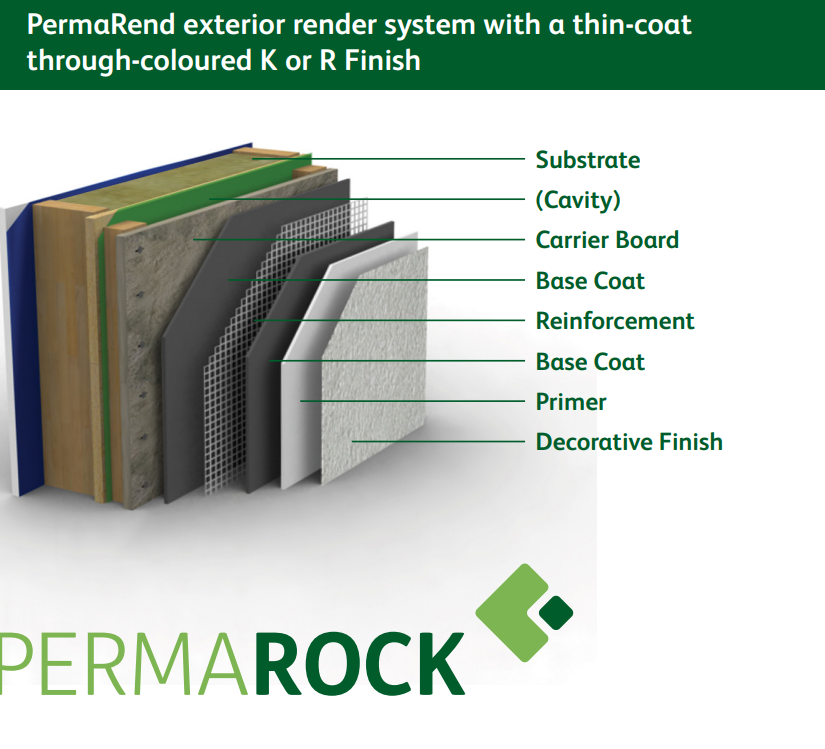

Permarock mineral wool insulation render installation

-

Have installers been trained prior to installation starting?

-

Have products been stored in a dry location?

-

Are GL's in place?

-

Has the old render been stripped off the building, bagged and safely removed?

-

Has the remaining render been hammer tested, dislodging any loose render to give a firm base to start?

-

HOLD POINT

-

Has the murmuring been applied to bring the surface with the sound render?

-

Are the permarock starter profiles fitted to the base of the wall and fixings at 300mm centres, with no fixings closer than 50mm from the edge?

-

Is the starter profile level and packers added where required?

-

Have the internal and external corners been oversailed then trimmed with tin snips?

-

Have plastic H connectors been used to connect the starter profiles?

-

Has the plastic drip edge been installed to the leading edge upstand of the starter track? Joints must be overlapped 200mm

-

Has sealant been added to the wall and back plate of the starter track?

-

HOLD POINT

-

Has the adhesive been applied as continous bead to the perimeter of the board as well as additional beads across the back of the board? The boards must have at least 40% contact area.

-

Are horizontal joints staggered by 50%? The minimum overlap is 200mm.

-

Are corners interlocked at all internal and external corners?

-

Is the installation cut into an L shape at corners of the openings

-

Are all joints tightly butted?

-

Are fixings used in accordance with the latest Rev fixing schedule?

-

Is the fixing pattern mirroring permarocks specified guide?

-

Are all joints that aren't tightly butted together sealed and using approved sealant?

-

HOLD POINT

-

Have the beads been bedded into around the heads and jambs of the openings? This must be aligned to give a straight corner edge.

-

Has an even application of the bedding mortar been applied evenly over the insulation and beads around openings?

-

Whilst the bedding mortar is wet, has the reinforcement mesh been installed to the surface? Joints of the mesh must overlap by 100mm at all junctions.

-

Has the mesh been extended past the starter track and troweled into the surface free from creases?

-

Have additional 500x250mm straps of mesh been applied diagonally to the corners of the openings?

-

Has the excess mesh that was applied to the base of the area been cut away?

-

HOLD POINT

-

Has an even thin second layer of premitting mortar been applied?

-

Has the final coloured coat been applied?

-

Is the area left clean and tidy?

-

May next task commence?

Sign off

-

A2O Representative

-

Subcontractors Supervisors Representative