Title Page

-

Conducted on

-

Prepared by

-

Location

Existing SFS

-

Is the condition of the SFS to a satisfactory quality?

-

Are there any screws missing in the system?

-

Has rust or corrosion affected the system including the fixings condition?

-

Any special constructions such as movement joints or sliders in good condition and able to support the new cladding?

-

Is the mineral wool infill in good condition and not missing in pockets?

-

Are other structural systems such as steel columns and posts in good condition?

-

Is the blockwork, slabs and sheer walls in good condition?

-

Next task may commence?

-

HOLD POINT

Y-Wall Board Installation

-

Are the fixings used to the latest Rev fixing schedule?

-

Is a 2-5mm gap maintained between boards?

-

Is 12-15mm edge distance for the screws maintained around the perimeter of the board?

-

Are fixings vertically no bigger distances apart than 300mm and horizontally no wider apart than 600mm?

-

Are fixings in the corner 50mm in from the bottom and top edge of the board as shown in 'Detail A' on the installation guide?

-

Has fire rated sealant and daffa tape been applied to all the edges of the sheathing board?

-

Any additional holes in the sheathing board sealed?

-

May the next task commence?

-

HOLD POINT

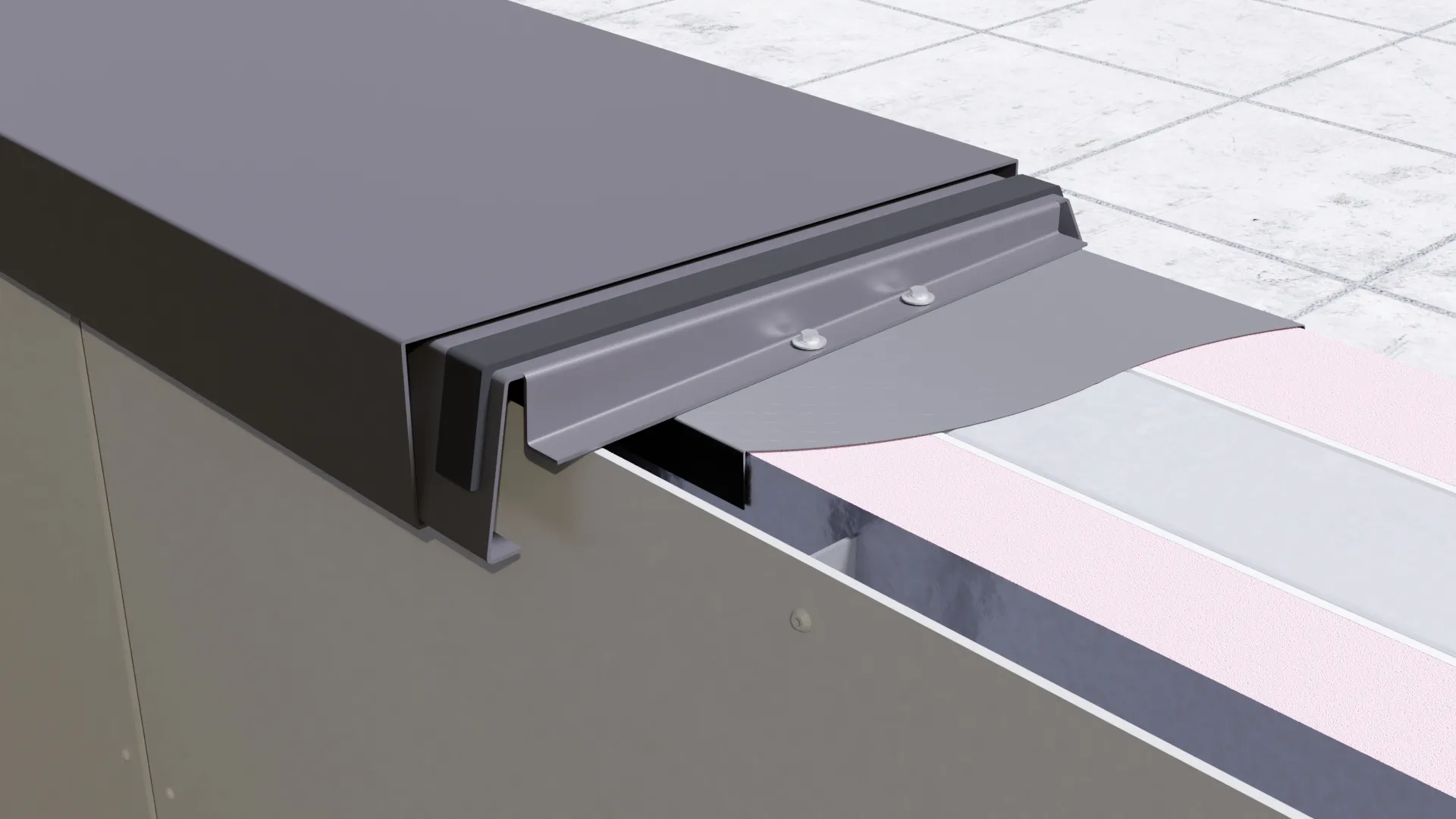

EPDM Installation

-

Has the correct EPDM membrane been used as shown in drawings?

-

Are all substrates clean and free from grease, dust or anything else that can affect the bonding of the membrane?

-

Has primer been used to porous surfaces?

-

Has the sequence of the membrane been installed correctly as shown in the installation guide? (Cill -> Jamb -> Head)

-

Has the adhesive paste been applied to both the frame and the substrates then spread for an even seal?

-

Is the membrane applied flat without creases?

-

Has a further bead of adhesive been applied around the perimeter of the membrane then tooled off ensuring no open edges?

-

Has a minimum of 100mm overlaps been maintained?

-

May the next task commence?

-

HOLD POINT

Tyvek installation

-

Has the products been kept in a dry and out of direct sunlight location?

-

Is double sided tape applied first to temporarily fix the tyvek to the substrate?

-

Are minimum vertical laps of 150mm achieved and taped back?

-

Are minimum horizontal laps of 100mm achieved and taped back?

-

Does the membrane extend 100mm minimum below the lowest structure to ensure maximum coverage?

-

Any holes in the tyvek taped and sealed?

Sign Off

-

A2O Representative sign off

-

Subcontractors supervisor sign off